Abstract

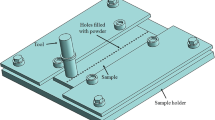

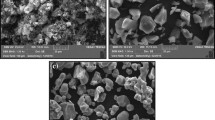

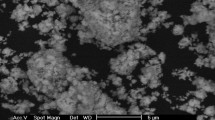

Friction stir processing (FSP) is used to produce surface composites with the retainment of bulk properties. In the present study, FSP was utilized to incorporate nano particles of Boron carbide (B4C) and Titanium carbide (TiC) into the matrix of Al5083 alloy individually and in combined form in order to produce mono and hybrid surface composite layer. The FSPed regions were analyzed through scanning electron microscope (SEM) and XRD studies. Mechanical properties of the FSPed surface composites were evaluated through micro hardness and tensile tests. Wear characteristics of the composites were evaluated through pin on disc dry sliding wear test at sliding speed of 1 m/s and under the normal load ranging from 20 to 100 N in steps of 20 N. The mechanical and wear resistance properties of the composite were higher than the base alloy. Among the processed composites, Al–B4C composites have exhibited the highest hardness and tensile strength. However the hybrid composites (Al–B4C–TiC) have exhibited significant increase in wear resistance. Worn out surfaces and wear debris were analyzed through SEM studies.

Similar content being viewed by others

References

Miracle D B, Comp Sci Tech 65 (2005) 2526.

Sharma V, Prakash U, and Kumar B V M, J Mater Process Technol 224 (2015) 117.

Mishra R S, and Ma Z Y, Mater Sci Eng R 50 (2005) 1.

Arora H S, Singh H, and Dhindaw B K, Int J Adv Manuf Technol 61 (2012) 1043.

Cam G, and Mistikoglu S, J Mater Eng Perform 23 (2014) 1936.

Saadatmand M, and Mohandesi J A, Trans Indian Inst Met 68 (2015) 319.

Zarghani A S, Bozorg S F K, and Hanzaki A Z, Wear 270 (2011) 403.

Shahraki S, Khorasani S, Behnagh R A, Fotouhi Y, and Bisadi H, Metall Mater Trans B 44 (2013) 1546.

Moghaddas M A, and Bozorg S F K, Mater Sci Eng A 559 (2013) 187.

Khodabakhshi F, Simchi S, Kokabi A H, Nosko M, Simancik F, and Svec P, Mater Sci Eng A 605 (2014) 108.

Yuvaraj N, Aravindan S, and Vipin, J Mater Res Tech 4 (4) (2015) 398.

Liu Q, Ke L, Liu F, Huang C, and Xing L, Mater Des 45 (2013) 343.

Hosseini S A, Ranjbar K, Dehmolaei R, and Amirani A R, J Alloys Compd 622 (2015) 725.

Asl A M, and Khandani S T, Mater Sci Eng A 559 (2013) 549.

Soleymani S, Zadeh AA, and Alidokht S A, Wear 278–279 (2012) 41.

Alidokht, S A, Zadeh A A, Soleymani S, and Assadi H, Mater Des 32 (2011) 2727.

Sudhakar I, Madhu V, Reddy G M, and Rao K S, Def Tech 11 (2015) 10.

Mahmoud E R I, Takahashi M, Shibayanagi T, and Keuchi K, Wear 268 (2010) 1111.

Devaraju A, Kumar A, and Kotiveerachari B, Mater Des 45 (2013) 576.

Rejil C M, Dinaharan I, Vijay S J, and Murugan N, Mater Sci Eng A 552 (2012) 336.

Topan F, Kerti I, and Rocha L A, Wear 290–291 (2012) 74.

Thangarasu A, Murugan N, Dinaharan I and Vijay S J, Arch Civil Mech Eng 15 (2015) 324.

Amra M, Ranjbar K, and Dehmolaei R, J Mater Eng Perform 24 (2015) 3169.

Hashemi R, and Hussain G, Wear 324-325 (2015) 45.

Yadav D, and Bauri R, Mater Sci Eng A 539 (2012) 85.

Bradeswaran A, and Perumal A E, Compos: Part B 54 (2013) 146.

Deuis R L, Subramanian C, and Yellup J M, Comp Sci Tech 57 (1997) 415.

Abdollahi A, Alizadeh A and Baharvandi H R, Mater Des 55 (2014) 471.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuvaraj, N., Aravindan, S. & Vipin Wear Characteristics of Al5083 Surface Hybrid Nano-composites by Friction Stir Processing. Trans Indian Inst Met 70, 1111–1129 (2017). https://doi.org/10.1007/s12666-016-0905-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0905-9