Abstract

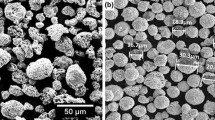

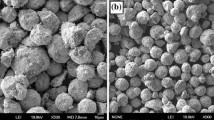

Slurry erosion behaviour of high velocity oxy fuel (HVOF) and high velocity oxy liquid fuel (HVOLF) sprayed coatings on hydraulic turbine material (i.e. CA6NM steel) was investigated at different levels of various parameters. The 50 % (WC–Co–Cr) and 50 % (Ni–Cr–B–Si) coating powder was deposited on CA6NM steel samples by HVOF and HVOLF thermal spraying techniques. Erosion tests were conducted on self-made erosion test rig with various factors as explained in the "experimentation" section. Coated and uncoated samples of CA6NM steel were investigated by following a design of experiments based on the L9 Taguchi technique, which was used to obtain the data of erosion test in a controlled way. Four parameters used in L9 experiment were velocity, impact angle, slurry concentration and average particle size. The study revealed that the velocity, impact angle and slurry concentration were most significant among various parameters, influencing the wear rate of the coatings. The average particle size did not show any significant effect on both the coatings. In comparison, coated samples showed approximately two times better results in erosion resistance than uncoated samples. Scanning electron microscopy of eroded surface showed different mechanisms of erosion on different samples under various conditions.

Similar content being viewed by others

References

Humphrey J, Int J Heat Fluid Flow 11 (1990) 170.

Grewal H, Agrawal A, and Singh H, Tribol Lett 52 (2013) 287.

Khurana S, Varun, and Kumar A, Int J Ambient Energy 50 (2015) 1.

Goyal D, Singh H, and Kumar H, Proc Inst Mech Eng J J Eng Tribol (2011) 1350650111412443.

Singh H, Goyal K, and Goyal D K, Manuf Sci Technol 2 (2014) 81.

Kumar L, Parashar C, and Kaur S, Int J Eng Sci Res I 4 (2013) 963.

Iwabuchi Y, and Sawada S, in Stainless Steel Castings, ed: ASTM International (1982).

Gysel W, Gerber E, and Trautwein A, in Stainless Steel Castings, ed: ASTM International (1982).

Goyal D K, Singh H, Kumar H, and Sahni V, J Therm Spray Technol 21 (2012) 838.

Harsha A, and Bhaskar D K, Mater Des 29 (2008) 1745.

Hidalgo V H, Varela F B, Menéndez A C, and Martınez S P, Tribol Int 34 (2001) 161.

Tabbara H, and Gu S, Surface Coat Technol 204 (2009) 676.

Chauhan A K, Goel D, and Prakash S, Bull Mater Sci 31 (2008) 115.

Goyal D K, Singh H, Kumar H, and Sahni V, Wear 289 (2012) 46.

Ji G-C, Li C-J, Wang Y-Y, and Li W-Y, Surface Coat Technol 200 (2006) 6749.

Solnordal C B, Wong C Y, Zamberi A, Jadid M, and Johar Z, Wear 305 (2013) 205.

Cantera E L, and Mellor B, Mater Lett 37 (1998) 201.

Grewal H, Agrawal A, Singh H, and Shollock B, J Therm Spray Technol 23 (2014) 401.

Thakur P A, Khairnar H S, Deore E, and More S, Int J Novel Res Eng Sci 2 (2014) 14–20.

Bhandari S, Singh H, Kumar H, and Rastogi V, J Therm Spray Technol 21 (2012) 1054.

Singh A, Virdi R L, and Goyal K, Manuf Sci Technol 2 (2014) 111.

Singh G, Virdi R L, and Goyal K, Univ J Mech Eng 3 (2015) 52.

Grewal H S, Bhandari S, and Singh H, Metall Mater Trans A 43 (2012) 3387.

Acknowledgments

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, H., Goyal, K. & Goyal, D.K. Experimental Investigations on Slurry Erosion Behaviour of HVOF and HVOLF Sprayed Coatings on Hydraulic Turbine Steel. Trans Indian Inst Met 70, 1585–1592 (2017). https://doi.org/10.1007/s12666-016-0956-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0956-y