Abstract

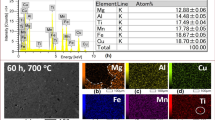

In the present work, one batch of prealloyed 6061Al powder was mixed with different lead compositions (5, 10, 15 vol.%) and another set with same composition was ball-milled for 5 h at 300 rpm. Microstructural features such as lattice constant, crystallite size, particle size and morphology were studied using XRD, particle size analyzer and SEM. Both the as-mixed as well as ball-milled powders were compacted at 300 MPa and sintered under N2 atmosphere for 1 h in tube furnace at 590 °C. The ball milling of 6061Al alloy powder improved sinter density and densification while lead addition showed negligible influence on these parameters. The microstructure of as-mixed 6061Al–Pb alloys exhibited equiaxial morphology whereas ball-milling resulted in elongated grains with uniform lead distribution. Quasi-static compressive mechanical behavior was investigated for 6061Al–Pb alloys at 1 × 10−3 s−1 strain rate. Results indicated that ultimate compressive and yield strength were sensitive to milling and lead volume fraction.

Similar content being viewed by others

References

Hunt W H, New Directions in Aluminum-Based P/M Materials for Automotive Applications. SAE Technical Paper (2000).

Daver E M, Ullrich W J, and Balubhai Patel K, Key Eng. Mater., Trans Tech Publ (1991) 401–428.

Zhu M, Gao Y, Chung C Y, Che Z X, Luo K C, and Li B L, Wear 242 (2000) 47.

An J, Liu Y B, and Lu Y, Mater Sci Eng A 373 (2004) 294.

Sastry C, and Ranga J G, Indian J Eng Mater Sci 17 (2010) 56.

McAlister A J, Bull Alloy Phase Diagr 5 (1984) 69.

MacKay M L, Met Prog 111 (1977) 32.

Moore K I, Zhang D L, and Cantor B, Acta Metall Mater 38 (1990) 1327.

Mohan S, Agarwala V, and Ray S, Wear 157 (1992) 9.

Benjamin J S, Metall Trans 1 (1970) 2943.

Suryanarayana C, Prog Mater Sci 46 (2001) 1.

Zhu M, Che X Z, Li Z X, Lai J K L, and Qi M, J Mater Sci 33 (1998) 5873.

Apelian D, and Saha D, in Proceedings of Second International P/M Light Alloys Automotive Conference (2000) 1.

Padmavathi C, and Upadhyaya A, Trans Indian Inst Met 64 (2011) 345.

Ziani A, and Pelletier S, Int J Powder Metall 35 (1999) 59.

Lefebvre L P, and Thomas Y, Int J Powder Metall 35 (1999) 45.

Simchi A, and Veltl G, Powder Metall 46 (2003) 159.

Lumley R N, Sercombe T B, and Schaffer G M, Metall Mater Trans A 30 (1999) 457.

Schaffer G B, Sercombe T B, and Lumley R N, Mater Chem Phys 67 (2001) 85.

Pieczonka T, Schubert T, Baunack S, and Kieback B, Mater Sci Eng A 478 (2008) 251.

Gökçe A, and Fındık F, J Achiev Mater Manuf Eng 30 (2008) 157.

Martin J M, Gomez-Acebo T, and Castro F, Powder Metall 45 (2002) 173.

Lumley R N, and Schaffer G B, Scr Mater 35 (1996) 589.

Pathak J P, and Mohan S, Bull Mater Sci 26 (2003) 315.

Sheng H W, Zhou F, Hu Z Q, and Lu K, J Mater Res 13 (1998) 308.

Williamson G K, and Hall W H, Acta Metall 1 (1953) 22.

Suryanarayana C, and Norton M G, Microsc Microanal 4 (1998) 513.

Cullity B D, Elements of X-Ray Diffraction. Addison-Wesley, New York, (1978), p 295.

Prabhu Y T, Rao K V, Kumar V S, and Kumari B S, World J Nano Sci Eng 4 (2014) 21.

Sivasankaran S, Sivaprasad K, Narayanasamy R, and Satyanarayana P V, Mater Charact 62 (2011) 661.

Jeyasimman D, Narayanasamy R, and Ponalagusamy R, Adv Powder Technol 26 (2015) 1171.

Asgharzadeh H, and Simchi A, Powder Metall 52 (2009) 28.

Padmavathi C, Upadhyaya A, and Agrawal D, Mater Res Innov 15 (2011) 294.

Schaffer G B, Hall B J, Bonner S J, Huo S H, and Sercombe T B, Acta Mater 54 (2006) 131.

German R M, Powder Metallurgy Science, Met. Powder Ind. Fed., Princeton, NJ (1994), p 290.

Momeni H, Razavi H, and Shabestari S G, Iran J Mater Sci Eng 8 (2011) 10.

Gaur D K, Sintering of 6061Al-Alloy and Its Based Composites, M.Tech Thesis, Indian Institute of Technology, Kanpur, India (1993).

Youseffi M, and Showaiter N, Powder Metall 49 (2006) 240.

Schaffer G B, and Huo S H, Powder Metall 42 (1999) 219.

Scattergood R O, Koch C C, Murty K L, and Brenner D, Mater Sci Eng A 493 (2008) 3.

Wei Q, Jiao T, Ramesh K T, Ma E, Kecskes L J, Magness L, Dowding R, Kazykhanov V U, and Valiev R Z, Acta Mater 54 (2006) 77.

Liu J, Li S, Fan A, and Sun H, Mater Sci Eng A 487 (2008) 235.

Acknowledgements

The authors gratefully acknowledge the characterization facilities and the staff support received from the Advanced Center for Materials Science (ACMS) of Indian Institute of Technology, Kanpur.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Rights and permissions

About this article

Cite this article

Paidpilli, M., Verma, K., Pandey, R. et al. Effect of Lead Addition and Milling on Densification and Mechanical Properties of 6061 Aluminium Alloys. Trans Indian Inst Met 70, 2017–2026 (2017). https://doi.org/10.1007/s12666-016-1024-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-1024-3