Abstract

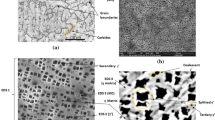

In this study, the effect of etchant type and etching conditions on the root and airfoil microstructure of a service-exposed IN738 turbine blade has been investigated. The microstructure of superalloy components used at high temperatures, in addition to the usual microstructural changes, experiences deterioration in micrometer dimensions. In order to investigate these changes, electrochemical etching was performed on the samples with the chemical solution including 80% phosphoric acid, solution containing Cr2O3 and 55% glycerol. Chemical etching was performed with marble and etchant solution containing 60% glycerol. The results in terms of specifying the deterioration effects on microstructure of the blade applied at high temperature, the amount of γ′ phase and the best etchant were investigated. Among the solutions used for chemical etching, the solution containing 10 ml HNO3, 50 ml HCl and 60 ml glycerol was appropriate for detection of segregations and dendrites, and among the electrochemical etching solutions, the Cr2O3 solution was found suitable for specifying γ′ precipitates’ morphology by scanning electron microscopy. In this research, the results of the quantitative analysis of the images provided by these etchants were also investigated.

Similar content being viewed by others

References

Ross E W, and Sims C T, Superalloy II, John wiley & Sons, New York (1987) p 97.

Steiner R, Metals Handbook, vol. 1, ASM International, MaterialsPark, OH (1990), p 950.

Briant C L, Mater Manuf Process 15 (2000) 155.

Schafrik R, and Sprague R, Adv Aater Process 162 (2004) 27.

Liburdi J, Lowden P, Nagy D, De Priamus T R, and Shaw S, ASME Turbo Expo 2009: Power for Land, Sea, and Air, p 819.

Walston W S, Schaeffer J C, and Murphy W H, Eight Inernashnal Symposium of Superalloys, The Minerals, Metals & Materials Society, Pittsburgh (1996) p 9.

Sims C T, and Hagel C W, The Superalloys-Vital High Temperature Gas Turbine Materials for Aerospace and Industrial Power, John Wiley & Sons, New York (1972).

Ross E W, and Sims C T, Superalloy I, John wiley & Sons, New York (1972).

Moshtaghin R S, Asgari S, Mater Des 24 (2003) 325.

Jayanth C S, Nash P, Mater Sci Technol 6 (1990) 405.

Ray A K, Singh S R, Swaminathan J, Roy P K, Tiwari Y N, Bose S C, and Ghosh R N, Mater Sci Eng A 419 (2006) 225.

Hosseini S S, Nategh S, and Ekrami A A, J Alloys Compd 512 (2012) 340.

Chellman D J, and Ardell A J, Acta Metall 22 (1974) 577.

Yang J, Zheng Q, Ji M, Sun X, and Hu Z, Mater Sci Eng 528 (2011) 1534.

Jafari A, Abbasi S M, Rahimi A, Morakabati M, and Seifollahi M, Assoc Metall Eng Serb 21 (2015) 167.

Liu L, Sommer F, and Fu H Z, Scripte Metallurgica et Materialia 30 (1994) 587.

Donachie M J, and Donachie S J, Superalloys–A Technical Guide, ASM International, Materials Park, OH (2002).

Zhao S, Xie X, Smith G D, and Patel S J, Mater Lett 58 (2004) 1784.

James A, Mater Sci Technol 17 (2001) 481.

Mazur Z, Luna-Ramirez A, and Juárez-Islas J A, Campos-Amezcua A, Eng Fail Anal 12 (2005) 474.

González M A, Martínez D I, Pérez A, and Garza A, MRS Proc 1275 (2010) S3.

Danis Y, Arvieu C, Lacoste E, Larrouy T, and Quenisset J M, Mater Des 31 (2010) 402.

Davis J R, ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys, ASM International Handbook Committee, Ohio (2000).

Salehi R, Samadi A, and Savadkoohi M, Metallogr Microstruct Anal 1 (2012) 290.

Brown J A, Freer R, and Rowley A T, J Eng Gas Turbines Power 123 (2001) 57.

Sugui T, Jun X, Xiaoming Z, Benjiang Q, Jianwei L, Lili Y, and Wuxiang W, Mater Sci Eng A 528 (2011) 2076.

Carter T J, Eng Fail Anal 12 (2005) 237.

R.A. Stevens, P.E.J. Flewitt, Mater. Sci. Eng. 37 (1979) 237-247.

Stevens R A, and Flewitt P E J, Mater Sci Eng 50 (1981) 271.

Lvova E, and Norsworthy D, J Mater Eng Perform 10 (2001) 299.

Lvova E, J Mater Eng Perform 16 (2007) 254.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khodabakhshi, A., Mashreghi, A., Shajari, Y. et al. Investigation of Microstructure Properties and Quantitative Metallography by Different Etchants in the Service-Exposed Nickel-Based Superalloy Turbine Blade. Trans Indian Inst Met 71, 849–859 (2018). https://doi.org/10.1007/s12666-017-1217-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1217-4