Abstract

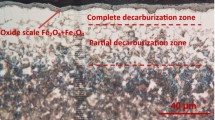

To investigate the diffusion of carbon in the iron sheet during gas–solid decarburization in a weak oxidative atmosphere (Ar + H2 + H2O), the microstructures of iron sheets following decarburization were observed through SEM. The carbon gradient following decarburization in the iron sheet along the thickness direction was detected in this study. The results showed that the iron sheet along the thickness direction following decarburization consisted of three layers: the L1 layer (ferrite phase) that was near the surface, the L2 layer (cementite phase) that was between the L1 + L3 layers, and the L3 layer (cementite + ferrite + graphite phase) that was in the center of the sample. The depth of the decarburization layer (L1 + L2) showed a good linear relation with the square root of the decarburization time. The carbon gradient in iron sheet along the thickness direction was of ladder type during decarburization. The carbon content in the center of iron sheet was influenced by the decarburization time or the temperature. The carbon migration in iron sheet consisted of stable carbon decomposition and free carbon diffusion. The carbon migration in the S2 stage of iron sheet was the controlling step of the entire decarburization process.

Similar content being viewed by others

References

Lu S J, and Wang F Y, Glob Met Bull 06 (2012) 1.

Hong L K, Ai L Q, and Cheng R, J Iron Steel Res Int 28 (2016) 37.

Song J M, Lui T S, and Cheng L H, Metall Mater Trans A 33 (2002) 1263.

Normura M, Morimoto H, and Toyama M, ISIJ Int 40 (2000) 619.

Lobanovm L, and Gomzikov A I, Met Sci Heat Treat 47 (2005) 478.

Lee W H, Park J O, and Lee J S, Ironmak Steelmak 39 (2012) 530.

Park J O, Van Long T, and Sasaki Y, ISIJ Int 52 (2012) 26.

Hong L K, and Ai L Q, Iron Steel 51 (2016) 17.

Georgead E T, and Maurice A H. Steel Heat Treatment Handbook, CRC Press Marcell Dekker (1997) p 678.

Marder A R, Perpetua S M, and Kowalik J A, Metall Trans A 16 (1985) 1160.

Dalley A M, Metall Micro Anal 1 (2012) 59.

Shu S L, Yu Fu Gu, and Guan Z Q, Trans Nonferr Metal Soc 24 (2014) 3372.

Yoshida C, Taniguchi K, Nakagawa T, et al, Characteristics of Rapidly Solidified Cast Iron and High Carbon Steel, Tetsu-to-Hagane (1986) p 2240.

Yoshida C, Yasunak H, and Nozaki T, Trans Iron Steel Inst 27 (1987) 819.

Chen Y L, Zuo M F, and Luo Z L, Trans Mater Heat Treat 36 (2015) 192

Luo H W, Xiang R, and Chen L F, Chin Sci Bull 59 (2014) 866.

Ren H R, Gao J T, and Wang Z, J Iron Steel Res Int 24 (2017) 844.

Gao M Q, Qu Y D, and Li G L, J Iron Steel Res Int 24 (2017) 838.

Funding

This work was supported by the National Natural Science Foundation of China under Grant (51374090).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hong, Lk., Cheng, R., Ai, Lq. et al. Mechanism of Carbon Diffusion in the Iron Sheet During Gas–Solid Decarburization. Trans Indian Inst Met 72, 335–342 (2019). https://doi.org/10.1007/s12666-018-1484-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1484-8