Abstract

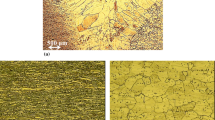

The frequently used aerospace materials, i.e., ultra-high-strength maraging steel (250) and corrosion-resistant 13-8 Mo stainless steel in the solution-annealed and cold-worked condition, have been joined by three fusion welding processes, namely interpulse TIG welding, and high energy density fusion processes like electron beam welding (EBW) and laser beam welding (LBW). The interpulse TIG welding process was carried out by using W2 grade maraging steel filler wire. The dissimilar joints were welded by EBW and LBW processes without any filler wire. All the dissimilar welded joints were characterized by microstructural observations and validated by mechanical properties in the as-welded as well as precipitation-hardened conditions after welding. The weld microstructures and microhardness profiles were correlated to the tensile strength of weld. Electron beam welded joint with precipitation hardening after welding, i.e., soaking at 510 °C and subsequent air cooling, demonstrated the superior mechanical properties among all the welds.

Similar content being viewed by others

References

Norrish J, Advances Welding Processes: Technologies and Process Control, Woodhead Publishing Limited, Cambridge (2006), p 85.

Tariq F, Baloch R A, and Naz B A N, J Mater Eng Perform 19 (2010) 64.

Nagarajan KV, in Proceedings of Symposium Steels for Engineering Industries-Trends in Weldability, Indian Institute of Metals, Tiruchirapalli (1998), p 43.

VBC report; http://vbcie.com

Lee Y J, Wu S C, Chang J L, Chou C P, and Lee I K, Sci Tech Weld Join 13 (2008) 462.

Chen X, Li J, Li Z, and Liu F, Steel Res 65 (1994) 557.

Kaidanov AA, Electron Beam Welding and Related Technologies, 2nd Rev. ed., Kiev: Ekotekhnologiya (2004).

Yu M, Meng F Y, and An J, Lasers Eng 20 (2015) 103.

Meng F, Liu H, Gao X, Wang Y, Wen Z, Lu Y, and An J, J Mater Design Appl 277 (2013) 16.

Liu H, Gao X, Wang Y, and An J, J Mech Eng 48 (2012) 69.

Tewari R, Mazumder S, Batra I S, Dey G K, and Banerjee S, Acta mater 48 (2000) 1187.

Servant C, and Bouzid N, Acta Metall 36 (1988) 2771.

Vasudevan V K, Kim S J, and Wayman C M, Metall Trans 21A (1990) 2655.

Lecomte J B, Servant C, and Cizeron G, J Mater Sci 20 (1985) 3339.

Sha W, Cerezo A, and Smith G D W, Metall Trans 24A (1993) 1221.

Sastry K Y, Narayanan R, Shamantha C R, Sundaresan S, Seshadri S K, Radhakrishnan V M, Iyer K J L and Sundararajan S, Mater Sci Technol 19 (2003) 375.

Canonico D A, WELD J 43 (1964) 433S.

Adams Jr C M, and Travis R E, Weld J 43 (1964) 193S.

Salmon Cox P H, Birkle A J, Reisdorf B G, and Pellisier G E, ASM Trans Q 60 (1967) 125.

Rohrbach K, and Schmidt M, Metals Handbook, Vol 1, 10th ed., ASM, Materials Park, OH (1990), p 793.

Lippold J C, and Kotechi D J, Welding Metallurgy and Weldability of Stainless Steels, John Wiley & Sons Inc Publishing, Hoboken, NJ, USA (2005) p 264.

Hochanadel P W, Robino C V, Edwards G R, and Cieslak M J, Metall Mater Trans A 25A (1994) 789.

Seetharaman V, Sundararaman M, and Krishnan R, Mater Sci Eng 47 (1981) 1.

Gallo F C, and de Almeida L H, Acta Microscopica 12 (2003) 901.

De Almeida L H, Magrani S J G, Ribeiro A F, and LeMay I, Microstruct Charact 22 (1995) 441.

Huang Z, Abad M D, Ramsey J K, Rebelode Figueiredo M, Kaoumi D, Li N, Asta M, Gronbech Jensen N, and Hosemann P, Mater Sci Eng A 651 (2016) 574.

Schnitzer R, Radis R, Nöhrer M, Schober M, Hochfellner R, Zinner S, Povoden-Karadeniz E, Kozeschnik E, and Leitner H, Mater Chem Phys 122 (2010) 138.

Leitner H, Schnitzer R, Schober M, and Zinner S, Acta Mater 59 (2011) 5012.

Mittra J, Dey G K, Seb D, Patra A K, Mazumder S, and De P K, Scr Mater 51 (2004) 349.

Li X, Zhang J, Chen J, Shen S, Yang G, Wang T, and Song X, Mater Sci Eng A 651 (2016) 474.

Tsay L, Chen H, Chiang M, and Chen C, Corros Sci 49 (2007) 2461.

Lang F H, and Kenyon N, Welding of maraging steels, WRC Bulletin 159, New York (1971) p 2.

Peters D T, Tans ASM Quart 61 (1968) 62.

Venkata Ramana P, and Madhusudhan Reddy G, Sci Technol Weld Join 13 (2008) 388.

Li K, Shan J, Wang C, and Tian Z, Mater Sci Eng A 663 (2016) 157.

Murthy C V S, Gopalkrishna A, and Reddy G M, Defence Technology 15 (2019) 111.

Acknowledgements

The authors are grateful for financial support extended by Defence Research and Development Organization (DRDO). The authors would like to sincerely thank Director, Defence Research and Development Laboratory (DRDL), Hyderabad, for his continued encouragement and permission to publish this work. The authors are also grateful to Materials Development Division of DRDL for their valuable support in characterization of samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Murthy, C.V.S., Krishna, A.G. & Reddy, G.M. Dissimilar Welding of Maraging Steel (250) and 13-8 Mo Stainless Steel by GTCAW, LBW and EBW Processes. Trans Indian Inst Met 72, 2433–2441 (2019). https://doi.org/10.1007/s12666-019-01695-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01695-z