Abstract

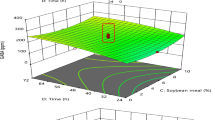

In the present work Lactobacillus delbrueckii was used to utilize agro-industrial byproduct (cane molasses) for lactic acid production under submerged fermentation process. Screening of LAB was done by Fourier transform infra red spectroscopy (FTIR). Effect of different amino acids (DL-Phenylalanine, L-Lysine and DL-Aspartic acid) on the fermentation process was done by high performance liquid chromatography (HPLC). Central composite rotatable design (CCRD) was used to optimize the levels of three parameters viz. tween 80, amino acid and cane molasses concentration during fermentative production of lactic acid. Under optimum condition lactic acid production was enhanced from 55.89 g/L to 84.50 g/L. Further, validation showed 81.50 g/L lactic acid production. Scale up was done on 7.5 L fermentor. Productivity was found to be 3.40 g/L/h which was higher than previous studies with reduced fermentation time from 24 h to 12 h. Further characterization of lactic acid was done by FTIR.

Similar content being viewed by others

References

Adnan AFM, Tan IKP (2007) Isolation of lactic acid bacteria from Malaysian foods and assessment of the isolates for industrial potential. Bioresour Technol 98:1380–1385

Akhtar M, Lentz MJ, Blanchette RA, Kirk TK (1997) Corn steep liquor lowers the amount on inoculum for biopulping. Tappi J 80:161–64

Altaf M, Naveena BJ, Reddy G (2007) Use of inexpensive nitrogen sources and starch for L(+) lactic acid production in anaerobic submerged fermentation. Bioresour Technol 98:498–503

Bhatt SM, Srivastava SK (2008) Lactic acid production from cane molasses by L. delbrueckii NCIM 2025 in submerged condition: optimization of medium component by DOE Taguchi methodology. Food Biotechnol 22:115–139

Curk MC, Peladan F, Hubert JC (1994) Fourier-transform infrared (FT-IR) spectroscopy for identifying Lactobacillus species. FEMS Microbiol Lett 123:241–248

De Lima CJB, Coelho LF, Blanco KC, Contiero J (2009) Response surface optimization of D(−) lactic acid production by Lactobacillus SMI8 using corn steep liquor and yeast autolysate as an alternative nitrogen source. African J Biotechnol 8:5842–5846

Dubois MKA, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Dumbrepatil A, Adsul M, Chaudhari S, Khire J, Gokhale D (2008) Utilization of molasses sugar for lactic acid production by Lactobacillus delbrueckii subsp. delbrueckii mutant Uc-3 in batch fermentation. Appl Environ Microbiol 74:333–335

Farooq U, Anjum FM, Zahoor T, Sajjad-ur-rahman RMA, Ahmed A, Akram K (2012) Optimization of lactic acid production from cheap raw material: sugarcane molasses. Pak J Bot 44:333–338

Helm D, Labischinski H, Schallehn G, Naumann D (1991) Classification and identification of bacteria by Fourier-transform infrared spectroscopy. J Gen Microbiol 137:69–79

Hofvendahl K, Hahn-Hagerdal B (2000) Factors affecting the fermentative lactic acid production from renewable resources. Enzyme Microb Technol 26:87–107

John RP, Gangadharan D, Nampoothir KM (2008) Genome shuffling of Lactobacillus delbrueckii mutant and Bacillus amyloliquefaciens through protoplasmic fusion for l-lactic acid production from starchy wastes. Bioresour Technol 99:8008–8015

Miller GL (1959) Use of Di-nitrosalicylic Acid Reagent for Determination of Reducing Sugar. Analytical Chem 31(3): 426–428

Tellez-Luis SJ, Moldes AB, Alonso JL, Vazquez M (2003) Optimization of lactic acid production by Lactobacillus delbrueckii through response surface methodology. J Food Sci 68(4):1454–1458

Nagarjun PA, Rao RS, Rajesham S, Rao LV (2005) Optimization of lactic acid production in SSF by Lactobacillus amylovorus NRRL B-4542 using Taguchi methodology. J Microbiol 43:38–43

Naumann D, Helm D, Labischinski H, Giesbrecht P (1991) The characterization of microorganisms by Fourier-transform infrared spectroscopy (FT-IR). In: Nelson WH (Ed.), Modern Techniques for Rapid Microbiological Analysis, VCH, New York, pp 43–96

Naveena BJ, Altaf M, Bhadryya K, Madhavendra SS, Reddy G (2005) Direct fermentation of starch to L (+) lactic acid in SSF by L amylophilus GV6 using wheat bran as support and substrate: medium optimization using RSM. Proc Biochem 40:681–690

Oh H, Wee YJ, Yun JS, Han SH, Jung S, Ryu HW (2005) Lactic acid production from agricultural resources as cheap raw materials. Bioresour Technol 96:1492–1498

Ryu HW, Yun JS, Wee YJ (2003) Lactic acid. In: Pandey A (ed) Concise Encyclopedia of Bioresour Technol. The Haworth Press, New York, p 635

Sriphochanart W, Skolpap W, Scharer JM, Moo-Young M, Douglas PL (2011) African J Microbiol Res 5:3815–3822

Tashiro Y, Kaneko W, Sun Y, Shibata K, Inokuma K, Zendo T, Sonomoto K (2011) Continuous D-lactic acid production by a novel thermotolerant Lactobacillus delbrueckii subsp. lactis qu 41. Appl Microbiol Biotechnol 89:1741–1750

Wee UJ, Kim JN, Yun JS, Ryu HW (2004) Utilization of sugar molasses for economical L (+) lactic acid production by bath fermentation of Eneterococcus faecalis. Enzyme Microbiol Technol 35:568–573

Yu L, Lei T, Ren X, Pei X, Feng X (2008) Response surface optimization of l-(+)-lactic acid production using corn steep liquor as an alternative nitrogen source by Lactobacillus rhamnosus CGMCC 1466. Biochem Eng J 39:496–502

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, A.K., Tripathi, A.D., Jha, A. et al. Production, optimization and characterization of lactic acid by Lactobacillus delbrueckii NCIM 2025 from utilizing agro-industrial byproduct (cane molasses). J Food Sci Technol 52, 3571–3578 (2015). https://doi.org/10.1007/s13197-014-1423-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1423-6