Abstract

During the past few decades, pharmaceutical industries have registered a quantum jump contributing to high economic growth, but simultaneously it has also given rise to severe environmental pollution. Untreated or allegedly treated pharmaceutical industrial wastewater (PIWW) creates a need for time to time assessment and characterization of discharged wastewater as per the standards provided by the regulatory authorities. To control environmental pollution, pharmaceutical industries use different treatment plans to treat and reuse wastewater. The characterization of PIWW using advanced and coupled techniques has progressed to a much advanced level, but in view of new developments in drug manufacture for emerging diseases and the complexities associated with them, better sophisticated instrumentation and methods of treatment are warranted. The bioremediation process to treat PIWW has undergone more intense investigation in recent decade. This results in the complete mineralization of pharmaceutical industries’ wastewater and no waste product is obtained. Moreover, high efficiency and low operation cost prove it to be an effective tool for the treatment of PIWW. The present review focuses on the characterization as well as bioremediation aspects of PIWW.

Similar content being viewed by others

Introduction

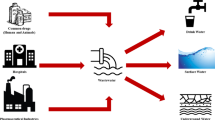

Environmental pollution is one of the major challenges of today’s civilization (Kaushik et al. 2012; Spina et al. 2012). In India, it is found that one-third of total water pollution comes in the form of industrial effluent discharge, solid wastes and other hazardous wastes. Industrial wastewater presents a potential hazard to the natural water system (Deepali 2012; Kansal et al. 2011; Lokhande et al. 2011; Modak et al. 1990). This wastewater contains many inorganic and organic matters, which are toxic to the various life forms of the ecosystem (Spina et al. 2012). Several research investigations have shown the widespread occurrence of these pollutants in wastewater, surface water and ground water (Debska et al. 2004; Heberer 2002). The increasing pollution load of pollutants from industrial water streams has also caused great harm to the rivers, posing major health risks on either direct bathing or drinking in the river water (Seth et al. 2013). Environmental pollution caused by industrial effluents results in adverse effects on the general health of the workers, as well as the habitants, who live near the chemical synthesis industries and farmers along with field workers (Asamudo et al. 2005).

Worldwide growth and expeditious industrialization have led to the recognition and increasing understanding of the interrelationship between pollution, public health and environment. Presently, 3.4 million people die each year in the world from waterborne diseases owing to rapid industrialization (Rajaram and Das 2008; Khan and Noor 2002). The surface water is the main source of industries for wastewater disposal (Kar et al. 2008). Untreated or allegedly treated industrial effluents have enhanced the level of surface water pollution up to 20 times the safe level in 22 critical polluted areas of the country. It is found that almost all rivers are polluted in most of the stretches by some industries (Lokhande et al. 2011; Modak et al. 1990). The level of wastewater pollution varies from industry to industry depending on the type of processes and the size of the industries (Garcia et al. 1995).

In India, during the past few decades pharmaceutical industries have registered a quantum jump. Pharmaceutical industry production includes raw material, antibiotics, variety of medicines and cosmetic products, which in turn generates the effluent containing constituents harmful to human and aquatic life (Dixit and Parmar 2013; Chang et al. 2008). Wastewater produced from these units is hazardous and toxic and also often has intensive colour and disgusting odour. The recalcitrant molecules survived through the wastewater treatment process and finally discharged into the environment. Although maintenance and housekeeping activities are similar in one plant to another, pharmaceutical industries do not generate uniform waste streams, due to the variety of medicines produced during any given manufacturing process (Kavitha et al. 2012; Wei et al. 2012; Madukasi et al. 2010; Chang et al. 2008; Rao et al. 2004). Though the volume of untreated or incompletely treated pharmaceutical industry wastewater is small, it contains a high level of pollutants because of the presence of non-biodegradable organic matter (such as antibiotics, other prescription drugs, non-prescription drugs, animal and plant steroids, reproductive hormones, beta-lactamides, anti-inflammatories, analgesics, lipid regulators, anti-depressants, cytostatic agents, personal care products, detergent metabolites, flame retardants, product of oil use and combustion and other extensively used chemicals, i.e. spent solvents, reaction residues, used filter media, etc., heavy metals (such as lead, mercury, cadmium, nickel, chromium) and other pollutants (Ramola and Singh 2013; Vuppala et al. 2012; Chelliapan et al. 2011). Table 1 depicts the summary of typical material inputs and pollution outputs in the pharmaceutical industry. Predicted impacts of wastewater on the flora and fauna vary widely due to the wide variations in the characteristics of the wastewater. The impact of pharmaceutical chemicals on public health and environment demands an increasing concern due not only to their acute toxicity, but also to their genotoxicity and mutagenic effects. When these pollutants are discharged on the ground or in water bodies, they accumulate in the system through the food chain and affect human health and other living organisms (Nadal et al. 2004).

Assessment and characterization of wastewater is important to evaluate the quality of wastewater. In India, the Central Pollution Control Board (CPCB) provides standards with their limiting concentrations for discharge of environmental pollutants from the pharmaceutical (manufacturing and formulation) industry (Table 2). Nowadays, pharmaceutical companies employ a variety of treatment methods, which includes primary: chemical and physicochemical, secondary: biological process and tertiary: advanced oxidation processes (Deegan et al. 2011; Vanerkar et al. 2013). Among others, bioremediation is one of the latest and widely used techniques used for the treatment of pharmaceutical industries’ wastewater.

Not much work has been done on characterization-assisted bioremediation methods in India and available reports elsewhere are scanty. Thus, identifying the need to explore the area in light of the gaps and lack of expensive work done, the present review gives a detailed account of available work in the area.

Characteristics of pharmaceutical industries’ wastewater

Wastewater characteristics play an important role in the selection of the treatment process of wastewater (Deegan et al. 2011). The wastewater characteristics generated during the manufacturing of pharmaceuticals vary greatly depending on the raw materials and equipments used, as well as the manufacturing, compounding and formulation process employed (Mayabhate et al. 1988). In designing the bulk manufacturing processes, consideration is given to the availability of the raw materials and their toxicity, as well as the wastes (i.e. mother liquor, filter residues and other by-products) and emission generated.

Damodhar and Reddy (2013) reported the impact of pharmaceutical industries-treated effluents on the water quality of River Uppanar, southeast coast of India. They studied the water quality of the river with reference to the following parameters (average value): pH range between 7 and 8, temperature between 26.25 and 28.87 °C, EC between 694.08 and 1733.13, TDS between 354.38 and 873.81 mg/l, TSS between 50 and 348.75 mg/l, BOD between 3.69 and 5.78 mg/l, COD between 131.31 and 218.42 mg/l, Ca between 36.75 and 55.86 mg/l, Mg 16.43–23.52 mg/l, hardness 162.97–236.1 mg/l, Na between 70.69 and 100.12 mg/l and chloride between 131.20 and 176.97 mg/l. They finally concluded that the effluent produced by pharmaceutical industries has a significant negative effect on the water quality of River Uppanar.

Some researchers have previously worked on the characterization of PIWW for physicochemical parameters, metals and other toxic pollutants, as shown in Tables 3 and 4.

Kavitha et al. (2012) studied the physicochemical analysis of pharmaceutical industrial effluent and treatment plant’s efficiency and found the variation in wastewater characteristics from the inlet point to the outlet point of septic tanks. They observed reduction in the following parameters: TSS 4,300–94 mg/l, TDS 2,846–1,308 mg/l, COD 7,280–9.9 mg/l, BOD 4,132–6.6 mg/l, chlorides 1,000–300 mg/l, sulphates 500–300 mg/l and pH between 7.43 and 7.14. Das et al. (2012) studied the control of pharmaceutical effluent parameters through bioremediation. They collected the samples from nine different points situated in the industry and observed the range of sulphates 44–1,527 mg/l, TDS 484–1,452 mg/l, total suspended solids 24–84 mg/l and COD 1,257.9–1,542.9 mg/l.

Madukasi et al. (2010) characterized the pharmaceutical wastewater and observed the concentration in mg/l for total suspended solids 425 ± 2.3, total dissolved solids 1,600 ± 1.1, total nitrogen 533.7, BOD 146.7 ± 0.3, Zn 0.056, iron 2.1, Mn 0.605, Cu 0.022, acetic acid 422.7, propionic acid 201.3 and butyric acid 304.5. A suspended growth photobioreactor employing the wild strain of purple nonsulphur photosynthetic bacterium Rhodobacter sphaeroides was utilized to treat the wastewater. The strain was found to be effective in ameliorating hazardous pollutants found in wastewater with over 80 % COD reduction. The strain shows the potential to improve the treatment process and may also be harvested and find use as SCP after further investigation.

Oktem et al. (2007) analysed the chemical synthesis-based pharmaceutical wastewater before anaerobic treatment and observed COD value 40,000–60,000 mg/l, total kjeldahl nitrogen 800–900 mg/l, phosphate 3–6 mg/l, volatile suspended solids 0.6–0.7 mg/l, alkalinity 900–1,000 mg/l and pH value 7–8.

Pharmaceutical industries in and around Hyderabad, India, produce a wide variety of products using both organic and inorganic substances as raw materials, thereby generating a large quantity of complex toxic organic liquids waste containing high concentrations of inorganic TDS, BOD and COD. Raj and Anjaneyulu (2005) analysed pharmaceutical wastewater after chemical treatment and obtained the mean value of the following parameters with standard deviation (SD): pH 12.9 ± 0.28, EC 25,230 ± 158.1, total solids 20,030 ± 317.4 mg/l, TDS 16,190 ± 108.4 mg/l, TSS 3,720 ± 192.35 mg/l, COD 8,480 ± 414.73, BOD 4,800 ± 316.23 mg/l, phosphate nil mg/l, nitrates 1,400 ± 306.2, alkalinity 1,100 ± 128.6 mg/l, sulphates 4,900 ± 207.5 mg/l and chlorides 950 ± 64.1 mg/l.

Ileri et al. (2003) characterized the raw mixed pharmaceutical industrial wastewater as BOD = 90–130 mg/l, COD = 200–300 mg/l, suspended solids = 900 mg/l, pH = 6.4–6.8, temperature = 20 °C, ammonia = 26 mg/l, phosphate = 8.5 mg/l. Lapara et al. 2001 achieved 7,320 ± 160 mg/l COD value in PIWW prior to treatment.

Rana et al. (2014a, b) also focused their study on the assessment of the physicochemical parameters and heavy metals in pharmaceutical industries’ wastewater in Pharma City, Selaqui, Dehradun, Uttarakhand, India. In this study five different sites were selected and every month sampling was done for 12 months to assess the physicochemical pollutants and heavy metals. It was observed that the average value for phenolic compounds, BOD and COD were above the standard limits and for pH, sulphate, chloride, boron, nitrate and fluoride below the standard limits provided by CPCB and BIS, India. Further, the heavy metal assessments were found to be within the permissible limits as promulgated by regulatory agencies. This study helped in designing the appropriate treatment plan using the microbial consortia for the pharmaceutical industries’ wastewater containing organic pollutants.

Treatment methods used in pharma industries

All pharmaceutical industries employ a wide array of treatment methods for disposal of wastewater (Deegan et al. 2011). Such methods include neutralization/pH adjustment, oxidation, sand filtration (Saleem 2007), ozone use, Fenton’s method, coagulation/flocculation, electrocoagulation (Dixit and Parmar 2013), photelectrocoagulation, peroxi-electrocoagulation, peroxi-photelectrocoagulation, sedimentation, membrane separation, UV irradiation, adsorption, chlorination, distillation, solar photo-Fenton, reverse osmosis, bacterial treatments (Madukasi et al. 2010), fungal treatment (Spina et al. 2012), algal treatment, phytoremediation and methods using membrane bioreactor (MBR) (Chang et al. 2008), anaerobic fixed film reactor (AFFR) (Rao et al. 2004), aerobic sequencing batch reactor (ASBR) (Patil et al. 2013), membrane-aerated biofilm reactor (MABFR) (Wei et al. 2012) and activated sludge (Mayabhate et al. 1988).

Vanerkar et al. (2013) studied the physicochemical treatment of herbal PIWW. Treatment studies were carried out using various conventional coagulants (lime, alum, ferrous sulphate and ferric chloride) individually and in combination with synthetic polyelectrolytes of three different charges (Magnafloc-E-207, Magnafloc-1011, Zetag-7563, Zetag-7650 and Oxyfloc-FL-11). The focus of this study was to evaluate the feasibility of primary physicochemical, secondary biological and advanced oxidation treatments. Physicochemical treatment using alum as coagulant in combination with cationic synthetic polyelectrolyte as primary viable process followed by secondary single stage activated sludge process and finally Fenton’s oxidation process can remove the non biodegradable organics to the level promulgated by regulatory agency.

Gome and Upadhyay (2013) utilized ozone for treatment of pharmaceutical wastewater, which required 32.73 mg/l ozone under acidic condition, whereas under alkaline conditions 30 mg/l ozone was needed. They reported that ozonation can improve biodegradability of wastewater at alkaline pH and higher treatment time favoured the enhanced biodegradability of wastewater. Farhadi et al. (2012) used electrocoagulation, photoelectrocoagulation, peroxi-electrocoagulation and peroxi-photoelectrocoagulation processes for the removal of COD from pharmaceutical wastewater originating from Osvah Pharmaceutical Company.

Tóth et al. (2011) used distillation and membrane filtration process for treatment of PIWW, which contains high chemical oxygen demand and adsorbable organically bound halogens (AOX). The distillation was capable of reducing volatile chemical oxygen demand (VOC-COD) and AOX, while the membrane filtration process was beneficial for the treatment of the bottom product of rectification to concentrate the non-volatile pollutants, reducing the COD values close to the emission limits.

Mayabhate et al. (1988) studied and reported the physicochemical and biological treatment of pharmaceutical wastewater. For physicochemical study, they used ferrous sulphate, ferric chloride and alum as coagulants and for biological treatment activated sludge process was used in an oxidation ditch.

Sirtori et al. (2009) reported that pharmaceutical industrial wastewater contained nalidixic acid (an antibiotic pertaining to the quinolone group), which cannot be easily biodegraded. The biodegradability of nalidixic acid was achieved by the chemical oxidation process followed by biological treatment. Chemical oxidation (photo-Fenton) enhances the biodegradability, followed by biological treatment using immobilized biomass reactor (IBR). The combined efficiency of treatment was over 95 %, of which 33 % corresponded to the solar photochemical process and 62 % to the biological process.

Kulik et al. (2008) studied the combined chemical treatment of pharmaceutical effluents from medical ointment production. They used a Fenton-like system in combination with lime coagulation. In this study, all effluent samples were subjected to pretreatment by adsorption/flocculation/filtration process. Under the most favourable treatment conditions, COD and BOD removal of 87–96 and 79–95 % was achieved, respectively. The application of combined Fenton-like treatment and lime coagulation improved the quality of effluents, helped to meet the requirements for wastewater discharge to sewage and also increased the biodegradability of pharmaceutical effluents.

Saleem (2007) studied the physicochemical treatment of pharmaceutical wastewater. He selected coagulation, sedimentation, flocculation, sand filtration followed by activated carbon adsorption for this treatment study. He concluded that coagulants (ferric chloride, alum and ferrous sulphate) were not very effective and required high dosage for the removal of TSS, BOD, COD and turbidity.

Raj and Anjaneyulu (2005) evaluated the treatability of a bulk drug pharmaceutical wastewater using a laboratory-scale activated sludge reactor with acclimatized mixed consortia. In the pretreatment process, they used lime as a coagulant for the reduction of sulphates and TDS level. This study evaluated the treatability (86.6 % reduction in COD from 4,000 mg/l concentration) of bulk drug pharmaceutical wastewater using activated sludge reactor with acclimatized mixed consortia by integrating with chemical coagulation as the pretreatment process. The reduction of 44–48 % of sulphate was achieved with lime as coagulant, reducing the TDS level and increasing the efficiency for better biological treatment.

Biological treatment (bioremediation/biodegradation) of pharmaceutical wastewater

The conventional chemical treatment methods of pharmaceutical industrial wastewater effluents have not been found successful in overcoming the complex pollution load of industrial effluents and sometimes they also contribute to another type of complex by-product, which is more difficult to treat and further pollutes the soil or water sources. Chemical/physicochemical purification methods utilize costly chemicals and treatment units, which are difficult to manage at the industrial unit level (Amin et al. 2013). It was reported that treatment of pharmaceutical wastewater with inorganic coagulants (salts of Fe and Al) in a pharmaceutical plant was less effective (Mayabhate et al. 1988). The chlorinated phenols are more toxic than the unsubstituted phenols. The toxicity of phenol increases with the degree of chlorination and with the chlorophenol lipophilicity (Krug et al. 1985; Lee et al. 1994). Many of the artificially made complex compounds, i.e., xenobiotics persist in the environment and do not undergo biological transformation.

Biological methods involve the use of microbes and plants for the treatment of wastewater. Microbes degrade or convert the waste into some other form. In both the cases, whether it is a degraded or converted product, it is very important to confirm that the end product is not more toxic and problematic than the initial compound. Biodegradation of the product depends on a number of factors, such as: (1) stereochemistry of the compound, (2) toxicity of the compound, (3) concentration of the compound, (4) efficiency of the microbial strain, (5) conditions during degradation, (6) retention time and (7) presence of other compounds and their concentration. Microorganisms play a vital role in the degradation of xenobiotics and in maintaining the steady-state concentration of chemicals in the environment (Misal et al. 2011). Microbial transformations result in residues that are more stable than the parent compound and are less toxic.

With the help of the biodegradation process, Raj and Anjaneyulu (2005) achieved maximum reduction of COD (86.6 %) in pharmaceutical industrial wastewater. Das et al. (2012) reported the remarkable reduction of COD, TSS, TDS and sulphate in pharmaceutical effluent by the bioremediation process. Further, a microbial consortia involving fungal and bacterial cultures for treatment was found effective in removing toxicity from pharmaceutical wastewater (Rosen et al. 1998).

Biological treatment of pharmaceutical industrial wastewater can be achieved by aerobic and anaerobic treatment (Deegan et al. 2011). Various high-rate reactors have been designed for the biological treatment at full-scale operation. Wei et al. (2012) utilized the membrane-aerated biofilm reactor (MABR) process for treatment of pharmaceutical wastewater and achieved a COD removal efficiency of 90 % and ammonium nitrogen removal efficiency of 98 %.

Sirtori et al. (2009) used the combined treatment process (solar photo-Fenton + immobilized biomass reactor) for the treatment of PIWW and achieved 95 % DOC reduction. In this treatment, 33 % reduction was carried out by solar photo-Fenton and 62 % reduction was carried out by the immobilized biomass reactor. This study supports the enhanced treatment efficiency with the biological process.

Mayabhate et al. 1988 have adopted biological process for treatment of PIWW. They compared the treatment efficiency of the physicochemical and biological processes. It was found that the physicochemical process using different coagulants (ferrous sulphate, ferric chloride and alum) were not effective and required high amount of doses for COD reduction, whereas by utilizing a biological process they achieved 86–91 % reduction in the COD level and 50 % reduction in the phenol level. Further, works carried out on different components of bioremediation are discussed below.

Anaerobic treatment

Anaerobic technology was used earlier for treating wastewaters of different industries such as paper and pulp, distilleries, tanneries, textile and food processing, ranging from high-strength waste to low-strength waste. Various reactor configurations such as anaerobic contact reactor (ACR), upflow anaerobic sludge blanket reactor (UASB), fluidized bed reactor (FBR) and anaerobic fixed film reactor (AFFR) have been developed to treat wastewaters from different industries. Each of these configurations have a variety of operational constraints, even though they are being applied extensively (Rao et al. 2004).

In anaerobic treatment, the high organic content in industrial wastewater decomposes into methane and CO2 with the help of microorganisms. Anaerobic treatment of industrial wastewater shows interesting advantages such as production of very little sludge, requirement of less amount of energy, operation at high organic loading rate, need of low nutrient amount and production of biogas which can be utilized for energy production in this treatment process (Nandy et al. 2002). Inoculum source and feed pretreatment are the main steps, which can affect the treatment efficiency. However, due to the presence of low pH and slow growth rate, longer hydraulic retention time (HRT) results. To solve this problem a high-rate configuration was developed to treat industrial wastewater at relatively shorter HRT (Patel and Madamwar 2000). Enright et al. (2005) studied the anaerobic biological treatment of pharmaceutical wastewater and achieved 60–70 % COD removal efficiency.

Upflow anaerobic sludge blanket (UASB) reactors

Upflow anaerobic sludge blanket (UASB) reactors have been widely used for the treatment of industrial wastewater (Tóth et al. 2011). This reactor has been successfully applied for high-rate anaerobic wastewater treatment. The success of UASB depends on the formation of active and able granules (Fang et al. 1994). These granules consist of self-immobilized, compact form of aggregate of organisms and lead to an effective retention of organisms in the reactor (Akunna and Clark 2000). The advantages of UASB reactor are independence from mechanical mixing, recycling of sludge biomass and ability to cope up with perturbances caused by the high loading rate. UASB reactor is effective in the treatment of industrial wastewater in psychrophile conditions. Some researchers have utilized a hybrid UASB reactor for the treatment of chemical synthesis-based pharmaceutical wastewater (Oktem et al. 2007). In 2009, hybrid UASB reactor was reported to treat bulk drug industrial wastewater utilizing thermophilic strain (Sreekanth et al. (2009). Tóth et al (2011) studied the performance of a laboratory-scale upflow anaerobic sludge blanket (UASB) reactor for treatment of a chemical synthesis-based pharmaceutical wastewater, under different operating conditions. The key feature of the UASB process that allows the use of high volumetric COD loadings as compared to other anaerobic processes is the development of a dense granulated sludge, characterized by the wastewater characterstics.

Anaerobic fixed film reactor (AFFR)

The anaerobic fixed film reactor has a biofilm support structure for biomass attachment. This reactor has advantages like simplicity of construction, elimination of mechanical mixing, better stability and capability to withstand toxic shock load. This type of reactor can recover very quickly after a period of starvation (Rajeshwari et al. 2000). In this reactor, glass bead, red drain clay, polyurethane foam, waste tyre rubber (Borja et al. 1996), splintered glass (Perez et al. 1997), polyacryl nitrile acryl amide, corrugated plastic (Garcia et al. 1995), coconut coir, charcoal and nylon fibre can be used as packing material in the treatment of industrial wastewater as a support media, which enhances the reactor performance (Acharya et al. 2008). This system ensures effective contact with anaerobic biomass in suspended form with organic load to achieve high organic load removal. Rao et al. (2004) studied the treatment of wastewater with high suspended solids from a bulk drug industry using anaerobic fixed film reactor (AFFR) and concluded that the AFFR could be used efficiently for the treatment of bulk drug industries’ wastewater having high COD (60–70 % removal), TDS, TSS and BOD (80–90 % removal).

Aerobic treatment

In aerobic methods, generally aerobic sequencing batch reactor (ASBR) and activated sludge process have been used for the treatment of industrial wastewater. This process consists of a primary settling tank, an intermediate retention trough, two storage tanks and an aerobic tank. Some researcher have reported the aerobic biological treatment of pharmaceutical wastewater (Lapara et al. (2001). Khan and Mostafa (2011) studied the aerobic treatment of pharmaceutical wastewater in a biological reactor. A laboratory-scale batch type of integrated aerobic biological treatment plant was constructed and operated for pharmaceutical wastewater treatment and its performance was evaluated. A cylindrical open tank was used as a reactor and air was passed through the bottom of the tank. In this study, the maximum hydraulic retention time (HRT) was 15 days. They collected the treated water samples every day and tested it for the following parameters: COD, TSS, pH, conductivity and TDS to evaluate the efficiency of the plant. About 75 % removal of COD was achieved employing HRT of 15 days. The analyses of the treated wastewater reveal that the parameters pH, BOD, COD, TSS, TDS and colour were found within the prescribed permissible limits, indicating the efficiency of the plant. They concluded that air injection accelerates the biological treatment process, with the greatest influence on COD removal from the wastewater. This treatment plant has high potential for COD and TSS removal and can be considered as a potential treatment technology for industrial wastewater treatment. To sum up, such a plant is environment friendly, minimize the use of chemicals, cost-effective and easy to operate for industrial effluent treatment.

Ileri et al. (2003) treated the mixed pharmaceutical industrial wastewater using sequencing batch reactor (SBR) and obtained significant removal in BOD (approximately 85 %), COD (approximately 87 %), suspended solids (approximately 98 %), ammonia (approximately 96 %) and phosphate (approximately 5 %). Vanerkar et al. (2013) used activated sludge system for treatment of wastewater of herbal pharmaceutical industry and achieved 68.98–91.02 % reduction in COD, 76.90–97.26 % reduction in BOD and 74.61–95.54 % reduction in suspended solids.

Elmolla et al. (2012) studied the optimization of SBR operating conditions for treatment of high-strength mixed pharmaceutical wastewater and achieved 94 % BOD removal and 83 % COD removal at 24 h HRT. Adishkumar et al. (2012) studied the coupled solar photo-Fenton process with aerobic sequencing batch reactor for treatment of pharmaceutical wastewater and achieved COD removal of 98 %. Ng et al. (1989) reported the biological treatment of pharmaceutical wastewater and achieved remarkable reduction in COD and BOD levels by using the sequencing batch reactor (SBR) concept.

Altaf and Ali (2010) carried out studies on pharmaceutical wastewater treatment using sequential batch reactor (SBR) and developed a biological method for the analysis of relative toxicity operating with dissolved oxygen 2.0 mg/l, at different pH (6.62, 6.69, 6.79 and 6.9) for 7, 14 and 21 days treatment. They observed a significant decrease in BOD, COD, oil and grease, TDS, TSS and ammonia levels, which meet the National Environmental Quality Standards (NEQS).

Fungal treatment

There are a number of fungal strains which play an important role in the treatment of industrial wastewater, but have limitations due to the presence of long growth cycle and spore formation. Spina et al. (2012) compared the fungal treatment with the activated sludge for treatment of pharmaceutical industrial wastewater. For this study, they used a fungal strain, Bjerkandera adusta MUT 2295, through which they achieved 91 % COD reduction as compared to activated sludge, which reduced 78 % COD.

Some fungal strains such as Aspergillus niger, Aspergillus fumigatus and Aspergillus niveus show COD reduction of diluted industrial effluents at different concentrations. A group of fungi known as Ascomycetes also play an important role in the treatment of industrial wastewater, e.g. Penicillium decumbens and Penicillium lignorum have shown significant reduction in COD, phenol and colour (Mohammad et al. 2006; Angayarkanni et al. 2003).

Bacterial treatment

Bacterial culture for bioremediation of industrial wastewater has also been used and demonstrated. Some bacterial strains like Pseudomonas, Enterobactor, Streptomonas, Aeromonas, Acinetobactor and Klebsiella show up to 44 % COD reduction (Ghosh et al. 2004). Chaturvedi et al. (2006) isolated 15 rhizosphere bacteria, which show 76 % colour reduction and 85–86 % BOD and COD reduction within 30 days. Use of cells of E.coli and methanogenic consortium has been reported for the removal of toxic pollutants. Substituted phenols/pentachlorophenols are even more dangerous, toxic and cause cancer and mutations. The bacterial community is required to provide all metabolic capabilities for complete mineralization of such toxic organic compounds, which is essential for degradation of organic pollutants (Tewari and Malviya 2002). Numerous bacteria are known to degrade phenolic and complex organic compounds mainly from the genera Arthrobacter, Comamonas, Rhodococcus and Ralstonia. Some Clostridium species (fermenting bacteria) are able to degrade resorcinol (Kavitha and Beebi 2003). Soil bacteria, especially Pseudomonas predominantly in rhizospheric soil, have a special phenolic biodegradation potential. Duffner et al. (2000) proposed phenol/cresol degradation by the thermophilic Bacillus thermoglucosidasius A7, which degrades phenol at 65 °C via the meta-cleavage pathway.

Kumar et al. (2005) reported the biodegradation kinetics of phenol and catechol using Pseudomonas putida MTCC 1194. The well-acclimatized culture of P. putida degraded the initial phenol concentration of 100 mg/l and initial catechol concentration of 500 mg/l completely in 162 and 94 h, respectively. The capability to degrade phenol and chlorophenols has also been reported for bacteria P. Fluorescence (Agarry and Solomon 2008).

Das et al. (2012) studied the control of pharmaceutical effluent parameters through bioremediation. They collected samples from nine different points situated in the industry and treated the effluent by using bacterial consortia and achieved reduction in the level of sulphates from 44–1,527 mg/l to 6–65.8 mg/l, TDS from 484–1,452 mg/l to 68–540 mg/l, total suspended solids from 24–84 mg/l to 12–56 mg/l and COD from 1,257.9–1,542.9 mg/l to 113.2–377.6 mg/l. Madukasi et al. (2010) used phototropic bacteria named as Rhodobactor spheroids for treatment of pharmaceutical wastewater and achieved 80 % COD removal. Previously, some investigators also achieved a significant COD removal (62 % at 30 °C and 38 % at 60 °C) in PIWW by using mixed bacterial culture (Lapara et al. 2001).

Phytoremediation

Phytoremediation of wastewater is an emerging low-cost technique for removal of hazardous metal ions from industrial wastewater and is still in an experimental stage. Heavy metals such as cadmium and lead are not easily absorbed by microorganisms. In such case, phytoremediation proves a better treatment tool for bio-treatment because natural plants or transgenic plants are able to bio-accumulate these toxins (Amin et al. 2013). Aquatic plants have excellent capacity to reduce the level of toxic metals, BOD and total solids from the wastewater. Billore et al. (2001) carried out the treatment of industrial effluent with the help of plants Typha latipholia and Phragmitis karka. This treatment eventually led to COD, BOD, total solids and phosphorus content reduction. Some researchers also reported the phytoremediation of phenol from industrial wastewater by peroxidases of tomato hairy root cultures (González et al. 2006).

Membrane bioreactor (MBR)

The MBR has been used for the large-scale wastewater treatment of industrial wastewater, domestic wastewater and municipal wastewater (Yang et al. 2006). This is used for the biological degradation of wastewater compounds and the physical separation of biomass and treated water by porous membrane filtration. The MBR has several advantages such as complete removal of suspended solids, compact plant size, high rate of degradation, flexibility in operation, low rate of sludge production, disinfection and odour control, prolonged microorganisms retention time and treatment of recalcitrant and toxic organic and inorganic pollutants.

Chang et al. (2008) achieved pharmaceutical wastewater treatment by the membrane bioreactor and observed COD and BOD removal of 95 and 99 %, respectively. Some investigator used Zee Weed MBR technology for the treatment of pharmaceutical wastewater (Noble 2006).

Conclusion

The pharmaceutical industry is one of the most important for modern civilization. The life of millions of humans and animals depends on the life-saving medicines manufactured by these industries. Apart from this, pollutants are also generated during the manufacturing process of medicines. Therefore, an increasing number of pharmaceutical industries lead to hazardous impact on water quality and thus affect the surrounding environment and human health. Thus, the pharmaceutical industry has become one of the major causes of concern. The day by day increased level of water pollution highlights the need for time to time assessment/characterization of pharmaceutical industrial wastewater. Due to the rapid decrease in the level of water resources and increasing demand of water for consumption in our daily life, it is necessary to reuse the wastewater by developing a sustainable treatment process to clean up contaminated wastewater economically and safely, which could be easily adopted by the common masses.

The pollutants generated during the manufacturing process are easier to handle, as an industry is a point source of pollution and it is possible to install pollutant-specific treatment facilities. Various treatment methods for pharmaceuticals in water and wastewater found in literature have contributed greatly regarding the fate of these recalcitrant organic compounds in different treatment systems. The behaviour of these compounds in these systems would allow further characterization of the fate and risk associated with pharmaceuticals in the environment, yet this description trend is hindered by the wide variation in removal efficiencies across treatment processes and even among separate studies for the same individual compound.

There are a number of promising new treatments including advanced oxidation processes such as oxidation, ozonation, perozonation, direct photolysis, TiO2 photocatalysis, solar photocatalysis, Fenton reaction and ultrasonic irradiation. These significantly enhance the removal rate and biodegradability of pharmaceuticals from wastewater. More inputs are required in this area to improve treatment efficiencies, identify the degradation compounds and determine the cost and feasibility of full-scale operations. Most of these physicochemical processes removed the majority of the colloidal organic substances and suspended materials; however, refractory compounds still remained in the water effluent. Employing biological processes, these recalcitrant organic compounds undergo mineralization and meet the requirements for the wastewater discharge to sewage. Such combined processes will be efficient and present potential application in the industrial scale.

Biological treatments methods have traditionally been used for the management of pharmaceutical wastewaters. They are subdivided into aerobic and anaerobic processes which include the use of activated sludge, membrane batch reactor, sequence batch reactor, anaerobic sludge reactors, anaerobic film reactors and anaerobic filters. The wastewater characteristics play a key role in the selection of biological treatments. However, hydraulic retention time (HRT), temperature, pH, dissolved oxygen (DO), organic load, microbial community, presence of toxic and recalcitrant substances and the batch operation of the pharmaceutical production are the few variables that require modifications for adaptation to pharmaceutical wastewater to enhance the efficiency of the biodegradability and mineralization capability of biological processes.

Thus, bioremediation processes are technological tools that hold great promise for the future. They produce almost no waste by-product, have the potential of being cheaper and in combination with the different physicochemical and advanced oxidation processes, offer a better treatment of pharmaceutical industrial wastewater and thus help in utilizing the available water resource in a sustainable manner. It is likely to become one of the best technologies used to clean up and protect our environment.

References

Acharya BK, Mohana S, Madamwar D (2008) Anaerobic treatment of distillery spent wash: a study on up flow anaerobic fixed film bioreactor. Bioresour Technol 99:4621–4626

Adishkumar S, Sivajothi S, Banu JR (2012) Coupled solar photo-fenton process with aerobic sequential batch reactor for treatment of pharmaceutical wastewater. Desalin Water Treat 48:89–95

Agarry SE, Solomon BO (2008) Kinetics of batch microbial degradation of phenols by indigenous Pseudomonas fluorescence. Int J Environ Sci Technol 5(2):223–232

Ahmed AT, Mehrdadi N (2011) Wastewater treatment from antibiotics plant (UASB reactor). Int J Environ Res 5(1):241–246

Akunna JC, Clark M (2000) Performance of a granular-bed anaerobic baffled reactor (GRABBR) treating whisky distillery wastewater. Bioresour Technol 74(3):257–261

Altaf MS, Ali TA (2010) Wastewater treatment using sequential batch reactor and development of microbiological method for the analysis of relative toxicity. Pak J Nutr 9(6):574–576

Amin A, Naik ATR, Azhar M, Nayak H (2013) Bioremediation of different waste waters—a review. Cont J Fish Aquat Sci 7(2):7–17

Angayarkanni J, Palaniswamy M, Swaminathan K (2003) Biotreatment of distillery effluent using Aspergillus niveus. Bull Environ Contam Toxicol 70:268–277

Asamudo NU, Daba AS, Ezeronye OU (2005) Bioremediation of textile effluent using Phanerochaete chrysosporium. Afr J Biotechnol 4(13):1548–1553

Billore SK, Singh N, Ram HK, Sharma JK, Singh VP, Nelson RM, Dass P (2001) Treatment of a molasses based distillery effluent in a constructed wetland in central India. Water Sci Technol 44(11–12):441–448

Borja R, Sanchez E, Marin A, Jimenez AM (1996) Kinetic behaviour of waste tyre rubber as microorganism support in an anaerobic digester treating cane molasses distillery slops. Bioprocess Biosyst Eng 16:17–23

Chang CY, Chang JS, Vigneswaran S, Kandasamy J (2008) Pharmaceutical wastewater treatment by membrane bioreactor process—a case study in southern Taiwan. Desalination 000:1–9

Chaturvedi S, Chandra R, Rai V (2006) Isolation and characterization of Phragmitis australis (L) rhizosphere bacteria from contaminated site for bioremediation of colored distillery effluent. Ecol Eng 27:202–207

Chelliapan S, Yuzir A, Md Din MF, Sallis PJ (2011) Anaerobic pre-treatment of pharmaceutical wastewater using packed bed reactor. Int J Chem Eng Appl 2(1):32–37

Choudhary S, Parmar N (2013) Hazard assessment of liquid effluent treatment plant in pharmaceutical industry. VSRD Int J Technol NonTechnol Res 4(9):209–214

Damodhar U, Reddy MV (2013) Impact of pharmaceutical industry treated effluents on the water quality of river Uppanar, South east coast of India: a case study. Appl Water Sci 3(2):501–514

Das MP, Bashwant M, Kumar K, Das J (2012) Control of pharmaceutical effluent parameters through bioremediation. J Chem Pharm Res 4(2):1061–1065

Debska J, Kot-Wasik A, Namiesnik J (2004) Fate and analysis of pharmaceutical residues in the aquatic environment. Crit Rev Anal Chem 34(1):51–67

Deegan AM, Shaik B, Nolan K, Urell K, Oelgemöller M, Tobin J, Morrissey A (2011) Treatment options for wastewater effluents from pharmaceutical companies. Int J Environ Sci Technol 8(3):649–666

Deepali, Joshi N (2012) Study of ground water quality in and around SIDCUL industrial area, Haridwar, Uttarakhand, India. J Appl Technol Environ Sanitation 2(2):129–134

Dixit D, Parmar N (2013) Treatment of pharmaceutical waste water by electro-coagulation and natural coagulation process: review. VSRD Int J Technol NonTechnol Res 4(5):79–88

Duffner FM, Kirchner U, Bauer MP, Muller R (2000) Phenol/cresol degradation by the thermophillic Bacillus thermoglucosidasius A7: cloning and sequence analysis of five genes involved in the pathway. Gene 256:215–221

El-Gohary FA, Abou-Elela SI, Aly HI (1995) Evaluation of biological technologies for wastewater treatment in the pharmaceutical industry. Water Sci Technol 32(11):13–20

Elmolla ES, Ramdass N, Choudhari M (2012) Optimization of Sequencing Batch Reactor operating conditions for treatment of high strength pharmaceutical wastewater. J Environ Sci Technol 5(6):452–459

Enright AM, McHugh S, Collins G, O’Flaherty V (2005) Low-temperature anaerobic biological treatment of solvent containing pharmaceutical wastewater. Water Res 39(19):4587–4596

Fang HHP, Chui HK, Li YY (1994) Microbial structure and activity of UASB granules treating different wastewaters. Water Sci Technol 30:87–96

Farhadi S, Aminzadeh B, Torabian A, Khatibikamal V, Fard MA (2012) Comparison of COD removal from pharmaceutical wastewater by electrocoagulation, photoelectrocoagulation, peroxi-electrocoagulation and peroxi-photoelectrocoagulation processes. J Hazard Mater 219–220:35–42

Garcia A, Rivas HM, Figueroa JL, Monroe AL (1995) Case history: pharmaceutical wastewater treatment plant upgrade, Smith Kline Beecham Pharmaceuticals Company. Desalination 102(1–3):255–263

Ghosh M, Verma SC, Mengoni A, Tripathi AK (2004) Enrichment and identification of bacteria capable of reducing chemical oxygen demand of anaerobically treated spent wash. J Appl Microbiol 6:241–278

Gome A, Upadhyay K (2013) Biodegradability assessment of pharmaceutical wastewater treated by ozone. Int Res J Environ Sci 2(4):21–25

González PS, Capozucca CE, Tigier HA, Milrad SR, Agostini E (2006) Phytoremediation of phenol from wastewater, by peroxidases of tomato hairy root cultures. Enzyme Microbial Technol 39(4):647–653

Heberer T (2002) Occurrence, fate and removal of pharmaceutical residues in the aquatic environment: a review of recent research data. Toxicol Lett 131(1–2):5–17

Idris MA, Kolo BG, Garba ST, Ismail MA (2013) Physico-chemical analysis of pharmaceutical effluent and surface water of river Gorax in Minna, Niger State, Nigeria. Bull Env Pharmacol Life Sci 2(3):45–49

Ileri R, Sengil IA, Kulac S, Damar Y (2003) Treatment of mixed pharmaceutical industry and domestic wastewater by sequencing batch reactor. J Environ Sci Health A 38(10):2101–2111

Imran H (2005) Wastewater monitoring of pharmaceutical industry: treatment and reuse options. Electron J Environ Agric Food Chem 4(4):994–1004

Kansal A, Siddiqui NA, Gautam A (2011) Assessment of heavy metals and their interrelationships with some physicochemical parameters in ecoefficient rivers of Himalayan Region. Int J Environ Sci 2(2):440–450

Kar D, Sur P, Mandal SK, Saha T, Kole RK (2008) Assessment of heavy metal pollution in surface water. Int J Environ Sci Technol 5(1):119–124

Kaushik KA, Dalal SJ, Panwar S (2012) Impact of industrialization on culture of Uttarakhand and its role on career enhancement. VSRD Int J Bus Manage Res 2(4):123–132

Kavitha GV, Beebi SK (2003) Biodegradation of phenol in a packed bed reactor using peat media. Asian J Microbiol, Biotechnol Environ Sci 5(2):157–159

Kavitha RV, Murthy VK, Makam R, Asith KA (2012) Physico-Chemical analysis of effluents from pharmaceutical industry and its efficiency study. Int J Eng Res Appl 2(2):103–110

Khan MZH, Mostafa MG (2011) Aerobic treatment of pharmaceutical wastewater in a biological reactor. Int J Environ Sci 1(7):1797–1805

Khan S, Noor M (2002) Investigation of pollutants in wastewater of Hayatabad Industrial Estate Peshawar. Pak J Agri Sci 2:457–461

Krug M, Ziegler H, Straube G (1985) Degradation of phenolic compounds by the yeast Candida tropicalis HP15.I. Physiology of growth and substrate utilization. J Basic Microbiol 25:103–110

Kulik N, Trapido M, Goi A, Veressinina Y, Munter R (2008) Combined chemical treatment of pharmaceutical effluents from medical ointment production. Chemosphere 70(8):1525–1531

Kumar A, Kumar S, Kumar S (2005) Biodegradation kinetics of phenol and catechol using Pseudomonas putida MTCC 1194. Biochem Eng J 22(2):151–159

Lapara TM, Nakatsu CH, Pantea LM, Alleman JE (2001) Aerobic biological treatment of a pharmaceutical wastewater: effect of temperature on COD removal and bacterial community development. Water Res 35(18):4417–4425

Lapara TM, Nakatsu CH, Pantea LM, Alleman JE (2002) Stability of the bacterial communities supported by a seven-stage biological process treating pharmaceutical wastewater as revealed by PCR-DGGE. Water Res 36(3):638–646

Lee CM, Lu CJ, Chuang MS (1994) Effects of immobilized cells on the biodegradation of chlorinated phenols. Water Sci Technol 30:87–90

Lokhande RS, Singare PU, Pimple DS (2011) Toxicity Study of heavy metals pollutants in waste water effluents samples collected from Taloja Industrial Estate of Mumbai, India. Resour Environ 1(1):13–19

Madukasi EI, Dai X, He C, Zhou J (2010) Potentials of phototrophic bacteria in treating pharmaceutical wastewater. Int J Environ Sci Technol 7(1):165–174

Mayabhate SP, Gupta SK, Joshi SG (1988) Biological treatment of pharmaceutical Wastewater. Water Air Soil Pollut 38(1–2):189–197

Melero JA, Martínez F, Botas JA, Molina R, Pariente MI (2009) Heterogeneous catalytic wet peroxide oxidation systems for the treatment of an industrial pharmaceutical wastewater. Water Res 43:4010–4018

Misal SA, Lingojwar DP, Shinde RM, Gawai KR (2011) Purification and characterization of azoreductase from alkaliphilic strains Bacillus badius. Process Biochem 46(6):264–269

Modak DP, Singh KP, Ahmed S, Ray PK (1990) Trace metal ion in Ganga water system. Chemosphere 21(1–2):275–287

Mohammad P, Azarmidokht H, Fatollah M, Mahboubeh B (2006) Application of response surface methodology for optimization of important parameters in decolorizing treated distillery wastewater using Aspergillus fumigatus UB2.60. Int Biodeterior Biodegrad 57:195–199

Nadal M, Schuhmacher M, Domingo JL (2004) Metal pollution of soils and vegetation in an area with petrochemical industries. Sci Total Environ 321(1–3):59–69

Nandy T, Shastry S, Kaul SN (2002) Wastewater management in a cane molasses distillery involving bio resource recovery. J Environ Manage 65:25–38

Ng WJ, Yap MGS, Sivadas M (1989) Biological treatment of a pharmaceutical wastewater. Biol Wastes 29(4):299–311

Noble J (2006) GE Zee Weed MBR technology for pharmaceutical wastewater treatment. Membr Technol 2006(9):7–9

Oktem YA, Ince O, Sallis P, Donnelly T, Ince BK (2007) Anaerobic treatment of a chemical synthesis-based pharmaceutical wastewater in a hybrid upflow anaerobic sludge blanket reactor. Bioresour Technol 99(5):1089–1096

Patel HD, Madamwar (2000) Biomethanation of low pH petrochemical wastewater using up-flow fixed film anaerobic bioreactors. World J Microbiol Biotechnol 16:69–75

Patil PG, Kulkarni GS, Kore SV, Kore VS (2013) Aerobic sequencing batch reactor for wastewater treatment: a review. Int J Eng Res Technol 2(10):534–550

Perez M, Romero LI, Nebot E, Sales D (1997) Colonisation of a porous sintered glass support in anaerobic thermophilic bioreactors. Bioresour Technol 59:177–183

Raj DSS, Anjaneyulu Y (2005) Evaluation of biokinetic parameters for pharmaceutical wastewaters using aerobic oxidation integrated with chemical treatment. Process Biochem 40(1):165–175

Rajaram T, Das A (2008) Water pollution by industrial effluents in India: discharge scenarios and case for participatory ecosystem specific local regulation. Futures 40(1):56–69

Rajeshwari KV, Balakrishnan M, Kansal A, Lata K, Kishore VVN (2000) State-of art of anaerobic digestion technology for industrial wastewater treatment. Renew Sust Energ Rev 4:135–156

Ramola B, Singh A (2013) Heavy metal concentrations in pharmaceutical effluents of Industrial Area of Dehradun (Uttarakhand), India. Int J Environ Sci Res 2(2):140–145

Rana RS, Singh P, Singh R, Gupta S (2014a) Assessment of physic-chemical pollutants in Pharmaceutical Industrial wastewater of Pharmacity, Selaqui, Dehradun. Int J Res Chem Environ 4(2):136–142

Rana RS, Kandari V, Singh P, Gupta S (2014b) Assessment of heavy metals in Pharmaceutical Industrial wastewater of Pharmacity, Selaqui, Dehradun, Uttarakhand, India. Anal Chem Lett 4(1):29–39

Rao AG, Naidu GV, Prasad KK, Rao NC, Mohan SV, Jetty A, Sharma PN (2004) Anaerobic treatment of wastewater with high suspended solids from a bulk drug industry using fixed film reactor (AFFR). Bioresour Technol 93:241–247

Rohit CK, Ponmurugan P (2013) Physico-chemical analysis of textile automobile and pharmaceutical industrial effluents. Int J Latest Res Sci Technol 2(2):115–117

Rosen M, Welander T, Lofqvist A, Holmgren J (1998) Development of a new process for treatment of a pharmaceutical wastewater. Water Sci Technol 37(9):251–258

Saleem M (2007) Pharmaceutical wastewater treatment: a physicochemical study. J Res (Sci) 18(2):125–134

Seth R, Singh P, Mohan M, Singh R, Aswal RS (2013) Monitoring of phenolic compounds and surfactants in water of Ganga Canal, Haridwar (India). Appl Water Sci 3(4):717–720

Sirtori C, Zapata A, Oller I, Gernjak W, Aguera A, Malato S (2009) Decontamination industrial pharmaceutical wastewater by combining solar photo-Fenton and biological treatment. Water Res 43:661–668

Spina F, Anastasi A, Prigione V, Tigini V, Varese GC (2012) Biological treatment of industrial wastewaters: a fungal approach. Chem Eng Trans 27:175–180

Sreekanth D, Sivaramakrishna D, Himabindu V, Anjaneyulu Y (2009) Thermophilic treatment of bulk drug pharmaceutical industrial wastewaters by using hybrid up flow anaerobic sludge blanket reactor. Bioresour Technol 100(9):2534–2539

Tewari L, Malviya P (2002) Biodegradation of catechol by fluorescent Psuedomonas for sustainable environment. J Sci Ind Res 61:70–74

Tóth AJ, Gergely F, Mizsey P (2011) Physicochemical treatment of pharmaceutical process wastewater: distillation and membrane processes. Chem Eng 55(2):59–67

Vanerkar AP, Satyanarayan S, Dharmadhikari DM (2013) Full scale treatment of herbal pharmaceutical industry wastewater. Int J Chem Phys Sci 2:52–62

Vuppala NVS, Suneetha C, Saritha V (2012) Study on treatment process of effluent in Bulk drug industry. Int J Res Pharm Biomed Sci 3(3):1095–1102

Wei X, Li B, Zhao S, Wang L, Zhang H, Li C, Wang S (2012) Mixed pharmaceutical wastewater treatment by integrated membrane-aerated biofilm reactor (MABR) system—a pilot-scale study. Bioresour Technol 122:189–195

Yang W, Cicek N, Ilg J (2006) State-of-the-art of membrane bioreactors: worldwide research and commercial applications in North America. J Membr Sci 207:201–211

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Rana, R.S., Singh, P., Kandari, V. et al. A review on characterization and bioremediation of pharmaceutical industries’ wastewater: an Indian perspective. Appl Water Sci 7, 1–12 (2017). https://doi.org/10.1007/s13201-014-0225-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-014-0225-3