Abstract

Surfactant adsorption in porous media is one of the major criteria which decide the economic viability of surfactant flooding in chemical enhance oil recovery applications (CEOR). In this study, the static adsorption of a novel in-house synthesized anionic surfactant was investigated onto crushed Berea sandstone. The point of zero (PZC) charge for Berea sandstone and critical micelle concentration (CMC) of anionic surfactant are also reported in this paper. The investigated PZC for Berea core was at pH 8.0 and the maximum adsorption of anionic surfactant was 0.96 mg/g. Furthermore, the effects of alkali, salinity and temperature on static adsorption of anionic surfactant were investigated at variable conditions. It was concluded that the anionic surfactant performs better at higher pH, higher temperature and lower salt concentration. An effective control of all these parameters can lead to the situation which helps in minimizing the surfactant loss and improved economic efficiency of CEOR process.

Similar content being viewed by others

Introduction

The term “surfactant” represents a long-chain molecule containing both hydrophilic and hydrophobic moieties. Surfactants are extensively used in a number of applications because of their abilities to alter the properties of surfaces and interfaces. The applications of surfactants in petroleum industries are significant and diverse, especially in enhanced oil recovery (EOR) processes (Grigg et al. 2004; Grigg and Mikhalin 2007).

Surfactant adsorption is a process of transfer of surfactant molecules from the bulk solution phase to the interface (Lv et al. 2011). The phenomena by which surfactant molecules adsorb onto the solid surface from an aqueous solution involve single ions, ion exchange, ion pairing, hydrophobic bonding, π electrons polarization and dispersion forces. However, the surfactant adsorption is a complex process and it depends on various characteristics of aqueous solution such as pH, salinity, temperature, ionic strength, divalent ions and in addition the type, concentration and composition of the surfactants involved (Grigg and Bai 2004; Dang et al. 2011; Lv et al. 2011). The loss of surfactant in the reservoir results in the unfeasible and uneconomical chemical enhanced oil recovery (CEOR) process (Grigg and Bai 2005).

Surfactant adsorption at solid/liquid interface is a multifaceted phenomenon; therefore, the driving force for adsorption involves a combination of electrostatic, chemical, lateral chain–chain associative interaction, hydrogen bonding and de-solvation of adsorbate species (Somasundaran and Huang 2000). The adsorption isotherm on an oppositely charged solid surface usually follows a four-stage mechanism (Zhang and Somasundaran 2006).

The electric double layer is always formed at any interface by the unequal distribution of electrical charges between two phases which causes one side of the interface to acquire a net charge of a particular sign and the other side to acquire a net charge of the opposite sign, giving rise to a potential across the interface. At low surfactant concentrations, the adsorption is fundamentally determined by the charge on the electrical double layer. The surfactant adsorption is increased by the commencement of hydrophobic interactions between adsorbed surfactant molecules. At higher surfactant concentrations, it reaches its maxima at the critical micelle concentration (CMC) (Paria et al. 2005). The charge on these mineral colloids depends on various factors such as the nature of the colloid, pH, ionic strength, and other solution properties; where, pH is the most prominent factor (Paria and Khilar 2004). In sandstone, the surface charge is typically positive at lower pH and decreases to a negative value as the solution pH shifts to the higher values. The pH value at which the net charge on a surface is zero is termed as point of zero charge (PZC) (Appel et al. 2003). The anionic surfactants being negatively charge can be used in CEOR process when the surface pH is greater than PZC.

The use of alkali has proven to reduce the adsorption of anionic surfactants (Hirasaki et al. 2008). Alkali increases the pH and decreases the number of positive sites available for the adsorption on the surface. Sodium carbonate is a conventional alkali used to achieve a low interfacial tension (IFT) by generating in situ surfactants by reacting with acidic compound present in the crude oil. It can also act as a sacrificial agent resulting in the decreased adsorption because it consumes the multivalent cations which would otherwise precipitate with surfactants and cause plugging in rock pores thereby reducing permeability (Grigg et al. 2004; Hirasaki et al. 2008). Another alkali, sodium tetraborate which is also known as Borax is a novel alkali which can isolate multivalent cations by coordination rather than precipitation. Sodium tetraborate has a high salinity tolerance due to comparatively less ionic strength as compared to sodium metaborate (Lv et al. 2011).

Most of the anionic surfactants are sensitive to temperature changes and can precipitate by variation in temperature. The adsorption of anionic surfactant is reduced at elevated temperature and at low surfactant concentrations (Borges and Díaz 2012). Increasing the salt concentration in the surfactant solution leads to an increase in charge sites and hence causes an abrupt increase in the adsorption of anionic surfactants onto negatively charged surfaces. Therefore, to a certain degree, moderate surfactant retention can be overcome by an imposed negative salinity gradient (Grigg and Bai 2005).

In this study we report the static adsorption of a novel in-house synthesized anionic surfactant onto crushed Berea sandstone. It includes the determination of the (PZC) for Berea cores using two different titration methods and the determination of the CMC of synthesized surfactant by conductivity method. Furthermore, the effects of various factors such as pH, NaCl salinity and temperature onto the adsorption of synthesized surfactant are also investigated.

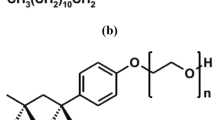

Materials

Anionic surfactant was synthesized in our laboratory. It contains 16–18 carbons chain with branching (five carbons chain) in the middle and a sulfonate head group. Sodium tetraborate, sodium metaborate, sodium hydroxide, hydrogen chloride, sodium chloride were purchased from J. T Baker, and methanol, sulfuric acid, sodium carbonate were obtained from Merck. Standard 0.004 M solution of Hyamine was purchased from Fisher Scientific. All chemicals were of analytical grade and used as received without further purification.

Berea Core was used as an adsorbent which was obtained from Cleveland Quarries. The Berea core was mechanically grinded to a powder with an average particle size of 450 μm (50–30 mesh size). The composition of the crushed core is reported in Table 1.

Analytical methods

Surfactant concentration was measured by titration method. A specific amount of surfactant sample was titrated against standard 0.004 M Hyamine solution on Metrohm Titrando 888 which uses a special electrode for the detection of anionic surfactants. The volume of Hyamine solution used for each titration was noted to measure the surfactant concentration. All solutions were prepared using deionized water.

Specific surface area of core sample was measured on Micromeritics ASAP 2020 by physisorption of N2 using Brunauer–Emmet–Teller (BET) method. The N2 adsorption isotherms were measured at −196 °C. The sample was degassed at 160 °C for 4 h before the analysis.

X-ray fluorescence spectroscopic (XRF) analysis of core for elemental analysis was done on the Bruker S4 PIONEER X-ray fluorescence Spectrometer. A Ru target at 4 kW power was used.

CMC of surfactant

The CMC of synthesized surfactant was measured by conductivity method. The conductivity (μS cm−1) of a series of surfactant solution with different concentrations was measured using the conductivity meter (H19033 Auto temperature control conductivity meter from HANNA instruments). The surfactant concentration was plotted against conductivity. The CMC is identified as the point on plot where it changes its slope for the first time.

PZC of Berea core

The PZC of Berea core was verified by two different methods namely as discussed in the following sections.

Salt addition method

A 0.01 M KCl solution was used as background electrolyte. An equal quantity of background solution (40 mL) was apportioned into 11 different flasks kept in series with increasing pH values from 2 to 12. The pH was recorded using Metrohm 888 Titrando. A constant weight of crushed Berea core (0.2 g) was added to all these flasks and the change in pH of each solution was recorded using the same pH meter after shaking the samples for 24 h. This change in pH was plotted against the initial pH values on the graph, and PZC was identified at pH when ∆pH = 0 (Mustafa et al. 2002).

Potentiometric mass titration (PMT)

Point of zero charge of Berea sandstone was also determined using potentiometric mass titration technique. In this method, Na+ solution was used as background electrolyte. A constant quantity of this background electrolyte (100 mL) was transferred into three different flasks kept in series. The crushed Berea core with different weights 0.2, 0.4 and 0.6 g was transferred to each flask, respectively. A blank solution was also prepared without the addition of core sample.

When all the four solutions were equilibrated with crushed core, a defined quantity of base 0.1 M NaOH (5 mL) was added to all these flasks. Each of these solutions was titrated against the same concentration of acid, i.e. 0.1 M HCl using 0.2 mL additions by Metrohm 888 Titrando. The pH was recorded after every 30 s and the common intersection point between the blank and sample solutions was identified as PZC (Farooq et al. 2011).

Adsorption studies

Static adsorption of anionic surfactant was determined using 2 g of crushed core sample in 20 mL of surfactant solution. The mixture of Berea core and anionic surfactant was agitated on a horizontal shaker for 24 h at 25 °C. Then, mixtures were centrifuged at 3,000 rpm for 30 min and supernatant was filtered through a syringe filter of 0.45 μm. The supernatant liquid (filtrate) was analyzed for surfactant concentration by titration method as stated earlier. The same method was employed to study the static adsorption of anionic surfactant on Berea sandstone in the presence of two different alkalis, different NaCl salinities and at different temperature range. A solution containing the same quantity of alkali, salinity and core sample was used as blank solution. A difference in the surfactant’s concentration before and after its contact with the core sample was calculated to record the amount of surfactant adsorbed (mg/g) onto the crushed core samples.

Results and discussion

Core properties

The Berea core sample was grinded in a ball mill and dried well before use. The specific surface area of Berea sandstone was found to be 22.54 m2/g.

The composition of core sample was determined by XRF analysis and is reported in Table 1. Silica and Alumina have the highest fractions among others and, therefore, the surface chemistry of Berea core depends on these two species.

CMC of surfactant

The CMC of surfactant sample is indicated on a plot in Fig. 1. The CMC for available anionic surfactant was found to be 0.179 wt.%. The conductivity rises linearly with increasing surfactant concentration until it reaches a specific point beyond which conductivity changes its slope and increases linearly with lower slope. The point on the graph where conductivity changes its slope following an increase in the concentration was identified as the CMC. The CMC indicates that further increase in surfactant concentration beyond this point does not increase surfactant adsorption onto the interface; however, the added surfactant only increases micellization in solution.

Point of zero charge (PZC)

The PZC was determined by two different techniques. The respective plots are shown in Figs. 2 and 3, respectively. The PZC by salt addition method was found to be 7.9. The PZC estimation by PMT is found to be 8.1 as shown in Fig. 3. The average PZC by the two methods was precisely at pH 8. A similar value of PZC is also reported elsewhere for Berea sandstone (Sharma and Yen 1984).

The PZC of Berea core sample indicates that beyond pH 8.0, the surface charge on Berea core is negative. The anionic surfactants experience a repulsion forces when it was introduced to a solid containing negative surface charge. Anionic surfactant adsorption decreases onto a negatively charge surface.

Adsorption isotherm

The adsorption isotherm is the plot of surfactant concentration against the adsorption density (mg/g). The adsorption isotherm of anionic surfactant onto Berea sandstone is shown in Fig. 4. A typical isotherm usually shows four regions (Paria and Khilar 2004). Region 1 which occurs at lower surfactant concentration and monomers is adsorbed onto substrate due to electrostatic interaction between the head group charge and net charge present onto the surface of the adsorbent. In this region, adsorption obeys Henry’s law and increases linearly with surfactant concentration; the slope of the curve is approximately 1 until it reaches region 2. In region 2 there is a sharp increase in adsorption density due to the formation of surface aggregates, called colloids (surface colloids) which include hemi-micelles, admicelles, etc. These surface aggregates are formed due to lateral interactions between hydrocarbon chains and surface monomers. Due to the additional driving force originating from the lateral interaction of monomers, the adsorption density increases sharply. In region 3, the adsorption density increases with a lower gradient, because in this region the solid surface is electrically neutralized by the adsorbed surfactant monomers and adsorption takes place due to lateral interactions only. In region 4, the surfactant reaches CMC; therefore, any further increase in surfactant concentration contributes to the micellization in solution and hence adsorption is constant. In this region, surfactant molecules adsorb onto the surface with reverse orientation which results in decreasing hydrophobicity of the particles (Paria and Khilar 2004; Somasundaran and Zhang 2006).

At the start of the adsorption isotherm, region 1 is identified by the oppositely charge interaction resulting in a higher adsorption rate. It is less dependent on surfactant concentration. A steady and higher adsorption occurs in the region 2. The region 3 is difficult to identify because of its occurrence over a narrow range. The region 4 specifies the upper limit of adsorption which shows that there is no further increase in adsorption density beyond 0.96 mg/g. This plateau is the region 4.

Effect of pH on surfactant adsorption

The silica fraction in Berea sandstone is the highest fraction. Silica group can acquire a different charge depending on the pH of the solution. At lower pH, silica acquires positive charge while at higher pH it contains negative surface charge. The mechanism by which silica surfaces acquires a charge is indicated by the following Eqs. (1 and 2):

PZC of Berea sandstone was found to be 8.0. At pH above 8.0, Berea rock sample carries negative surface charge; therefore, anionic surfactants will have a lower adsorption values due to repulsion forces between each other. This is experimentally evident from its low values in the presence of different alkalis.

Two different alkalis, i.e. sodium metaborate (pH 9.5) and sodium teraborate (pH 10.5) were used at low ionic strengths and at higher concentration of divalent cations. The adsorption values of surfactant were reduced to 0.28 mg/g and 0.36 mg/g using the sodium tetraborate and sodium metaborate, respectively. Figure 5 illustrates the effect of both alkalis on surfactant adsorption. Surfactant appears to adsorb lesser onto Berea sandstone in the presence of sodium tetraborate as compared to sodium metaborate.

Effect of salinity on surfactant adsorption

Adding NaCl decreases the functional group electrostatic repulsion in the adsorbed layer. Electrical double layer can be compressed strongly by increasing the salt concentration; as a result, adsorption of anionic surfactant will increase with an increase of salt concentration (Dang et al. 2011).

The adsorption of anionic surfactant was found to be higher by increasing the salt concentration. Sodium chloride salinity with 1 and 2 wt.% was employed to conduct static adsorption test in Berea sandstone. The adsorption density was increased to 1.29 and 1.56 mg/g using 1 wt.% NaCl and 2 wt.% NaCl, respectively, as shown in Fig. 6. Bai and Grig also reported similar trends on adsorption density by increasing salt concentration (Bai and Grigg 2005).

Effect of temperature on surfactant adsorption

The adsorption of anionic surfactant onto Berea sandstone at 70 and 90 °C was reduced to 0.82 and 0.75 mg/g, respectively, when compared to adsorption density at 25 °C (0.96 mg/g). The results for surfactant adsorption at higher temperature are illustrated in Fig. 7. The effect of temperature on surfactant adsorption has also been reported to show the similar behavior (Grigg and Bai 2004).

The adsorption of surfactant is found to be slightly decreased at higher temperature due to the onset of higher translational kinetic energy. The force of interaction between the surfactant and Berea sandstone becomes weaker at higher temperatures. The relatively high kinetic energy and subsequent high entropy are factors behind the low adsorption of surfactants at high temperature (Paria and Khilar 2004). The consistent perturbations of the surfactant monolayers caused by the high kinetic energy resist the formations of any organized layer of surfactants molecules and subsequently lead to the low adsorption at high temperatures.

Conclusions

The adsorption of a novel in-house synthesized anionic surfactant at various conditions onto Berea sandstone was investigated in this study. The CMC of the surfactant was determined by the conductivity method. The PZC of Berea sandstone sample was estimated by employing two methods namely salt addition method and Potentiometric mass titration methods. Static adsorption experiments at various pH, salinity and temperature conditions were performed. Based on the results of surfactant adsorption experiments using Berea sandstone, the following conclusions can be drawn:

The CMC of synthesized anionic surfactant using conductivity method was found to be 0.179 wt.% (1790 ppm). The mean PZC value determined using the two methods was 8.0 which indicated that the Berea sandstone carries a negative charge at pH above 8.0. It was noted that the surfactant adsorption was slightly higher 0.96 mg/g at pH value lower than the PZC pH. However, the surfactant adsorption was reduced significantly with the incorporation of the alkalis. Sodium tetraborate had a marked effect by decreasing the surfactant adsorption considerably (0.28 mg/g) onto Berea sandstone as compared to sodium metaborate (0.36 mg/g). This pronounced effect may be attributed to the lowering of the ionic strength and high salinity tolerance of sodium tetraborate as compared to sodium metaborate. Both alkalis decreased the positive charge of the surface of Berea sandstone due to an increase in the pH. Increasing NaCl concentration also elevated the surfactant adsorption onto Berea sandstone until 2 wt.% concentration. After this value, any increase in salinity did not significantly affect the surfactant adsorption. Surfactant adsorption was increased to 1.29 and 1.56 mg/g by the addition of 1 and 2 wt.% NaCl, respectively. However, temperature had the reverse effect to salinity, the surfactant adsorption is reduced with increasing temperature. Surfactant adsorption onto Berea sandstone was reduced to 0.82 and 0.75 mg/g at 70 and 90 °C, respectively.

References

Appel C, Ma LQ, Dean Rhue R, Kennelley E (2003) Point of zero charge determination in soils and minerals via traditional methods and detection of electroacoustic mobility. Geoderma 1131–2:77–93

Bai B, Grigg RB (2005) Kinetics and equilibria of Calcium lignosulfonate adsorption and desorption onto limestone. In: SPE International Symposium on oilfield chemistry. Society of Petroleum Engineers Inc., The Woodlands, Texas

Borges ME, Díaz L (2012) Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: a review. Renew Sustain Energy Rev 165:2839–2849

Dang CTQ, Chen ZJ, Nguyen NTB, Bae W, Phung TH (2011) Development of isotherm polymer/surfactant adsorption models in chemical flooding. In: SPE Asia Pacific Oil and Gas Conference and Exhibition. Society of Petroleum Engineers, Jakarta

Farooq U, Tweheyo MT, Sjöblom J, Øye G (2011) Surface characterization of model, outcrop, and reservoir samples in low salinity aqueous solutions. J Dispers Sci Technol 324:519–531

Grigg RB, Bai B (2004) Calcium lignosulfonate adsorption and desorption on Berea sandstone. J Colloid Interface Sci 2791:36–45

Grigg RB, Bai B (2005) Sorption of surfactant used in CO2 flooding onto five minerals and three porous media. In: SPE International Symposium on Oilfield Chemistry, The Woodlands, Texas

Grigg RB, Mikhalin AA (2007) Effects of flow conditions and surfactant availability on adsorption. In: International Symposium on Oilfield Chemistry. Society of Petroleum Engineers, Houston, Texas, USA

Grigg RB, Bai B, Liu Y (2004) Competitive adsorption of a hybrid surfactant system onto five minerals, Berea sandstone, and limestone. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, Houston, Texas

Hirasaki GJ, Miller CA, Puerto M (2008) Recent advances in surfactant EOR. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, Denver, Colorado, USA

Lv W, Bazin B, Ma D, Liu Q, Han D, Wu K (2011) Static and dynamic adsorption of anionic and amphoteric surfactants with and without the presence of alkali. J Petrol Sci Eng 772:209–218

Mustafa S, Dilara B, Nargis K, Naeem A, Shahida P (2002) Surface properties of the mixed oxides of iron and silica. Colloids Surf, A 2053:273–282

Paria S, Khilar KC (2004) A review on experimental studies of surfactant adsorption at the hydrophilic solid–water interface. Adv Colloid Interface Sci 1103:75–95

Paria S, Manohar C, Khilar KC (2005) Adsorption of anionic and non-ionic surfactants on a cellulosic surface. Colloids Surf, A 2522–3:221–229

Sharma MM, Yen TF (1984) Interfacial electrochemistry of oxide surfaces in oil-bearing sands and sandstones. J Colloid Interface Sci 981:39–54

Somasundaran P, Huang L (2000) Adsorption/aggregation of surfactants and their mixtures at solid–liquid interfaces. Adv Colloid Interface Sci 881–2:179–208

Somasundaran P, Zhang L (2006) Adsorption of surfactants on minerals for wettability control in improved oil recovery processes. J Petrol Sci Eng 521–4:198–212

Zhang R, Somasundaran P (2006) Advances in adsorption of surfactants and their mixtures at solid/solution interfaces. Adv Colloid Interface Sci 123–1260:213–229

Acknowledgments

Financial support of PETRONAS Research Sdn. Bhd. (PRSB) through PRF Project 158200042 and usage of EOR Centre of Excellence facilities is highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Azam, M.R., Tan, I.M., Ismail, L. et al. Static adsorption of anionic surfactant onto crushed Berea sandstone. J Petrol Explor Prod Technol 3, 195–201 (2013). https://doi.org/10.1007/s13202-013-0057-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-013-0057-y