Abstract

The dye-sensitized solar cells (DSSCs) are attractive due to their low cost and promising efficiency. One of the research perspectives in the respective field is to replace the expensive and photodegradable ruthenium metal-based dyes. Present work describes a simple, modified in situ route designed by mimicking the adsorption principle of dyes in DSSCs for surface modification and linking of CdS-Quantum Dots (QDs) to TiO2 electrode. An organic compound 2-mercaptoethanol (ME) was used as a surface modifying and linking agent. By following this route it was expected to get a well assembled layer of CdS QDs for better cell performance but performances were not as expected. The main reason for low photocurrent density is the partial coverage of QDs surface by ME and the spatial distance between QDs and TiO2 electrode. Additional surface treatment of the CdS QDs sensitized TiO2 electrode resulted in an increase in the photocurrent density and photovoltage. This indicates that ME is not an effective capping agent and thus partially covers the QDs surface. The remaining sites, not covered by ME were passivated by sulfur ions in the ionic solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Challenging issues of limited reserves and pollutant emissions of fossil fuels are now directing the research intentions toward the development of alternative, sustainable and renewable initiatives to meet the demand of clean energy. Amongst the various options of renewable sources, solar energy acts as a prominent and abundant source of clean energy. Over the past years tremendous amount of research has been done in the study of solar cells.

In 1991 Professor Michael Grätzel, reported a new architecture for solar cells based upon nanocrystalline TiO2 electrode and chemical dyes as a photo sensitizer (Regan and Grätzel 1991), termed as dye sensitized solar cells (DSSC). Presently DSSC acts as a promising alternative to the conventional silicon solar cells due to their special features such as low cost, environmental friendly, and moderately high energy conversion efficiency.

Nowadays, enormous efforts are aimed for the performance improvement and long term stability of DSSC. In this regard a variety of investigations have been made by designing dye molecules (Robertson 2006), using organic dyes (Sanghoon et al. 2006) and robust electrolytes (Wang et al. 2003). Currently DSSC based upon ruthenium complex dyes (N3) has reached the power conversion efficiency of about 11 % (Nazeeruddin et al. 2005).

In addition to the dye sensitizers, inorganic semiconductor quantum dots (QDs) have received a wider attention for photovoltaic application. Semiconductor quantum dots can be considered as a good candidate to be a sensitizer due to their specific advantages over chemical dyes. Firstly due to quantum confinement effect they possess tunable band gaps and thus their photoresponse can be tuned (Yu et al. 2003). Secondly semiconductor QDs open a new way to utilize hot electrons via impact ionization (Nozik 2002). In addition to these, semiconductor QDs are easy to synthesize, cheaper, more stable alternative and posses a larger extinction coefficient as compared to conventional dyes. To fascinate such unique properties of QDs, the QDs are attached to the electrode material surface for solar cell application and the device configuration is termed as quantum dot sensitized solar cell (QDSC). At present there exist various reports about different semiconductor quantum dots such as CdS (Lin et al. 2007), CdSe (Lee and Chang 2008), PbS (Plass et al. 2002), InAs (Yu et al. 2006) and InP (Zaban et al. 1998) which have been synthesized and employed as a photosensitizer.

For the sensitization of semiconductor QDs to the electrode material, generally two routes are followed:

-

(i)

In situ synthesis and deposition of QDs by chemical bath deposition (CBD) (Niitsoo et al. 2006) or successive ionic layer adsorption and reaction (SILAR) (Nicolau et al. 1990) method. In this route the QDs are directly grown onto the electrode material surface by the chemical reaction of respective ionic species.

-

(ii)

Ex situ route linking the synthesized colloidal QDs to the electrode material surface via a bifunctional linker (Robel et al. 2006).

Both routes have their own advantages and disadvantages. The former route shows better performance due to less spatial distance between the QDs and the substrate surface. While the later route has an advantage of controlling the QDs properties like size and shape. However, despite of the advantages known for using QDs, the efficiency of QDSC is still low as compared to DSSC and requires further development. The possible reasons for low photovoltaic performance of QDSC includes the difficulty of assembling QDs into mesoporous film of TiO2 and presence of a large number of unpassivated or partially passivated surface states. These surface states can act as trap centers for holes and electrons, leading to lower photovoltage and photocurrent (Hodes 2008).

It’s well known fact that the carboxylic group in the dyes plays vital role for the adsorption of the dyes upon TiO2 surface in DSSCs (Thavasi et al. 2008; Statthatos et al. 2001). Adopting the same principle an attempt was made to modify the surface of the CdS QDs by rendering the surface with hydroxyl group using suitable bifunctional linker material. It was expected that with surface representation of hydroxyl group it will lead to better assembling of CdS QDs into mesoporous TiO2 layer. The experimental procedure based upon in situ route consists of two main steps:

-

(i)

First step consists of synthesis of CdS QDs using conventional CBD method.

-

(ii)

Second step includes the addition of bifunctional linker in the chemical bath. The purpose of this addition is the surface modification of the CdS QDs and linking the QDs to the electrode material simultaneously in the same bath.

This route is expected to yield better coverage of surface modified CdS QDs which in turn may result in the better assembling upon TiO2 surface.

In this paper, we report our observations, following this route. 2-Mercaptoethanol (ME) has been used as the bifunctional linker. The role of ME has been verified and been shown to work as a linker with the TiO2 electrodes. QDSC properties have also been examined upon ME linkage. Furthermore we have also analyzed the effect of additional surface treatment of the TiO2/CdS QDs electrode using an ionic solution providing sulfur ions and evaluate the cell performance before and after the surface treatment. After the surface treatment an increase in the cell efficiency was observed which was mainly contributed by increase in the photocurrent. This demonstrates that after the sensitization of QDs followed by this route there are still many unpassivated sites in terms of Cd2+ dangling bonds, acting as electron trap centers. Sulfur ions in the ionic solution may coordinate with these sites and thus enhances photocurrent by removal of these electron trap centers.

Experimental section

Materials used

The precursors employed in this investigation to synthesize CdS QDs include cadmium acetate dihydrate [(C2H3O2)2 Cd·2H2O, 98 %], thiourea [(CH4N2S), 99 %], ammonium chloride[(NH4Cl), 99.5 %], liquid ammonia[(NH4OH), 28 %] and 2-mercaptoethanol (98.0 %). Sodium sulfide nonahydrate [(Na2S·9H2O), 98 %] ionic solution was used for surface treatment of TiO2/CdS QDs electrode. All the chemicals except liquid ammonia were purchased from Aldrich and used as such. Liquid ammonia was purchased from Junsei Chemicals and also used as procured.

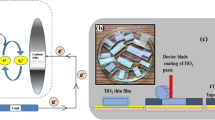

Preparation of CdS/TiO2 Photoelectrode

Synthesis of CdS QDs

Firstly the solutions of 0.3 M cadmium acetate dihydrate [(C2H3O2)2 Cd·2H2O, 98 %] and 0.9 M ammonium chloride [(NH4Cl), 99.5 %], were mixed and vigorously stirred. Then this solution was mixed with 2.1 M thiourea [(CH4N2S), 99 %] solution. The pH of the complete mixture was maintained between 9 and 12 by adding liquid ammonia with the temperature maintained at 45 °C. Liquid ammonia acts as a complexing agent forming intermediate cadmium complex [Cd(NH3) 2+4 ] releasing cadmium ions and also making the medium alkaline to release sulfide ions from thiourea. The ionic states of both precursors combine to form CdS nanocrystals. The reaction mechanism considered to be the same as proposed by Ortegu-Borges (Borges and Lincot 1993).

Sensitizing of CdS QDs

Just after the addition of the liquid ammonia the growth prevention and linking of the QDs were carried out by adding 0.1 mM ME directly into the mixed solution. In the meanwhile, already prepared TiO2 electrode was dipped in the chemical bath with CdS QDs solution and the CdS QDs got linked to the TiO2 electrode via bifunctional linker. The TiO2 electrode was immersed in the CdS QDs solution for 1 h. After that the TiO2 electrode was washed with DI water and air dried. The nanoporous TiO2 electrode was prepared according to procedure described elsewhere (Bhattacharya et al. 2007).

Surface treatment

The surface treatment of above prepared TiO2/CdS QDs electrode was performed by dipping in 0.3 M ionic solution of sodium sulfide nonahydrate [(Na2S·9H2O), 98 %]. The TiO2/CdS QDs electrode was dipped for 15 min in the ionic solution, taken out, washed with DI water and air dried.

Solar cell fabrication

TiO2/CdS QDs electrode and a drilled platinum coated counter electrode were used to fabricate a solar cell. The procedure followed for platinum coated counter electrode is described elsewhere (Bhattacharya et al. 2007). 60 μm thick Surlyn (Solaronix) film was used as a spacer and sealant. The Surlyn film was sandwiched between front and counter electrode and pressed for 2 min at 100 °C. The liquid electrolyte was injected by using syringe via drilled holes. The holes were sealed by using 0.5 × 0.5 cm2 dimensions of Surlyn film. Both pieces of Surlyn film were placed on the holes, covered with cover glass and pressed for 1 min at 100 °C.

Two samples of solar cells were prepared. One having TiO2/CdS QDs electrode without additional surface treatment while the other with TiO2/CdS QDs electrode after the surface treatment by sodium sulfide ionic solution.

The liquid electrolyte used here was based upon polysulfide redox couple. The electrolyte was prepared as reported by Lee et al. (2008). Briefly 0.5 M Na2S (nonahydrate) and 2.0 M sulfur were dissolved in methanol/water system having ratio of 7:3 respectively. The electrolyte used was without any additives.

Measurements

To confirm the change in bandgap, the UV Vis spectra of CdS QDs, bare TiO2 electrode, TiO2/CdS QDs electrode and surface treated TiO2/CdS QDs electrode were recorded using Optizen 3220 UV (Mecasys) spectrometer. The transmission electron microscopy (TEM) of CdS QDs sample was carried out in order to analyze the size of CdS QDs. For TEM, samples of CdS QDs were prepared as described above. One drop of this suspension was loaded onto a copper grid and dried prior to the TEM examination. For TEM observations, Techni 20G2 TEM operationg at 200 kV was used. Raman Spectroscopy of the TiO2/CdS QDs electrode was carried out to confirm the linking of CdS QDs to the substrate. Photoluminescence measurements were performed using a Perkin-Elmer Model LS-55 with a Xenon flash lamp and gratings to provide required excitation. All the measurements were carried out at room temperature with excitation wavelength of 370 nm.

Photocurrent density–photovoltage (J–V) characteristics of the solar cells were recorded with a computer controlled digital source measure meter (Solartron 1287 potentiostat/galvanostat) by applying external potential bias to the cell and measuring the photocurrent generated under a solar simulator (LS-150, ABET technologies) with a 1.5 AM filter.

Results and discussion

Synthesis and characterization of QDs

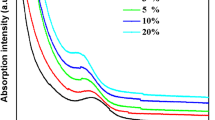

The CdS QDs were synthesized, surface modified and linked to TiO2 electrode as per the scheme mentioned above. The bare TiO2 electrode and TiO2/CdS QDs electrode (linked via ME) were subjected to UV–Vis spectroscopy. Figure 1 shows the UV Vis absorption spectra of the bare and TiO2/CdS QDs electrode. On comparison with bare electrode, a shift in the absorption towards the longer wavelength is observed for the TiO2/CdS QDs electrode and is indicated by absorption peak around 380 nm. This shift indicates the presence of the CdS QDs upon TiO2 electrode.

The optical bandgap for bare TiO2 electrode and TiO2/CdS QDs electrode were calculated using Tauc’s relationship (Bhattacharya et al. 2009).

(Where n = 1/2 for CdS).

The plots between the (αhν)2 and hν (incident light) is shown in Fig. 2. It is obvious from figure, the bandgap of bare TiO2 electrode is shifted from 3.4 to ~2.9 eV in case of TiO2/CdS QDs electrode. This shift is attributed to the linking of the CdS QDs to the bare TiO2 electrode thus reconfirms the shifting of absorption spectra towards the red region.

Optical bandgaps of bare TiO2 and TiO2/CdS QDs electrode. Optical bandgaps estimated by plotting (αhν)2 (a. u) versus photon energy hν (eV) using the data of Fig. 1

For the assurance of quantum confinement effect and size estimation, the UV Vis spectra and bandgap calculation were also conducted for colloidal CdS QDs. The colloidal CdS QDs were prepared by following proposed experimental procedure. Figure 3 shows the UV Visible absorption spectra and bandgap estimation for the as prepared CdS QDs colloidal solution. It is evident from the figure the CdS QDS shows a blue shift in the absorption as compared to the bulk CdS. The absorption region for the CdS QDs was observed in the range of 375–450 nm while the absorption region corresponding to bulk CdS appears in the range of 475–550 nm (Thangadurai et al. 2008). This shift is attributed due to the increase in bandgap with decrease in size assuring the quantum confinement effect. The bandgap estimated is shown in Fig. 3(b). The bandgap for CdS QDs was found to 2.8 eV showing the shift in the excitonic peak to higher energy as compared to bulk CdS bandgap which is 2.42 eV. This shift again indicates the quantum size effect due to decrease in particle size. According to the absorption peak position, the size of the QDs was estimated around 4.0 nm. The size was estimated using the data reported by Yu et al. (2003).

For further confirmation of size, the QDs were examined under TEM. The TEM image of the Cds QDs is shown in Fig. 4. The particles could be seen as clusters of random orientation and sizes. The average size of the dots, as estimated from the image is ~4–5 nm which is in good agreement with that obtained from the absorption data.

As mentioned earlier for CdS QDs sensitization, the TiO2 electrodes were immersed in the chemical bath just after the addition of ME. ME here is assumed to acts as surface modifying, capping as well as linking agent. ME consists of the thiol (HS−) group at one end and the hydroxyl (OH−) group at the other end. The thiol group is known as a soft electron donor and coordinates with the cadmium ions present on the surface of CdS nanocrystal. Thus ME can be easily adsorbed to the CdS nanocrystal surface, rendering the CdS surface by hydroxyl group at the other end at the same time acts as capping agent restricting the further growth of the CdS. While the hydroxyl group is a hard electron donor and coordinates with the TiO2 electrode surface and thus plays the linking role of ME.

For confirmation of our presumption that ME works as the linker, dispersive Raman spectra was obtained for the TiO2/CdS QDs electrode and is shown in Fig. 5. It can be seen with the absorption bands of TiO2 (645, 520, 395, 145 cm−1) and CdS (300, 600 cm−1), the appearance of absorption band near 2,935 cm−1 corresponding to the CH2 stretching indicates the presence of the ME as a linker. Inset shows the enlarged view of the region showing CH band.

Surface treatment

The TiO2/CdS QDs electrode was subjected to surface treatment by ionic solution providing the sulfur ions. The TiO2/CdS QDs was dipped in 0.3 M sodium sulfide solution for 15 min, taken out, washed and air dried. After the surface treatment the UV–Vis spectra of the samples were recorded and compared with the untreated sample. The UV–Vis spectra of untreated TiO2/CdS QDs and treated TiO2/CdS QDs electrodes are shown in Fig. 6. It is clear from figure that there is no difference in the absorption peak in either of the cases indicating no modification in the electronic states of CdS but shows an increased energy absorbance after treatment. This means that some surface states still exist upon CdS QDs surface in the form Cd2+ bonds even after the surface modification. The sulfur ions (S2− or HS−) in ionic solution, therefore, partially coordinates with the available uncoordinated Cd2+ sites thus increasing the optically active CdS sites.

Thus it can be described that the ME acts as surface modifier and linker but not an effective capping agent as there still remains uncoordinated Cd2+ bonds upon the QDs surface. The reason for partial passivation or capping can be described as ME is a bulky organic compound and the surface of the CdS QDs might be partially covered by the ME limited by steric hindrance (Lee et al. 2009). The sulfur ions (S2− or HS−) provided by the ionic solution of sodium sulfide might coordinate with the remaining Cd2+ dangling bonds, removing the electron trap centers and thus might lead to increase in cell efficiency.

In order to further confirm the surface treatment effect of sulfide ions, photoluminescence spectra (PL) of colloidal solutions containing CdS QDs and surface treated CdS QDs were obtained and are shown in Fig. 7. It is evident from the figure that the PL spectra for both CdS QDs and surface treated CdS QDs exhibits two peaks. For CdS QDs, the peak appearing around wavelength of 400 nm is attributed to the band edge emission of CdS QDs while a broader peak appearing near 532 nm is considered to cause by the electron hole recombination due to surface defect states. After the surface treatment of CdS QDs it was observed that the intensity of the band edge emission was increased in comparison to that of untreated CdS QDs. During this time a broader peak due to surface state emissions also decreases in intensity thus indicating the surface passivation of defect states in the untreated CdS QDs bandgap (Zhang et al. 2008).

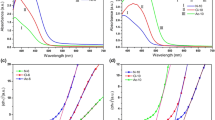

Solar cell application

Two batches of solar cells were fabricated and tested for photovoltaic performance, one having TiO2/CdS QDs electrode (as detailed above) while the other having surface treated TiO2/CdS QDs electrode by sodium sulfide ionic solution. The photovoltaic parameters of the QDSCs were measured at 100 % sun (AM 1.5,100 mW cm−2). The photocurrent-voltage curves for these cells are shown in Fig. 8. The cell parameters corresponding to both cells are calculated and presented in Table 1.

Comparison of both devices indicate that the efficiency obtained for the first device without surface treatment is less (η = 0.18 %) as compared to the device after surface treatment (η = 0.38 %). The efficiency of the first device with polysulfide electrolyte is less due to low Jsc and Voc. Low short circuit current density is expected due to surface states which exist within the bandgap due to partial passivation by ME. These surface states act as electron traps and thus may reduce the photocurrent. After the surface treatment, an increase in the photocurrent density was observed which reveals the removal of electron trap centers or the passivation of the remaining surface states leading to increase in the density of photo excited electrons. The increase in Voc can be attributed to increase in the quasi Fermi level of TiO2 by an increase in the density of electrons injected into TiO2 conduction band (Rotherberger et al. 1992). However the decrease in the fill factor (FF) is observed after surface treatment. The reason predicted for this may be the less rate of hole scavenging of polysulfide redox electrolyte and high electron recombination losses. In addition, the spatial distance between the QDs and TiO2 electrode created by linker can be a possible reason for the low fill factor and cell efficiency (Iván et al. 2008). The distance can be reduced by selection of feasible deposition method and an energy barrier shell approach can be employed to prevent the electron recombination losses.

The IPCE spectra of both cells were also measured as shown in Fig. 9. The IPCE spectra carried out at different wavelengths measured for short circuit currents. The spectra of the cells closely resembles with absorption spectra of both electrodes shown in Fig. 6. It is clear from figure, the IPCE measurement shows the max. value at a wavelength of 350 nm. At this wavelength an increase in IPCE was observed from 14 to 19 % after surface treatment of the TiO2/CdS QDs electrodes. This increase in IPCE leads to the increase in the charge collection efficiency after surface treatment due to increased optically active CdS sites leading to increase of photo injected electrons in TiO2 conduction band. This is in confirmation with our earlier statement on the passivation of surface states of TiO2/CdS QDs electrode before and after surface treatment.

Conclusions

An in situ route mimicking the adsorption principle of dyes in DSSCs, was employed for synthesis, surface modification and linking the CdS QDs to the TiO2 electrode. Following this route it was expected to obtain a well-covered monolayer of QDs upon TiO2 electrode thus enhancing the cell performance. An organic compound ME was used for QDs surface rendering and linking simultaneously in single bath. The thiol moiety of ME coordinates with the surface Cd2+ ions by donating electron and thus can be considered as surface passivating agent. On additional surface treatment of the TiO2/CdS QDs electrode it was observed that the ME partially coordinates with the CdS surface and there still remain surface states. The possible reason for the partial passivation is the less coverage of CdS QDs by bulky organic compound due to steric effects. An increase in the photocurrent density was observed after the surface treatment of TiO2/CdS QDs electrode by sodium sulfide solution. This increase is due to coordination of sulfur ions with the uncoordinated Cd2+ dangling bonds upon the QDs surface which were previously not coordinated by ME. However the fill factor and efficiency are still very low and requires enormous efforts for improvement. Low hole scavenging rate of polysulfide redox couple and the spatial distance between the QDs and TiO2 electrode created by linker are considered to be the possible reasons for low fill factor and cell efficiency.

References

Bhattacharya B, Tomar SK, Park JK (2007) A nanoporous TiO2 electrode and new ionic liquid doped solid polymer electrolyte for dye sensitized solar cell application. Nanotechnology 18:485711

Bhattacharya B, Tomar SK, Saxena A, Lee JY, Park JK (2009) Ageing and temperature-dependent behavior of CdS nanoparticles. Phys Status Solidi B 246:832–836

Borges RO, Lincot D (1993) Mechanism of chemical bath deposition of cadmium sulfide thin films in the ammonia-thiourea system. J Electrochem Soc 140:3464

Hodes G (2008) Comparison of dye- and semiconductor-sensitized porous nanocrystalline liquid junction solar cells. J Phys Chem C 112:17778–17787

Iván MS, Giménez S, Moehl T, Santiago FF, Villareal TL, Gómezand R, Bisquert J (2008) Factors determining the photovoltaic performance of a CdSe quantum dot sensitized solar cell: the role of the linker molecule and of the counter electrode. Nanotechnology 19:424007

Lee YL, Chang CH (2008) Efficient polysulfide electrolyte for CdS quantum dot-sensitized solar cells. J Power Sources 185:584–588

Lee YL, Huang BM, Chien HT (2008) Highly efficient CdSe-sensitized TiO Photoelectrode for quantum-dot-sensitized solar cell applications. Chem Mater 20:6903–6905

Lee JJ, Bang J, Yang H (2009) Highly stable colloidal ZnO nanocrystals by MgO passivation. J Phys D Appl Phys 42:025305

Lin SC, Lee YL, Chang CH, Shen YJ, Yang YM (2007) Quantum-dot-sensitized solar cells: assembly of CdS-Quantum-dots coupling techniques of self-assembled monolayer and chemical bath deposition. Appl Phys Lett 90:143517

Nazeeruddin MK, Angelis FD, Fantacci S, Selloni A, Viscardi G, Liska P, Ito S, Takeru B, Grätzel M (2005) Combined experimental and DFT-TDDFT computational study of photoelectrochemical cell ruthenium sensitizers. J Am Chem Soc 127:16835

Nicolau YF, Dupuy M, Brunel M (1990) ZnS, CdS and Zn1-xCdxS thin films deposited by the successive ionic layer adsorption and reaction process. J Electrochem Soc 137:2915–2924

Niitsoo O, Sarkar SK, Pejoux C, Rűhle S, Cahen D, Hodes G (2006) Chemical bath deposited CdS/CdSe-sensitized porous TiO2 solar cells. J Photochem Photobiol, A 181:306–313

Nozik AJ (2002) Quantum dot solar cells. Physica E 14:115–120

Plass R, Pelet S, Krueger J, Grätzel M (2002) Quantum dot sensitization of organic–inorganic hybrid solar cells. J Phys Chem B 106:7578–7580

Regan OB, Grätzel M (1991) A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353:737

Robertson N (2006) Optimizing dyes for dye-sensitized solar cells. Angew Chem Int Ed 45:2338–2345

Robel I, Subramanian V, Kuno M, Kamat PV (2006) Quantum dot solar cells. Harvesting light energy with CdSe nanocrystals molecularly linked to mesoscopic TiO2 films. J Am Chem Soc 128(7):2385–2393

Rotherberger G, Fitzmaurice D, Grätzel M (1992) Spectroscopy of conduction band electrons in transparent metal oxide semiconductor films: optical determination of the flatband potential of colloidal titanium dioxide films. J Phys Chem 96:5983–5986

Sanghoon K, Jae KL, SangOok K, Jaejung K, Yum JH, Fantacci S, Angelis FD, Censo DD, Nazeeruddin MK, Grätzel M (2006) Molecular engineering of organic sensitizers for solar cell applications. J Am Chem Soc 128:16701–16707

Statthatos E, Lianos P, Laschewsky A, Quari O, Cleuvenbergen V (2001) Synthesis of a Hemicyanine dye bearing two carboxylic groups and its use as a photosensitizer in dye-sensitized photoelectrochemical cells. Chem Mater 13:3888–3892

Thangadurai P, Balaji S, Manoharan PT (2008) Surface modification of CdS quantum dots using thiols: structural and photophysical studies. Nanotechnology 19:435708

Thavasi V, Renugopalakrishnan V, Jose R, Ramakrishna S (2008) Controlled electron injection and transport at materials interfaces in dye sensitized solar cells. Mater Sci Eng R 63:81

Wang P, Zakeeruddin SM, Moser JE, Nazeeruddin MK, Sekiguchi T, Grätzel M (2003) A stable quais-solid-state dye-sensitized solar cell with an amphiphillic ruthenium sensitizer and polymer gel electrolyte. Nat Mater 2:402

Yu WW, Qu L, Guo W, Peng X (2003) Experimental determination of the extinction coefficient of CdTe, CdSe and CdS nanocrystals. Chem Mater 15:2854–2860

Yu P, Zhu K, Norman AG, Ferrere S, Frank AJ, Nozik AJ (2006) Nanocrystalline TiO2 solar cells sensitized with inAs quantum dots. J Phys Chem B 110:25451–25454

Zaban A, Mićić OI, Gregg BA, Nozik AJ (1998) Photosensitization of nanoporous TiO2 electrodes with InP quantum dots. Langmuir 14:3153–3156

Zhang TL, Xia YS, Diao XL, Zhu QC (2008) Preparation and formation mechanism of strong violet luminescent CdS quantum dots by using a ligand exchange strategy. J Nanopart Res 10:59–67

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Razzaq, A., Lee, J.Y., Bhattacharya, B. et al. Surface treatment properties of CdS quantum dot-sensitized solar cells. Appl Nanosci 4, 745–752 (2014). https://doi.org/10.1007/s13204-013-0259-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-013-0259-0