Abstract

Laboratory investigations and field applications have proved injection of polymer solution to be an effective means to improve oil recovery for reservoirs of medium oil viscosity. The incremental oil produced in this case is the result of an increase in areal and vertical sweep efficiencies. Biopolymers and synthetic polymers are the major categories used in the petroleum industry for specific reasons. Biopolymers like xanthan are limited in their application as they are more susceptible to biodegradation. Synthetic polymers like Hydrolyzed PolyAcrylaMide (HPAM) have a much wider application as they are less susceptible to biodegradation. Furthermore, development of nanotechnology has successfully provided technical and economical viable alternatives for present materials. The objective of this study is to investigate the effect of combining clay nanoparticles with polymer solution on oil recovery. This paper includes a history match of both one-dimensional and two-dimensional polymer floods using a three-dimensional numerical model for fluid flow and mass transport. Results indicated that the amount of polymer adsorption decreased when clay nanoparticles were added to the PolyAcrylaMide solution; however, mobility ratio improvement is believed to be the main contributor for the proposed method in order to enhance much oil recovery compared to xanthan flood and HPAM flood.

Similar content being viewed by others

Introduction

Perhaps the simplest chemical flooding method is polymer flooding. In this process water soluble polymers are injected into the reservoir to increase the efficiency of the water flooding by decreasing the mobility of water. Polymer flooding is one of the most promising enhanced oil recovery (EOR) processes in many reservoirs because of its relative capital cost (Silva et al. 2007). Polymer flooding was first studied during the 1960s. Pye (1964), Sandiford (1964), Mungan et al. (1966), and Gogarty (1967) are recognized as the first pioneers of polymer flooding (Sorbie and Phill 2000). Then, the polymer flooding proved to be successful for field applications during the 1970s. There are also many publications that present how successful polymer flooding is as an improved oil recovery method. Koning et al. (1988) presented a successful result for a pilot polymer flood in Oman. Another successful polymer flooding field project was implemented by Putz et al. (1988). They tried injecting a larger slug size of polymer than usual in an inverted five-spot well pattern of the Chateaurenard field outside Paris in France. Littmann et al. (1992) showed results regarding a polymer pilot test performed in the Eddesse-Nord sandstone reservoir in Germany. About 800 ppm of xanthan polymer solution was injected from 1985 to 1988. This project was recognized as being successful in terms of injection and oil production performance. In addition, the xanthan polymer was found no degradation. An adsorption of xanthan was also relatively low at about 30–40 µg/g rock.

In addition, nanoparticles have become an attractive agent for improved and EOR at laboratory scale. They are two orders of magnitude smaller than colloidal particles. This allows them to flow through rock pores with little to no retention. Most researchers have proposed promising results and increased ultimate oil recovery by injecting nanoparticles suspension in laboratory experiments (Maghzi et al. 2012; Zargartalebi et al. 2015). There are different examples of nanoparticle applications for instance; high viscosity emulsions can be generated with silica nanoparticles. Viscous emulsions can be used to manage mobility control in high viscosity oil reservoirs (Gabel 2014). Other emerging applications in the improved oil recovery processes include injecting nanoparticles dispersion (“Smart fluid”) into reservoirs for improved oil recovery via wettability alteration and advanced drag reduction (Evdokimov et al. 2006). Cheraghian et al. (2014) and Cheraghian and Khalili Nezhad (2015) reported new experimental observations of the effect of silica nanoparticles and clay nanoparticles on the performance of PolyAcrylaMide (PAM) solution. This paper includes a history match of both one-dimensional and two-dimensional polymer floods using a three-dimensional numerical model for fluid flow and mass transport. Results indicated that the amount of polymer adsorption decreased when clay nanoparticles were added to the PAM solution; however, mobility ratio improvement is believed to be the main contributor for the proposed method in order to enhance much oil recovery compared to xanthan flood and HPAM flood.

Description of reservoir simulator

The reservoir simulator used in this paper is UTCHEM, a three-dimensional, multiphase, multi-component chemical flooding simulator developed in the center for Petroleum and Geo-systems Engineering at The University of Texas at Austin (Delshad et al. 2000). UTCHEM is briefly defined as an implicit pressure, explicit saturation formulation that has the option to simulate several species such as water, oil, surfactant, co-solvent, polymer, cations, anions, and tracers. Particularly, UTCHEM shows better results for simulation of polymer flood because of the fact that polymer adsorption and subsequent reduction in polymer concentration is modeled in UTCHEM. (Goudarzi et al. 2013).

Validation of one-dimensional simulation model

Ehrenfried (2013) conducted several core floods to investigate the effect of polymer injection on oil recovery from sandstone core plugs. The core flood of our interest is one of his experiments. A high permeable sandstone core with the length of 29.08 cm and a diameter of 4.93 cm was used. A 2.2 (Pore Volumes) PVs polymer slug containing 1000 ppm xanthan solution in water with 1.5 % NaCl was injected. The core flood was conducted at flow rate of 0.1 ml/min and an oil recovery of about 50 % was obtained. The remaining oil saturation at the end of the polymer flood was about 35.1 %. The details of experimental results can be found elsewhere (Ehrenfried 2013). The UTCHEM simulator was used to history match average oil saturation data. The numerical model uses 100 grid blocks to simulate the behavior of the core.

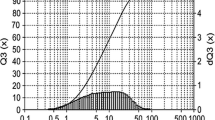

UTCHEM uses Corey-type relative permeability for both oil and water (Delshad et al. 2000). It was assumed that the core has the water-wet surface as it is a sandstone core (Ehrenfried 2013). A few relative permeability exponents and endpoints for both oil and water phases were tested to select the best results based on the history match of average oil saturation data. The adjusted relative permeability curve is shown in Fig. 1. This curve can present the behavior of fluid flow in the core sample. Table 1 also shows the main rock and fluid properties.

The agreement between the results calculated from the simulation model and the experimental data, including saturation profile, is generally good. Figure 2 depicts the comparison of the results as well as ultimate oil recovery factor, and oil cut results. Oil saturation from simulation is much closer to the experimental data after injecting 0.5 PV of polymer solution. As the results show, ultimate oil recovery factor was about 50 % of original oil in-place (OOIP) and the oil cut was high in the beginning, then it decreased gradually which was a reasonable result.

Effect of clay nanoparticles

In this section, the performance of polymer solution injection containing clay nanoparticles is investigated and compared to other types of polymer solutions. Local sodium bentonite with a mesh size of 200 and a particles size less than 50 nm was used in this study. The bentonite was produced in Iran and amended with the chemicals shown in Table 2. Oxford-ED2000 XRF and GC-2550TG (Teif Gostar Faraz Company, Iran) were used for all chemical analyses.

Concentration of nanoparticles in aqueous solutions was 0.45, 0.9, and 1.8 wt%. The solution of dispersed clay nanoparticles in PAM (DCNP) was prepared by Nano-clay powder in 0.45 wt% under normal conditions at 25 °C for 2 h which was proved to be more stable solution according to the experimental observations (Cheraghian and Khalili Nezhad 2015). Nano-clay powder was dissolved in double-distilled water in order to produce a homogeneous solution. The PAM polymer with a concentration of 3150 ppm was added and mixed in the prepared solution. The prepared solution salinity is about 20000 ppm. The SEM scan (Fig. 3) was performed on the samples to determine the morphology of each layer. The clay nanoparticle in polymer solution was dispersed completely.

The solution viscosities at different polymer concentrations were measured at laboratory and values were matched using UTCHEM polymer model (Fig. 4). Moreover, the solution viscosities at various shear rates were measured using a DV-III ULTRA + Brookfield rheometer in the laboratory. The rheological behavior of the prepared solution can be observed in Fig. 5. UTCHEM uses a Langmuir-type to describe the adsorption level of polymer which takes into account the salinity and polymer concentration (Delshad et al. 2000). The adsorption of the prepared solution as a function of polymer concentration was measured and values were matched (Fig. 6) using UTCHEM adsorption model. The details of experimental procedure (such as stability tests of the prepared solution) can be found elsewhere (Cheraghian et al. 2014; Cheraghian and Khalili Nezhad 2015).

The polymer parameters and physical properties of HPAM (SNF’s FP 3630S) solution and xanthan solution were based on the laboratory data collected at The University of Texas at Austin laboratory, (Mohammadi 2008; Wu 1996), respectively. The amount of injection rate, injection pore volumes, polymer concentration, and solution salinity, in the simulation model, are the same as base case (xanthan core flood) for both HPAM solution and DCNP solution. The rheological data for HPAM, xanthan, and DCNP solutions were imported to the simulator, and then simulations were carried out. Moreover, water flood was simulated as a base case in order to evaluate the performance of different polymer flood processes. It should be mentioned that the rheological behavior of the prepared solution is relatively similar to xanthan solution. Accordingly, the validated model can be used in the simulation of DCNP core flood.

Figure 7 illustrates the simulation results of the injection of different polymer solutions for one-dimensional model. According to the simulation results, cumulative oil recovery for the case of DCNP flood is slightly higher than xanthan flood and it is about 52 % of OOIP. Moreover, HPAM flood has a much lower cumulative oil recovery compared with two others while water flood has the lowest ultimate oil recovery which is merely 29 % of OOIP. According to the simulation results depicted in Fig. 7, the difference between breakthrough time for injection of HPAM flood, xanthan flood, and DCNP flood is not noticeable. Moreover, the cumulative oil recovery until the breakthrough time is equal for all of them. However, the difference between the performances of different polymer solutions (ultimate oil recovery factor) is remarkable. We are seeking to find out some reasons for the effectiveness of DCNP flood in the following part.

Figure 8 shows the average oil saturation profile between injector and producer in the simulation model (core sample) after 2.2 PVs polymer slug is injected. Obviously, injection of polymer solution (regardless of the polymer type) results in very low oil saturation compared to the amount of oil saturation during water flooding. The plot shows that both DCNP flood and xanthan flood are extremely effective in mobilizing the oil. In addition, the amount of oil saturation is fairly low for the case of DCNP flood (compared to the other cases) in more 80 % of the distance between injector and producer. This relatively low oil saturation signifies the effectiveness of DCNP flood.

Mechanisms of improved oil recovery using clay nanoparticles

In our earlier publications (Cheraghian et al. 2014; Cheraghian and Khalili Nezhad 2015), we have focused on the impact of nanoparticles on the performance of PAM solution for EOR. Our experimental results showed that using clay nanoparticles and silica nanoparticles can decrease the adsorption of PAM solution onto the rock and its ability to improve the mobility ratio of the displacing fluid and displaced fluid may increase. In this paper, the amount of improvement in polymer adsorption and viscosity of polymer solutions will be compared numerically when they are injected to the core sample. Figure 9 compares the amount of polymer adsorption for three different polymer solutions. As the results show, xanthan solution has a less adsorption onto the rock on account of the fact that it is a biopolymer which has an ultra low adsorption. In addition, DCNP solution has a less adsorption onto the rock compared to the HPAM solution. This is the first reason that demonstrates the effectiveness of the DCNP slug in mobilizong the residual oil. As expected, the adsorption of PAM solution should be much higher than HPAM and xanthan solutions, but clay nanoparticles decreased the amount of PAM adsorption even much lower than HPAM adsorption. Figures 10 and 11 show the polymer concentration profiles after 0.2 days (0.27 PV) for DCNP flood and HPAM flood, respectively. As the results show, the DCNP slug is moving faster and more effectively due to low polymer adsorption onto the rock surface compared to the HPAM slug.

Figure 12 shows the water viscosity profiles after 1 PV injection for HPAM slug, and DCNP slug, respectively. This figure shows that, the water viscosity profile for the case of DCNP flood is more favorable than HPAM flood to push out the viscous oil. The increased viscosity of the injected solution decreases the mobility ratio, thereby improving oil-displacing efficiency. Consequently, injection of DCNP solution can lead to enhance oil recovery using both polymer adsorption reduction and mobility ratio improvement.

Validation of two-dimensional simulation model

In this part, the effect of DCNP solution on oil recovery in two-dimensional model is investigated. Emami Meyboodi et al. (2011) conducted a comprehensive experimental study using five two-dimensional glass micromodels. A combination of three wettability condition and five different pore structures was used in their study. The selected scenarios include four homogeneous synthetic pore networks at water-, mixed-, and oil-wet conditions. The displacement experiments have been carried out in a horizontal mounting to neglect the effect of gravity. A random network that represents the pore space in Berea sandstone was also used for further investigation. The oil sample which was used in their experiments was West Paydar, (A sample taken from one of the oil reservoirs in southwest of Iran) crude oil; with an API of 19.8○ and viscosity 74.9 cp measured at 26 ○C. Synthetic brine with the concentration of 20,000 ppm was prepared and selected for both connate water and polymer solution. The polymer used in their experiments was HPAM with degree of hydrolysis of 25 % and molecular weight of 8 × 106 g/mol. Among their different micromodels, the pattern C was chosen as a random network that represents the pore space in Berea sandstone for our further numerical investigations. An injection rate of 0.0006 cm3 min−1 was considered as the optimum value. This optimum value simulates underground fluid flow within the oil reservoirs. A 1.5 PVs polymer slug was injected containing 500 ppm HPAM solution in water with 20,000 ppm salinity. Finally, an oil recovery of about 44 % was obtained. The details of experimental results can be found elsewhere (Emami Meyboodi et al. 2011).

The UTCHEM simulator was used to history match oil recovery factor data. It should be mentioned that the main following assumptions should be considered for the micro-scale simulation of polymer flooding using UTCHEM:

-

1.

The relative permeability curves are varied (tuned) to match the oil recovery factor from the micromodel and the micromodels satisfy the same equation as solved by simulator

-

2.

The capillary number is assumed constant in both experimental and simulation model systems

-

3.

More importantly, the amount of polymer adsorption which was calculated both experimentally and numerically in the last section for the sandstone core is equal to glass surface (very challenging parameter).

According to the physical properties of the selected micromodel, the simulation model was constructed. The model was developed as a quarter 5-spot symmetry with a constant injection rate of 0.0006 cm3 min−1 and a constant bottom-hole production of 1 atm. A two-dimensional Cartesian grid system was used with 45 × 45 × 1 grid blocks to simulate the flow behavior of polymer solution through micromodel. The capillary pressure was set up to be water-wet. The capillary desaturation curve (CDC) is the relationship between the residual saturation of non-aqueous or aqueous phase and a local capillary number or more general, the trapping number, which was unknown for the glass micromodel. Table 3 shows the main micromodel and fluid properties.

As the flow of polymer solution in a two-dimensional model is more complex than one-dimensional model and different parameters can affect the results, the following is a list of assumed matching parameters:

-

1.

Relative permeability parameters

-

2.

Capillary pressure parameters

-

3.

Capillary desaturation parameters.

A wettability of a rock/glass has some effect on the rate of oil recovery. The more water-wet surface, is the faster oil produced. Oil flows more easily when the surface is water-wet as water tends to adhere to the surface. Clearly, the oil recovery is related particularly to the properties of oil relative permeability curve. In relative permeability curves, for each phase, three parameters can be changed to achieve the best values based on the history match of the ultimate oil recovery factor. They are (1) residual saturation (2) relative permeability endpoint (3) relative permeability exponent. A few relative permeability curve parameters for both oil and water phases were tested in an acceptable range of apparatus measurement to select the best values based on the history match of oil recovery factor data. The tuned relative permeability curve is shown in Fig. 13.

As it was mentioned before, the status of surface wettability determine the amount of oil production rate. The more water-wet rock, the faster the oil is produced. Therefore, the capillary pressure sensitivity study is also conducted to match the breakthrough time point. A few capillary pressure curve parameters were tested in an acceptable range to select the best results based on the history match of oil recovery factor data. Figure 14 gives the oil recovery between experiment and simulation model. The results from simulation match the value from laboratory closely, but the simulation model is not precisely predicted the breakthrough time. The results from laboratory show that the cumulative oil recovery starts out with a steep positive slope. It then levels off to much flatter increase until it reaches about 46 % of OOIP at 1.5 PVs. The simulated cumulative oil recovery increases to about 32 % at 0.4 PV and then assumes a gentler slope until it reaches to about 46 % of OOIP. Matching performance in this section indicates that the simulation model is reliable. This model can be taken into account as a basis for further investigations.

The effect of clay nanoparticles on oil recovery during polymer flooding in two-dimensional model

In this section, the performance of polymer solution injection containing clay nanoparticles is investigated in micromodel and compared with HPAM flood. Rheology of the prepared polymer solution is shown in Figs. 4 through 6. The polymer parameters and physical properties of HPAM solution were based on the laboratory data collected by Emami Meyboodi et al. (2011). The amount of injection rate, injection pore volumes, polymer concentration, and solution salinity, in the simulation model, are as the same as base case (HPAM flood) for DCNP flood. Table 4 gives the composition of each polymer slug.

The rheological data for HPAM, and DCNP solutions were imported to the simulator, and then simulations were carried out. The simulation results in last section for one-dimensional model indicate that clay nanoparticles can decrease the adsorption of PAM solution onto the rock surface and its ability to improve the mobility ratio of the displacing fluid and displaced fluid may increase. Figure 15 compares the cumulative oil recovery for injection of HPAM solution with the injection of DCNP solution. As the results show, the cumulative oil recovery for the injection of DCNP solution is much higher than injection of HPAM solution. According to the results, both the breakthrough time and the amount of cumulative oil recovered was improved.

Figure 16 compares the amount of oil cut during the injection of HPAM solution and the injection of DCNP solution. According to the simulation results, the oil cut begins with nearly 100 % since the polymer injection started. It then decreased to nearly 4 % at 1.5 PV. The main difference between the performance of the two polymer slugs is that the amount of oil cut for the injection of DCNP solution is much higher than injection of HPAM solution before 0.7 PV injection. The main reason for this difference is that the viscosity of the DCNP solution is much higher than HPAM solution so that the mobility ratio is favorable to push out the viscous oil more easily.

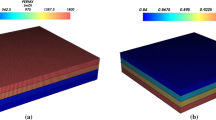

As discussed earlier, DCNP solution has a less adsorption onto the rock compared to the HPAM solution. Moreover, the amount of polymer adsorption onto the glass surface was considered as the same as the rock surface. Accordingly, the reduction of polymer adsorption onto the glass surface is one of the main mechanisms of improved oil recovery by injection of DCNP solution. Figure 17 and 18 show the distribution of oil saturation at the end of 1 PV injection of HPAM solution and DCNP solution, respectively. These figures show that DCNP solution is more effective to mobilize the oil. In other words, when the viscosity of the injected solution is improved the mobility ratio of displacing and displaced fluid will decrease; therefore, it can push out the viscous oil from the porous medium more easily.

Summary and conclusions

On the basis of experimental and simulation results, the following conclusions were drawn:

-

1.

Two sets of experimental data were used to validate different simulation models. Using the recently published xanthan core flood, a one-dimensional simulation model was constructed. According to the rock and fluid properties, core flood history match was performed to validate the simulation model. Changing the relative permeability curve, and capillary pressure curve parameters were the main factors when xanthan core flood history match was performed. Chemical compositional simulator was used for a series of polymer flood simulations. The calculated capillary pressure and relative permeability parameters were used in other simulations. A two-dimensional simulation model was developed using the physical properties of a recently published micromodel flood. According to the experimental data related to the injection of HPAM solution, simulation model was validated. Capillary pressure parameters, relative permeability parameters, and capillary desaturation curve parameters were the matching parameters.

-

2.

Using the chemical compositional simulator, the amount of polymer adsorption was calculated numerically for one-dimensional model. Simulation results revealed that DCNP solution has a less adsorption onto the rock rather than HPAM solution. The amount of DCNP solution adsorption is comparable to the xanthan solution which is a biopolymer.

-

3.

Moreover, the amount of mobility ratio improvement for different polymer solutions was calculated numerically for both one-dimensional and two-dimensional models. Clay nanoparticles, as expected before, increase the viscosity of polymer solutions and the injected solution can improve the cumulative oil recovery both in one-dimensional and two-dimensional models.

-

4.

Thus, the main factors that improve oil recovery of DCNP solution (compared to the HPAM solution) are reduction in polymer adsorption and increase in the ability of polymer solution to improve the mobility ratio.

Abbreviations

- CDC:

-

Capillary desaturation curve

- EOR:

-

Enhanced oil recovery

- HPAM:

-

Hydrolyzed polyacrylamide

- OOIP:

-

Original oil in-place

- PAM:

-

Polyacrylamide

- PV:

-

Pore volume

- UTCHEM:

-

The University of Texas chemical compositional simulator

- Soi :

-

Initial oil saturation

References

Cheraghian G, Khalili Nezhad SS (2015) Effect of nanoclay on heavy oil recovery during polymer flooding. J Pet Sci Technol 33:999–1007

Cheraghian G, Khalili Nezhad SS, Kamari M, Hemmati M, Masihi M, Bazgir S (2014) Adsorption polymer on reservoir rock and role of the nano-particles, clay and silica. Int Nano Lett 4:114–122

Delshad M, Pope GA, Sepehrnoori K (2000) UTCHEM technical documentation version 9.0, Center For Petroleum and Geosystems Engineering, The University of Texas at Austin

Ehrenfried HD (2013) Impact of viscoelastic polymer flooding on residual oil saturation in sandstones M.S Thesis, The University of Texas at Austin, Texas, Austin

Emami Meyboodi H, Kharrat R, Nasehi Araghi M (2011) Experimental studying of pore morphology and wettability effects on microscopic and macroscopic displacement efficiency of polymer flooding. J Pet Sci Eng 78:347–363. doi:10.1016/j.petrol.2011.07.004

Evdokimov IN, Eliseev NY, Losev AP, Novikov MA (2006) Emerging petroleum-oriented nanotechnologies for reservoir engineering. Paper SPE 102060 presented at SPE Russian oil and gas technical conference and exhibition, Moscow. doi: 10.2118/102060-MS

Gabel ST (2014) Generation, stability, and transport of nano-particles-stabilized oil-in-water emulsions in porous media M.S Thesis, The University of Texas at Austin, TX

Gogarty WB (1967) Mobility control with polymer solutions. Soc Pet Eng J 7:161–173. doi:10.2118/1566-B

Goudarzi A, Delshad M, Sepehrnoori K (2013) A critical assessment of several reservoir simulators for modeling chemical enhanced oil recovery processes. Paper SPE 163578 presented at the SPE reservoir simulation symposium, Woodlands, TX, 18–20 Feb. doi: 10.2118/163578-MS

Koning EJL, Mentzer E, Heemskerk J (1988) Evaluation of a pilot polymer flood in the marmul field, Oman. Paper SPE 18092 presented at 63rd annual technical conference and exhibition of the society of petroleum engineers, Houston, TX, 2–5 Oct. doi: 10.2118/18092-MS

Littmann W, Kleinitz W, Christensen BE, Stokke BT, Haugvallstad T (1992) Late results of a polymer pilot test: performanced, simulation adsorption, and xanthan stability in the reservoir. Paper SPE 24120 presented at SPE/DOE 8th symposium on enhanced oil recovery, Tulsa, OK, 22–24 April. doi: 10.2118/24120-MS

Maghzi A, Mohammadi S, Ghazanfari MH, Kharrat R, Masihi M (2012) Monitoring wettability alteration by silica nanoparticles during water flooding to heavy oils in a five-spot systems: a pore level investigation. J Exp Thermal Fluid Sci 40:168–176. doi:10.1016/j.expthermflusci.2012.03.004

Mohammadi H (2008) Mechanistic modeling, design, and optimization of alkaline/surfactant/polymer flooding. Ph.D Dissertation, The University of Texas at Austin, TX

Mungan N, Smith FW, Thompson JL (1966) Some aspects of polymer floods. J Petrol Technol 18:1143–1150. doi:10.2118/1628-PA

Putz AG, Lecourtier JM, Bruckert L (1988) Interpretation of high recovery obtained in a new polymer flood in the Chateaurenard field. Paper SPE 18093 presented at 63rd annual technical conference and exhibition of the society of petrolum engineers, Houston, TX, Oct 2–5. doi: 10.2118/18093-MS

Pye DJ (1964) Improved secondary recovery by control of water mobility. J Petrol Technol 16:911–916. doi:10.2118/845-PA

Sandiford BB (1964) Laboratory and field studies of water floods using polymer solutions to increase oil recoveries. J Petrol Technol 16:917–922. doi:10.2118/844-PA

Silva IG, De Melo MA, Luvizotto JM (2007) Polymer flooding: a sustainable enhnaced oil recovery in the current senario. Paper SPE 107727 presented at the SPE latin American caribbean petroleum engineering conference. Buenous Aires, 15–18 April. doi: 10.2118/107727-MS

Sorbie KS, Phill D (2000) Polymer-improved oil recovery. CRC Press, Boca Raton

Wu WJ (1996) Optimum design of field-scale chemical flooding using reservoir simulation. Ph.D Dissertation, The University of Texas at Austin, TX

Zargartalebi M, Kharrat R, Barati N (2015) Enhancement of surfactant flooding by the use of silica nanoparticles. Fuel 143:21–27. doi:10.1016/j.fuel.2014.11.040

Acknowledgments

The authors gratefully acknowledge the Islamic Azad University of Quchan for its financial support and express their sincere thanks and appreciation to the Young and Elite researchers club at Islamic Azad University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Khalili Nezhad, S.S., Cheraghian, G. Mechanisms behind injecting the combination of nano-clay particles and polymer solution for enhanced oil recovery. Appl Nanosci 6, 923–931 (2016). https://doi.org/10.1007/s13204-015-0500-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-015-0500-0