Abstract

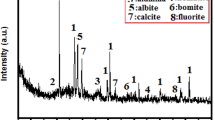

Waste materials utilization as value-added materials and micro, nanoparticles inclusion is gaining huge attention. The sludge generated from the textile industry constitutes a high toxic compound and hazardous in nature. Currently, large quantities of solid sludge remain unattended and undisposed in various effluent plants, waiting to be disposed of at the landfills. In this study, the waste sludge generated from the textile industry was processed and reused as a substitute for cement material. The specimens prepared from the textile waste sludge along with nanoparticles were tested for durability and mechanical properties. The usage of textile sludge decreases the strength properties marginally until a replacement level of 10%. Beyond the addition of 10% textile sludge waste reduces the strength and durability properties significantly. Textile waste sludges were replaced for cement of varying proportions, i.e., 2.5%, 5%, 7.5%, 10%, 15% and 20%. The addition of alumina nanoparticles has dual effects, enhances the hydration properties and also acts as a filler material. The formation of calcium silicate hydrate gel was improved significantly due to the utilization of nano alumina. The optimum amount of alumina nanoparticles observed from the previous studies was found to be 3% by weight of cement due to high durability and mechanical properties. The combination of 10% textile waste sludge along with 3% nano alumina blended cement concrete leads to enhanced strength and durability characteristics as compared to all other concrete specimens and it was found to better eco-friendly construction material.

Similar content being viewed by others

References

Ansari AA, Thakur BD (2001) Sludge management in textile industry. Asian Tex J Bombay 10(7):55–60

Baker PG, Bishop PL (1997) Prediction of metal leaching rates from solidified/stabilized wastes using the shrinking unreacted core leaching procedure. J Hazard Mater 52:311–333

Balasubramanian J, Sabumon PC, Lazar JU, Ilangovan R (2006) Reuse of textile effluent treatment plant sludge in building materials. Waste Manage 26:22–28. https://doi.org/10.1016/j.wasman.2005.01.011

Baskar R, Begum KMMS, Sundaram S (2006) Characterization and reuse of textile effluent treatment plant waste sludge in clay bricks. J Univ Chem Technol Metall 41:473–478

Batchelor B (2006) Overview of waste stabilization in cement. Waste Manage 26:689–698

Bautista-Gutierrez KP, Herrera-May AL, Santamaría-López JM, Honorato-Moreno A, Zamora-Castro SA (2019) Recent progress in nanomaterials for modern concrete infrastructure: advantages and challenges. Mater (Basel) 12:1–40

Chandanshive VV, Kadam SK, Khandare RV, Kurade MB, Jeon BH, Jadhav JP, Govindwar SP (2018) In situ phytoremediation of dyes from textile wastewater using garden ornamental plants, effect on soil quality and plant growth. Chemosphere 1(210):968–976

Coelho A, De Brito J (2012) Influence of construction and demolition waste management on the environmental impact of buildings. Waste Manag 32(3):532–541

Goyal S, Siddique R, Jha S, Sharma D (2019) Utilization of textile sludge in cement mortar and paste. Construct Buil Mater 214:169–177

Haque N (2020) Mapping prospects and challenges of managing sludge from effluent treatment in Bangladesh. J Clean Prod 259:120898

Idachaba MA, Nyavor K, Egiebor NO, Rogers RD (2001) Stability evaluation of a cement based waste form to microbially induced degradation. Waste Manage Res 19:284–291

Jalal M, Fathi M, Farzad M (2013) Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self-compacting concrete. Mech Mater 61:11–27

Joseph P, Kumar CKS (2017) Comparative study on effects of quartz powder and textile sludge on strength of concrete. Int J Eng Trends Technol. 47:60–65

Limbachiya M, Meddah MS, Ouchagour Y (2012) Use of recycled concrete aggregatein fly-ash concrete. Construct Build Mater 27:439–449

Lynn CJ, Dhir RK, Ghataora GS, West RP (2015) Sewage sludge ash characteristics and potential for use in concrete. Constr Build Mater 98:767–779. https://doi.org/10.1016/j.conbuildmat.2015.08.122

Malviya R, Chaudhary R (2006) Leaching behaviour and immobilization of heavy metals in solidified/stabilized products. J Hazard Mater B137:207–217

Man X, Ning XA, Zou H, Liang J, Sun J, Lu X, Sun J (2018) Removal of polycyclic aromatic hydrocarbons (PAHs) from textile dyeing sludge by ultrasound combined zero-valent iron/EDTA/Air system. Chemosphere 1(191):839–847

Manigandan S, Praveenkumar TR, Al-Mohaimeed AM, Brindhadevi K, Pugazhendhi A (2021) Characterization of polyurethane coating on high performance concrete reinforced with chemically treated Ananas erectifolius fiber. Prog Org Coat 150:105977

Meddah MS, Praveenkumar TR, Vijayalakshmi MM, Manigandan S, Arunachalam R (2020) Mechanical and microstructural characterization of rice husk ash and Al2O3 nanoparticles modified cement concrete. Construct Build Mater 255:119358

Meng Y, Ling TC, Mo KH (2018) Recycling of wastes for value-added applications in concrete blocks: an overview. Resour Conserv Recycl 1(138):298–312

Olmo IF, Chacon E, Irabien A (2001) Influence of lead, zinc, iron (III) and chromium (III) oxides on the setting time and strength development of Portland cement. Cement Concrete Res 31:1213–1219

Palanivelu K, Rajkumar R (2001) Characterization and leachability studies on textile effluent treatment plant sludge. Environ Pollut Control 5(1):38–40

Patel H, Pandey S (2012) Evaluation of physical stability and leachability of Portland Pozzolona Cement (PPC) solidified chemical sludge generated from textile wastewater treatment plants. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2011.05.028

Paz A, Carballo J, Pérez MJ, Domínguez JM (2017) Biological treatment of model dyes and textile wastewaters. Chemosphere 1(181):168–177

Praveenkumar TR, Vijayalakshmi MM (2019) Microstructural properties of nano-rice husk ash concrete. Nanotechnol Environ Eng 4:9. https://doi.org/10.1007/s41204-019-0056-4

Rahman A, Urabe T, Kishimoto N, Mizuhara S (2015) Effects of waste glass additions on quality of textile sludge-based bricks. Environ Technol 36:2443–2450. https://doi.org/10.1080/09593330.2015.1034188

Rahman MM, Khan MMR, Uddin MT, Islam MA, Rahman MAI, Mostafizur Md, Khan Md, Maksudur Rahman Md, Uddin T (2017) Textile effluent treatment plant sludge: characterization and utilization in building materials. Arab J Sci Eng 42:1435–1442. https://doi.org/10.1007/s13369-016-2298-9

Rath B, Deo S, Ramtekkar G (2022) An experimental study on strength and durability of glass fiber reinforced cement concrete with partial replacement of cement and sand with coal ashes available in central chhattisgarh region. Curr Appl Sci Technol 1:1–28

Silva RV, De Brito J, Dhir RK (2018) Fresh-state performance of recycled aggregate concrete: a review. Construct Build Mater 178:19–31

Soundararajan R (1990) An overview of present day immobilization technologies. J Hazard Mater 24:199–212

Tony MA (2020) Zeolite-based adsorbent from alum sludge residue for textile wastewater treatment. Int J Environ Sci Technol 29:1–4

Vellingiri S, Velumani P, Senthilkumar S (2015) An experimental approach to evaluate the performance for the reuse of textile industry sludge. Int J Appl Eng Res 10:28172–28175

Wang M, Mao M, Zhang M, Wen G, Yang Q, Su B, Ren Q (2019) Highly efficient treatment of textile dyeing sludge by CO2 thermal plasma gasification. Waste Manage 1(90):29–36

Xie C, Liu J, Xie W, Kuo J, Lu X, Zhang X, He Y, Sun J, Chang K, Xie W, Liu C (2018) Quantifying thermal decomposition regimes of textile dyeing sludge, pomelo peel, and their blends. Renew Energy 1(122):55–64

Zhan BJ, Poon CS (2015) Study on feasibility of reutilizing textile effluent sludge for producing concrete blocks. J Clean Prod 101:174–179. https://doi.org/10.1016/j.jclepro.2015.03.083

Zhan BJ, Li JS, Xuan DX, Poon CS (2020) Recycling hazardous textile effluent sludge in cement-based construction materials: Physicochemical interactions between sludge and cement. Journal of hazardous materials. 381:121034

Zhao Q, Wei J (2020) Zero-waste recycling method for textile dyeing sludge by magnetizing roasting–magnetic separation process and ceramic filter preparation. Chem Pap 74(12):4389–4399

Acknowledgements

Our grateful acknowledgement goes to the Wollega University for the extensive support. No funding received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Praveenkumar, T.R., Manigandan, S., Gemede, H.F. et al. Effective utilization of waste textile sludge composite with Al2O3 nanoparticles as a value-added application. Appl Nanosci 13, 1251–1261 (2023). https://doi.org/10.1007/s13204-021-02001-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-021-02001-4