Abstract

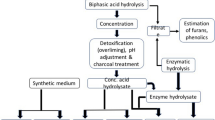

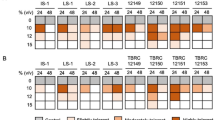

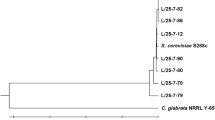

Large amount of cassava pulp is produced as by-product of industrial tapioca production. The value-added process of this low-cost waste is to use it as a substrate for bioethanol production. However, during the pulp pretreatment by acidification combined with steam explosion, many yeast inhibitors including acetic acid, formic acid, levulinic acid, furfural and 5-hydroxymethylfurfural are generated and these compounds have negative effects on the subsequent fermentation step. Therefore, the objective of this study was to investigate whether the repeated cultures of Saccharomyces cerevisiae SC90 could alleviate this problem. To obtain the inhibitor tolerable cells, the repeated culture was performed by growing yeast cells to a specific growth rate (µ) of 0.22 h−1 or higher (80% of the µ in control) and then transferring them to progressively higher concentrations of hydrolysate ranging from 20 to 100% (v/v). The results showed a tendency of longer lag phase as well as time to reach maximum cell number (tmaxc) with an increase in hydrolysate concentration. However, the repeated culture at the same hydrolysate concentration could shorten both lag period and tmaxc. Interestingly, the growth and fermentation efficiency of adapted cells in 100% hydrolysate were significantly higher (p ≤ 0.05) than those of non-adapted cells by 38% and 27%, respectively.

Similar content being viewed by others

References

Agu RC, Amadife AE, Ude CM, Onyia A, Ogu EO, Okafor M, Ezejiofor E (1997) Combined heat treatment and acid hydrolysis of cassava grate waste (cgw) biomass for ethanol production. Waste Manag 17:91–96

Almeida JR, Modig T, Petersson A, Hähn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energ Convers Manag 52:858–875

Bauer BE, Rossington D, Mollapour M, Mamnun Y, Kuchler K, Piper PW (2003) Weak organic acid stress inhibits aromatic amino acid uptake by yeast, causing a strong influence of amino acid auxotrophies on the phenotypes of membrane transporter mutants. Eur J Biochem 15:3189–3195

Cao GL, Ren NQ, Wang AJ, Guo WQ, Xu JF, Liu BF (2010) Effect of lignocellulose-derived inhibitors on growth and hydrogen production by Thermoanaerobacterium thermosaccharolyticum W16. Int J Hydrogen Energy 35:13475–13480

Dubois M, Gilles DA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for the determination of sugars and related substances. Anal Chem 28:350–356

El-Mansi EMT, Bruce Ward F (2006) Microbiology of industrial fermentation. In: El-Mansi EMT, Bryce CFA, Demain AL, Allman AR (eds) Fermentation microbiology and biotechnology, 2nd edn. Taylor & Francis, Boca Raton, pp 11–46

El-Naggar NE, Deraz S, Khalil A (2014) Bioethanol production from lignocellulosic feedstocks based on enzymatic hydrolysis: current status and recent developments. Biotechnology 13:1–21

Fein JE, Tallim SR, Lawford GR (1984) Evaluation of d-xylose fermenting yeasts for utilization of a wood-derived hemicellulose hydrolysate. Can J Microbiol 30:682–690

Greetham D (2014) Presence of low concentrations of acetic acid improves fermentations using Saccharomyces cerevisiae. J Bioprocess Biotech 5:192

Huang X, Wang Y, Liu W, Bao J (2011) Biological removal of inhibitors leads to the improved lipid production in the lipid fermentation of corn stover hydrolysate by Trichosporon cutaneum. Bioresour Technol 102:9705–9709

Keating JD, Panganiban C, Mansfield SD (2006) Tolerance and adaptation of ethanologenic yeasts to lignocellulosic inhibitory compounds. Biotechnol Bioeng 93:1196–1206

Koppram R, Albers E, Olsson L (2012) Evolutionary engineering strategies to enhance tolerance of xylose utilizing recombinant yeast to inhibitors derived from spruce biomass. Biotechnol Biofuels 5:32

Kouteu Nanssou PA, Jiokap Nono Y, Kapseu C (2016) Pretreatment of cassava stems and peelings by thermohydrolysis to enhance hydrolysis yield of cellulose in bioethanol production process. Renew Energ 97:252–265

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Lacerda TM, Zambon MD, Frollini E (2013) Effect of acid concentration and pulp properties on hydrolysis reactions of mercerized sisal. Carbohyd Polym 93:347–356

Landaeta R, Aroca G, Acevedo F, Teixeira JA, Mussatto SI (2013) Adaptation of a flocculent Saccharomyces cerevisiae strain to lignocellulosic inhibitors by cell recycle batch fermentation. Appl Energ 102:124–130

Lane J (2017) Thailand announces $11.3 billion 10-year plan to build sugarcane and cassava bioeconomy. Biofuelsdigest. http://www.biofuelsdigest.com/bdigest/2017/01/25/thailand-announces-11-3-billion-10-year-plan-to-build-sugarcane-and-cassava-bioeconomy-2. Accessed 26 Nov 2018

Larsson S, Palmqvist E, Hahn-Hägerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant NO (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb Technol 24:151–159

Larsson S, Cassland P, Jönsson LJ (2001) Development of a Saccharomyces cerevisiae strain with enhanced resistance to phenolic fermentation inhibitors in lignocellulose hydrolysates by heterologous expression of laccase. Appl Environ Microbiol 67:1163–1170

Liu ZL, Slininger PJ, Dien BS, Berhow MA, Kurtzman CP, Gorsich SW (2004) Adaptive response of yeasts to furfural and 5-hydroxymethylfurfural and new chemical evidence for HMF conversion to 2,5-bis-hydroxymethylfuran. J Ind Microbiol Biotechnol 31:345–352

Luján-Rhenals DE, Morawicki RO (2016) Production of fermentable sugars and a high protein meal by dilute acid hydrolysis of soybean meal at high temperatures. Bioresources 11(4):8155–8165

Martín C, Wei M, Xiong S, Jönsson LJ (2017) Enhancing saccharification of cassava stems by starch hydrolysis prior to pretreatment. Ind Crop Prod 97:21–31

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10

Narayanan V, Sànchez Nogué V, van Niel Ed WJ, Gorwa-Grauslund MF (2016) Adaptation to low pH and lignocellulosic inhibitors resulting in ethanolic fermentation and growth of Saccharomyces cerevisiae. AMB Expr 6:1–13

Nilvebrant NO, Persson P, Reimann A, De Sousa F, Gorton L, Jönsson LJ (2003) Limits for alkaline detoxification of dilute-acid lignocellulose hydrolysates. Appl Biochem Biotechnol 105–108:615–628

Olsson L, Hahn-Hägerdal B (1993) Fermentative performance of bacteria and yeasts in lignocellulose hydrolysates. Process Biochem 28:249–257

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Parawira W, Tekere M (2011) Biotechnological strategies to overcome inhibitors in lignocellulose hydrolysates for ethanol production: review. Crit Rev Biotechnol 31(1):20–31

Parekh SR, Yu S, Wayman M (1986) Adaptation of Candida shehatae and Pichia stipitis to wood hydrolysates for increased ethanol production. Appl Microbiol Biotechnol 25:300–304

Pornpukdeewattana S, Khamfun J, Phatyenchai N (2014) Adaptation of commercial yeast Saccharomyces cerevisiae SC90 to tolerate inhibitors generated during cassava pulp hydrolysis. Suranaree J Sci Technol 21:335–345

Silva CJ, Roberto IC (2001) Improvement of xylitol production by Candida guilliermondii FTI 20037 previously adapted to rice straw hemicellulosic hydrolysate. Lett Appl Microbiol 32:248–252

Silva JPA, Mussatto SI, Roberto IC, Teixeira JA (2011) Ethanol production from xylose by Pichia stipitis NRRL Y-7124 in a stirred tank bioreactor. Braz J Chem Eng 28:151–156

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2012) Determination of structural carbohydrates and lignin in biomass, laboratory analytical procedure (LAP). National Renewable Energy Laboratory (NREL) Web. https://www.nrel.gov. Accessed 17 Jan 2019

Smart KA, Chambers KM, Lambert I, Jenkins C (1999) Use of methylene violet staining procedures to determine yeast viability and vitality. J Am Soc Brew Chem 57:18–23

Soleymanpour Z, Nikzad M, Talebnia F, Niknezhad V (2018) Xanthan gum production from acid hydrolyzed broomcorn stem as a sole carbon source by Xanthomonas campestris. 3 Biotech 8:296

Srinorakutara T, Kaewvimol L, Saengow L (2006) Approach of cassava waste pretreatments for fuel ethanol production in Thailand. J Sci Res Chula Univ 31:77–84

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Thomas KC, Hynes SH, Ingledew WM (2002) Influence of medium buffering capacity on inhibition of Saccharomyces cerevisiae growth by acetic and lactic acids. Appl Environ Microb 4:1616–1623

Thompson OA, Hawkins GM, Gorsich SW, Doran-Peterson J (2016) Phenotypic characterization and comparative transcriptomics of evolved Saccharomyces cerevisiae strains with improved tolerance to lignocellulosic derived inhibitors. Biotechnol Biofuels 9:200

Tian S, Zhu J, Yang X (2011) Evaluation of an adapted inhibitor-tolerant yeast strain for ethanol production from combined hydrolysate of softwood. Appl Energy 88:1792–1796

Tomás-Pejó E, Ballesteros M, Oliva JM, Olsson L (2010) Adaptation of the xylose fermenting yeast Saccharomyces cerevisiae F12 for improving ethanol production in different fed-batch SSF processes. J Ind Microbiol Biot 37:1211–1220

Trakulvichean S, Chaiprasert P, Otmakhova J, Songkasiri W (2017) Comparison of fermented animal feed and mushroom growth media as two value-added options for waste cassava pulp management. Waste Manag Res 35:1210–1219

Wallace-Salinas V, Gorwa-Grauslund MF (2013) Adaptive evolution of an industrial strain of Saccharomyces cerevisiae for combined tolerance to inhibitors and temperature. Biotechnol Biofuels 6:151

Zhu JJ, Yong Q, Xu Y, Chen SX, Yu SY (2009) Adaptation fermentation of Pichia stipitis and combination detoxification on steam exploded lignocellulosic prehydrolyzate. Nat Sci 1:47–54

Acknowledgements

This research was financially supported by King Mongkut’s Institute of Technology Ladkrabang (KMITL) (A118-59-070) and National Research Council of Thailand. The contribution of Prof. Dr. Anthony Keith Thompson and Prof. Dr. George Srzednicki (visiting Professor at Faculty of Agro-Industry, KMITL) for critically editing the manuscript is acknowledged.

Author information

Authors and Affiliations

Contributions

PPNA: literature review, design of the research outline, design of research tools, analysis of data, interpretation of the data analysis, and drafting of the article (first draft). TC: design of the research outline, design of research tools, decision on the data analysis method, interpretation of the data analysis, revision of the draft of the article (second draft), and final approval of the article (final draft). WK: conception of the project, design of the research outline, interpretation of the data analysis, and final approval of the article (final draft). SP: conception of the project, literature review, design of the research outline, design of research tools, decision on the data analysis method, analysis of data, interpretation of the data analysis, revision of the draft of the article (second draft), and final approval of the article (final draft).

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Palakawong Na Ayutthaya, P., Charoenrat, T., Krusong, W. et al. Repeated cultures of Saccharomyces cerevisiae SC90 to tolerate inhibitors generated during cassava processing waste hydrolysis for bioethanol production. 3 Biotech 9, 76 (2019). https://doi.org/10.1007/s13205-019-1607-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-019-1607-x