Abstract

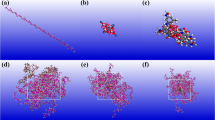

Melt-extruded poly(vinylidene fluoride) (PVDF)/poly(methyl methacrylate) (PMMA) blend films were prepared at different rutile (titanium dioxide, TiO2) concentrations for use as a protective sheet on a photovoltaic cell and module. The rheology, structure, morphology, crystalline behavior, thermal, and mechanical properties of PVDF/PMMA/TiO2 composite films were investigated through reflectance difference spectrometer (RDS), Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), differential scanning calorimeter (DSC), thermogravimetric analysis (TGA), scanning electron microscope (SEM), and color spectrometry. The results showed that the blended material and its film have favorable thermal and mechanical properties. The TiO2 is finely dispersed in the composite, as shown by the crystalline regions of the PVDF and the homogeneous amorphous regions consisting of PVDF and PMMA, resulting in advantageous and optical properties of PVDF/PMMA/TiO2 composite films. However, the TiO2 can also greatly narrow the thermally stable region of the PVDF in PVDF/PMMA/TiO2 composite film because of the catalytic decomposition effect. The tensile strength and elongation at break are higher than those of a PVDF/PMMA blend as TiO2 content increases. Increases in the crystalline behavior and rheological properties appeared below 20 wt% TiO2 content.

Similar content being viewed by others

References

J. E. Dohany, in Encyclopedia of Chemical Technology, John Wiley & Sons, New York, 1994, Vol. 11, p 694.

A. J. Lovinger, in Developments in Crystalline Polymers, G. C. Bassett, Ed., Elsevier, Barking, 1982, Vol. 1, p 195.

J. E. Dohany and J. S. Humphrey, in Encyclopedia of Polymer Science and Engineering, H. F. Mark, N. M. Bikales, C. G. Overberger, and G. Menges, Eds., John Wiley & Sons, New York, 1987, Vol. 17, p 532.

K. S. Kim and S. J. Park, Macromol. Res., 18, 981 (2010).

D. W. Chae and S. M. Hong, Macromol. Res., 19, 326 (2011).

D. Silagy, P. Bussi, and G. Marot, J. Fluorine Chem., 104, 79 (2000).

Z. H. Liu, P. Macechal, and R. Jerome, Polymer, 39, 1779 (1998).

T. Nishi, Polymer, 27, 483 (1978).

T. Nishi and T. T. Wang, Macromolecules, 8, 909 (1975).

K. Nakagawa and Y. Ishida, J. Polym. Sci. Part B: Polym. Phys., 1, 2153 (1973).

C. Huang and L. Zhang, J. Appl. Polym. Sci., 92, 5 (2004).

H. Horibe and F. Baba, Nippon Kagaku Kaishi, 115 (2000).

E. S. Park, E. B. Cho, and D. J. Kim, Macromol. Res., 7, 617 (2007).

R. E. Bernstein, C. A. Cruz, D. R. Paul, and J. W. Barlow, Macromolecules, 10, 681 (1977).

H. Yoshida, J. Therm. Anal., 49, 101 (1997).

H. Yoshida, G. Z. Zhang, and T. Kitamura, J. Therm. Anal. Calorim., 64, 577 (2001).

Y. Hirata and T. Kotaka, Polym. J., 13, 273 (1981).

J. Kijovic, H. L. Luo, and C. D. Han, Polym. Eng. Sci., 22, 234 (1982).

S. R. Murff, J. W. Barlow, and D. R. Paul, Adv. Chem. Ser., 211, 313 (1986).

S. Schneider, X. Drujon, J. C. Wittmann, and B. Lotz, Polymer, 42, 8799 (2000).

Z. P. Fang and Y. Z. Xu, J. Mater. Sci. Eng., 21, 279 (2003).

P. He and A. C. Zhao, Macromolecule Aviso, 2, 74 (2001).

X. C. Cao, J. Ma, and X. H. Shi, Appl. Surf. Sci., 253, 2003 (2006).

L. Y. Yu, H. M. Shen, and Z. L. Xu, J. Appl. Polym. Sci., 113, 1763 (2009).

A. Chatterjee, J. Appl. Polym. Sci., 118, 2890 (2010).

B. A. Smillie and G. M. Lenges, US Patent 0057392 (2006).

L. Wei, L. Hong, and M. Z. Yong, J. Mater. Sci., 44, 2977 (2009).

J. G. Lee and S. H. Kim, Macromol. Res., 19, 72 (2011).

D. Z. Chen, H. Y. Yang, P. S. He, and W. A. Xhang, Compos. Sci. Technol., 65, 1593 (2005).

Ye. Bormashenko, R. Pogreb, O. Stanevsky, and E. Bormashenko, Polym. Test., 23, 791 (2004).

M. Kobayashi, K. Tashiro, and H. Tadokoro, Macromolecules, 8, 158 (1975).

R. Gregorio Jr., J. Appl. Polym. Sci., 100, 3272 (2006).

S. Ahmad, T. K. Saxena, S. Ahmad, and S. A. Agnihotry, J. Power Sources, 159, 205 (2006).

K. Matsushige and T. Takemura, J. Polym. Sci. Part B: Polym. Phys., 16, 921 (1978).

R. M. Hodge, G. H. Edward, and G. P. Simon, Polymer, 37, 1371 (1996).

D. C. Yang and E. L. Thomas, J. Mater. Sci. Lett., 3, 919 (1984).

G. A. Gallagher, R. Jakeways, and L. M. Ward, J. Polym. Sci. Part B: Polym. Phys., 29, 1147 (1991).

W. Feng, E. Sun, A. Fujii, H. Wu, K. Niihara, and K. Yoshino, Bull. Chem. Soc. Jpn., 73, 2627 (2000).

J. D. Rancourt and L. T. Taylor, Macromolecules, 20, 790 (1987).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.G., Kim, S.H., Kang, H.C. et al. Effect of TiO2 on PVDF/PMMA composite films prepared by thermal casting. Macromol. Res. 21, 349–355 (2013). https://doi.org/10.1007/s13233-013-1017-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-013-1017-6