Abstract

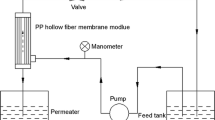

Polyvinylidene fluoride (PVDF) hollow fiber membranes prepared by thermally-induced phase separation (TIPS) have excellent porosity but weak tensile strength. In this study, we stretched and annealed these hollow fiber membranes in an attempt to improve their tensile strength and water permeability. This was done by introducing a stretching process into the manufacturing process. In this study, the stretching temperature ranged from 30 to 90 °C, the stretching speed ranged between 4 and 60 mm/s, and the stretching ratio was varied between 100 and 200%. According to field-emission scanning electron microscopy (SEM) images, the structure of the surface varied under different stretching conditions. The tensile strength was increased as the degree of stretching increased, and annealing conditions of 130 °C for 2 h resulted in an increase in the crystallinity. These results indicate that changing the stretching conditions can increase the water permeability and the mechanical strength of the membrane by more than 20%; these improvements are brought about by changes in the surface structure of the membrane.

Similar content being viewed by others

References

S. P. Rwei, J. Appl. Polym. Sci., 82, 2896 (2001).

C. H. Du, Y. Y. Xu, and B. K. Zhu, J. Appl. Polym. Sci., 106, 1753 (1998).

J. H. Kim, S. S. Kim, M. S. Park, and M. S. Jang, J. Membr. Sci., 318, 201 (2008).

C. H. Du, B. K. Zhu, and Y. Y. Xu, J. Appl. Polym. Sci., 104, 2254 (2007).

Z. Xi, Y. Y. Xu, L. P. Zhu, C. H. Du, and B. K. Zhu, Polym. Adv. Techonol., 19, 1616 (1998).

C. H. Du, B. K. Zhu, and Y. Y. Xu, Macromol. Mater. Eng., 290, 786 (2005).

B. S. Sprague, J. Macromol. Sci. B: Phys., 8, 157 (1973).

G. H. Lee, J. H. Kim, K. G. Song, and S. S. Kim, Polym. Korea, 30, 175 (2006).

J. J. Kim, T. S. Jang, Y. D. Kwon, U. Y. Kim, and S. S Kim, J. Membr. Sci., 93, 209 (1994).

C. Marega and A. Marigo, Eur. Polym. J., 39, 1713 (2003).

J. Y. Kim, S. H. Kim, and T. Kikutani, J. Polym. Part B., 42, 395 (2004).

Z. W. Wilchinsky, J. Poly. Sci., 30, 792 (1959).

B. R. Jung, Y. Son, Y. T. Lee, and N. Kim, Membrane J., 23, 80 (2013).

B. S. Sprgue, J. Macromol. Sci., 12, 182 (1973).

R. Gregorio, J. Polym. Sci., Part B: Polym. Phys., 45, 2793 (2007).

R. Gregorio and E. M. Uneo, J. Mater. Sci., 34, 4489 (1999).

R. Gregorio and N. C. Soucanocita, J. Phys., 28, 432 (1995).

A. Keller, Rep. Prog. Phys., 31, 623 (1968).

J. M. Samon, J. M. Schultz, and B. S. Hsiao, Polymer. 41, 2169 (2000).

R. S. Stein and F. H. Norris, J. Polym. Sci., 21, 381 (1956).

A. Galeski, Prog. Polym. Sci., 28, 1643 (2003).

K. Nakagawa and Y. Ishida, J. Polym. Sci., Part B: Polym. Phys., 11, 2153 (1973).

K. Kurumada, T. Kitamura, N. Fukumoto, M. Oshima, M. Tanigaki, and S. Kanazawa, J. Membr. Sci., 149, 51 (1998).

N. Betz, A. L. Moel, E. Balanzat, J. M. Ramillon, J. Lamotte, J. P. Gallas, and G. A. Jaskierowicz, J. Polym. Sci., Part B: Polym. Phys., 32, 1493 (1994).

B. Mohajir and N. Heymans, Polym. Sci., 42, 5661 (2001).

A. Pawlak, Polymer, 48, 1397 (2007).

R. Gregorio, Jr. and M. Cestari, J. Polym. Sci., Part B: Polym. Phys., 32, 859 (1994).

Y. Yang, H. Zhang, P Wang, Q. Zheng, and J. Li, J. Membr. Sci., 288, 231 (2007).

K. Nakagawa and Y. Ishida, J. Polym. Sci., Polym. Phys., 11, 1503 (1973).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, T.H., Jee, K.Y. & Lee, Y.T. The improvement of water flux and mechanical strength of PVDF hollow fiber membranes by stretching and annealing conditions. Macromol. Res. 23, 592–600 (2015). https://doi.org/10.1007/s13233-015-3087-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-015-3087-0