Abstract

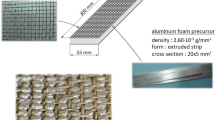

The work presented in this article is directed towards the application of CFRP foam core sandwich structures as primary structures in commercial aviation. With closed cell rigid foams, it is possible to produce comparatively low priced high-integral sandwich components having a complex geometry in terms of a curved and a variable lateral cut. Sandwich structures are offering a good bending stiffness and strength to weight ratio. Thus, they are suited for using in structures which are at risk to fail by buckling (Herrmann et al. Sandwich structures 7: advancing with sandwich structures and materials, 2005). The investigations are focused on a CFRP sandwich structure with polymethacrylimide (PMI) foam core, named ROHACELL®RIST. Besides good structural stability at thermal conditions, the foam is characterized by a good strength and stiffness to weight ratio (Seibert, Reinforced Plast 50(1):44–48, 2006). Primary structures in aircraft applications are exposed to a superposition of in-service loads and environmental conditions. The typical working loads in combination with environmental conditions were investigated. The structure needs a sizing with respect to large temperature changes and influences of humidity. Thus, the time, temperature, and moisture dependency of the mechanical behavior were studied for the single components of the structure and for the composite itself. Therefore, Finite Element Models on macroscopic level were built with reference to the experiments. For each in-service case, the residual stresses arising during manufacturing have to be regarded and quantified (John et al. ECCM14, 2010). During manufacturing, the sandwich structure is cured at 180°C. Due to the different stiffnesses and coefficients of thermal expansion of the foam and the CFRP face sheets, residual stresses are induced by cooling down to service temperature. Among others, some tests were made at laterally closed CFRP sandwich structures with a storage time up to half a year at certain climate conditions. The aging process is not only controlled by external conditions, but also by a rearrangement of molecules, for example, the relaxation behavior of the PMI foam (Gutwinski et al. Verbundwerkstoffe. Wiley, Weinheim, 2009). Another question of the long-term behavior of the CFRP foam core sandwich structure is the characteristic of delamination of the face sheets from the inner core after an impact has occurred. To describe the crack growth behavior of the sandwich structure fracture mechanical principles can be used estimating the damage tolerance. Sandwich specimens with initial damage were loaded up to 3 million mechanical load cycles.

Similar content being viewed by others

References

Apicella, A., Nicolais, L.: Environmental aging of epoxy resins: synergistic effect of sorbed moisture, temperature, and applied stress. Ind. Eng. Chem. Prod. Res. Dev. 20(1), 138–144 (1981)

Berggreen, C.: Damage tolerance of debonded sandwich structures. Ph.D. thesis, Technical University of Denmark (2004)

Briscoe, B.J., Savvas, T.: Gas diffusion in dense poly(ethylene) foams. Adv. Polym. Technol. 17(2), 87–106 (1998)

Brüller, O.: Zur Charakterisierung des Langzeitverhaltens von Kunststoffen. Arch. Appl. Mech. 63, 363–376 (1993)

Earl, J.S., Shenoi, R.A.: Determination of the moisture uptake mechanism in closed cell polymeric structural foam during hygrothermal exposure. J. Compos. Mater. 38(15), 1345–1365 (2004)

Evonik: Properties of Rohacell®Rist. Produktdatenblatt, Evonik Röhm GmbH Performance Polymers 64293, Darmstadt, Germany (2008)

Gutwinski, M., Schäuble, R.: Einfluss von Temperaturwechseln auf die Struktureigenschaften von CFK-Schaum-Sandwichstrukturen. In: Krenkel, W. (ed.) Verbundwerkstoffe. Wiley, Weinheim (2009)

Herrmann, A., Zahlen, P., Zuardy, I.: Sandwich structures technology in commercial aviation. In: Thomsen, O.T., et al. (eds.) Sandwich structures 7: advancing with sandwich structures and materials. Springer, Aalborg (2005)

ITWM, N.: Software MAVI (modular algorithms for volume images). Fraunhofer Institut für Techno- und Wirtschaftsmathematik ITWM (2010) http://www.itwm.fhg.de/bv/projects/MAVI

John, M., Rinker, M., Zahlen, P., Schäuble, R.: Effects of thermal and humidity treatment on mechanical properties of CFRP foam core sandwich structures. In: Asp, L.E., et al. (eds.) ECCM14. Budapest University of Technology and Economics, Budapest (2010)

Katzman, H.A., Castaneda, R.M., Lee, H.S.: Moisture diffusion in composite sandwich structures. Compos. A Appl. Sci. Manuf. 39(5), 887–892 (2008)

Lautensack, C.: Random Laguerre tessellations. Ph.D. thesis, Fakulät für Mathematik der Universität Karlsruhe (TH) (2007)

Nurge, M.A., Youngquist, R.C., Starr, S.O.: Mass conservation in modeling moisture diffusion in multi-layer composite and sandwich structures. J. Sandwich Struct. Mater. 12(6), 755–763 (2010)

Ohser, J., Mncklich, F.: Statistical Analysis of Microstructures in Materials Science. Wiley, Chichester (2000)

Pilon, L., Fedorov, A.G., Viskanta, R.: Gas diffusion in closed-cell foams. J. Cell. Plast. 36(6), 451–474 (2000)

Rinker, M., Gutwinski, M., Schäuble, R.: Experimental and theoretical investigation of thermal stress in CFRP foam-core sandwich structures. In: 13th International Conference on Composite Materials European Society for Composite Materials (2008)

Rinker, M., John, M., Schäuble, R.: Untersuchungen zur Schadenstoleranz von CFK-Schaum-Sandwich-strukturen mit Hilfe von DCB- und ENF-Tests. In: Deutscher Luft- und Raumfahrtkongress (2010)

Rinker, M., John, M., Zahlen, P.C., Schäuble, R.: Face sheet disbonding in CFRP/PMI sandwich structures under quasi-static and fatigue loading considering residual stress. Eng. Fract. Mech. (Manuscript submitted for publication) (2011)

Roth, A., Goldmann, F.: Ganzheitliche Betrachtung von Schaum-Sandwich-Bauweisen in der Luftfahrt. In: Deutscher Luft- und Raumfahrtkongress (2010)

Roth, A., Kraatz, A.: New failure criterion for sandwich foam cores based on PMI. In: Ferreira, A.J.M. (ed.) 8th International Conferencen on Sandwich Structures (2008)

Seibert, H.F.: Applications for PMI foams in aerospace sandwich structures. Reinforced Plast. 50(1), 44–48 (2006)

Sharma, N., Gibson, R.F., Ayorinde, E.O.: Fatigue of foam and honeycomb core composite sandwich structures: a tutorial. J. Sandwich Struct. Mater. 8, 263–319 (2006)

Soille, P.: Morphological Image Analysis: Principles and Applications, 2nd edn. Springer, Secaucus (2003)

Yang, C.T., Lee, K.L., Lee, S.T.: Dimensional stability of LDPE foams: modeling and experiments. J. Cell. Plast. 38(2), 113–128 (2002)

Zahlen, P.C., Rinker, M., Heim, C.: Advanced manufacturing of large, complex foam core sandwich panels. In: 8th International Conference on Sandwich Structures (2008)

Zuardy, M.I., Zahlen, P.C., Vöge, W., Herrmann, A.S.: Eine Hochentwickelte CFK-Sandwichbauweise fnr hauptlasttragende Luftfahrtstrukturen. In: Deutscher Luft- und Raumfahrtkongress (2010)

Acknowledgments

The work presented in this article was partially funded by CTC Stade GmbH. The authors wish to acknowledge this support.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is based on a presentation at the German Aerospace Congress, September 27–29, 2011, Bremen, Germany.

Rights and permissions

About this article

Cite this article

John, M., Schlimper, R., Rinker, M. et al. Long-term durability of CFRP foam core sandwich structures. CEAS Aeronaut J 2, 213–221 (2011). https://doi.org/10.1007/s13272-011-0028-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13272-011-0028-2