Abstract

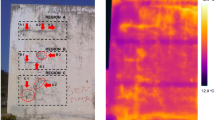

The study of facade cracking is of great importance in the investigation of pathologies and degradation, as well as in the rehabilitation processes of buildings. Cracking is one of the major defects in facades; so assessing damage severity is necessary to define the best maintenance and rehabilitation strategies. The infrared thermography has been increasingly used as an inspection technique to identify and map facade defects and their severity. The use of hygrothermal simulation to understand the dynamics of the heat flux allows to observe important references that can help in the interpretation of the thermogram under different heating or cooling conditions. This study investigates the use of the quantitative passive thermography to measure the damage degree of cracks in a building facade. The crack depth was evaluated by the Delta-T values investigated in the three cracked regions. For the width, the variation of the studied temperature in a line transversal to the crack was used. The analysis was performed at a distance of 33 m from the facade. The conclusions corroborated the importance of the hygrothermal simulation as a pre-thermography technique, which made it possible to limit the period of investigation focusing on the phenomena of interest. It is also observed that it is possible to obtain quantitative values of the degree of damage by thermographic investigation. The measurement of the damage degree, in turn, brings important contribution to the application of the inspection technique.

Similar content being viewed by others

References

Flores-Colen VP, de Brito I, de Freitas J (2009) Methodology for in-service performance assessment of rendering facades for predictive maintenance. TG75, W014, W080, W083 &W086, 388

Silvestre J, de Brito JD (2014) Durability of current renderings: a probabilistic analysis. Autom Constr 44:92–102. https://doi.org/10.1016/j.autcon.2014.04.002

Kanniyapan S, Mohammad G, Nesan IS, Mohammed LJ, Ganisen AH (2015) Façade material selection criteria for optimising building maintainability. Sci Eng 75(10):17–25

Bisegna F, Ambrosini D, Paoletti D, Sfarrab S, Gugliermettia F (2013) A qualitative method for combining thermal imprints to emerging weak points of ancient wall structures by passive infrared thermography—a case study. J Cult Herit 15(2):199–202. https://doi.org/10.1016/j.culher.2013.03.006

Martínez I, Castillo A, Martínez E, Castellote M (2013) Physico-chemical material characterization of historic unreinforced masonry buildings: the first step for a suitable intervention. Constr Build Mater 40:352–360. https://doi.org/10.1016/j.conbuildmat.2012.09.091

Lourenço T, Matias L, Faria P (2017) Anomalies detection in adhesive wall tiling systems by infrared thermography. Constr Build Mater 148:419–428. https://doi.org/10.1016/j.conbuildmat.2017.05.052

de Souza JS (2016) Evolution of façade degradation—effect of degradation agents and constituents of the elements. Dissertation, Universidade de Brasília (UnB), Brasília, p 114 (in Portuguese)

Silvestre JD, de Brito J (2009) Ceramic tiling inspection system. Constr Build Mater 23(2):653–668. https://doi.org/10.1016/j.conbuildmat.2008.02.007

Gaspar PL, de Brito J (2008) Quantifying environmental effects on cement-rendered facades: a comparison between different degradation indicators. Build Environ 43(11):1818–1828. https://doi.org/10.1016/j.buildenv.2007.10.022

Clemente P (2018) Extending the life-span of cultural heritage structures. J Civil Struct Health Monit 8(2):171–179

Edis E, Flores-Colen I, De Brito J (2015) Time-dependent passive building thermography for detecting delamination of adhered ceramic cladding. J Nondestruct Eval 34:1–16

Rodrigues MFS, Teixeira JMC, Cardoso JCP (2011) Buildings envelope anomalies: a visual survey methodology. Constr Build Mater 25(5):2741–2750. https://doi.org/10.1016/j.conbuildmat.2010.12.029

Sá G, Sá J, de Brito J, Amaro B (2015) Statistical survey on inspection, diagnosis and repair of wall renderings. J Civ Eng Manag 21:623–636

CIB (2014) Defects in masonry walls. Guidance of cracking: indentification, prevention and repair. CIB Commission W023, Rotterdam

Nascimento MLM, Bauer E, de Souza JS, Zanoni VAG (2016) Wind-driven rain incidence parameters obtained by hygrothermal simulation. J Build Pathol Rehabil 1:1–7

Barreira E, Almeida RMSF, Delgado JMPQ (2016) Infrared thermography for assessing moisture related phenomena in building components. Constr Build Mater 110:251–269. https://doi.org/10.1016/j.conbuildmat.2016.02.026

Edis E, Flores-Colen I, De Brito J (2015) Building thermography: detection of delamination of adhered ceramic claddings using the passive approach. J Nondestruct Eval 34:1–13

Kominsky JR, Luckino JS, Street NH, Martin TF (2007) Passive infrared thermography—a qualitative method for detecting moisture anomalies in building envelopes. Tedford Pond pp 1–11

Pérez-Bella JM, Domínguez-Hernández J, Cano-Suñén E, del Coz-Díaz JJ, Alonso-Martínez M (2017) On the significance of the climate-dataset time resolution in characterising wind-driven rain and simultaneous wind pressure. Part I: scalar approach. Stoch Environ Res Risk Assess 32:1783–1797

Ferraz GT, De Brito J, De Freitas VP, Silvestre JD (2013) State-of-the-art review of building inspection systems. J Perform Constr Facil 30:1–8

ISO 15686-2 (2012) Buildings and constructed assets—service life planning part 2: service life prediction procedures. ISO—International Organization for Standardization, London

Flores-Colen I (2009) Methodology to evaluate the performance in service of towed façades from the perspective of predictive maintenance. Doctoral thesis, Universidade Técnica de Lisboa, p. 541 (in Portuguese)

Souza J, Silva A, De Brito J, Bauer E (2018) Analysis of the influencing factors of external wall ceramic claddings’ service life using regression techniques. Eng Fail Anal 83:141–155. https://doi.org/10.1016/j.engfailanal.2017.10.005

Lourenço T, Matias L, Faria P (2016) Anomaly diagnosis in ceramic claddings by thermography a review. In 7th International Conference on Safety and Durability of Structures ICOSADOS

Dias JM, Luís Matias, Maria J. Henriques, Maria Do Rosário Veiga (2016) thermography (in Portuguese). In 10o Congresso Nacional de Mecânica Experimental, pp 2–4

Bauer E, de Freitas VP, Mustelier N, Barreira E, de Freitas SS (2015) Infrared thermography—evaluation of the results reproducibility. Struct Surv 33:20–35

Pavón E (2017) Criteria and behavioral patterns for evaluation of ceramic detachments with infrared thermography. Doctoral thesis, Universidade de Brasília (UnB), Brasília, p 250 (in Portuguese)

Kylili A, Fokaides PA, Christou P, Kalogirou SA (2014) Infrared thermography (IRT) applications for building diagnostics: a review. Appl Energy 134:531–549. https://doi.org/10.1016/j.apenergy.2014.08.005

Bauer E, Pavón E, Pereira CHF, Nascimento MLM (2016) Criteria for identification of ceramic detachments in building facades with infrared thermography. Recent developments in building diagnosis techniques 5. Springer, Singapore, pp 51–68

Madruga FJ, Ibarra-Castanedo C, Conde OM, Lpez-Higuera JM, Maldague X (2010) Infrared thermography processing based on higher-order statistics. NDT E Int 43(8):661–666. https://doi.org/10.1016/j.ndteint.2010.07.002

Maldague XP (2001) Theory and practice of infrared technology for nondestructive testing. Wiley, NY

Watase A, Birgul R, Hiasa S, Matsumoto M, Mitani K, Catbas FN (2015) Practical identification of favorable time windows for infrared thermography for concrete bridge evaluation. Constr Build Mater 101:1016–1030. https://doi.org/10.1016/j.conbuildmat.2015.10.156

Bauer E, Pavón E, Barreira E, De Castro EK (2016) Analysis of building facade defects using infrared thermography: laboratory studies. J Build Eng 6:93–104. https://doi.org/10.1016/j.jobe.2016.02.012

Aggelis DG, Kordatos EZ, Soulioti DV, Matikas TE (2010) Combined use of thermography and ultrasound for the characterization of subsurface cracks in concrete. Constr Build Mater 24(10):1888–1897. https://doi.org/10.1016/j.conbuildmat.2010.04.014

Avdelidis NP, Moropoulou A (2004) Applications of infrared thermography for the investigation of historic structures. J Cult Herit 5:119–127. https://doi.org/10.1016/j.culher.2003.07.002

Theodorakeas P, Avdelidis NP, Cheilakou E, Koui M (2014) Quantitative analysis of plastered mosaics by means of active infrared thermography. Constr Build Mater 73(1):417–425. https://doi.org/10.1016/j.conbuildmat.2014.09.089

Junyan L, Qingju T, Xun L, Yang W (2012) Research on the quantitative analysis of subsurface defects for non-destructive testing by lock-in thermography. NDT E Int 45:104–110. https://doi.org/10.1016/j.ndteint.2011.09.002

Dufour MB, Derome D, Zmeureanu R (2009) Analysis of thermograms for the estimation of dimensions of cracks in building envelope. Infrared Phys Technol 52(2–3):70–78. https://doi.org/10.1016/j.infrared.2009.01.004

Lai WWL, Lee KK, Poon CS (2015) Validation of size estimation of debonds in external wall’s composite finishes via passive Infrared thermography and a gradient algorithm. Constr Build Mater 87:113–124. https://doi.org/10.1016/j.conbuildmat.2015.03.032

Weritz F, Arndt R, Röllig M, Maierhofer C, Wiggenhauser H (2005) Investigation of concrete structures with pulse phase thermography. Mater Struct Constr 38:843–849

Kobayashi K, Banthia N (2011) Corrosion detection in reinforced concrete using induction heating and infrared thermography. J Civil Struct Health Monit 1(2):25–35

Barreira E, de Freitas VP (2007) Evaluation of building materials using infrared thermography. Constr Build Mater 21(1):218–224. https://doi.org/10.1016/j.conbuildmat.2005.06.049

Sciarretta F, Antonelli F, Peron F, Caniglia S (2018) Final outcomes on the multi-disciplinary long-term monitoring and preservation state investigation on the medieval external façades of Palazzo Ducale in Venice, Italy. J Civil Struct Health Monit 8(1):111–133

Bauer E, Pavón E, Oliveira E, Pereira CHF (2016) Facades inspection with infrared thermography: cracks evaluation. J Build Pathol Rehabil 1(1):1

Azenha M, Faria R, Figueiras H (2011) Thermography as a technique for monitoring early age temperatures of hardening concrete. Constr Build Mater 25(11):4232–4240. https://doi.org/10.1016/j.conbuildmat.2011.04.065

Barreira E, Almeida RMSF (2015) Drying evaluation using infrared thermography. Energy Procedia 78:170–175

Bauer E, Pavón E, Hildenberg A (2015) Errors in the use of thermographic parameters of the mortar and ceramics in the detection of coating anomalies. In Simpósio Brasileiro de Tecnologia das Argamassas. p 12 (in Portuguese)

Taylor T, Counsell J, Gill S (2014) Combining thermography and computer simulation to identify and assess insulation defects in the construction of building façades. Energy Build 76:130–142. https://doi.org/10.1016/j.enbuild.2014.02.080

De Freitas SS, De Freitas VP, Barreira E (2014) Detection of façade plaster detachments using infrared thermography—a nondestructive technique. Constr Build Mater 70:80–87. https://doi.org/10.1016/j.conbuildmat.2014.07.094

Acknowledgements

The authors are grateful to Capes and CNPq for the grants and to the Material Testing Laboratory of the University of Brasilia for providing the equipment used in the inspections.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bauer, E., Milhomem, P.M. & Aidar, L.A.G. Evaluating the damage degree of cracking in facades using infrared thermography. J Civil Struct Health Monit 8, 517–528 (2018). https://doi.org/10.1007/s13349-018-0289-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13349-018-0289-0