Abstract

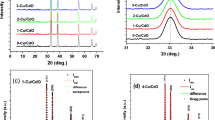

CuSbS2 nanocrystals have been synthesized through mechanical alloying Cu, Sb and S elemental powders for 40 hs. The optical spectrum of as-milled CuSbS2 nano-powders demonstrates a direct gap of 1.35 eV and an indirect gap of 0.36 eV, which are similar to that of silicon and reveals the evidence for the indirect semiconductor characterization of CuSbS2. Afterwards, CuSbS2 nanocrystals were capped with trioctylphosphine oxide/trioctylphosphine/pyridine (TOPO/TOP). There appear four sharp absorption peaks within the region of 315 to 355 nm for the dispersion solution containing the capped nanocrystals. The multiple peaks are proposed to be originating from the energy level splitting of 1S electronic state into four discrete sub-levels, where electrons were excited into the conduction band and thus four exciton absorption peaks were produced.

Similar content being viewed by others

References

M. V. Kovalenko, M. Scheele, and D. V. Talapin, Science 324, 1417 (2009).

S. Li, Z. Zhao, Q. Liu, L. Huang, G. Wang, D. Pan, H. Zhang, and X. He, Inorg. Chem. 50, 11985 (2011).

M. D. Regulacio and M. Y. Han, Acc. Chem. Res. 43, 621 (2010).

X. G. Peng, Acc. Chem. Res. 43, 1387 (2010).

M. A. Malik, M. Afzaal, and P. O’Brien, Chem. Rev. 110, 4417 (2010).

K. S. Leschkies, R. Divakar, J. Basu, E. Enache-Pommer, J. E. Boercker, C. B. Carter, U. R. Kortshagen, D. J. Norris, and E. S. Aydil, Nano Lett. 7, 1793 (2007).

S. Smith, P. Zhang, T. Gessert, and A. Mascarenhas, Appl. Phys. Lett. 85, 3854 (2004).

C. Bertoni, D. Gallardo, S. Dunn, N. Gaponik, and A. Eychmuller, Appl. Phy. Lett. 90, 0341071 (2007).

B. Pukowska, J. Jaglarz, B. Such, T. Wagnerc, A. Kisiela, and A. Mycielski, J. Alloys Compd. 335, 35 (2002).

M. Q. Chu, M. X. Song, D. Cheng, S. P. Liu, and J. Zhu, Nanotechnology 17, 5428 (2006).

D. Y. Xu, S. L. Shen, Y. J. Zhang, H. W. Gu, and Q. B. Wang, Inorg. Chem. 52, 12958 (2013).

M. V. Kovalenko, M. Scheele, and D. V. Talapin, Science 324, 1417 (2009).

S. Manolache, A. Duta, L. Isac, M. Nanu, A. Goossens, and A. Schoonma, Thin Solid Films 515, 5957 (2007).

B. D. Weil, S. T. Connor, and Y. Cui, J. Am. Chem. Soc. 132, 6642 (2010).

J. van Embden, K. Latham, N. W. Duffy, and Y. Tachibana, J. Am. Chem. Soc. 135, 11562 (2013).

J. Zhou, G. Q. Bian, Q. Y. Zhu, Y. Zhang, C. Y. Li, and J. Dai, J. Sol. Stat. Chem. 182, 259 (2009).

Y. Rodríguez-Lazcano, M. T. S. Nair, and P. K. Nair, J. Cry. Grow. 223, 399 (2001).

B. Yang, L. Wang, and J. Han, Chem. Mater. 26, 3135 (2014).

Q. Zhang, H. H. Zhang, and G. L. Tan, Electron. Mater. Lett. 11, 187 (2015).

R. E. Bailey and S. J. Nie, J. Am. Chem. Soc. 125, 7100 (2003).

Y. C. Cao and J. H. Wang, J. Am. Chem. Soc. 126, 14336 (2004).

I. J. Lin and S. Nadiv, Mater. Sci. Eng. 39, 193 (1979).

P. G. McCormick, T. Tsuzuki, and J. S. Robinson, J. Ding, Adv. Mater. 13, 1008 (2001).

Y. Ma, Q. Hao, B. Poudel, Y. C. Lan, B. Yu, D. Z. Wang, G. Chen, and Z. F. Ren, Nano Lett. 8, 2580 (2008).

J. L. Guimarães, M. Abbate, S. B. Betim, and M. C. M. Alves, J. Alloys Compd. 352, 16 (2003).

G. L. Tan, U. Hommerich, D. Temple, N. Q. Wu, J. G. Zheng, and G. Louts, Script. Mater. 48, 1469 (2003).

G. L. Tan, J. H. Du, and Q. J. Zhang, J. Alloys Compd. 468, 421 (2009).

G. L. Tan, L. Zhang, and X. F. Yu, J. Phy. Chem. C 114, 290 (2009).

P. Balaz, L. Takacs, T. Ohtani, D. E. Mack, E. Boldizarova, V. Soika, and M. Achimovicova, J. Alloys Compd. 434-435, 773 (2007).

P. M. Allen, W. H. Liu, V. P. Chauhan, J. Lee, A. Y. Ting, D. Fukumura, R. K. Jain, and M. G. Bawendi, J. Am. Chem. Soc. 132, 2909 (2010).

G. L. Tan, S. H. Li, J. B. Murowchick, C. Wisner, N. Leventis, and Z. H. Peng, J. Appl. Phy. 110, 1243061 (2011).

J. T. R. Dufton, A. Walsh, P. M. Panchmatia, L. M. Peter, D. Colombara, and M. S. Islam, Phy. Chem. Chem. Phy. 14, 7229 (2012).

C. Yan, Z. Su, E. Gu, T. Cao, J. Yang, J. Liu, F. Liu, Y. Lai, J. Li, and Y. Liu, J. Mater. Sci. Mater. Electron. 26, 1932 (2015).

K. Ramasamy, H. Sims, W. H. Butler, and A. Gupta, J. Am. Chem. Soc. 136, 1587 (2014).

G. L. Tan, Y. Chen, and X. F. Yu, Nanotechnology 21, 338 (2010).

L. Spanhel, M. Haase, H. Weller, and A. Henglein, J. Am. Chem. Soc. 109, 5649 (1987).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Xu, Q. & Tan, G. Physical preparation and optical properties of CuSbS2 nanocrystals by mechanical alloying process. Electron. Mater. Lett. 12, 568–573 (2016). https://doi.org/10.1007/s13391-016-6075-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-016-6075-4