Abstract

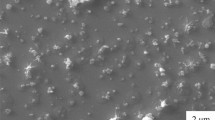

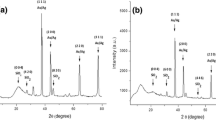

Bimetallic Ag–Au alloy nanoparticles with a tunable size and composition were synthesized by laser beam power density. A set of Psi substrates with different morphologies fabricated by laser-assisted etching process with laser power density from 10 to 40 mW/cm2 was explored as a substrate for materialization bimetallic Ag–Au alloy nanoparticles by a simple immersion plating process of Psi in a mixture of AgNO3 and HAuCl4 solutions. The materialization of alloy nanoparticles was confirmed by scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy-dispersive X-ray analysis (EDS). The results showed that the sizes and distribution of Ag–Au alloy nanoparticle sizes were easily well-ordered by changing the surface morphologies of Psi layer. Pore-like structures with different pores shapes: ultra-fine pores, irregular (grotto form), circular, and star full pore shape (gambling pores) with different sizes were prepared by changing the irradiation laser power density. Bimetallic Ag–Au alloy nanoparticles, phases, crystalline size, specific surface area, and growth sites of Ag–Au alloy nanoparticles were significantly influenced by pore shape. The lower nanoparticle size with higher S.S.A was obtained when the laser power intensity was about 30 mW/cm2.

Similar content being viewed by others

References

Canham LT (1990) Silicon quantum wire array fabrication by electrochemical and chemical dissolution of wafers. Appl Phys Lett 57(10):1046–1048

Thust M, Schoning MJ, Frohnhoff S, Arens-Fischer R, Kordos P, Luth H (1996) Porous silicon as a substrate materials potentiometric biosensor. Meas Sci Technol 7:26

Schoning MJ, Ronkel F, Crott M, Thust M, Kordos P, Luth H (1997) Miniaturization of potentiometric sensors using porous silicon microtechnology. Electrochim Acta 42:20

Alwan AM, Yousif AA, Wali LA (2017) The growth of the silver nanoparticles on the mesoporous silicon and macroporous silicon: a comparative study. Indian J Pure Appl Phys 55:813–820

Harraz FA, Ismail AA, Bouzid H, Al-Sayari S, Al-Hajry A, Al-Assiris M (2015) Surface –enhanced Raman scattering (SERS)—active substrates from silver plated-porous silicon for detection of crystal violet. Appl Surf Sci 331:241–247

Yang L, Li X, Tuo X, Van Nguyen TT, Luo X, Hong M (2011) Alloy nanoparticle plasmon resonance for enhancing broadband antireflection of laser-textured silicon surfaces. Opt Express 19:4

Alwan, AM, Yousif, AA, Wali, LA (2017) A study on the morphology of the silver nanoparticles deposited on the n-Type porous silicon prepared under different illumination types, Plasmonics, pp. 1557–1955

Alwan AM, Dheyab AB (2017) Room temperature CO2 gas sensors of AuNPs/mesoPSi hybrid structures. Appl Nanosci 7:335–341

Jabbar AA, Alwan AM, Haider AJ (2017) Modifying and fine controlling of silver nanoparticle nucleation sites and SERS performance by double silicon etching process. Plasmonics

Lee S, Kim DY (2005) Effect of incoherent light illumination during electrochemical anodization on the formation and the properties of porous Si. J Korean Phys Soc 47(5):880–883

Alwan AM, Hayder AJ, Jabbar AA (2015) Study on morphological and structural properties of silver plating on laser etched silicon. Surf Coat Technol 283:22–28

Rashid RB, Alwan AM, Dheyab AB (2018) Morphological and electrical properties of gold nanoparticles /macroPorous silicon for CO2 gas. 59(1A):57–66

Feng Z, Yu J, Li K, Feng Y, Padmanabhan K, Yang T (2006) Combined optical, surface and nuclear microscopic assessment of porous silicon formed in HF-acetonitrile. Surf Coat Technol 200:3254–3260

Hayder AJ, Alwan AM, Jabbar AA (2016) Optimizing of porous silicon morphology for synthesis of silver nanoparticles. Microporous Mesoporous Mater 227:152–160

Ahmed AM, Alwan AM (2007) Light-induced etching of silicon. Eng Technol 25(3)

Alwan AM, Wali LA, Yousif AA (2018) Optimization of AgNPs/mesoPS active substrates for ultra–low molecule detection process. Springer Silicon 1876–9918

Alwan AM (2007) Organic vapors sensor based on dangling bonds of porous silicon. Eng Technol 25(8)

Abbas RA, Alwan AM, Amer BD (2018) Study the characteristic of planer and sandwich PSi gas sensor (Comparative Study). Silicon (2):1876–9918

Alwan AM, Abdulrazaq OA (2008) Aging effect on the photosynthesized porous silicon. Int J Mod Phys B 22(4):417–422

Zhang H, Lv X, Lv C, Jia Z (2012) N-type porous silicon as an efficient surface enhancement Raman scattering substrate. Opt Eng 51:099003–1-099003-5

Virga A, Rivolo P, Descrovi E, Chiolerio A, Digregorio G, Frascella F (2012) SERS active Ag nanoparticles in mesoporous silicon: detection of organic molecules and peptide–antibody assays. J Raman Spectrosc 43:730–736

Devarajan S, Vimalan B, Sampath S (2004) Phase transfer of Au–Ag alloy nanoparticles from aqueous medium to an organic solvent: effect of aging of surfactant on the formation of Ag-rich alloy compositions. J Colloid Interface Sci 278:126–113

Stephen A, Hashmi K, Hutchings GJ (2006) Gold catalysis. Angew Chem Int Ed 45:7896–7936

Carrettin S, Carmen Blanco M, Corma A, Stephen A, Hashmib K (2006) Heterogeneous gold-catalysed synthesis of phenols. Adv Synth Catal 348:1283–1288

Liu X, Wang A, Li L, Zhanga T, Moub C-Y, Leec J-F (2013) Synthesis of Au–Ag alloy nanoparticles supported on silica gel via galvanic replacement reaction. Prog Nat Sci Mater Int 23(3):317–325

Wang YQ, Ma S, Yang QQ, Li XJ (2012) Size-dependent SERS detection of R6G by silver nanoparticles immersion-plated on silicon nanoporous pillar array. Appl Surf Sci 258:5881–5885

Zanoni R, Righini G, Mattogno G, Schirone L, Sotgiu G, Rallo F (1998) X-ray photoelectron spectroscopy characterization of stain-etched luminescent porous silicon films. J Lumin 80:159–162

Kraut C, Stern WB (2000) The density of gold-silver-copper alloys and its calculation from the chemical composition. Gold Bull 33(2):52–55

Loni A, M. pSiMedica Ltd. (2014), Porous silicon formation by anodization. Springer

Acknowledgments

The authors would like to express their gratitude to the Department of Applied Sciences/University of Technology and Razi metallurgical research center, Iran, for using the SEM (MIRA3 TESCAN) and the EDS analyses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alwan, A.M., Hashim, D.A. & Jawad, M.F. Optimizing of porous silicon alloying process with bimetallic nanoparticles. Gold Bull 51, 175–184 (2018). https://doi.org/10.1007/s13404-018-0242-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-018-0242-3