Abstract

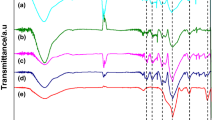

Glycidyloxypropyl-polyhedral oligomeric silsesquioxanes (G-POSS) were prepared from 3-glycidyloxypropyl-trimethoxysilane (GTMS) by hydrolytic condensation. The hybrid cationic thermal polymerization of G-POSS with bisphenol A epoxy resin (E-51) using diphenyliodonium fluoride borate (DPI·BF4) as a cationic initiator and benzoyl peroxide (BPO) as a co-initiator was investigated by DSC and FTIR. The structure of G-POSS was characterized by liquid chromatography–mass spectrometry (LC/MSD), FTIR and NMR. The effect of BPO content on reaction system, the distribution of G-POSS in the curing system, curing reaction activation energy E a and dynamic mechanical properties of the E51/G-POSS nanocomposites were characterized. The results showed that octa(3-glycidyloxypropyl)-POSS (G-POSS) had been synthesized and displayed uniform dispersion in E51/G-POSS curing system. The DPI·BF4, which was capable to initiate the thermal ring-opening curing of epoxy resin, showed an initial curing temperature of epoxy resin decreased by 54.7 °C when the added amount of BPO was 2 wt%. The reaction process was well accorded with Kissinger’s kinetics model, and the average curing reaction activation energy E a was increased as the content of G-POSS increased. The T g and storage modulus of the E-51/G-POSS nanocomposites reached its optimum when the content of G-POSS was 2 wt%. The T g of nanocomposite was 8.3 °C higher than that of the pure epoxy resin. The T g and storage modulus decreased with the further increasing of G-POSS content.

Similar content being viewed by others

References

Mohan P (2013) A critical review: the modification, properties, and applications of epoxy resins. Polym Plast Technol Eng 52:107–125

Clayton AM (1988) Epoxy resins chemistry and technology, 2nd edn. Marcel Dekker, New York

Jin H, Mangun CL, Griffin AS, Moore JS, Sottos NR, White SR (2014) Thermally stable autonomic healing in epoxy using a dual-microcapsule system. Adv Mater 26:282–287

Rakshit PB, Jain RC, Shah SR, Shrinet V (2011) Synthesis and characterization of cycloaromatic polyamines to cure epoxy resin for industrial applications. Polym Plast Technol Eng 50:647–680

Crivello JV, Lam JHW (1977) Diaryliodonium salts. A new class of photoinitiators for cationic polymerization. Macromolecules 10:1307–1315

Wang T, Wang ZH (2005) Cationic photopolymerization of epoxy systems initiated by cyclopentadien-iron-biphenyl hexafluorophosphate ([Cp-Fe-biphenyl]+PF6 −). Polym Bull 53:323–331

Abu-Abdoun II, Ledwith A (2007) Photoinitiated cationic polymerization of epoxide and vinyl monomers by p-trimethoxytrityl salts. J Polym Res 14:99–105

Oxman JD, Jacobs DW, Trom MC, Sipani V, Ficek B, Scranton AB (2005) Evaluation of initiator systems for controlled and sequentially curable free-radical/cationic hybrid photopolymerizations. J Polym Sci, Part A: Polym Chem 43:1747–1756

Sangermano M, Malucelli G, Priola A, Mannea M (2006) Synthesis and characterization of acrylate-oxetane interpenetrating polymer networks through a thermal-UV dual cure process. Prog Org Coat 55:225–230

Pappas SP (1985) Photoinitiation of cationic and concurrent radical-cationic polymerization. Part V. Prog Org Coat 13:35–64

Chen M, Chen QD, Xiao SQ, Hong XY (2001) The mechanism and application of hybrid UV curing system. Photogr Sci Photochem 19:208–216

Park YJ, Lim DH, Kim HJ, Park DS, Sung IK (2009) UV- and thermal-curing behaviors of dual-curable adhesives based on epoxy acrylate oligomers. Int J Adhes Adhes 29:710–717

Qi YS, Meng X, Yang JW, Zeng ZH, Chen YL (2005) Synthesis and properties of ultraviolet/moisture dual-curable polysiloxane acrylates. J Appl Polym Sci 96:846–853

Hofmeier H, El-Ghayoury A, Schubert US (2004) Free radical and thermal curing of terpyridine-modified terpolymers. J Polym Sci, Part A: Polym Chem 42:4028–4035

Crivello JV, Lam JHW (1981) Redox cationic polymerization: the diaryliodonium salt/ascorbate redox couple. J Polym Sci, Part A: Polym Chem 19:539–548

Hou GX, Gao JG, Tian C (2013) Hybrid free radical-cationic thermal polymerization of methylacryloylpropyl-POSS/epoxy resins nanocomposites. J Polym Res 20:221–231

Shokrieh MM, Esmkhani M, Vahedi F, Shahverdi HR (2013) Improvement of mechanical and electrical properties of epoxy resin with carbon nanofibers. Iran Polym J 22:721–727

Wang J, Feng L, Feng Y, Yan A, Ma X (2012) Preparation and properties of organic rectorite/epoxy resin nano-composites. Polym Plast Technol Eng 51:1583–1588

Frank KL, Exley SE, Thornell TL, Morgan SE, Wiggins JS (2012) Investigation of pre-reaction and cure temperature on multiscale dispersion in POSS-epoxy nanocomposites. Polymer 53:4643–4651

Chen SH, Gao JG, Han HZ, Wang C (2014) Mechanical and thermal properties of epoxy-POSS reinforced-(biphenyl diol formaldehyde/epoxy hybrid resin) composites. Iran Polym J 23:609–617

Pistor V, Ornaghi FG, Ornaghi HL Jr, Zattera AJ (2012) Degradation kinetic of epoxy nanocomposites containing different percentage of epoxycyclohexyl-POSS. Polym Compos 33:1224–1232

Choi J, Yee AF, Laine RM (2003) Organic/inorganic hybrid composites from cubic silsesquioxanes. Epoxy resins of octa(dimethylsiloxyethylcyclohexylepoxide) silsesquioxane. Macromolecules 36:5666–5682

Gao JG, Kong DJ, Zhao HC, Li SR (2011) Curing kinetics, thermal, mechanical, and dielectric properties based on o-cresol formaldehyde epoxy resin with polyhedral oligomeric (N-aminoethyl-g-aminopropyl) silsesquioxane. Polym Adv Technol 22:1395–1402

Crivello JV (1979) Photoinitiators. US patent 4136102 A

Saito H, Isosaki M, Ando H (2002) Manufacturing methods of cage-type silsesquioxane resins with functional groups. Jpn Kokai patent 285387

Rosu D, Mititelu A, Cascaval CN (2004) Cure kinetics of a liquid-crystalline epoxy resin studied by non-isothermal data. Polym Test 23:209–215

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Vyazovkin S, Sbirrazzuoli N (2003) Isoconversional analysis of calorimetric data on nonisothermal crystallization of a polymer melt. J Phy Chem B 107:882–888

Vyazovkin S, Mititelu A, Sbirrazzuoli N (2003) Kinetics of epoxy–amine curing accompanied by the formation of liquid crystalline structure. Macromol Rapid Commun 24:1060–1065

Gillham JK (1977) The TBA torsion pendulum: a technique for characterizing the cure and properties of thermosetting systems. Polym Int 44:262–276

Achorn PJ, Ferrillo RG (1994) Comparison of thermal techniques for glass transition measurements of polystyrene and cross-linked acrylic polyurethane films. J Appl Polym Sci 54:2033–2043

Acknowledgments

The authors gratefully acknowledge the financial support of the Nature Science Foundation (No: E2007000204) and High Level Talents Foundation (No. A201400504) of Hebei Province, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, G., Li, N., Han, H. et al. Hybrid cationic ring-opening polymerization of epoxy resin/glycidyloxypropyl-polyhedral oligomeric silsesquioxane nanocomposites and dynamic mechanical properties. Iran Polym J 24, 299–307 (2015). https://doi.org/10.1007/s13726-015-0321-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0321-8