Abstract

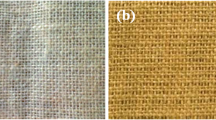

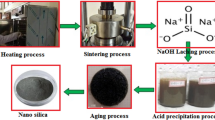

In this study, an attempt has been made to utilize banana fiber (a natural fiber from agricultural waste) as reinforcement for low-density polyethylene (LDPE) to develop environmental friendly composite materials. LDPE/banana fiber composites were fabricated at different fiber loadings (10, 15, 20, 25, and 30 wt %) using compression molding technique. The composite with the composition of 25 wt % banana fiber was observed to be optimum on the basis of biodegradability and mechanical properties. Further, the effect of banana fiber surface treatment (alkali and acrylic acid) on the mechanical properties, morphology and water absorption behavior of the LDPE/banana fiber composites in the absence and presence of compatibilizer (maleic anhydride grafted LDPE, MA-g-LDPE) was comparatively studied. The alkali and acrylic acid treatment of the banana fibers led to enhanced mechanical properties and water resistance property of the composites, and these properties got further improved by the addition of the compatibilizer. The addition of compatibilizer to the acrylic acid treated banana fiber composites showed the most effective improvement in the flexural and impact strength and also, exhibited a reduction in the water absorption capacity. However, the tensile strength of the compatibilized composites with treated fibers resulted in slightly lower values than those with untreated fibers, because of the degradation of fibers by chemical attack as was evidenced by scanning electron microscopy (SEM) micrographs. SEM studies carried out on the tensile fractured surface of the specimens showed improved fiber-matrix interaction on the addition of compatibilizer.

Similar content being viewed by others

References

Ayrilmis N, Jarusombuti S, Fueangvivat V, Bauchongkol P, White RH (2011) Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers Polym 12:919–926

Kumar V, Tyagi L, Sinha S (2011) Wood flour-reinforced plastic composites: a review. Rev Chem Eng 27:253–264

Murherjee PS, Satyanarayana KG (1984) Structure and properties of some vegetable fibres, part 1, Sisal fiber. J Mater Sci 19:3925–3934

Knothe J, Rebstock K, Schloesser T (2000) Natural fibre reinforced plastics in automotive exterior applications. In: 3rd International wood natural fibre Composites Symposium, Kassel, Germany, pp B 1–12

Alamri H, Low IM (2013) Effect of water absorption on the mechanical properties of nanoclay filled recycled cellulose fibre reinforced epoxy hybrid nanocomposites. Compos Part A Appl S 44:23–31

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos Part B Eng 43:2883–2892

Shaktawat V, Pothan LA, Saxena NS (2008) Temperature dependence of thermo-mechanical properties of banana fiber-reinforced polyester composites. Adv Compos Mater 17:89–99

Indira KN, Jyotishkumar P, Thomas S (2014) Viscoelastic behaviour of untreated and chemically treated banana fiber/PF composites. Fibers Polym 15:91–100

Venkateshwaran N, Perumal AE, Arunsundaranayagam D (2013) Fiber surface treatment and its effect on mechanical and visco-elastic behaviour of banana epoxy composite. Mater Des 47:151–159

Jannah M, Mariatti M, Abu Bakar A, Khalil HPSA (2009) Effect of chemical surface modifications on the properties of woven banana-reinforced unsaturated polyester composites. J Reinf Plast Compos 28:1519–1532

Mittal V, Sinha S (2015) Effect of chemical treatment on the mechanical and water absorption properties of bagasse fiber-reinforced epoxy composite. J Polym Eng 35:545–550. doi:10.1515/polyeng-2014-0270

Li X, Panigrahi S, Tabil LG (2009) A study on flax fiber-reinforced polyethylene biocomposites. Appl Eng Agric 25:525–531

Punyamurthy R, Sampathkumar D, Bennehalli B, Srinivasa CV (2013) Influence of esterification on the water absorption property of single abaca fiber. Chem Sci Trans 2:413–422

Bettini SHP, Biteli AC, Bonse BC, Morandim-Giannetti ADA (2015) Polypropylene composites reinforced with untreated and chemically treated coir: effect of the presence of compatibilizer. Polym Eng Sci 55:2010–2057

Lei Y, Wu Q, Yao F, Xu Y (2007) Preparation and properties of recycled HDPE/natural fiber composites. Compos Part A Appl S 38:1664–1674

Yu T, Jiang N, Li Y (2014) Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos Part A Appl S 64:139–146

Vilaseca F, Valadez-Gonzalez A, Herrera-Franco PJ, Pelach MA, Lopez JP, Mutje P (2010) Biocomposites from abaca strands and polypropylene. Part I: evaluation of the tensile properties. Bioresour Technol 101:387–395

Bledzki AK, Mamun AA, Faruk O (2007) Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites. eXPRESS Polym Lett 1:755–762

Prasad N, Agarwal VK, Sinha S (2015) Physico-mechanical properties of coir fiber/LDPE composites: effect of chemical treatment and compatibilizer. Korean J Chem Eng 32:2534–2541. doi:10.1007/s11814-015-0069-z

Mohanty S, Nayak SK (2006) Interfacial, dynamic mechanical, and thermal fibre reinforced behaviour of MAPE treated sisal fibre reinforced HDPE composites. J Appl Polym Sci 102:3306–3315

Mohanty S, Verma SK, Nayak SK (2006) Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos Sci Technol 66:538–547

Keener TJ, Stuart RK, Brown TK (2004) Maleated coupling agents for natural fibre composites. Compos Part A Appl S 35:357–362

Gu H (2009) Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater Des 30:3931–3934

Bilba K, Arsene MA, Ouensanga A (2007) Study of banana and coconut fibers Botanical composition, thermal degradation and textural observations. Bioresour Technol 98:58–68

Ouajai S, Shanks RA (2005) Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym Degrad Stab 89:327–335

Marcovich NE, Reboredo MM, Aranguren MI (2001) Modified woodflour as thermoset fillers II. Thermal degradation of woodflours and composites. Thermochim Acta 372:45–57

Supri AG, Lim BY (2009) Effect of treated and untreated filler loading on the mechanical, morphological, and water absorption properties of water-hyacinth fibers-low density polyethylene composites. J Phys Sci 20:85–96

Karmarkar A, Chauhan SS, Modak JM, Chanda M (2007) Mechanical properties of wood-fiber reinforced polypropylene composites: effect of a novel compatibilizer with isocyanate functional group. Compos Part A Appl S 38:227–233

Velmurugan R, Manikandan V (2005) Mechanical properties of glass/palmyra fiber waste sandwich composites. Indian J Eng Mater Sci 12:563–570

Geethamma VG, Mathew KT, Lakshminarayanan R (1998) Composite of short coir fibres and natural rubber: effect of chemical modification, loading and orientation of fibre. Polymer 39:1483–1491

Rahman R, Huque M, Islam N, Hasan M (2009) Mechanical properties of polypropylene composites reinforced with chemically treated abaca. Compos Part A Appl S 40:511–517

Parsania PH, Patel VA (2010) Performance evaluation of alkali and acrylic acid treated-untreated jute composites of mixed epoxy-phenolic resins. J Reinf Plast Compos 29:725–730

Yang HS, Kim HJ, Park HJ, Lee BJ, Hwang TS (2006) Water absorption behavior and mechanical properties of lignocellulosic filler-polyolefin bio-composites. Compos Struct 72:429–437

Acknowledgments

This study was supported by the Indian Institute of Technology Roorkee, Uttrakhand, India and the Ministry of Human Resources and Development (MHRD), New Delhi, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasad, N., Agarwal, V.K. & Sinha, S. Banana fiber reinforced low-density polyethylene composites: effect of chemical treatment and compatibilizer addition. Iran Polym J 25, 229–241 (2016). https://doi.org/10.1007/s13726-016-0416-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-016-0416-x