Abstract

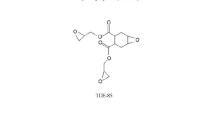

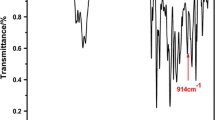

A bio-based shape memory epoxy resin (DGEAPA) was synthesized from rosin to achieve the sustainability of shape memory epoxy resin, and its chemical structure was determined by FTIR and 1H NMR. For comparison, a petroleum-based epoxy, diglycidyl ester of terephthalic acid (DGT) having one benzene ring, was also synthesized. The properties, including thermal and mechanical properties, as well as shape memory properties of the epoxy resins cured with poly(propylene glycol)-bis (2-aminopropyl ether) (D230), were studied by differential scanning calorimeter, dynamic mechanical analysis, thermogravimetric analysis, tensile test, and U-type shape memory test. The effect of the stoichiometric ratio nDGEAPA/nDGT on the properties was studied as well. The thermal and mechanical properties, including thermal stability, glass transition temperature, tensile strength, and modulus of the cured epoxy systems, were found to be increased with DGEAPA incremental content, and the cured neat rosin-based epoxy system exhibited the highest properties. Both the cured rosin-based epoxy and the cured DGEAPA showed significant shape memory performance. Meanwhile, the rosin ring structure made the cured rosin-based epoxy systems display excellent shape recovery fixity, while small lower shape recovery and shape recovery rate relative to the cured neat DGT system. Therefore, the rosin-based epoxy resin has a great potential in the shape memory material applications.

Similar content being viewed by others

References

Yasar RM, Marc B, Karl K, Andreas L (2013) Multifunctional hybrid nanocomposites with magnetically controlled reversible shape-memory effect. Adv Mater 25:5730–5733

Ariraman M (2015) Shape memory effect on the formation of oxazoline and triazine rings of BCC/DGEBA copolymer. RSC Adv 5:69720–69727

Lendlein A, Jiang HY, Junger O, Langer R (2005) Light-induced shape-memory polymers. Nature 434:879–882

Ping P, Wang WS, Chen XS, Jing XB (2005) Poly(epsilon-caprolactone) polyurethane and its shape-memory property. Biomacromolecules 6:587–592

Dolog R, Weiss RA (2013) Shape memory behavior of a polyethylene-based carboxylate ionomer. Macromolecules 46:7845–7852

Gu L, Cui B, Wu Q, Yu H (2016) Bio-based polyurethanes with shape memory behavior at body temperature: effect of different chain extenders. RSC Adv 6:17888–17895

Kumar KSS, Nair CPR (2014) Hydrophobic shape memory poly(oxazolidone-triazine) cyclomatrix networks with high transition temperatures. RSC Adv 4:2969–2973

Rousseau IA (2008) Challenges of shape memory polymers: a review of the progress toward overcoming SMP’s limitations. Polym Eng Sci 48:2075–2089

Wu Y, Hu J, Zhang C, Han J, Wang Y, Kumar B (2015) A facile approach to fabricate a UV/heat dual-responsive triple shape memory polymer. J Mater Chem A 3:97–100

Liu Y, Du H, Liu L, Leng J (2014) Shape memory polymers and their composites in aerospace applications: a review. Smart Mater Struct 23:23001–23022

Flint S, Markle T, Thompson S, Wallace E (2012) Bisphenol A exposure, effects, and policy: a wildlife perspective. J Environ Manage 104:19–34

Coativy G, Gautier N, Pontoire B, Buleon A, Lourdin D, Leroy E (2015) Shape memory starch-clay bionanocomposites. Carbohydr Polym 116:307–313

Oun AA, Rhim JW (2014) Preparation and characterization of sodium carboxymethyl cellulose/cotton linter cellulose nanofibril composite films. Carbohydr Polym 127:101–109

Badgujar KC, Bhanage BM (2015) Immobilization of lipase on biocompatible copolymer of polyvinyl alcohol and chitosan for synthesis of laurate compounds in supercritical carbon dioxide using response surface methodology. Proc Biochem 50:1224–1236

Azhar NA, Soloi S, Majid RA, Jamaluddin J (2015) Grafting efficiency of lignin-grafted-polyacrylic acid. Appl Mech Mater 735:182–185

Lligadas G, Ronda JC, Galia M, Cadiz V (2013) Monomers and polymers from plant oils via click chemistry reactions. J Polym Sci Part A Polym Chem 51:2111–2124

Ma Q, Liu X, Zhang R, Zhu J, Jiang Y (2013) Synthesis and properties of full bio-based thermosetting resins from rosin acid and soybean oil: the role of rosin acid derivatives. Green Chem 15:1300–1310

Zhu YZ, Zhang SZ, Geng ZM, Wang DY, Liu F, Zhang MH, Bian H, Xu WM (2014) Simultaneous determination of abietic acid and dehydroabietic acid residues in duck meat by HPLC-PAD-FLD. Food Anal Meth 7:1627–1633

Ma S, Li T, Liu X, Zhu J (2016) Research progress on bio-based thermosetting resins. Polym Int 65:164–173

Atta AM, Mansour R, Abdou MI, Sayed AM (2004) Epoxy resins from rosin acids: synthesis and characterization. J Hazard Mater 15:514–522

Brocas AL, Llevot A, Mantzaridis C, Cendejas G, Caillol S, Carlotti S, Cramail H (2014) Epoxidized rosin acids as co-precursors for epoxy resins. Des Monomers Polym 17:301–310

Qin J, Liu H, Zhang P, Wolcott M, Zhang J (2014) Use of eugenol and rosin as feedstocks for biobased epoxy resins and study of curing and performance properties. Polym Int 63:760–765

Li C, Liu X, Zhu J, Zhang C, Guo J (2013) Synthesis, characterization of a rosin-based epoxy monomer and its comparison with a petroleum-based counterpart. J Macromol Sci A 50:321–329

Liu XQ, Huang W, Jiang YH, Zhu J, Zhang CZ (2012) Preparation of a bio-based epoxy with comparable properties to those of petroleum-based counterparts. Express Polym Lett 6:293–298

Liu X, Zhang J (2010) High-performance biobased epoxy derived from rosin. Polym Int 59:607–609

Zhang L, Jiang Y, Xiong Z, Liu X, Na H, Zhang R, Zhu J (2013) Highly recoverable rosin-based shape memory polyurethanes. J Mater Chem A 1:3263–3267

Xia JL, Shang S, Xie H, Huang H, Wang DX (2002) Study on curing reaction and properties of the acrylic modified rosin based epoxy resin. Thermoset Resin 17:1–5

Deng L, Shen M, Gan L, Yu J, Ha C (2011) Properties of epoxy resins based on acrylic acid rosin with different flexible chains. Polym Mater Sci Eng 27:106–108

Atta AM, Mansour R, Abdou MI, Sayed AM (2005) Synthesis and characterization of tetra-functional epoxy resins from rosin. J Polym Res 12:127–138

Xie T, Rousseau IA (2009) Facile tailoring of thermal transition temperatures of epoxy shape memory polymers. Polymer 50:1852–1856

Ma SQ, Liu XQ, Fan L, Jiang Y, Cao L, Tang Z, Zhu J (2014) Synthesis and Properties of a bio-based epoxy resin with high epoxy value and low viscosity. Chemsuschem 7:555–562

Ma SQ, Liu XQ, Jiang YH, Tang ZB, Zhang CZ, Zhu J (2013) Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem 15:245–254

Ma SQ, Liu WQ, Hu CH, Wang ZF, Tang CY (2010) Toughening of epoxy resin system using a novel dendritic polysiloxane. Macromol Res 18:392–398

Ma SQ, Liu WQ, Yu D, Wang ZF (2010) Modification of epoxy resin with polyether-grafted-polysiloxane and epoxy-miscible polysiloxane particles. Macromol Res 18:22–28

Chang R, Qin J, Gao J (2014) Retracted article: fully biobased epoxy from isosorbide diglycidyl ether cured by biobased curing agents with enhanced properties. J Polym Res 21:1–7

Bicu I, Mustata F (2007) Polymers from a levopimaric acid-acrylic acid Diels-Alder adduct: synthesis and characterization. J Polym Sci Part A Polym Chem 45:5979–5990

Wang H, Wang H, Zhou G (2011) Synthesis of rosin-based imidoamine-type curing agents and curing behavior with epoxy resin. Polym Int 60:557–563

Liu X, Xin W, Zhang J (2009) Rosin-based acid anhydrides as alternatives to petrochemical curing agents. Green Chem 11:1018–1025

Wei K, Zhu G, Tang Y, Tian G, Xie J (2012) Thermomechanical properties of shape-memory hydro-epoxy resin. Smart Mater Struct 21:55022–55029

Acknowledgments

The authors acknowledge financial support from Projects 51473180 and 51373194 supported by the National Natural Science Foundation of China, and Project 2012229 from Youth Innovation Promotion Association of the Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, T., Liu, X., Jiang, Y. et al. Bio-based shape memory epoxy resin synthesized from rosin acid. Iran Polym J 25, 957–965 (2016). https://doi.org/10.1007/s13726-016-0482-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-016-0482-0