Abstract

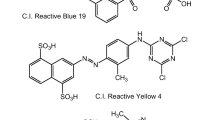

Bleached cotton muslin fabric with or without pre-oxidized with NaIO4 (oxy-cotton) was chemically modified with glycine (amino acid) by pad dry calendar process to investigate the changes in textile properties and its dyeability with reactive dye. This glycine modified cotton incorporates new functional groups producing –NH3 + or –C=NH+ -ion (cationic groups) in acid bath to obtain cationized cotton making it amenable to a newer route of salt free reactive dyeing in acid bath. In the present work the process variables of reactive dyeing in the salt free acid bath for dyeing of amine (glycine) modified cationized cotton were studied and optimized. The present study also includes thorough investigation of changes in important textile related properties and dyeability with reactive dye after such chemical modifications. Between oxidized and unoxidized cotton muslin fabric, unoxidized cotton fabric shows better reactive dye uptake in both conventional alkaline bath dyeing and nonconventional salt free acid bath dyeing particularly for high exhaustion class of reactive dye with acceptable level of colour fastness and overall balance of other textile related properties. Moreover, application of dye fixing agent further improves surface colour depth (K/S) of the glycine treated cotton fabric for HE brand of reactive dyes. Corresponding reaction mechanisms for such modifications were supported by FTIR spectroscopy. Finally unoxidized cotton and pre-oxidized cotton further treated with glycine (amino acid) provide a new route of acid bath salt free reactive dyeing showing much higher dye uptake and higher degree of surface cover with amino acid residue anchored to modified cotton.

Similar content being viewed by others

References

Textile engineers of Bangladesh (TEB) www.Facebook.com/teb.bd/posts/115253738628482. Accessed 05 Oct 2014

A.K. Samanta, A. Konar, D. Ghosh, S. Acharya, Effect of solvent pretreatment and selective dye bath additives on physical properties and dyeing behaviour of micro denier polyester fabric. Indian J. Fibre Text. Res. 28(3), 312–321 (2003)

A.K. Samanta, D.P. Chattopadhyay, A. Konar, D.P. Sharma, Selective chemical pretreatments and post-treatments on microdenier polyester fabric for improving surface depth of colour. Indian J. Fibre Text. Res. 28(1), 76–85 (2003)

M.N. Chapatwala, N. Naik, D.H. Sopariwala, R.S. Gandhi, Mantra Bulletin (APDL, London, 1995)

M D Teli, G R Andhorikar and B Rama Rao, Comfort properties of micro denier polyester vis-a-vis its dyeability and weight reduction, paper presented in 5th Asian Textile Conference at Taiwan, June, 1997

A. Lallam, J. Michalowska, L. Schache, P. Viallier, Diffusion and adsorption of dye by polyester microfibers. Soc. Dyers Color. 113, 107 (1997)

S.M. Burkinshaw, Chemical Principles of Synthetic Fiber Dyeing (Blackie Glasgow-part of Chapmann and Hall, Bishopbriggs, 1995), pp. 194–217

P. Ghosh, D. Dev, A.K. Samant, Graft copolymerization of acrylamide on cotton cellulose in a limited Aqueous system following Pretreatment Technique. J. Appl. Polym. Sci. 58, 1724–1734 (1994)

V.N. Sharma, E.H. Daruwala, Thermal behavior of cotton grafted with vinyl monomers individually and in mixture compositions. J. Appl. Polym. Sci. 21, 331–341 (1977)

P. Ghosh, J.C. Dalal, Graft copolymerization of methyl methacrylate (MMA) on hydrazine treated oxy cellulose in limited aqueous system. J. Appl. Polym. Sci. 31, 189–196 (1986)

D.P. Chattopadhyay, Cat ionization of cotton for low salt or salt-free dyeing. Indian J. Fiber Text. Res. 26, 108–115 (2001)

Y.J. Kim, hyung-Min Choi, Cat ionization of period ate oxidized cotton cellulose with choline chloride. Cellul. Chem. Technol. 48(1–2), 25–32 (2014)

N.A. Ibrahim, B.M. Eid, H. El-Batal, A novel approach for adding smart functionalities to cellulosic fabrics. Carbohydr. Polym. 87, 744–751 (2012)

W. Jia, J. Li, J. Zhou, W. Wang, Studies on cationic modification of cotton fabric and dyeing of it. Text. Aux. 20, 26–30 (2003)

H. Wang, D.M. Lewis, Chemical modification of cotton to improve fiber dyeability. Color. Technol. 118, 159–168 (2002)

N. Ristic, I. Ristic, Cationic modification of cotton fabrics and reactive dyeing characteristics. J. Eng. Fibers Fabr. 7, 4 (2012)

Adwaita Konar, Ashis Kumar Samanta, Sarmistha Mukherjee, Salt-free reactive dyeing of amino-acid modified jute. Indian J. Natural Fiber 1, 15–28 (2014)

Adwaita Konar, Ashis Kumar Samanta, Sarmistha Mukherjee, Tapas Ranjan Kar, Effects of amino-acid modification of jute fabric on its textile related properties and dye ability with selective reactive dyes. Int. Rev. Appl. Eng. Res. 4(1), 45–61 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samanta, A.K., Kar, T.R., Mukhopadhyay, A. et al. Studies on Dyeing Process Variables for Salt Free Reactive Dyeing of Glycine Modified Cationized Cotton Muslin Fabric. J. Inst. Eng. India Ser. E 96, 31–44 (2015). https://doi.org/10.1007/s40034-015-0062-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-015-0062-4