Abstract

Purpose

The disposal of solid waste is a serious environmental problem for humanity. Vermicomposting is used as one of the methods for recycling of organic waste, resulting in a humified material of great agronomic potential which promotes carbon sequestration when applied to the soil. The aim of this study was to evaluate the chemical characteristics of vermicomposts from cattle manure (CM), orange peel (OP) and filter cake (FC).

Methods

Three compost piles were set up, 2:1 OP + CM, 3:1 FC + CM and CM. The piles were initially composted for 60 days. Thereafter, earthworms were added to the piles to initiate the vermicomposting process.

Results

The pH and the organic carbon contents were above the minimum recommended values for organic fertilizers. The N content was below the minimum value but the C/N ratio was in the required range. The C/N values where lower in OP + CM and FC + CM than in CM. Further, the N contents of treatments were different with OP + CM having the highest value. The C/N ratios of the piles were 9.52, 9.62 and 11.03 for OP + CM, FC + CM and CM, respectively, and were lower than the maximum recommended value by the Ministry of Agriculture, Livestock and Food (Ministry of Agriculture 2009).

Conclusion

Thus, co-vermicomposting of filter cake and orange peel with cattle manure has the potential for application sustainable agriculture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Increase in agricultural production appears to be a major threat to soil sustainability. This is due to increasing demand for food by the increasing human population. There is a need to sustain the physical, chemical and biological properties of the soil if more food is to be produced. The use of inorganic fertilizers only supplies plant nutrients and cannot improve soil quality. Rather, it promotes soil degradation and environmental pollution. However, the use of organic fertilizers had been shown to be a good means of improving soil quality and promoting sustainable agriculture (Rezende et al. 2014).

Enormous amounts of wastes generated from agricultural activities are a vast sources of plant nutrients, including macro- and micro-nutrients in organic forms. The inappropriate disposal of agro-wastes can lead to environmental problems and affect human health. However, these wastes are resources that could be of immense benefit to agriculture and the environment if properly harnessed (Rodella and Alcarde 1994). Vermicomposting has been adjudged superior to composting due to its ability to reduce the concentration of toxic elements contained in organic wastes (Rezende et al. 2014). Vermicomposting involves the transformation of organic matter (OM) into stable form through the action of earthworms and microorganisms living in their gut (Juárez et al. 2011). It is considered a most economical and high technology-free practise for onsite waste processing (Suthar 2012). Earthworms increase aeration and promote fast decomposition of organic substances during this process. Physical and chemical parameters such as pH, temperature, aeration, moisture content, OM and C/N ratio govern the development of the vermicomposting process (Pramanik et al. 2007; Juárez et al. 2011; Suthar 2012). The life cycle of the earthworms is regulated by these parameters. Adult worms require 60–80 % moisture content, optimal temperature of 15–25 °C and pH 6.8–7.8 for development (Juárez et al. 2011). The recommended specifications for organic fertilizers in Brazil are minimum values of 5 % of total N, 10 % organic C, minimum pH of 6.0, maximum C/N ratio of 14 (Brazil 2009).

The central administrative region of São Paulo state, in which lies the city of São Carlos, is characterized by intense agro pastoral activity, especially livestock feedlot and extensive cattle rearing. There is also intense sugar cane production, in addition to traditional orange production. These activities generate organic wastes that could be used as feedstock for vermicomposting, obtaining final products with different chemical characteristics and fertility. Thus, due to the wide availability, low cost, and the possibility of proposing a more environmentally viable alternative to some wastes generated in the region of São Carlos, the following organic residues were studied: orange peel, filter cake and cattle manure. Orange peel (citrus processing industry) and filter cake (from sugar and ethanol industrial residue obtained during the process of production of sugarcane juice) were used for this study due to their high availability as byproducts in São Paulo state, Brazil. Orange peel has 23 % crude protein, 3 % lignin, high content of pectin and soluble carbohydrate content ranging around 37.1–43.2 % of dry matter (Itavo et al. 2000). The filter cake had mineral impurities and the pulp of the sugarcane particles retained in sieves during the juice filtration. The main nutrients found in filter cake were: P (13.5–26.1 g kg−1) in the form of P2O5 followed by Ca (21.0–50.4 g kg−1) and C (8.7–14.1 g kg−1) (Morelli 2004).

It is necessary to evaluate specific characteristics of the residues to be vermicomposted, such as C, total N, P and macro- and micro-nutrient contents to understand the ability of the so produced vermicompost to supply nutrients to plant and not contaminate the environment. Thus, the aim of this work was to evaluate the chemical transformations of agricultural wastes during vermicomposting to apply the so produced vermicomposts to the soil for the maintenance of soil organic matter (SOM).

Materials and methods

Vermicomposting

The experiment was conducted on an outdoor concrete platform on a farm located in the region of São Carlos, São Paulo state, Brazil. The experiment was initiated in September 2011 and lasted for 6 months. In natura, residues were dried at room temperature and ground in a knife mill. The piles were 2.25 m3 with dimensions of 1.5 m length × 1.5 m width × 1 m height. The treatments were orange peel (OP) + cattle manure (CM) in the ratio of 2:1 (OP + CM), filter cake (FC) + cattle manure in the ratio 3:1 (FC + CM) and cattle manure only (CM) by dry weight. Three piles were prepared in triplicate using different organic residues with the following wet weights: Pile 1, 2 and 3 (P1, P2, P3): 300 kg of orange peel + 150 kg of fresh cattle manure; Pile 4, 5 and 6 (P4, P5, P6): 450 kg of filter cake + 150 kg of fresh cattle manure; Pile 7, 8 and 9 (P7, P8, P9): 400 kg of cattle manure (used as reference of slow composting process). Sawdust was used as structuring agents and to assist in the aeration of the piles. The proportions of mixed waste with cattle manure were determined according to the amount of material available and to obtain a C/N ratio suitable for starting the composting process, around 20 and 30 for the piles. An adequate C:N ratio promotes the activity of the microorganisms in organic waste degradation process. A C:N ratio around 20–30 is considered appropriate for the beginning of the co-vermicomposting process, enabling the production of vermicompost in less time. At the end of the degradation process, the humified compost should have a C:N ratio around 10:1. The piles were assembled layer by layer with each layer being approximately 20 cm in height independent of mass, in the following order: sawdust—cattle manure—orange peel or filter cake, repeatedly. Water was added to each layer, so that at the end the piles were moist. The mixtures were composted and their moisture contents adjusted to about 60 % once a week during the composting process. The piles were manually turned each week until the 6th week. At the end of the 6th week, the composting process returned to mesophilic phase, as observed by temperature measurements, and then the organic composts were moved to boxes. Five hundred earthworms (Eisenia fetida) were added in each box. Young earthworms were used. Young worms are worms with no clitellum. When mature, a swollen area of the epidermis called clitellum, located in particular segments, forms a cocoon in which the eggs or ova are deposited, and are then passed over the anterior segment (Edwards and Bohlen 1996). The mass of each worm was about 10.0 g and the total mass was about 5.0 kg of earthworms per box. The contents in the boxes were manually turned every 15 days until the end of the process. Random samples were taken from within the piles and the outer layer at the start and at 7, 15, 30, 45, 60, 75, 90, 105, 120 and 135 days after the beginning of the composting process. Each sample was a mixture of eight subsamples taken from different points along the pile. The samples were dried at 60 °C, grounded and passed through a 0.5 mm sieve.

Chemical characterization of the wastes

The chemical properties of the wastes are presented in Table 1. These results were used for adjusting the C/N ratios to the appropriate levels of around 20 and 30 for the vermicomposting process.

Temperature measurements

Temperature was taken daily at three different points (base, middle and top) between 6 and 7 a.m., by inserting a thermometer into the pile. The temperatures were monitored weekly until the sixth week of the composting process, then become constants.

Chemical analyses

To measure the pH, samples were mixed together with of 0.01 mol L−1 CaCl2 (1:10, w/v) and stirred for 30 min. The pH was measured in the slurry using a Tecnal TEC-2 electronic pH meter combined with glass electrode. Total C, N, H and S contents of collected samples were determined using a CHNS-O analyser (CE Instruments EA1110). The determinations were made from an eluted mixture separated by chromatography column and detected by a detector in response to N2, CO2, H2O and SO2. The C/N ratios were calculated as the quotient of elemental concentration and atomic weight. The macronutrients (N, P and K) and micronutrients (Fe, Mn, Cu, Zn, Cr, Ca, and Mg) were determined for samples collected at time zero and after 135 days of vermicomposting. Samples were digested using the microwave oven digester (BERGHOF Speed Wave Four). The determinations of Fe, Mn, Cu, Zn, K, Cr, Ca and Mg were made using Atomic Absorption Spectrophotometer. Total Kjeldahl nitrogen (TKN) and phosphorus were determined by Hach® method 399 and Hach® method 480, respectively; and the cation exchange capacity (CEC), through the occupation of active sites to exchange with hydrogen ions in solution 1 mol L−1 of glacial acetic acid. All the determinations were performed in triplicates (Rezende et al. 2014).

Statistical analysis

Data generated from all analyses were subjected to analysis of variance (ANOVA) and pair wise comparison using Tukey test (p < 0.05). The SAS 9.0 Software Package program was used (SAS Institute 2004).

Results and discussion

Temperature changes with vermicomposting

During the vermicomposting, the temperature variation in all piles showed similar trends as observed during composting processes (Ros et al. 2006; Fialho et al. 2010). At the beginning of the first week, the temperature ranged from 25 to 30 °C which is the mesophilic phase. At the end of the second week, maximum temperatures of between 50 and 60 °C were recorded in piles 2:1 OP + CM and 3:1 FC + OM while in pile CM, the maximum temperature was 40 °C. The heat generated in composting thermophilic phase results in higher temperatures. After 60 days, the temperature decreased to about 25 °C in the cooling and maturation phase. According to Fialho et al. (2010) these changes in temperatures were the consequences of microbial degradation activities on the residues and also of the microbial population dynamics. The nature of composted materials affected the maximum temperature attained (Ros et al. 2006). The initial increase in temperature of the composting pile was a result of the rapid breakdown of the readily available OM and nitrogenous compounds by microorganisms. The high temperatures (40–60 °C) ensured that OM was stabilised and that pathogenic microorganisms are suppressed. The rate of decomposition decreased as the OM became more stabilised thus signifying the end of the thermophilic phase also as indicated by Ros et al. (2006).

The maximum temperature reached in piles 2:1 OP + CM and 3:1 FC + CM could be attributed to the increased microbial activity due to higher nutrient content than CM. According to Fialho et al. (2010), microbial growth and efficiency of composting process also depends on the type of substrate.

The pH of the vermicomposts

During the experiment, some variations in the pH were observed in the piles (Fig. 1). In the 2:1 OP + CM pile, there was a slight increase of pH from 7.09 to 8.26, while in pile 3:1 FC + CM there was a slight decrease of pH (8.40–7.55) and in pile CM, the pH was practically the same at the beginning and at the end of the process (~7.8). The pH values in the piles were near neutrality or slightly alkaline at the end of the process. This indicates expected conditions of stabilized compost. Forty-five days after the addition of earthworms, pH values tended to decrease 1 unit from basic to slightly basic or neutral. Bhat et al. (2015) also observed a decrease in pH during the vermicomposting process of mixtures of bagasse waste of the sugar industry and cattle dung. The authors explain that the decline in pH during vermicomposting is due to the mineralization of nitrogen and phosphorus compounds and the production of humic and fulvic acids.

It is noteworthy that pile 2:1 OP + CM only achieved neutral pH values early in the process due to the addition of cattle manure, because the pH of pure orange peel was 2.5 ± 0.4 (Table 1). Furthermore, the first stage of vermicomposting process was the composting in piles, allowing a stabilization of the material before the addition of the earthworms.

The C and C/N ratio of the vermicomposts

There was a decrease in the C contents in the three different treatments at the end of the process (Table 2). This was as a result of the mineralization of the organic matter (OM) by microorganisms. A decrease in C content had earlier being reported by Huang et al. (2006) during the composting of pig manure with sawdust. Bhat et al. (2015) also reported a decrease of organic carbon in all the end products of post-vermicomposting of mixtures of bagasse waste of the sugar industry and cattle dung. The C content in piles CM and 3:1 FC + CM decreased by 58 % while in pile 2:1 OP + CM it reduced by 53 %. This could be due to the characteristics of the orange peel as it contains more lignin which is not easily degraded. The rates of mineralization of the OM decreased in the three piles at the end of 105 days as no further significant decreases were observed. Total N contents of the three piles at the beginning and at the end of the vermicomposting were not significantly different. At the end of 90 days, the total N in the three piles was of maxima having increased by 152, 19.5 and 99 % in piles 2:1 OP + CM, 3:1 FC + CM and CM, respectively (Table 2). According to Bernal et al. (2009), the loss of N during composting occurs through volatilization of ammonium, thus making the total N to reduce at the end of the process. It is also possible for the nitrogen to have been lost through denitrification.

Figure 2 shows the C/N ratio versus time for the three systems. The C/N ratio is often used to assess the evolution of the degradation process (Huang et al. 2004). There was a rapid decrease in the C/N ratio of the pile 2:1 OP + CM from initial value of 25.96–14.36 after 30 days of composting, and this gradually continued to decrease to 6.65 at the end of 105 days. In pile 3:1 FC + CM, the C/N ratio decreased gradually until a minimum of 6.62 at the end of 105 days while in pile CM the minimum C/N ratio was 6.10 after 105 days. This was due to the continuous loss of C through microbial respiration during the process. This was similar to the report by Juárez et al. (2011). At the end of 90 days, the C/N ratios of the three piles were less than 8.14. According to Bernal et al. (1998) a C/N ratio less than 12 indicates the maturity of the compost and its suitability for addition to soils. It could be concluded that the compost reached maturation after 90 days. It has been suggested that the C/N ratio index should be considered along with other parameters when monitoring compost stabilization (Fialho et al. 2010). These authors also observed that in some compost piles, although the C/N had stabilized, the temperature range was still in the thermophilic phase, which is an indication that the composts were not yet stabilized at that time. The evolution of the process depends strongly on the nature of the material used in the compost and/or vermicompost and the C/N ratio affects the rate at which the material is stabilized in terms of microbiological activity. Similar results were also observed by Bhat et al. (2015). At the end of the vermicomposting process, the C/N ratios in the OP + CM, FC + CM and OM piles were 9.51, 9.62 and 11.03, respectively. These values indicated lower microbial activity and the possible stabilization of the material as also suggested by Provenzano et al. (2001), Bernal et al. (1998) and Chefetz et al. (1996). The decrease in C/N ratio as a function of vermicomposting time is indicative of increased humification of OM, which is directly related to the quality and maturity of the vermicompost. The C/N is also indicative of the degree of incorporation of N into the humic structure. Table 2 shows the increase of N content up to 120 days for vermicomposts from FC + CM, OP + CM and CM. N incorporation provides increased fertility of this material, because the N is released to plant roots in the form of NO3 − through various mechanisms of mineralization of SOM.

The vermicomposting process in FC + CM pile lasted longer than other treatments. This might be due to the characteristics of the filter cake which contains more lignin that is not easily degraded. In general, the C/N ratio determines the ability of the microbial degradation of the wastes, but some organic wastes, such as those derived from plants, despite of having adequate C/N ratios may contain a high proportion of lignin, a component that is difficult to degrade. After 105 days, earthworms’ activities were no longer observed in 2:1 OP + CM and CM piles while their activity was still observed in 3:1 FC + CM pile. To confirm that the vermicomposts were mature, additional 100 earthworms were added to each container. After 7 days, there were no more earthworms in 3:1 FC + CM and CM. Since the humidity was kept constant and the medium slightly basic, this shows that there was no more substrate for the earthworms to feed on. However in FC + CM pile, earthworms’ activities ceased after 135 days.

The N contents of the vermicomposts

Among the three piles, 2:1 OP + CM had the highest N content at the end of the vermicomposting process (Table 2). The N content of 3:1 FC + CM and CM piles were not significantly different (p ≤ 0.05). There was no significant difference in the C, H and S content of all the vermicomposts. Further, while the C/N ratios of the vermicomposts from pile 2:1 OP + CM and 3:1 FC + CM were not significantly different, they were significantly lower than that of the CM. This shows that 3:1 FC + CM and 2:1 OP + CM piles exhibited a higher level of molecular condensation meaning that they exhibited a more advanced stage of humification than CM did (Bernal et al. 1998). Decline in C/N ratio was due to higher loss of carbon through microbial respiration in the form of CO2 along with an increase in nitrogen and stabilization of waste by the action of worms (Hait and Tare 2011).

Macro and micronutrient content of the vermicomposts

In the three different treatments, the Ca, Mg, Mn and Fe contents significantly (p ≤ 0.05) increased at the end of the vermicomposting process when compared with the initial contents (Table 3). While the K content in 2:1 OP + CM and CM piles were significantly (p ≤ 0.05) higher at the end, the K content in 3:1 FC + CM was not. There was a significant (p ≤ 0.05) increase in the Cu content of 2:1 OP + CM and CM while a significant decrease was observed in 3:1 FC + CM. While, the Zn content significantly (p ≤ 0.05) increased in 2:1 OP + CM and 3:1 FC + CM, there was no significant increase in CM.

There was no significant (p ≤ 0.05) increase in the P contents across the three treatments while the Cr content in 3:1 FC + CM was close to zero at the end of the vermicomposting unlike in 2:1 OP + CM and CM where no significant difference was observed. This could be attributed to the continuous presence of earthworms in 3:1 FC + CM after 105 days. The Cr level in 3:1 FC + CM at the end of the vermicomposting was close to zero. Bhat et al. (2015) reported an increase of nutrients like N, P and Na and an increase of metallic elements Fe, Zn and Mn from pre-vermicompost to post-vermicompost of mixtures of bagasse waste from the sugar industry and cattle dung. The authors also observed a significant decrease (p < 0.05) in Cr over initial. According Sangwan et al. (2008) in India, vermicomposting of filter cake in combination with equine manure accelerated mineralization of nutrients and was adequate for growth and reproduction of earthworms.

After 105 days of vermicomposting, earthworms were no longer present in piles 2:1 OP + CM and CM suggesting that all the biodegradable material had been decomposed at this time. On the other hand, after 105 days, earthworms were still very active in 3:1 FC + CM pile probably because filter cake is rich in fibre and lignin.

This suggests that due to the increased duration of decomposition in 3:1 FC + CM pile, the earthworms were able to bioaccumulate Cr resulting in decreased values at the end of the process.

At the end of the vermicomposting process, 2:1 OP + CM and 3:1 FC + CM had higher contents of macro and micronutrients than CM (Table 4). This might be due to the characteristics of the filter cake and orange peel. The Ca, Mg and K were highest in 2:1 OP + CM while the P content in 2:1 OP + CM and 3:1 FC + CM were not significantly different but both had significantly (p ≤ 0.05) higher P values than in CM (Ca and Mg: 2:1 OP + CM > 3:1 FC + CM > CM, P: 2:1 OP + CM = 3:1 FC + CM > CM). Potassium presented the highest level in 2:1 OP + CM and the lowest in 3:1 FC + CM (2:1 OP + CM > CM > 3:1 FC + CM).

The results obtained in this study confirm those obtained by Sangwan et al. (2010): it can be said that the costs of agricultural production could be minimized with the use of vermicompost obtained from organic wastes.

Correlations between macro and micronutrients, elemental analysis, C/N, pH and CEC

The values of CEC at post-vermicomposts were 652.50 ± 14.36, 490.44 ± 15.76 and 596.19 ± 15.02 mmolc kg−1 for OP + CM, FC + CM and CM piles, respectively. OP + CM had significantly highest CEC (p ≤ 0.05). It was observed that the pH and CEC parameters were strongly positively correlated (r = 0.851 **). This correlation was due to the basic cations which also shows a positive correlation with the CEC (Mg: r = 0.713*, K: r = 0.977**). This is so because the basic cations influence the pH, which consequently affects the CEC. The CEC and C contents were also positively correlated (r = 0.706*). This is because the OM, the source of CEC was decomposed by microorganisms during the process of vermicomposting. Likewise, C and H showed strong positive correlations (r = 0.911**), which is related to the evolution of the organic matter humification process, loss of labile C and the formation of double bonds in the aromatic molecules.

The linear increase and positive correlation between the levels of C and N (r = 0.941**) is related to the mineralization process. At the end of the vermicomposting process, with the death of earthworms and microorganisms, there is a greater availability of nutrients, which initially had been immobilized, as they used them as sources of energy and nutrients. There were positive correlations between Mg and K (r = 0.806**) and P and Ca (r = 0.867**).

Conclusions

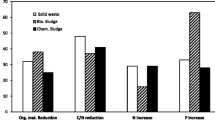

The chemical compositions of the vermicomposting materials had effect on the duration of the process. The pH and the organic carbon contents were above the minimum recommended values for organic fertilizers. Co-vermicomposting of cattle manures with orange peel or filter cake also resulted in a lower C/N ratio. Co-vermicomposting of cattle manure resulted in higher contents of macronutrients, like N (up to 120 days of vermicomposting). The N content was below the minimum value but the C/N ratio was in the required range. The C/N values where lower in OP + CM and FC + CM piles than in CM pile. Further, the N contents of the piles were different, with OP + CM having the highest value. The micronutrient values in the matured piles decreased in some piles and increased in others. Ca, Mg, Mn and Fe contents significantly increased at the post-vermicompost than the pre-vermicompost for all treatments. The mature FC + CM differed very significantly in the content of Cr due to increased earthworm activity suggesting the bioaccumulation of Cr by the earthworms. It was observed that vermicomposts from filter cake and orange peel mixed with cattle manure resulted in a better vermicomposts than the ones produced from cattle manure only. Thus, it is recommended that these agricultural wastes can be co-vermicomposted and utilized for sustainable agriculture. The vermicomposts so obtained attend the needs of the Brazilian legislation and the vermicomposting could be introduced as efficient technology to convert wastes of cattle manure with orange peel and filter cake into organic fertilizer. Further studies are also been carried out on the potential of vermicomposted orange peels to reduce pest incidence in soil.

References

Bernal MP, Paredes SMC, Cegarra J (1998) Maturity and stability parameters of composts prepared with a wide range of organic wastes. Bioresour Technol 63:91–99. doi:10.1016/S0960-8524(97)00084-9

Bernal MP, Alburquerque JA, Moral R (2009) Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour Technol 100:5444–5453. doi:10.1016/j.biortech.2008.11.027

Bhat SA, Singh J, Vig AP (2015) Potential utilization of bagasse as feed material for earthworm Eisenia fetida and production of vermicompost. Springerplus 4:11. doi:10.1186/s40064-014-0780-y

Chefetz B, Hatcher P, Hadar Y, Chen Y (1996) Chemical and biological characterization of organic matter during composting of municipal solid waste. J Environ Qual 25:776–785. doi:10.2134/jeq1996.00472425002500040018x

Edwards CA, Bohlen PJ (1996) Biology and ecology of earthworms, vol 3. Springer Science & Business Media, pp 426. ISBN: 0412561603

Fialho LL, Silva WTL, Milori DMBP, Simões ML, Martin-Neto L (2010) Characterization of organic matter from composting of different residues by physicochemical and spectroscopic methods. Bioresour Technol 101:1927–19346. doi:10.1016/j.biortech.2009.10.039

Hait S, Tare V (2011) Vermistabilization of primary sewage sludge. Bioresour Technol 102:2812–2820. doi:10.1016/j.biortech.2010.10.031

Huang GF, Wong JWC, Wu QT, Nagar BB (2004) Effect of C/N on composting of pig manure with sawdust. Waste Manag 24:805–813. doi:10.1016/j.wasman.2004.03.011

Huang GF, Wong JWC, Wu QT, Nagar BB (2006) Transformation of organic matter during co-composting of pig manure with sawdust. Bioresour Technol 97:1834–1842. doi:10.1016/j.biortech.2005.08.024

Itavo LCV, Santos GT, Jobim CC, Voltolini TV, Faria KP, Ferreira CCB (2000) Composição e digestibilidade aparente da silagem de bagaço de laranja. Revista Brasileira de Zootecnia (In Portuguese) 5:1485–1490. doi:10.1590/S1516-35982000000500029

Juárez PDA, Fuente JL, Paulín RV (2011) Vermicomposting as a process to stabilize organic waste and sewage sludge as an application for soil. Trop Subtrop Agroecosyst 14:949–963. doi:10.1007/s11356-011-0606-1

Morelli JL (2004) Compostagem de resíduos produzidos pelas usinas de cana-de-açúcar. In: SIMPÓSIO SOBRE COMPOSTAGEM: SICOM, 1, 2004, Botucatu. Anais. Botucatu: UNESP, CD-ROM (In Portuguese)

Pramanik P, Ghosh GK, Ghosal PK, Banik P (2007) Changes in organic: C, N, P and K and enzyme activities in vermicompost of biodegradable organic wastes under liming and microbial inoculants. Bioresour Technol 98:2485–2494. doi:10.1016/j.biortech.2006.09.017

Provenzano MR, Oliveira SC, Silva MRS, Senesi N (2001) Assessment of maturity degree of composts from domestic solid wastes by fluorescence and Fourier transform infrared spectroscopies. J Agric Food Chem 49:5874–5879. doi:10.1021/jf0106796

Rezende MOO, Dores-Silva PR, Silva MD, Zozolotto TCB, Landgraf MD (2014) Understanding the vermicompost process in sewage sludge: a Humic fraction study. Int J Agric For 4(2):94–99. doi:10.5923/j.ijaf.20140402.08

Rodella AA, Alcarde JC (1994) Assessment of organic materials used as fertilizers (in Portuguese). Sci Agric 51(3):556–562

Ros M, García C, Hernández T (2006) A full-scale study of treatment of pig slurry by composting: Kinetic changes in chemical and microbial properties. Waste Manag 26:1108–1118. doi:10.1016/j.wasman.2005.08.008

Sangwan P, Kaushik CP, Garg VK (2008) Feasibility of utilization of horse dung spiked filter cake in vermicomposters using exotic earthworm Eisenia foetida. Bioresour Technol 99(7):2442–2448. doi:10.1016/j.biortech.2007.04.061

Sangwan P, Kaushik CP, Garg VK (2010) Growth and yield response of marigold to potting media containing vermicompost produced from different wastes. Environmentalist 30:123–130. doi:10.1007/s10669-009-9251-3

SAS Institute (2004) The SAS system for Windows. SAS Inst., Cary

Suthar S (2012) Earthworm production in cattle dung vermicomposting system under different stocking density loads. Environ Sci Poll Res Int 19(3):748–755. doi:10.1007/s11356-011-0606-1

Acknowledgments

The authors are grateful to the Brazilian Research Funding Agencies FAPESP (projects 2011/13294-7 and 2011/13918-0) and CNPq (project 306713/2013-9) for their financial support and the Institute of Chemistry of São Carlos, University of São Paulo for the provision of infrastructure.

Authors’ contributions

All authors, LBFP, IAA, OAO, AVB and MOOR have made adequate effort on all parts of the work necessary for the development of this manuscript according to his/her expertise. All authors read and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Pigatin, L.B.F., Atoloye, I.A., Obikoya, O.A. et al. Chemical study of vermicomposted agroindustrial wastes. Int J Recycl Org Waste Agricult 5, 55–63 (2016). https://doi.org/10.1007/s40093-016-0117-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40093-016-0117-7