Abstract

Nanocrystalline α-MoO3 thin films were prepared successfully by thermal annealing of molybdenum (Mo) thin films deposited on quartz and silicon substrates using DC magnetron sputtering method. The influence of annealing temperatures ranging from 400 to 1,000 °C on the structural, morphological and optical properties of the prepared films was investigated by X-ray diffraction, Fourier transform infrared spectrophotometer (FTIR) atomic force microscopic and UV–vis spectroscopy, respectively. The results show that the crystallinity and surface morphology of the films are strongly dependent on the annealing temperature. Also, the optimum annealing temperature of Mo films in our experiment was 600 °C and the films formed at this temperature exhibit only the (0k0) reflections and indicated the layered structure of α-MoO3. The FTIR spectra confirm the formation of MoO3. The transmittance of the MoO3 films on quartz substrate was improved with increasing annealing temperature.

Similar content being viewed by others

Introduction

Molybdenum oxide (MoO3) is a wide band gap n-type semiconductor material and one of the transition metal oxides. Some of the molybdenum oxide compounds are thermodynamically stable normal phase of orthorhombic (α-MoO3), metastable phase of monoclinic (β-MoO3) and the hexagonal phase (h-MoO3) [1–8]. The orthorhombic MoO3 has a layered structure, containing two layers of octahedral MoO6, held together by double covalent forces in the a and c axes; contiguous layers are kept together along the b axes by Van der Waal’s forces [6]. MoO3 thin films have attracted much interest for technological and industrial applications in recent years, including elements for energy efficient window technology, optical switching, coating high-density, memory devices, gas sensors, and lithium ion batteries [1–12, 15]. In addition, the optical property of MoO3 is higher than those of many other inorganic materials because the incorporator indicates stronger and more uniform absorption of light in its colored state [13]. Different deposition techniques have been used for the growth of molybdenum oxide films on various substrates. Nirupama and Uthanna [2] have fabricated MoO3 thin films on glass and silicon substrates using DC magnetron sputtering technique and investigate the influence of sputtering powers on the structural, electrical and optical properties of prepared films. Pulsed laser deposition method was employed by Al-Kuaili et al. [3] for preparation of MoO3 thin films. Pardo and Torres [4] have synthesized MoO3 thin films on silicon and glass substrates at different substrate temperature and annealing temperature. Yang et al. [5] have fabricated nanocrystalline MoO3 thin films at various substrate temperatures by electron beam evaporation. Navias et al. [7] have fabricated MoO3 nanorods by RF magnetron sputtering of molybdenum oxide target and study the structural properties. Flow rate effect on the structure and morphology of molybdenum oxide nanoparticles deposited by atmospheric pressure microplasma processing was studied by Bose et al. [8]. However, there are still only a few reports on the study of the preparation of MoO3 nanostructures on thin films. In the present investigation, the thermal oxidation of molybdenum (Mo) thin films was employed for the preparation of MoO3 thin films. The effect of annealing temperatures on structural, surface morphological and optical properties of the films on quartz substrates are elaborately studied and presented here.

Experimental procedure

Firstly, Mo thin films were deposited on quartz and silicon substrates (1 cm × 1 cm) by dc magnetron sputtering (EDS-160) technique at room temperature. The purity of molybdenum target was 99/999 %. The chemical pretreatment of substrates was carried out with acetone and ethanol successively in ultrasonic bath for 10 min and dried in N2 gas before introducing into the deposition chamber. The sputter chamber was evacuated to an ultimate pressure of 4 × 10−5 mbar using diffusion and rotary pumps before sputtering. The pure argon gas was admitted into the chamber and the working pressure was maintained at ~2 × 10−2 mbar throughout the depositions process. Before deposition, the target was pre-sputtered for 15 min to remove any surface contamination layer. The distance between the target and the substrate was kept at 7 cm. The cathode voltage and discharge current were 300 V and 180 mA, respectively. The thickness of the films and the rate of deposition were controlled using the quartz crystal monitor in the chamber. The rate of sputtering (0.1 nm s−1) was used to deposit all Mo films to a thickness of 140 nm. During the deposition, the substrates are not intentionally heated. In the second step, thin films were annealed in the electrical furnace at various annealing temperature of 400, 600, 800, 1,000 °C under constant oxygen flow for 1 h. The flow rate of the O2 gas (purity 99/999 %) was 80 sccm. Temperature variations are imparted very slowly to avoid additional stresses or cracks in the films. The as-deposited films and those formed during thermal oxidation at temperatures of 400, 600, 800 and 1,000 °C are abbreviated as Q0, Q1, Q2, Q3 and Q4, respectively. The films formed on silicon substrates were analyzed with Fourier transform infrared spectrophotometer (FTIR, Perkin Elmer spectrum 100) in the wave number range of 400–1,200 cm−1 to determine the chemical binding configuration. The crystal structure of the films was characterized by X-ray diffraction (XRD, Philips, pw 1800) using Cuκα radiation (λ = 0.1506 nm) at 40 kV and 30 mA in the 2θ scan ranging from 10 to 90. The morphology of MoO3 thin films was studied by atomic force microscopic (AFM, park Scientific Instrument, Auto probe cp USA). The transmittance spectra of the MoO3 thin films deposited on the quartz substrates were recorded using a spectrophotometer.

Results and discussion

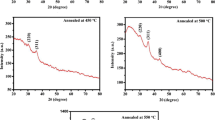

The XRD patterns of the Mo thin films and MoO3 films prepared at different annealing temperatures are shown in Figs. 1, 2, 3, 4 and 5. The as-deposited film (sample Q0) shows that three peaks belong to Mo crystalline structure in (110), (211), (220) crystallography directions. Obviously, the Mo (110) peak is dominant. By annealing Mo films at temperature of 400 °C (sample Q1), the polycrystalline MoO3 can be observed. By increasing the annealing temperature to 600 °C (sample Q2), the film showed only (0k0) reflections related to orthorhombic α-phase of molybdenum oxide. The presence of (0k0) reflections indicated the layered structure of α-MoO3. In addition, the high intense and sharp peaks observed in the XRD pattern of this films confirmed the highly oriented and polycrystalline nature of the film. In XRD pattern of sample Q3 that was prepared at temperature of 800 °C, the crystalline properties were reduced in comparison with sample Q2, because the member and intensity of peaks were decreased. Finally, for sample Q4 the crystallinity of MoO3 film was deteriorated maybe for disassembled the lattice arrangement and the structure of film is amorphous. The XRD results show that the optimum temperature of thermal oxidation of Mo films for preparation of single phase of orthorhombic α-phase MoO3 film in our experiment was 600 °C, because in this temperature the best crystallinity was observed.

The average crystalline size and microstrain of the prepared films have been obtained from the following Scherrer relations [14]:

Here, λ is the X-ray wavelength (1.5406 nm for Cuκα), θ is the brag diffraction angle and β hkl is the full-width at half-maximum (FWHM) in radians of the main peak in the XRD pattern. The average crystal sizes for all samples are shown in Table 1. The average crystalline size of the MoO3 films calculated from the Scherrer’ formula was in the range of 24.34–41.74 nm, which confirms the presence of nanocrystal’s in the films prepared in this study. Also, we can observe that annealing temperature augmentation up to 600 °C leads to increase in average crystal size and decrease in microstrain. The increase in crystallite size is related to decrease in strain.

The Fourier transform infrared spectra of MoO3 thin films formed on silicon substrate at different annealing temperatures are shown in Fig. 6a, b. The films prepared at annealing temperatures of 400, 800 and 1,000 °C have similar spectra and three peaks can be observed at 612.26, 737.6 and 1,108.26 cm−1. The peak of 612.26 cm−1 corresponds to silicon substrate and two other peaks are belonging to molybdenum oxide films. By increasing the annealing temperature, the intensity of the peaks is increased. The films annealed at 600 °C have a different FTIR spectrum and exhibit characteristics peaks at 814.4, 993.6 and 1,108.26 cm−1 that two intense peaks seen at 814.4, 993.6 cm−1 were attributed to the Mo=O stretching vibration, which is an indicator for the layered orthorhombic MoO3 phase. These results confirm the results obtained by XRD analysis. The FTIR studies of the present work agree well with the reports on MoO3 thin films prepared using dc magnetron sputtering method by Uthanna et al. [15].

The three-dimensional AFM images of the prepared films are shown in Fig. 7. The AFM images show the features of structural change and grain growth for MoO3 thin films on quartz substrates at various annealing temperatures.

The AFM images show the growth of grain and smooth surface for sample Q0 and by thermal oxidation, the grains combine and make bigger grains and roughness of film increases. The increase in films’ surface roughness probably attributed to the coalescence of grains in the film structure that leads to the formation of large grain aggregates. Also, the layered structure of the MoO3 films is clearly seen in AFM images and the AFM results are in good agreement with the results obtained by the X-ray analysis. The plot of surface roughness versus thermal annealing temperatures is shown in Fig. 8. It can be considered that the surface roughness of the films is dependent mainly on surface morphology. Changes in rms roughness of the films may also due to the different crystal structure of MoO3 thin films at various annealing temperatures [16].

Optical properties

The as-deposited film (sample Q0) is dark, whereas those annealed at different oxidation temperatures are almost different colors, such as deep blue (sample Q1), light blue (sample Q2), grayish/blue (sample Q3) and transparent (sample Q4). The influence of thermal oxidation temperature on the optical transmittance of MoO3 films deposited on quartz substrate was studied in the wavelength range between 200 and 800 nm and the recorded spectra are shown in Fig. 9a, b. Figure 9a shows that the MoO3 film prepared at temperature of 400 °C has no transmittance (0 %) and for thermal oxidation temperature of 600 °C, very low transmittance (1.5 %) can be observed. This can be due to the large scattering introduced by the enhanced roughness in these films, as revealed by AFM (Fig. 7). By enhancement of thermal annealing temperature, the MoO3 film transmittances in the wavelength range of 200–800 nm change from 30 to 70 % for temperature of 800 °C and 35 to 80 % for temperature of 1,000 °C, respectively (Fig. 9b). These results show that the transmittance of MoO3 films was very sensitive to the annealing temperatures and increasing annealing temperature leads to an improvement in the optical transmittance [17].

Conclusion

Thin films of MoO3 were prepared by thermal annealing of Mo films deposited on quartz and silicon substrate using dc magnetron sputtering method. The annealing temperatures were varied between 400 and 1,000 °C. The XRD studies revealed that the films structure changes from crystalline to amorphous by enhancing the annealing temperature. Also, the best crystallinity and layered structure were observed at annealing temperature of 600 °C. The layered structure of the MoO3 films is clearly seen in AFM images. Also, the AFM and FTIR results are in good agreement with the results obtained by the X-ray analysis. The optical transmittance of the MoO3 thin films as a wavelength indicated that the annealing temperature strongly affected the optical transmittance of films and the good transparency was observed at annealing temperature of 800 and 1,000 °C.

References

Song, J., Li, Y., Zhu, X., Zhao, S., Hu, Y., Hu, G.: Preparation and optical properties of hexagonal and orthorhombic molybdenum trioxide thin films. Mater. Lett. 95, 190–192 (2013)

Nirupama, V., Uthanna, S.: Influence of sputtering power on the physical properties of magnetron sputtered molybdenum oxide films. J. Mater. Sci. Mater. Electron. 21, 45–52 (2010)

Al-Kuhaili, M.F., Durrani, S.M.A., Bakhtiari, I.A., Al-Shukri, A.M.: Optical constants and thermocoloration of pulsed laser deposited molybdenum oxide thin films. Opt. Commun. 283, 2857–2862 (2010)

Pardo, A., Torres, J.: Substrate and annealing temperature effects on the crystallographic and optical properties of MoO3 thin films prepared by laser assisted evaporation. Thin Solid Films 520, 1709–1717 (2012)

Yang, W., Wei, Z-R., Zhu, X-H., Yang, D-Y.: Strong influence of substrate temperature on the growth of nanocrystalline MoO3 thin films. Phys. Lett. A 373, 3965–3968 (2009)

Bouzidi, A., Benramdane, N., Tabet-Derraz, H., Mathieu, C., Khelifa, B., Desfeux, R.: Effect of substrate temperature on the structural and optical properties of MoO3 thin films prepared by spray pyrolysis technique. Mater. Sci. Eng. B 97, 5–8 (2003)

Navas, I., Vinodkumar, R., Lethy, K.J., Detty, A.P., Ganesan, V., Sathe, V., Mahadevan Pillai, V.P.: Growth and characterization of molybdenum oxide nanorods by RF magnetron sputtering and subsequent annealing. J. Phys. D Appl. Phys. 42, 175305 (2009). (8 pp)

Bose, A.C., Shimizu, Y., Mariotti, D., Sasaki, T., Terashima, K., Koshizaki, N.: Flow rate effect on the structure and morphology of molybdenum oxide nanoparticles deposited by atmospheric-pressure microplasma processing. Nanotechnology 17, 5976–5982 (2006)

Gretener, C., Perrenoud, J., Kranz, L., Baechler, C., Yoon, S., Romanyuk, Y.E., Buecheler, S., Tiwari, A.N.: Development of MoOx thin films as back contact buffer for CdTe solar cells in substrate configuration. Thin Solid Films 535, 193–197 (2013)

Tseng, YCh., Mane, A.U., Elam, J.W., Darling, S.B.: Ultrathin molybdenum oxide anode buffer layer for organic photovoltaic cells formed using atomic layer deposition. Sol. Energy Mater. Sol. Cells 99, 235–239 (2012)

Ramana C.V., Atuchin, V.V., Kesler, V.G., Kochubey, V.A., Pokrovsky, L.D., Shutthanandan, V., Becker, U., Ewing, R.C.: Growth and surface characterization of sputter-deposited molybdenum oxide thin films. Appl. Surf. Sci. 253, 5368–5374 (2007)

Manno, D., Giulio, M.Di., Serra, A., Siciliano, T., Micocci, G.: Physical properties of sputtered molybdenum oxide thin films suitable for gas sensing applications. J. Phys. D Appl. Phys. 35, 228–233 (2002)

Sivakumar, R., Gopalakrishnan, R., Jayachnandran, M., Sanjeeviraja, C.: Characterization on electron beam evaporated a-MoO3 thin films by the influence of substrate temperature. Curr. Appl. Phys. 7, 51 (2007)

Khojier, K., Savaloni, H., Jafari, F.: Structural, electrical, and decorative properties of sputtered zirconium thin films during post-annealing process. J. Theor. Appl. Phys. 7, 55 (2013)

Uthanna, S., Nirupama, V., Pierson, J.F.: Substrate temperature influenced structural, electrical and optical properties of dc magnetron sputtered MoO3 films. Appl. Surf. Sci. 256, 3133–3137 (2010)

Dorranian, D., Dejam, L., Sari, A.H., Hojabri, A.: Structural and optical properties of copper nitride thin films in a reactive Ar/N2 magnetron sputtering system. Eur. Phys. J. Appl. Phys. 50, 20503 (2010)

Matheswaran, P., Sarava Kumar, R., Sathyamoorthy, R.: Effect of annealing on the structural and optical properties of InSe bilayer thin films. Vacuum 85, 820–826 (2011)

Acknowledgments

This work was supported by Islamic Azad University, Karaj Branch, Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Hojabri, A., Hajakbari, F. & Meibodi, A.E. Structural and optical properties of nanocrystalline α-MoO3 thin films prepared at different annealing temperatures. J Theor Appl Phys 9, 67–73 (2015). https://doi.org/10.1007/s40094-014-0161-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40094-014-0161-5