Abstract

The cast pin tear test (CPTT) was originally developed by F.C. Hull in the 1960s to study solidification cracking in austenitic stainless steels. Over a past 5 years, researchers at the Ohio State University have modified the original test and apparatus design to study solidification cracking in a range of Ni-base alloys and stainless steels. This paper describes the development of the test apparatus, the techniques that are used, and results from the testing of several alloy systems. It is shown that the CPTT closely reproduced the trends in solidification cracking behavior determined by the Transvarestraint test and experienced in actual welds. Very good correlation is found between rankings of the solidification cracking susceptibility in various high-alloy stainless steels and high-Cr Ni-base filler metals generated using the CPTT and other solidification cracking tests. In addition, the application of the CPTT to study dilution effects in dissimilar material combinations is described.

Similar content being viewed by others

References

Finton T, Lippold J, Bowers R (1999) Comparison of weld hot cracking tests, summary of an IIW round robin study, IIW Doc. IX-H-459-99 (II-C-175-99)

Wilken K, Kleistner H (1990) The classification and evaluation of hot cracking tests for weldments. Weld World 28(7/8):37–48

Prokhorov NN (1956) The problem of the strength of metals while solidifying during welding, Svar. Proiz. vol. 6, pp 5–11 (Prokhorov, N. N.: The technological strength of metals while crystallising during welding. Doc IX-479-65, 1965)

Kannengiesser T, Boellinghaus T (2013) Hot cracking tests: an overview of present technologies and applications IIW. Doc. II-A-258-13

ISO (2005) ISO 17641: destructive tests on welds in metallic materials. Hot cracking tests for weldments. Arc welding processes. ISO, Geneva

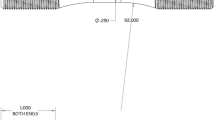

Hull F (1959) Cast-pin tear test for susceptibility to hot cracking. Weld J 38:176s–181s

Talento JA (1969) Laboratory test to determine the weldability of alloy 600/EN 82 Ni–Cr–Fe base filler alloy combinations. In: Proceedings of “effects of minor elements on the weldability of high-nickel alloys” symposium sponsored by the Welding Research Council

Armao FG, Yeniscavich W (1974) Grooved copper mold testing of Inconel Alloy 600. Weld J 53:170s–174s

Ryan DP (2003) Development of modified cast-pin tear test to evaluate the solidification cracking susceptibility of fully austenitic materials. M.S. thesis, The Ohio State University

Alexandrov BT, Lippold JC, Nissley NE (2007) Evaluation of weld solidification cracking in Ni-base superalloys using the cast pin tear test. In: Hot cracking phenomena in welds II. Springer, Berlin, pp 193–213

Alexandrov BT, Lippold JC (2010) Further development of the cast pin tear test for evaluating solidification cracking in welds. In: Hot cracking phenomena in welds III. Springer, Berlin, pp 317–331

Wilken K (1999) Investigation to compare hot cracking tests—externally loaded specimen, IIW Doc. IX-1945-99 (II-C-168-99)

Finton TL, Lippold JC (2004) Standardization of the Transvarestraint test: a statistical study using austenitic stainless steels and nickel-base alloys, EWI summary report SR0402, January

McCracken SL, Smith, RE (2010) Behavior and hot crack susceptibility of filler metal 52M (ERNiCrFe-7A) on cast austenitic stainless steel base materials. In: Hot cracking phenomena in welds III. Springer, Berlin, pp 333–342

Dupont JN, Robino CV, Marder AR (1998) Solidification in Nb-bearing super alloys: part II. Pseudoternary solidification surfaces. Metall Mater Trans A 29A:2797–2806

Dupont JN, Robino CV, Marder AR (1998) Modeling solute redistribution and microstructural development in fusion welds of Nb-bearing super alloys. Acta Mater 46:4781–4790

Sowards JW, Liang D, Alexandrov BT, Frankel GS, Lippold JC (2011) A new chromium-free welding consumable for joining austenitic stainless steels. Weld J 90:63s–76s

Sowards JW, Liang D, Alexandrov BT, Frankel GS, Lippold JC (2011) Solidification behavior and weldability of dissimilar welds between a Cr-free, Ni–Cu welding consumable and type 304L austenitic stainless steel. Metall Mater Trans. doi:10.1007/s11661-011-0961-z

Alexandrov BT, Lippold JC (2011) Method and device for investigation of phase transformations in metals and alloys. United States patent no. 7,909,505, March 22

Alexandrov BT, Lippold JC (2007) Single sensor differential thermal analysis of phase transformations and structural changes during welding and postweld heat treatment. Weld World 51:48–59, n° 11/12

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2379, recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding.”

Rights and permissions

About this article

Cite this article

Alexandrov, B.T., Lippold, J.C. Use of the cast pin tear test to study solidification cracking. Weld World 57, 635–648 (2013). https://doi.org/10.1007/s40194-013-0061-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0061-3