Abstract

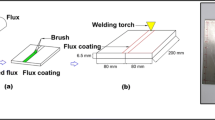

Metallurgical characterization and qualification of activated flux TIG (ATIG) weld joints of titanium produced using in-house developed activating flux are presented. The flux formulation was optimized after carrying out trials with different sets of flux powders and subsequent metallographic observation of weld bead profile. ATIG welding of titanium using this flux, with optimized welding parameters, produces full penetration welds in 6-mm-thick plates having weld bead depth-to-width ratio of 1.25 compared to 0.25 of conventional TIG welds. ATIG weld joints were prepared using 6-mm-thick titanium plates using square-butt joint geometry and these joints were qualified by radiography. Root and face bend tests passed 4T bend radius as per American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code-Section IX requirements with bend angle of 180°. Transverse tensile testing of weld joints showed fracture in the weld metal with sufficient ductility and tensile strength of 398 MPa, which was close to the base material tensile strength of 402 MPa thereby meeting ASME Section IX requirements. Uniform hardness across the weld confirmed that the weld was not contaminated by components of flux or atmospheric gases, which can result in increased hardness of the weld metal leading to embrittlement. The corrosion test of the weld joints in 11.5 M boiling nitric acid showed improved corrosion resistance compared to base material.

Similar content being viewed by others

References

Baeslack WA, Davis JR, Cross CE (1993) Selection and weldability of conventional titanium alloys’, 10th ed. ASM Handbook 6:507–523

Terrance, R Welding of titanium alloys: ASM Handbook, 10th ed., Vol. 6, pp.783–786

Tanaka M, Shimizu T, Terasaki H, Ushio M, Koshi-ishi F, and Yang CL (1993) Effects of activating flux on arc phenomena in gas tungsten arc welding, Science and Technology of Welding and Joining 2000, Vol.5, No.6, PP. 397–402

Shamping LU, Hidetoshi Fujii, Hiroyuki Sugiyama, Manabu Tanaka and Kiyoshi Nogi (2003) Marangoni Convection and Welding Penetration in A-TIG Welding, Trans. JWRI, Vol.32, No.1

Lowke JJ, Tanaka M, Ushio M (2005) Mechanisms giving increased weld depth due to a flux. J Phys D: Appl Phys 38:3438–3445

Leconte S, Paillard P, Chapelle P, Henrion G, Saindrenan J (2007) Effects of flux containing fluorides on TIG welding process. Sci Technol Weld Join 12(2):120–126

Furuya T, Kawafuku J, Satoh H, Shimogori K, Aoshima A, Takeda S (1991) A corrosion testing method for titanium in nitric acid environments. ISIJ Int 31(2):189–193

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2402, recommended for publication by Commission IX "Behaviour of Metals Subjected to Welding."

Rights and permissions

About this article

Cite this article

Dey, H.C., Albert, S.K., Bhaduri, A.K. et al. Activated flux TIG welding of titanium. Weld World 57, 903–912 (2013). https://doi.org/10.1007/s40194-013-0084-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0084-9