Abstract

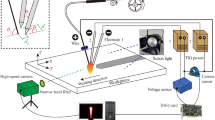

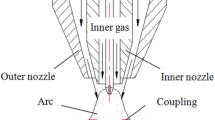

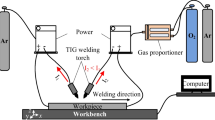

On TIG-MIG hybrid welding process (TIG: DCEN and MIG: DCEP), the stability of MIG arc can be kept even in pure inert shielding gas by the effect of hybridization with TIG arc, and it becomes possible to achieve the new welding method which has both merits of high quality as TIG welding process and high efficiency as MIG welding process. In this report, we performed two experiments mainly as follows to solve two problems: (1) Analysis of output from TIG power source in hybrid welding state to prove experimentally the existence of direct current path which flows between TIG cathode and MIG anode via in hybrid arc plasma. (2) Measurement of actual heat input based on evaporation amount of liquid nitrogen to investigate detailed heat source property of this process. As results, it was shown that output of TIG power source in hybrid welding condition is lower than it in single TIG welding, and the heat efficiency in hybrid welding condition decreases about 10 % rather than it in single heat source of TIG or MIG arc. Moreover, in specific condition that value of TIG current is lower than value of MIG current, output of TIG power source becomes entirely zero even though TIG arc shape is observed clearly, and thus, the stability of MIG arc is lost then. It can be said that these findings reveal the existence of direct current and explain one of mechanisms that TIG arc can control the arc stability and heat input of MIG arc.

Similar content being viewed by others

References

Kanemaru S, Sasaki T, Sato T, Mishima H, Tashiro S, Tanaka M (2012) Study for TIG-MIG Hybrid Welding Process, IIW Doc.XII-2101-12

Kanemaru S, Sasaki T, Sato T, Mishima H, Tashiro S, Tanaka M (2012) 3D Numerical analysis model for TIG-MIG hybrid welding process. Q J Jpn Weld Soc 30(1):29–34 (in Japanese)

Morimoto K, Doi T, Manabe H, Ahmed T, Hiraki E, Hyun-woo L, Nakaoka M (2006) Advanced high power DC-DC converter using a novel type voltage source full-bridge soft-switching PWM inverter with high frequency transformer link for Arc welding applications, the transactions of the institute of electrical engineers of Japan. D, A Publ Ind Appl Soc 126(3):237–247, in Japanese

Liskevych O, Quintino L, Vilarinho LO, Scotti A (2013) Intrinsic errors on cryogenic calorimetry applied to arc welding. Weld World 57(3):349–357

Author information

Authors and Affiliations

Corresponding author

Additional information

IIW-2517, recommended for publication by Study Group SG-212 “The Physics of Welding”.

Rights and permissions

About this article

Cite this article

Kanemaru, S., Sasaki, T., Sato, T. et al. Study for the mechanism of TIG-MIG hybrid welding process. Weld World 59, 261–268 (2015). https://doi.org/10.1007/s40194-014-0205-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0205-0