Abstract

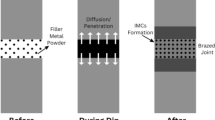

In this paper, a metallic foam interlayer is used to relieve the stresses between the ceramic to metal brazed joint. The brazing of Al2O3 and 1Cr18Ni9Ti stainless steel was accomplished using different thicknesses of Ni foam interlayer. The shear test of the brazing joint was carried out, and the maximum shear strength of 119.86 MPa was achieved when using 0.2 mm thickness Ni foam as an interlayer. The microstructures and chemical compositions of the joint interfaces were investigated by scanning electron microscopy. It was found that the change of the distribution of element Ti in the interface would restrain the formation of brittle intermetallic compounds when using a Ni foam as the interlayer, which drastically improves the performance of the brazed joint.

Similar content being viewed by others

Abbreviations

- SiC:

-

Silicon carbide

- DSC:

-

Differential scanning calorimetry

- SEM:

-

Scanning electron microscope

- EDS:

-

Energy dispersive spectrometry

References

Kar A, Sudipta M, Venkateswarlu K (2007) Characterization of interface of Al2O3-304 stainless steel braze joint. Materials Characterization 58:555–562

Travessa D, Ferrante M, den Ouden G (2002) Diffusion bonding of aluminium oxide to stainless steel using stress relief interlayers. Materials Science and Engineering A 337:287–296

Yang M, Lin T, He P (2012) Cu + TiB2 composite filler for brazing Al2O3 and Ti-6Al-4 V alloy. Journal of Alloys and Compounds 512:282–289

Kar A, Mainak hosh G, Kumar Ray A (2008) Effect of interfacial thickness and residual stress on the mechanical property of the alumina-stainless steel braze joint interface. Materials Science and Engineering A 498:283–288

Yang M, He P, Lin T (2013) Effect of brazing conditions on microstructure and mechanical properties of Al2O3/Ti-6Al-4 V alloy joints reinforced by TiB whiskers. J Mater Sci Technol 29(961–970)

Liu WS, Cai QS, Ma YZ (2013) Microstructure and mechanical properties of diffusion bonded W/steel joint using V/Ni composite interlayer. Materials Characterization 86:212–220

Barrena MI, Gómez de Salazar JM, Gómez-Vacas M (2014) Numerical simulation and experimental analysis of vacuum brazing for steel/cermet. Ceramics International 40:10557–10563

Yue X, He P, Feng JC (2008) Microstructure and interfacial reactions of vacuum brazing titanium alloy to stainless steel using an AgCuTi filler metal. Materials Characterization 59:1721–1727

Kliauga AM, Travessa D, Ferrante M (2001) Al2O3/Ti interlayer/AISI 304 diffusion bonded joint microstructural characterization of the two interfaces. Materials Characterization 46:65–74

Park J-W, Mendez PF, Eagar TW (2005) Strain energy release in ceramic-to-metal joints by ductile metal interlayers. Scripta Materialia 53:857–861

Jadoon AK, Ralph B, Hornsby PR (2004) Metal to ceramic joining via a metallic interlayer bonding technique. Journal of Materials Processing Technology 152:257–265

Dong-hau KUO, Kai-Ting YEH, Ren-Kae SHIUE (2011) Joining of Al2O3 to 316SS using braze-infiltrated Ni Net. ISIJ International 51:1017–1019

Yang W, He P, Lin T (2013) Diffusion bonding of ZrB2-SiC and Nb using dynamic compressed Ni foam interlayer. Materials Science and Engineering A 573:1–6

Jarvis T, Voice W, Goodall R (2011) The bonding of nickel foam to Ti-6Al-4 V using Ti-Cu-Ni braze alloy. Materials Science and Engineering A 528:2592–2601

Shirzadi AA, Zhu Y, Bhadeshia HKDH (2008) Joining ceramics to metals using metallic foam. Materials Science and Engineering A 496(501–506)

Acknowledgments

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (NSFC, Grant number 11372019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2536 recommended for publication by Commission XVII “Brazing, Soldering, and Diffusion Bonding.”

Rights and permissions

About this article

Cite this article

Zhu, Y., Qi, D., Guo, W. et al. The braze joint between Al2O3 to 1Cr18Ni9Ti using a nickel foam. Weld World 59, 491–496 (2015). https://doi.org/10.1007/s40194-015-0224-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0224-5