Abstract

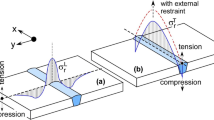

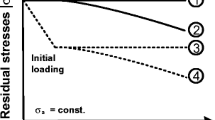

This paper starts with a brief state of the art assessment on what has been learned over the last few decades in understanding residual stress development mechanisms, particularly those uniquely associated with weld repairs. A special emphasis will be given to how some of the residual stress features contribute to structural integrity of a component containing weld repairs. In contrast to initial fabrication welds, residual stresses associated with finite length repair welds tend to exhibit important invariant features, regardless of component configurations, materials, and to some degree, welding procedures. Such invariant features are associated with the severe restraint conditions present in typical repair situations. A number of weld repair cases are examined in this paper. In addition to highlighting important residual stress distribution features, fracture mechanics calculations are performed to examine how repair weld residual stresses quantitatively contribute to crack driving force as a function of crack location and size. One simple and effective technique for mitigating detrimental residual stress effects on structural integrity is also demonstrated by considering overall weld repair dimensions.

Similar content being viewed by others

References

Dong P, Hong JK, Rogers P (1998) Analysis of residual stresses in AI-Li repair welds and mitigation techniques. Welding J Res Supplement 77:439-s

Dong P, Hong JK, Zhang J, Rogers P, Bynum J, Shah S (1998) Effects of repair weld residual stresses on wide-panel specimens loaded in tension. J Press Vessel Technol 120(2):122–128. https://doi.org/10.1115/1.2842229

George, D., Smith, D.J., and Bouchard, P.J. (1999) Evaluation of through wall residual stresses in stainless steel repair welds, Proc. Fifth European Conference on Residual Stresses (ECRS5) Delft-Noordwijkerhout, The Netherlands

Bouchard PJ, George D, Santisteban JR, Bruno G, Dutta M, Edwards L, Kingston E, Smith DJ (2005) Measurement of the residual stresses in a stainless steel pipe girth weld containing long and short repairs. Int J Press Vessel Pip 82(4):299–310. https://doi.org/10.1016/j.ijpvp.2004.08.008

Dong P, Brust FW (2000) Welding residual stresses and effects on fracture in pressure vessel and piping components: a millennium review and beyond, The Millennium Issue, ASME Transactions. J Press Vessel Technol 122(3):329–328. https://doi.org/10.1115/1.556189

Dong P, Zhang J, Bouchard PJ (2002) Effects of repair weld length on residual stress distribution. J Press Vessel Technol 124(1):74–80. https://doi.org/10.1115/1.1429230

Dong P, Hong JK, Bouchard PJ (2005) Analysis of residual stresses at weld repairs. Int J Press Vessel Pip 82(4):258–269. https://doi.org/10.1016/j.ijpvp.2004.08.004

Zhang, J., Dong, P., and Brust, F.W. (1997) A 3-D composite shell element model for residual stress analysis of multi-pass welds, Transactions of the 14th International Conference on Structural Mechanics in Reactor Technology (SMiRT 14), Lyon, France, Vol. 1, pp. 335–344

Dong P (2001) Residual stress analyses of a multi-pass girth weld: 3-D special shell versus axisymmetric models. J Press Vessel Technol 123(2):207–213. https://doi.org/10.1115/1.1359527

BS7910:2013 (2013) Guide to Methods of Assessing the Acceptability of Flaws in Metallic Structures. British Standards Institution, London

EDF Energy (2015) R6: assessment of the integrity of structures containing defects, Revision 4, with amendments to Amendment 11, Gloucester

American Petroleum Institute/ASME (2007) Fitness-for-Service, API 579-1/ASME FFS-1, Washington DC

Dong P (2014) Residual Stresses in Weld Repairs. In: Hetnarski RB (ed) Encyclopedia of Thermal Stresses. Springer, Dordrecht

Song S, Dong P (2016) Residual stresses at weld repairs and effects of repair geometry. Sci Technol Weld Join 22(4):265–277. https://doi.org/10.1080/13621718.2016.1224544

Dong P (2008) Length scale of secondary stresses in fracture and fatigue. Int J Press Vessel Pip 85(3):128–143. https://doi.org/10.1016/j.ijpvp.2007.10.005

Dong P, Song S, Zhang J, Kim MH (2014) On residual stress prescriptions for fitness for service assessment of pipe girth welds. Int J Press Vessel Pip 123:19–29

Brust FW, Dong P, Zhang J (1997) A constitutive model for welding process simulation using finite element methods. In: Atluri S, Yagawa G (eds) Advances in Computational Engineering Sciences. Tech Science Press, Anaheim, pp. 51–56

Dong P, Song S, Zhang J (2014) Analysis of residual stress relief mechanisms in post-weld heat treatment. Int J Press Vessel Pip 122:6–14. https://doi.org/10.1016/j.ijpvp.2014.06.002

Dong P, Song S, Pei X (2016) An IIW residual stress profile estimation scheme for girth welds in pressure vessel and piping components. Weld World J 60(2):283–298. https://doi.org/10.1007/s40194-015-0286-4

Song S, Dong P, Pei X (2015) A full-field residual stress estimation scheme for fitness-for-service assessment of pipe girth welds: Part II–A shell theory based implementation. Int J Pres Vess Pip 128(4/30):8–17

Song S, Dong P, Pei X (2015) A full-field residual stress estimation scheme for fitness-for-service assessment of pipe girth welds: Part I—Identification of key parameters. Int J Press Vess Pip 126-127(1/20):58–70

Song S, Dong P (2016) A framework for estimating residual stress profile in seam-welded pipe and vessel components part I: weld region. Int J Press Vessel Pip 146:74–86. https://doi.org/10.1016/j.ijpvp.2016.07.009

Song S, Dong P (2016) A framework for estimating residual stress profile in seam welded pipe and vessel components part II: outside of weld region. Int J Press Vessel Pip 146:65–73. https://doi.org/10.1016/j.ijpvp.2016.07.010

Ashok N, Dong P, Zhang J, Brust F, Dong Y (2004) Method for determining a model for a welding simulation and model thereof, US Patent 6,768,974s

Acknowledgments

The authors acknowledge the support of this work through a grant from the National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) through GCRC-SOP at the University of Michigan under Project 2-1: Reliability and Strength Assessment of Core Parts and Material System and a grant from the State Key Laboratory of Advanced Welding and Joining, under grant no. 13-M-02.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission X - Structural Performances of Welded Joints - Fracture Avoidance

Rights and permissions

About this article

Cite this article

Dong, P. On repair weld residual stresses and significance to structural integrity. Weld World 62, 351–362 (2018). https://doi.org/10.1007/s40194-018-0554-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0554-1