Abstract

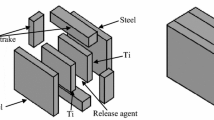

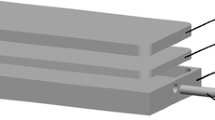

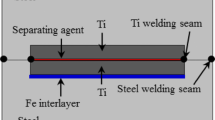

Vacuum hot roll bonding (VHRB) was used to bond pure titanium (Ti) plate to a 304 stainless steel (SS) plate with a niobium (Nb) interlayer, with the aim of producing a high-quality Ti-SS clad plate. The roll-bonding process was performed at different temperatures in the range of 850–1000 °C, followed by characterization of microstructure and mechanical properties. The study demonstrates that the interfaces are free from cracks and discontinuities, and interdiffusion between the stainless steel and the titanium is effectively prevented by inserting a layer of pure Nb foil. No intermetallic reaction layer occurred at the Nb-Ti interface at any of the investigated temperatures. An intermetallic FeNb phase was formed at the Nb-SS interface when bonding was performed at 950 °C and above. The presence of the FeNb layer was confirmed by x-ray diffraction. The maximum shear strength of ∼396 MPa was obtained when bonding is carried out at 900 °C. However, the formation of the FeNb layer at roll bonding temperature greater than 900 °C led to decrease in shear strength. Ductile fracture occurred through the Ti-Nb interface for roll-bonded temperatures of up to 900 °C. On the other hand, at temperature of 950 °C and above, failure occurred through the Nb-SS interface, with brittle fracture characteristics.

Similar content being viewed by others

References

G. Lutjering and J.C. Williams, Titanium, Springer, Berlin, 2007, pp. 5–18.

M. Ghosh and S. Chatterjee, Mater. Charact. 54 (2005) 327.

K. Fumio, Surf. Interface. Anal. 12 (1988) 203.

P. Manikandan, K. Hokamoto, M. Fujita, K. Raghukandan and R. Tomoshigee, J. Mater. Process Technol. 195 (2008) 232.

S. A.A. Akbari Mousavi and P. Farhadi Sartangi, Mater. Des. 30 (2009) 459.

J. Song, A. Kostka, M. Veehmayer and D. Raabe, Mater. Sci. Eng. A 528 (2011) 2641.

F. Fehim. Mater. Design. 32 (2011) 1081.

D.S. Zhao, J.C. Yan, Y. Wang and S.Q. Yang, Mater. Sci. Eng. A 499 (2009) 282.

G.M. Xie, Z.A. Luo, G.L. Wang, L. Li and G.D. Wang, Mater. Trans. 52 (2011) 1709.

Y.M. Hwang, H.H. Hsu and Y.L. Hwang, Int. J. Mech. Sci. 42 (2000) 2417.

G.B. Kale, R.V. Patil and P.S. Gawade, J. Nucl. Mater. 257 (1998) 44.

B. Qin, G.M. Sheng, J.W. Huang, B. Zhou, S.Y. Qiu and C. Li, Mater. Charact. 56 (2006) 32.

M. Ghosh, K. Bhanumurthy, G.B. Kale, J. Krishnan and S. Chatterjee, J. Nucl. Mater. 322 (2003) 235.

T. Vigraman, D. Ravindran and R. Narayanasamy, Mater. Des. 36 (2012) 714.

M. Eroglu, T.I. Khan, N. Orhan, Mater. Sci. Technol. 18 (2002) 68.

S. Kundu and S. Chatterjeem, J. Mater. Sci. 42 (2007) 7906.

J.C. Yan, D.S. Zhao, C.W. Wang, L.Y. Wang, Y. Wang and S.Q. Yang, Mater. Sci. Technol. 25 (2009) 914.

A. Elrefaey and W. Tillmann, J. Mater. Process. Technol. 209 (2009) 2746.

S. Kundu and S. Chatterjee, ISIJ. Int. 50 (2010) 1460.

ASTM B265-11. Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate. ASTM International, 1 September, 2011.

S.A.A. Akbarimousavi and M. GohariKia, Mater. Design. 32 (2011) 3066.

ASTM B898-11. Standard Specification for Reactive and Refractory Metal Clad Plate. ASTM International, 1 September, 2011.

H. Baker, ASM Handbook: Alloy Phase Diagrams. ASM International, Ohio, 1992, pp.158–205.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, Z., Wang, G., Xie, G. et al. Interfacial microstructure and properties of a vacuum hot roll-bonded titanium-stainless steel clad plate with a niobium interlayer. ACTA METALL SIN 26, 754–760 (2013). https://doi.org/10.1007/s40195-013-0283-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-013-0283-9