Abstract

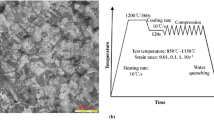

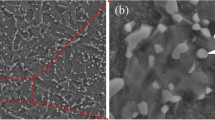

The dynamic recrystallization behavior of 25CrMo4 steel was systematically investigated by compression deformation at different temperatures and strain rates on a Gleeble 1500 thermal mechanical simulation tester. The flow curves under different deformation conditions were obtained, and the effects of deformation temperature and strain rate on the appearance of the flow curves were discussed. Based on the experimental flow curves, the activation energy determined by regression analysis was Q = 337 kJ/mol, and the constitutive model was constructed. All the characteristic points of the flow curves were identified from the work hardening rate curves (\(\theta = {\text{d}}\sigma /{\text{d}}\varepsilon \;{\text{vs}} \;\sigma\)), which were derived from the flow curves. Then, the kinetics model of dynamic recrystallization was determined by combining the Avrami equation with the stress loss resulted from the dynamic recrystallization. With the aid of the kinetics model, the effect of strain on the efficiency of power dissipation was discussed. Furthermore, the optimum parameters for the forging process were determined based on the processing maps.

Similar content being viewed by others

References

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Prog. Mater. Sci. 60, 130 (2014)

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, A.D. Rollett, Mater. Sci. Eng. A 238, 219 (1997)

H.J. McQueen, Mater. Sci. Eng. A 387–389, 203 (2004)

F. Chen, Z.S. Cui, S.J. Chen, Mater. Sci. Eng. A 528, 5073 (2011)

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, M. He, Mater. Des. 57, 568 (2014)

G. Gottstein, M. Frommert, M. Goerdeler, N. Schafer, Mater. Sci. Eng. A 387–389, 604 (2004)

E.I. Poliak, J.J. Jonas, Acta Mater. 44, 127 (1996)

A. Najafizadeh, J.J. Jonas, ISIJ Int. 46, 1679 (2006)

A.I. Fernández, P. Uranga, B. López, J.M. Rodriguez-Ibabe, Mater. Sci. Eng. A 361–362, 367 (2003)

Y.C. Lin, X.M. Chen, Mater. Des. 1733, 32 (2011)

Y. Wu, M. Zhang, X. Xie, J. Dong, F. Lin, S.Q. Zhao, J. Alloys Compd. 656, 119 (2015)

F.S. Qu, Z.Y. Reng, R.R. Ma, Z.H. Wang, D.M. Chen, J. Alloys Compd. 663, 552 (2016)

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Mater. Trans. A 15, 1883 (1984)

Y.V.R.K. Prasad, T. Seshacharyulu, Int. Mater. Rev. 43, 243 (1997)

H. Ziegler, Progress in solid mechanics (Wiley, New York, 1983), p. 93

A.K.S. Kalyan Kumar, Dissertation, Indian Institute of Science, 1987

Y.V.R.K. Prasad, Indian J. Technol. 28, 435 (1990)

N. Khanafi-Benghalem, E. Felder, K. Loucif, P. Montmitonnet, Wear 268, 23 (2010)

Y.M. Huo, B.Y. Wang, Q. Bai, J.G. Lin, Key Eng. Mater. 622–623, 679 (2014)

J.P. Luo, Y.X. Zhong, Q.X. Ma, X. Gao, Forg. Stamp. Technol. 35, 117 (2010)

J.J. Jonas, X. Quelennec, L. Jiang, E. Martin, Acta Mater. 57, 2748 (2009)

H. Miura, H. Aoyama, T. Sakai, J. Jpn. Inst. Met. 58, 267 (1994)

H. Miura, T. Sakai, R. Mogawa, J.J. Jonas, Philos. Mag. 87, 4197 (2007)

C. Zener, H. Hollomon, J. Appl. Phys. 15, 22 (1944)

C.M. Sellars, Acta Metall. 14, 1136 (1966)

J.L. Uvira, J.J. Jonas, Trans. Metall. Soc. AIME 1619, 242 (1968)

S. Naghdy, A. Akbarzadeh, Mater. Des. 53, 910 (2014)

L. Chen, Y.J. Zhang, F. Li, X.G. Liu, B.F. Guo, M. Jin, Mater. Sci. Eng. A 663, 141 (2016)

C. Zhang, L.W. Zhang, W.F. Shen, C.R. Liu, Y.N. Xia, R.Q. Li, Mater. Des. 804, 90 (2015)

Z.W. Cai, F.X. Chen, F.J. Ma, J.Q. Guo, J. Alloys Compd. 670, 55 (2016)

Acknowledgement

This work was financially supported by the National Basic Research Program of China (No. 2011CB012903).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Zhou, P., Ma, QX. Dynamic Recrystallization Behavior and Processing Map Development of 25CrMo4 Mirror Plate Steel During Hot Deformation. Acta Metall. Sin. (Engl. Lett.) 30, 907–920 (2017). https://doi.org/10.1007/s40195-017-0613-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0613-4