Abstract

It is essential to capture CO2 from flue gas stream, which is considered as one of the prime reasons of global warming. Although various CO2 capture technologies already exist, most of these techniques are still unfit to be employed at a large scale. In the past one decade, oxides have emerged as a strong candidate to capture CO2 for post-, pre- and oxy-combustion conditions. Oxides combine with CO2 present in the flue gas and form carbonate, which when heated regenerates the oxides and thus liberates almost pure stream of CO2. The selection criteria for potential oxides entail their CO2 capture capacity, absorption rate, thermal stability, regeneration heat, cost and structural properties. Thus, here, we review the technical merit of all the suitable oxides which can be used for CO2 capture at any fossil fuel burning plants.

Similar content being viewed by others

Introduction

The problem of carbon dioxide (CO2) emission from various fossil fuel burning plants (such as power, steel, cement and gasifiers) has become an important issue that may tremendously affect our future survival. Carbon dioxide, one of the greenhouse gasses, contributes to the global warming effect once released into the atmosphere [1, 2]. CO2 is thus far regarded as the most important contributor to global warming and accounts for 64 % of the increased greenhouse effect [3]. At present, there is ample scientific evidence to support the claim that global warming is human induced [4]. Many researchers believe that if such extensive use of fossil fuels continues for another 50 years, the CO2 concentration will rise to 580 ppm, which would trigger a severe climate change.

The atmospheric concentration of CO2 rose from 280 ppm in 1,800 to 397.8 in early 2014. Figure 1a presents the world energy-related CO2 emissions. According to International Energy Outlook (IEO) 2013, the emission is projected to grow from 31.2 billion metric tons in 2010 to 45.5 billion metric tons in 2040. As expected, much of the growth is attributed to the developing countries (non-OECD). Non-OECD countries heavily rely on the supply of fossil fuels to meet their energy demand. The CO2 emissions from the use of different fuel types such as coal, liquid fuels and natural gas are shown in Fig. 1b. Effluent emissions from coal use account for 44 % in 2010 and are projected to increase to 47 % in 2020–2030, before dropping marginally to 45 % in 2040. Liquid fuels have the slowest growth, resulting in an increment of only 3.5 billion metric tons of CO2 from 2010 to 2040. The world consumption of natural gas is growing more rapidly than that of coal or liquid fuel. As natural gas has relatively low carbon intensity, its projected contribution to world energy-related CO2 emissions is only 22 % in 2040.

Currently, most of the world energy requirement for transportation and heating (two-thirds of the primary energy demand) is satisfied through petroleum and natural gas. These two fuels are generally chosen due to the relative ease of transportation of liquid or gaseous forms. It is noteworthy that the combustion of hydrocarbon fuels for transportation and heating contributes over half of all greenhouse gas emissions and a large fraction of air pollutant emissions. The current carbon emissions have to be reduced by at least a factor of three to maintain the CO2 level in the atmosphere while meeting the ever-increasing global energy demand.

Therefore, it is essential to capture CO2 from the industrial flue gas stream, one of the leading contributors of the anthropogenic gasses [5]. The development of carbon capture and sequestration (CCS) technologies can be seen as a viable solution to mitigate the vast carbon emission. The separation of a pure CO2 stream, combined with a well-managed geological storage site, is being considered as a mitigation option for climate change. The CCS technologies could be applied using available technologies as many of the components in these systems are already in use. However, it is widely accepted that there is a large scope for cost reduction and energy efficiency improvements in CO2 capture systems.

Currently, various CO2 capture technologies exist including physical absorption [6, 7], chemical absorption [8, 9], adsorption [10] and membranes [11]. However, they are still far from being considered as a technologically viable solution. The obvious bottlenecks are the huge amount of flue gas which needs to be treated as well as low mass transfer rate during the processes. Among all the proposed techniques, chemical absorption using aqueous alkanolamine solutions is the most conventional way for CO2 capture. But these amine-based solutions suffer severe drawbacks such as high energy consumption in regeneration process, high corrosive rate of equipment, essential pretreatment steps, large absorber volume and high sorbent cost. Because of these limitations of the chemical absorption techniques, an alternative way for post-, oxy- or pre-combustion CO2 capture at fossil fuel burning power plants, mainly a solid adsorption/absorption method, can be proposed.

A schematic diagram on Fig. 2 is depicted to demonstrate the concept of cyclic CO2 capture process by metal oxides. The metal oxides (MO), such as CaO and MgO, combine with CO2 to form thermodynamically stable carbonates. Metal carbonates, when heated, liberate pure stream of CO2 gas and regenerate the oxides. The combined use of exothermic carbonation reaction and endothermic regeneration reaction forms a cyclic process. Eventually, the generated pure CO2 gas can either be sequestered underground or used for enhanced oil recovery [12]. In general, any metal oxides that can qualify for CO2 capture application must be abundant in earth’s crust, react with CO2 at low temperature, require low regeneration energy, should have suitable reaction kinetics and must form a carbonate that is stable in the environment at ambient conditions. Porous oxides, namely alkali and alkaline-earth metals, have been reported as promising candidates for CO2 capture. These metal oxides possess properties such as long durability, good mechanical strength, wide availability, and low cost since they are present as natural minerals and high CO2 absorption capacity at moderate working temperatures [13–16]. In this study, we review the CO2 capture capacity of these different potential oxides.

Selection criteria for metal oxides

Recently, researchers proposed a theoretical screening methodology to identify the most promising CO2 sorbent candidates from the vast array of possible solid materials [17–19]. The methodology uses both the thermodynamic database searching with first principles density functional theory and phonon lattice dynamics calculations. The thermodynamic properties of solid materials are used for computing the thermodynamic reaction equilibrium properties of CO2 absorption/desorption cycle based on the chemical potential and heat of reaction analysis. The selection is based on the pre- and post-combustion technologies and conditions in power plants. This includes only those solid materials that may be suitable as CO2 sorbent candidates and further be considered for experimental validation, if they meet the following criteria: lead to lowering in energy cost for the capture and regeneration process and could operate at desired conditions of CO2 pressure and temperature. Figure 3 illustrates the thermodynamic properties and CO2 wt% absorbed by different metal oxides. However, the thermodynamic properties and CO2 wt% absorbed by any sorbent could not be the only factors to select them for experimental studies. Various other important parameters such as availability or cost, regeneration temperature, kinetics, reversibility and durability must also be carefully considered before selecting any metal oxides for a large-scale application.

Based on the above figure, it can deduce that BeO has a favorable thermodynamics, but this system is not a viable candidate for CO2 capture because of the health issues related to beryllium powder or dust. It should be noted that a high exothermic forward reaction (MO(s) + CO2 (g) = MCO3(s)) generally requires a large regeneration temperature for the oxide (MCO3(s) = MO (s) + CO2 (g)). Also, a low CO2 wt% (~40–50) will require a large amount of the solid materials to deal with a huge volume of flue gas stream at any fossil fuel burning plants. Thus, a high regeneration temperature and low CO2 wt% can cause a vast energy or carbon emission penalty. Moreover, such oxides can eventually increase the electricity cost by a significant factor and thus may not be suitable for CO2 capture at any plants.

The turnover temperature represents the value above which sorbents cannot absorb CO2 and the release of CO2 begins. The flue gas conditions are different for pre- and post-combustion CO2 capture at power plants. Under pre-combustion conditions, after water–gas shift reaction, the gas stream mainly contains CO2, H2O and H2. The partial CO2 pressure in this case is around 20–25 bar, and the temperature is about 300–350 °C. But for post-combustion conditions, the flue gas stream mainly contains CO2 and N2. In this case, the partial pressure of CO2 is around 0.1–0.2 bar, while the temperature range can vary around 27–77 °C. The goal set up by the US Department of Energy is to capture at least 90 % CO2 with an increase in the electricity cost of no more than 10 and 35 % for pre- and post-combustion technologies, respectively [20]. To minimize the energy consumption, the ideal sorbents should work in the above-indicated pressure and temperature ranges to separate CO2 from H2. A list of turnover temperatures for different oxides can be found elsewhere [17–19].

Based on the above-discussed limitations, exclusively few oxides seem to be promising and thus chosen to study for the experimental validation. The two alkaline-earth metal oxides (such as CaO and MgO) draw the tremendous attention because of accessibility and favorable thermodynamics. Recently, lithium-, sodium- and potassium-based silicates or zirconates also gained interest due to their high CO2 absorption capacity. Moreover, FeO can also be seen as a promising material for CO2 capture at both power and non-power sectors (iron and steel industry). In the following sections, we review the experimental studies for the most promising CO2 sorbent candidates.

Metal oxides

Alkali metal-based oxides

Lithium zirconate (Li2ZrO3)

The reaction between lithium carbonate (Li2CO3) and zirconium dioxide (ZrO2) is well known to synthesize lithium zirconate (Li2ZrO3). However, the reverse reaction was not considered for CO2 capture until 1998 [21]. Nakagawa and Ohashi first investigated the capture of CO2 using Li2ZrO3 at high temperatures (400–600 °C) [21]. Li2ZrO3 has great potential because it has an excellent CO2 sorption capacity (28 wt%) as well as a small volume change during the CO2 sorption/desorption cycles [22]. The reaction (1) occurs mainly due to the Li ion mobility in the ceramics [23, 24]. As can be seen from Fig. 4, during CO2 sorption, the Li ions diffuse from the core of the particles to the surface and react with CO2 to form Li2CO3. The diffusion of CO2 in the solid Li2CO3 is recognized as the rate-limiting step.

The separation of CO2 with aid of Li2ZrO3 works in a temperature range of 450–700 °C. The main advantage of this new material with respect to calcium-based absorbents is its unique thermal stability that allows achieving many absorption/regeneration cycles (over 20) without loss of capacity. Previous reports suggest that only 11–13 wt% change after absorption of CO2 using Li2ZrO3 at 500–700 °C in more than an hour is possible. Thus, it is evident that Li2ZrO3 has extremely slow absorption kinetics, and hence, recently, the addition of dopants was proposed as a solution. Hence, the addition of dopants such as K2CO3 and Y2O3 to Li2ZrO3 could potentially accelerate its CO2 sorption kinetics.

In the case of the pure Li2ZrO3 (without K2CO3 additive), formation of an impervious shell of Li2CO3 on the surface leads to a residual unreactive Li2ZrO3 core (Fig. 4). This observation suggests that the diffusion resistance of CO2 through the solid Li2CO3 surface layer is the rate-limiting step. At 500 °C, Li2CO3 and K2CO3 form a eutectic mixture. During the absorption process, the eutectic mixture helps to diffuse more CO2 toward the inner unreacted particles [25]. K2CO3- and Li2CO3-containing Li2ZrO3 sample reacts with gaseous CO2 at 500 °C to form an outer layer of a molten liquid and a solid interior ZrO2 core. Consequently, CO2 diffuses through the molten carbonate layer at a much faster rate. Such difference in CO2 sorption rate of doped and undoped Li2ZrO3 can be partially attributed to the molten carbonate layer.

Another dopant, Y2O3, can improve the O−2 ionic diffusion in the ZrO2 layer that is formed during the absorption. Unfortunately, Y2O3 failed to increase the CO2 absorption kinetics of Li2ZrO3 [26]. Other findings reveal that solid solutions of lithium and potassium meta zirconates (Li2−xK x ZrO3) increase both the kinetics and CO2 absorption capacity compared to undoped Li2ZrO3 [27]. In the same line, solid solutions of lithium and sodium zirconates were also explored [28]. It was concluded that the higher the Na content in the samples the faster the absorption kinetics. On the contrary, the higher the Li content in the mixture the faster the regeneration kinetics.

Lithium orthosilicate (Li4SiO4)

Lithium silicate-based (Li4SiO4) sorbent material has been considered as a promising candidate for high-temperature CO2 removal in the recent times [29, 30]. Li4SiO4 could adsorb different concentrations of CO2 in the temperature range of 450–700 °C, but it has relatively (compared to amine solutions) higher decomposition temperature (>800 °C). A high decomposition temperature implies that more heat input and costly equipment would be required to perform the process. However, compared to other solid sorbents such as CaO, the decomposition temperature is low and thus less supply of energy will be needed [31]. As can be calculated from reaction (2), the theoretical CO2 adsorption capacity of Li4SiO4 is 36.7 wt% (~8.34 mmol CO2/g Li4SiO4).

In a study, Wang et al. [32] reported an interesting way to synthesize Li4SiO4 using rice husk, which were calcined at 800 °C in the presence of Li2CO3. This material is ideally suited for CO2 removal from synthesis gas (syngas) derived from gasification of carbonaceous fuels (coal, coke, natural gas, biomass, etc.) and is hence considered as a pre-combustion CO2 sorbent.

Li4SiO4 has shown the ability to remove more than 90 % of the CO2 from simulated syngas in both fixed-bed and fluidized-bed process configuration. The lithium silicate-based sorbent is highly effective at temperatures of 250–550 °C, pressures of 0–20 atm, CO2 concentrations of 2–20 % and in the presence of contaminants such as hydrogen sulfide. Yamachui et al. [33] reported a carbonation yield of 87.2 % under 100 cm3/min flow rate of pure CO2. The water vapor plays a major role in increasing the CO2 absorption rates of Li4SiO4. About 22–26 wt% (capacities of ~5−6 mmol/g) were obtained using a gas stream containing about 15 % CO2 and 10 % H2O in N2 at 550 °C [34]. Moreover, the sorbent has shown excellent regenerability and attrition resistance in thermal cycling tests. Recent analysis has shown that the lithium silicate-based sorbent has the capability not only to separate CO2 from syngas, but also to promote the water–gas shift reaction [35]. It is reported that dopants such as Al, Fe, Na, K and Cs increase the CO2 uptake of lithium orthosilicate [36, 37].

Researchers have attempted to improve the reaction kinetics of CO2 adsorption by altering the synthesis routes [38]. The new methods are aimed at reducing the particle size of Li4SiO4. The experimental results reveal that a smaller particle size yields higher CO2 adsorption efficiency and adsorption rate. Further studies focused on decreasing the precursor particle size [39] or choosing more sintering-resistant precursor to result in the smaller product grain size [40]. Similarly, based on the particle size effects on Li4SiO4, the reactivity of Li4SiO4 was modeled as a reaction of CO2 at the solid surface followed by the rate-limiting diffusion of lithium [41].

A calculation based on the most optimistic assumptions illustrates that despite the fact that Li4SiO4-based absorbent demonstrates high CO2 uptake capacity, it would be impractical to perform the process at the scale of a fixed-bed temperature swing process at a 500-MW coal-fired power plant [34]. However, efforts have been made to modify the Li4SiO4 synthesis methods such as solid-state reactions [30, 42], sol–gel method [38, 43], impregnated suspension [44], precipitation method [45], amorphous silica [40], Quartz [39], fly ashes [46], rice husk ashes [47] and diatomite [48].

Sodium zirconate (Na2ZrO3)

Sodium zirconate has gained attention due to its favorable thermodynamics and high theoretical CO2 sorption capacity [23, 49, 50]. Na-based sorbents can be used as solid CO2 acceptors at high temperatures. The use of sodium-based oxides is more economical than lithium-based oxides. Moreover, previous reports suggest that Na2ZrO3 can have a better reaction rate than the synthetic sorbents such as Li2ZrO3 and Li4SiO4 [51].

Na2ZrO3 has a lamellar structure, where sodium ions are located among the zirconate layers, which permits for sodium diffusion. The mechanism for CO2 chemisorption on Na2ZrO3 has already been proposed. Initially, the surface of the alkaline ceramic particles reacts with CO2 and forms carbonates on the periphery. Once the external layer of carbonate is completely formed, sodium atoms have to diffuse throughout this external carbonate shell to reach the surface and be able to react with CO2.

The maximum theoretical CO2 absorption should correspond to an increase of weight equal to 23.75 wt%. The reaction (3) is controlled by two different processes—CO2 absorption over the surface of Na2ZrO3 particles and sodium diffusion. Alcerreca-Corte et al. [52] performed the kinetic analysis for chemisorption of CO2 on the Na2ZrO3 particles in the temperature range of 150–700 °C. A fast kinetics was observed between 550 and 700 °C. However, at low temperatures, kinetics was relatively low and was attributed to the sintering effect as well as diffusion problems. The optimum temperature for the reaction (3) was 600 °C. All the isotherms were fitted to a double exponential model. The activation energies for the CO2 absorption and the diffusion of sodium were calculated to be 33.87 and 48.01 kJ/mol, respectively. Therefore, it was concluded that sodium diffusion is the limiting step of the process. Similarly, Jimenez et al. reported the CO2 sorption kinetics of Na2ZrO3 at similar temperatures and \( P_{{{\text{CO}}_{2} }} \) = 0.4–0.8 atm. Contrary to previous study, the surface reaction is identified to be the rate-limiting step for the reaction and attributed to the fast CO2 sorption kinetics of Na2ZrO3 [53].

In general, the addition of steam enhances the capture kinetics and also favors the regeneration. It is believed that the presence of steam increases the mobility of alkaline ions and therefore accelerates the reactions. Therefore, several studies have been performed to evaluate the effect of steam addition on the CO2 capture properties of Na2ZrO3 [54, 55]. One such study was performed by Santillán-Reyes et al. in the presence of water vapor and low temperature range (30–70 °C). They synthesized Na2ZrO3 by solid-state reaction using the reagents Na2CO3 and ZrO2 in the molar ratio of 1.1:1.0, respectively. Further, the reaction mechanism of Na2ZrO3–CO2–H2O was proposed and illustrated in (4). Na2ZrO3 reacts with water vapor to produce hydroxyl species at the particle surfaces and then absorbs 2 mol of CO2 and 1 mol of H2O to eventually form NaHCO3 and ZrO2.

Na2ZrO3 was able to absorb 5.8 mmol/g of CO2 (which has theoretical capacity is 10.8 mmol/g). Therefore, Na2ZrO3 can also be used as CO2 sorbent at low temperatures and in the presence of water vapor. The reported absorption results for Na2ZrO3 are still higher than for other materials in the same temperature conditions (≤6 mmol/g of material) [56].

Nanosized materials are expected to increase the CO2 capture/regeneration rates due to their improved characteristics, such as high surface area and higher surface reactivity because of unsaturated bonds on their pristine surfaces [57–59]. Therefore, Zhao et al. synthesized nanosized Na2ZrO3 using a soft-chemical route starting with the formation of a complex from zirconoxy nitrate and sodium citrate, followed by highly exothermic reaction between citrate and nitrate during calcination in a controlled atmosphere [49]. It was found that much faster CO2 capture rates can be achieved on the monoclinic Na2ZrO3 compared to the hexagonal one, even at a very low CO2 pressure (0.025 bar). Thus, a higher CO2 capture rate is obtained for nanosized Na2ZrO3 due to the dual effect of its crystal size and structure.

Moreover, the doping effect of Li to Na2ZrO3 was investigated. The change in sorption/regeneration kinetics was evident from the experimental data. The greater the Li content, the lower the CO2 sorption kinetics. This observation can be attributed to the fact that Li substitutes some of the Na in the Na2ZrO3 structure and results in the formation of small amount of Li2ZrO3 [60]. Lopez-Ortiz et al. concluded that the highest activity toward CO2 sorption was exhibited by Na2ZrO3, followed by sodium antimoniate (Na3SbO4) and finally sodium titanate (Na2TiO3). Other applications for Na2ZrO3 may involve its use for the development of inorganic membranes for CO2 separations [24, 61].

Sodium metasilicate (Na2SiO3)

Sodium metasilicate has not yet been extensively examined. One of the first studies illustrates the synthesis of Na2SiO3 using solid-state and precipitation methods [62]. It was noticed that Na2SiO3 can absorb only a small quantity (~1–2 wt%) of CO2 in the range of room temperature and 130 °C. Further, the kinetic analysis of CO2 absorption was also performed, and the results indicate that the sorption mechanism proceeds through a two-step process: (1) superficial chemical sorption and (2) sodium diffusion process. The calculated activation energies for surface reaction and sodium diffusion were 17.48 and 23.97 kJ/mol, respectively. The sodium diffusion is recognized as the limiting step for the carbonation process. Moreover, the CO2 absorption increases with the decrease in the particle size of Na2SiO3 and can be attributed to the subsequent increase in the surface area.

Another study was performed at much lower temperatures (30–60 °C) for the Na2SiO3–CO2–H2O system [63]. Na2SiO3 was synthesized using two methods—(1) solid-state reaction (Na2CO3 + SiO2); and (2) combustion method (NaOH, SiO2 and urea (CO (NH2)2). The reactions were performed under the flow of two different carrier gasses—N2 and CO2. In the presence of N2 as a carrier gas, Na2SiO3 traps water physically and chemically, where the water vapor adsorption and/or absorption depend on temperature and relative humidity. When CO2 was used as the carrier gas, Na2SiO3 traps both water vapor and CO2. Interestingly, the presence of water vapor promotes the higher CO2 chemisorption (>1 wt%). It can be seen in reaction series (5) that at first, Na2SiO3 reacts with water superficially, producing Na–OH and Si–OH species. Further, superficially activated Na2SiO3 combines with CO2 to form NaHCO3.

It has also been observed that under the condition of thermal humidity, Na2SiO3 absorbs up to 16.39 mmol of CO2/gm of ceramic, twice more CO2 than the quantity absorbed under dry conditions. The synthesis method of Na2SiO3 influences its CO2 capture capacity. Higher the surface area, the better is the CO2 absorption. Here, the surface areas were 0.5 and 1.6 m2/g for solid-state and combustion method, respectively. Hence, the latter has about 8.6 mmol/g CO2 capture efficiency, almost twice of that of the former sample. Thus, CO2 absorption capacity of Na2SiO3 is governed by the combined effect of water vapor and surface area. These recent results support the potential of Na2SiO3 as a CO2 capture sorbents at moderate or environmental temperatures.

Alkali-earth metal oxides

Magnesium oxide (MgO)

MgO combines with CO2 to form MgCO3. MgCO3 is thermodynamically stable at ambient conditions. A simple calculation shows that to capture 1 ton of CO2, about 0.92 ton of MgO is required (assuming 100 % conversion). Thus, it is certain that to capture CO2 using MgO at any power plant site, a large quantity of MgO will be needed. Moreover, the kinetics and recycling efficiency of MgO–CO2 reaction are also the major issues to use MgO as a sorbent for practical applications. MgO is an attractive candidate for both pre- and post-combustion capture technologies due to its low regenerating temperatures: T2 = 287 °C (post-combustion) and T1 = 447 °C (pre-combustion) [64]. One should note that MgO when recycled between naturally occurring magnesite and dolomite can cause relatively lesser energy and carbon emission penalty, respectively [65].

Many researchers studied the heterogeneous reaction between magnesium species and CO2 in the presence or absence of H2O. Although a majority of research was not directly aimed at carbon capture, still the results are valuable additions to the mineral carbonation research. The CO2 uptake capacity on different MgO sorbents at various conditions is listed in Table 1. Most of the experiments are restricted to low-temperature and ambient or low-pressure conditions. Hence, the reported sorption capacities of CO2 on MgO are not very high. In contrast, recent work of Highfield et al. reports a conversion of about 70–80 % MgO to MgCO3 in about 2 h with steam pressure between 5 and 10 % of the total pressure 20–40 bar and temperature around 300–350 °C.

One of the key factors in gas–solid reaction is the presence of water. There have been several observations when water catalyzed the reaction [80, 81]. Figure 5 depicts the absorption/adsorption model of MgO–CO2–H2O.

MgO particles are surrounded by water vapor where CO2 reacts to form CO32− ions and H+ ions. Free Mg+2 ions could further react with the CO32− ions to form MgCO3. Recently, Fagerlund et al. [78] proposed the reaction mechanism for MgO carbonation in the presence of steam:

However, MgCO3 forms an impervious layer around unreacted MgO particles and hinders the further diffusion of CO2 molecules. Thus, only increasing the amount of water vapor cannot lead to the complete carbonate conversion of MgO. Therefore, besides the amount of steam, surface properties of MgO (such as surface area, particle size and porosity) are also very crucial parameters for the carbonation process. It is observed that in the absence or low partial pressure of water vapor, MgO·2MgCO3 is formed. It can be easily calculated that the CO2 capture capacity of MgO·2MgCO3 is about two-thirds that of MgCO3. Hence, formation of MgO·2MgCO3 can significantly reduce the further uptake of CO2 by MgO particles. But at a high temperature (>350 °C), MgO·2MgCO3 decomposes to MgO.

MgO–CO2 reaction has been studied to some extent. The role of water vapor in increasing the activity of MgO is now well established. The direct relation of porosity, surface area and particle size with the carbonation yield has been examined. However, several factors such as carbonation kinetics, sorbent reversibility and durability are still not completely resolved and thus need to be investigated.

Calcium oxide (CaO)

In 1995, Silaban and Harrison proposed the method that involves the separation of CO2 at high temperatures (>600 °C) using the reversible reaction of CaO [82].

The low price (because of naturally occurring mineral, limestone) and favorable thermodynamics of CaO have attracted a lot of interest in the past one decade, and thus, the CaO–CO2 system has been extensively studied. A great advantage of calcium-based sorbents is that the absorption of CO2 can occur at temperatures above 600 °C (possibility of heat recovery) [83]. The efficiency of the CO2 capture depends on many parameters such as diffusion resistance, which depends on the size of sorbent particles, volume and the pore structure, as well as surface size and reaction kinetics [84]. These parameters influence carbonation, but many of them also affect calcination. A detailed list of recent methods used to enhance the CO2 uptake by CaO-based sorbents can be found elsewhere [85].

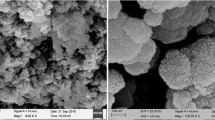

Bulk CaO, as a CO2 sorbent, has three severe limitations: (1) kinetics of the carbonation reaction, despite being highly exothermic, becomes slow after the first layer of carbonate formation because the reaction is limited by the diffusion of CO2 through the thin surface layer of CaCO3 formed on CaO [86, 87]. The uptake kinetics of CaO-based sorbents was improved by innovative synthesis methods or precursors [88, 89]. (2) Regeneration step is very energy intensive (>800°C for CaCO3 decomposition), so excessive sintering and mechanical failure of the oxide occur. This leads to a drastic loss in adsorption activity after a few sorption and regeneration cycles [90]. (3) To be an effective sorbent, CaO, that is suitable for high surface area exposure, such as a powder. However, powders can be used in fluidized beds but the pressure drop associated with them is very large. Also, use of fine powders can be problematic due to entrainment in the process flow and attrition of the material [91].

The improvement in the sorbent reversibility can be seen as a major challenge for extended operation purpose. Decrease in absorption capacity is associated with sintering of the sorbent surface because of the influence of temperature and the reduction in porosity and active surface [92–95]. Other factors that reduce the activity of sorbents are the attrition of sorbent grains during the process and chemical inactivation [96]. It should be noted that the reaction with sulfur oxide (SO2) is competitive to the carbonation reaction. Sulfurization and carbonation reactions are similar because of being heterogeneous and occurring in the porous structure of the sorbent. However, sulfurization is irreversible in the temperature range 500–900 °C, occurs in small pores and covers the surface of the sorbent [97–100]. Decrease in the absorption capacity after 45 cycles was 60 % for limestone, 40 % for dolomite and less than 20 % for huntite, and can be attributed to the differences in the sorbent structure [101]. The decrease in absorption capacity by CaO can be limited in several ways. The parameters that have impact are dopant (NaCl, Na2CO3, KCl, KMnO4, MgCl2, CaCl2, Mg (NO3)2), sorbent grain size, raw material for calcium-based sorbent, thermal pretreatment of the sorbent and steam reactivation. The properties of CaO obtained from calcium acetate are better than the properties of CaO obtained from natural limestone because it has a much better conversion and greater durability [102].

Calcium silicate (CaSiO3)

Calcium silicate received attention because it is inexpensive and has lower sorption temperature compared to CaO. Wang et al. [103] explored the sorption–desorption property of CaSiO3. CaSiO3 is synthesized through solid chemical reaction of CaCO3 and SiO2 at 800 °C. CaSiO3 starts to absorb CO2 at 400 °C with about 28.72 % sorption efficiency, using 15 % CO2 and rest N2. The observed regeneration temperature for CaSiO3 was 800 °C. However, the CO2 capture capacity drastically decreases from large number of cycles and could be attributed to sintering of the materials which leads to the loss of specific surface area. Similarly, Gupta and Fan reported that CaSiO3 captured 27.85 % CO2 at 700 °C and 1 atm [104]. Under the same conditions, Tilekar et al. reported the CO2 capture capacity of CaSiO3 to be 14.19 wt% [105]. The water molecules in the CaSiO3 facilitate the capture of CO2.

Transition metal-based oxides

Transition metal-based oxides act as an oxygen carrier in the chemical looping process. In 1983, Richter and Knoche introduced chemical looping for heat generation using metal oxides as chemical ingredients, which are now considered as a potential solution for the simultaneous power generation and CO2 capture [106]. Metal oxide (Me x O y ) is reduced by the carbonaceous fuel to generate CO2 and/or H2O in the fuel reactor. The reduced metal (Me x Oy−1) is then oxidized back to Me x O y by oxygen in the air reactor, which is an exothermic reaction. In the process, transition metal oxides (oxygen carriers) are transported within and between the fuel reactor and the air reactor.

The widely developed oxygen carriers include Ni-, Cu- and Fe-based metal oxides and their composited particles. Despite the great reactivity of Ni- or Cu-based oxygen carriers, their development is restricted because of their relatively high cost. Fe-based oxides are the strong candidates to be commercialized because of their economic feasibility. A number of reviews about the current status of the chemical looping process have been published in recent times [107–111]. Here, the focus is on the direct interaction of CO2 with transition metal-based oxides via carbonation–calcination cycle.

Iron-based oxides

Iron oxide-based materials can be used for CO2 capture purpose in both the power and non-power sectors. The main advantages of iron-based sorbent are as follows: (1) accessibility, (2) favorable thermodynamics and (3) slow degradation of sorption capacity.

Recently, Ohio State University developed an iron oxide-based oxygen carrier for particles suitable for operation in the coal direct chemical looping (CDCL) process. CDCL is an efficient power generation process. The process consists of a unique moving bed reactor, namely the reducer, where pulverized coal is fully converted using iron oxide.

Fe2O3, an oxygen carrier, is reduced to FeO and Fe while the exhaust gas is a stream of pure CO2 that can be sequestered or used for enhanced oil recovery [eq. (12)]. The reduced FeO and Fe mixture can then be oxidized to Fe2O3 using air in the combustor reactor, liberating heat to produce steam [112]. Another recent study presents the CO2 capture technique for iron and steel industries using iron-based raw materials easily available at the iron-making sites [113].

The global steel production is growing rapidly, from 1,248 Mt in 2006 to 1,490 Mt in 2011—an increase of about 16 % in a short span of 5 years [114]. Steel production is an energy intensive process and thus consumes huge amount of fossil fuels. On world average, each ton of steel production emits 2.2 ton of CO2. Therefore, iron-making industry is one of the biggest targets next to power plants to curb vast emission of greenhouse gasses.

A mixture of magnetite and iron combines with CO2 and forms siderite. The reaction generates heat and thus can be utilized to produce steam. Siderite once formed can further decompose back to magnetite in the presence of oxygen at 350 °C. Once the absorption capacity of magnetite degrades, it can be sent back to blast furnace for further processing. For example, the sorbents can be processed in a blast furnace for the production of iron or steel. Thus, the proposed method can advantageously reduce or even eliminate the loss of raw materials. This system and method can be more thermodynamically favorable and can save energy. The reversibility and suitable kinetics can make the system highly favorable for CO2 capture for iron and steel industries.

Other transition metal oxides

It is considered that MnO can be used for both post- and pre-combustion conditions. At \( P_{{{\text{CO}}_{2} }} \) = 0.1 bar, the driving force for MnO to convert in MnCO3 was high even at a low temperature 77 °C. The CO2 could be released at about 377°C at partial \( P_{{{\text{CO}}_{2} }} \) = 10 bar. For pre-combustion, MnO will capture CO2 at a partial pressure of about 10 bar below 327 °C and then could be regenerated by heating above 377 °C to produce a stream of pure CO2. According to the thermodynamics, CdO can be used for both pre- and post-combustion conditions. However, the toxicity of Cd system would be a big hurdle in its practical applications.

ZnO can be used for post-combustion but not for pre-combustion. The equilibrium temperature required for carbonate formation is 77 °C at \( P_{{{\text{CO}}_{2} }} \) = 0.1 bar and around 167 °C for \( P_{{{\text{CO}}_{2} }} \) = 10 bars [18]. Therefore, it may be essential to cool post-combustion gasses prior to carbonation for high driving force and thus make the sorbent unfit for post-combustion capture. Few researcher groups studied the heterogeneous reaction between ZnO and CO2 in the presence or absence of H2O under mild conditions. Previous experiments were performed under mild conditions, mainly room temperature and \( P_{{{\text{CO}}_{2} }} \) varied from 0.01 atmospheres to 1 atmosphere (atm) [115–117]. Basic zinc carbonate with chemical formula Zn3CO3 (OH)4·2H2O was reported as a predominant phase at these conditions. Chen et al. synthesized the compound, zinc carbonate hydroxide hydrate (JCPDS #11-0287), using chemical precipitation method [5.0 % Na2CO3 (aq.) added to 0.1 mol/L ZnSO4(aq.)] [118]. A direct relation of heating rate of the sample to its decomposition temperature was noticed. Interestingly, only one endothermic peak for zinc carbonate hydroxide hydrate was observed and was thus attributed to the combined evolution of water vapor and CO2. The decomposition temperature was observed in the range of 197–257 °C for various heating rate (5–20 °C/min).

ZnO–CO2–H2O process is favored by low operating and regeneration temperature and could be ideal for post-combustion CO2 capture. However, its application is limited due to its rare occurrence in the nature, and this could be the reason for the sparse study of ZnO–CO2 system.

Similarly, NiO can be considered for post-combustion capture, but not for pre-combustion capture. According to thermodynamics, post-combustion absorption will occur below 77 °C and NiO could be regenerated above 187 °C. However, NiO availability is still a significant concern for its practical application. Therefore, the catalytic potential of NiO leads to its huge application in the CO2 utilization field. Under sunlight, CO2 can be converted into methanol in the presence of NiO/lnTaO4 [119–121].

Perovskites

Perovskites have a stable structural framework, despite the movement of active ions into and out of the structure. Such materials have the potential to obviate the challenges associated with the other oxides. Currently, the main issues that most of the oxides face are as follows: (1) rapid degradation of their CO2 capture capacity over repeated cycles and (2) a large volume change when oxide is converted into carbonate. Recent reported experimental results have substantially attracted the interest toward perovskites, as potential CO2 capture materials.

One such study by Galven et al. investigates the CO2 adsorption behavior of Li2SrTa2O7, a layered perovskite family of the Ruddlesden–Popper (RP) phase (general formula, An−1 A′2 B n X3n+1, where A, A′ and B are cations, X is an anion, and n is the number of the layers of octahedra in the perovskite-like stack) [122]. Under humid CO2 environment, Li2SrTa2O7 is transformed into LiHSrTa2O7 releasing LiOH, which then locks CO2 in the form of Li2CO3.

It is interesting to note that the operating temperature of Li2SrTa2O7 is 140 °C compared to ~400 °C of most of the other inorganic solid compounds. On heating, Li2SrTa2O7 can be fully recovered at increased temperature (~700 °C) showing that the CO2 capture is reversible and can be performed for a number of cycles. Similar CO2 absorption capacity was observed for Li2SrNb2O7. These materials, Li2SrTa2O7 and Li2SrNb2O7, have phases consisting of layers of corner-connected TaO6 or NbO6 octahedra separated by a layer of corner-connected LiO4 tetrahedra [123]. In the presence of water at room temperature, H+ shifts Li+ in the layered structure and allows the shifted Li+ to react with CO2 to form Li2CO3. During regeneration, Li+ is reinserted into the Ruddlesden–Popper structure, as in alkali garnet materials [124–127].

Another perovskite material, Ba4Sb2O9, can be synthesized using a solid-state reaction in air from BaCO3 and Sb2O3 [128]. 6H-Ba4Sb2O9 reacts with CO2 to form BaSb2O6 and BaCO3.

6H-Ba4Sb2O9, was found to be able to capture CO2, mixed with N2, at 600 °C while the regeneration temperature was around 950 °C under N2 atmosphere [129]. No significant reduction in the CO2 absorption capacity was observed for 100 cycles. After 100 cycles, the capacity [~0.1 g (CO2)/g sorbent] is stable and translates to 73 % of the total molar capacity. The reaction between 6H-Ba4Sb2O9 and CO2 has similar equilibrium constant to that of CaO-based sorbents. However, the CO2 absorption capacity was stable for a large number of cycles, unlike CaO that degrades rapidly over cycles under same operating conditions.

Miscellaneous

Aluminosilicate zeolite is attractive for post-combustion CO2 capture due to its selective CO2 adsorption and high CO2 capacities [130]. An extensive research has been carried out on aluminosilicate zeolite, and the results exhibit high uptake capacity than pure-silica zeolites [131–133]. In general, adsorption kinetics of CO2 on zeolites is relatively fast and can achieve equilibrium capacity within a few minutes. The temperature and pressure strongly govern the CO2 adsorption on zeolites. As the temperature increases, the adsorption of CO2 decreases but as the gas-phase partial pressure of CO2 increases, CO2 adsorption increases accordingly. However, the presence of water vapor may limit the application of zeolite sorbents by decreasing its capacity. It is clear that optimizing different factors, such as basicity, pore size of zeolites and electric field strength (due to the exchangeable cations in the cavities), can significantly influence the CO2 adsorption capacities of zeolites.

Conclusion

It is certain that an improved and cost-efficient process for CO2 capture obtained from flue gas streams from power plants burning fossil fuels is needed to mitigate the huge emission of greenhouse gasses. Among several different proposed processes, metal oxides are promising options for suitable sorbent and have a great potential in the future. However, these sorbents also have limitations and challenges which must be solved before these can be employed commercially for CO2 capture purpose. Based on the current scenario, following suggestions are proposed for the future research on CO2 capture using metal oxides:

-

(a)

Improvement in the potential sorbent performance, in terms of capture capacity, reversibility rate, carbonation kinetics, multi-cycle durability and sorbent reversibility;

-

(b)

In-depth analysis of performance check of potential sorbent under actual flue gas conditions;

-

(c)

A detailed techno-economic assessment of the potential sorbents;

References

Aaron, D., Tsouris, C.: Separation of CO2 from flue gas: a review. Sep. Sci. Technol. 40, 321–348 (2005)

White, C.M., Strazisar, B.R., Granite, E.J., Hoffman, J.S., Pennline, H.W.: Separation and capture of CO2 from large stationary sources and sequestration in geological formations. J. Air Waste Manag. Assoc. 53, 645–715 (2003)

Bryant, E.: Climate Process and Change. Cambridge University Press, Cambridge (1997)

Oreskes, N.: The scientific consensus on climate change. Science 306, 1686 (2004)

Merkel, T.C., Lin, H., Wei, X., Baker, R.: Power plant carbon dioxide capture: an opportunity for membranes. J. Membr. Sci. 359, 126–139 (2010)

Little, R.J., Versteeg, G.F., Van Swaaij, W.P.M.: Physical absorption into non-aqueous solutions in a stirred cell reactor. Chem. Eng. Sci. 46, 3308–3313 (1991)

Chiesa, P., Consonni, S.P.: Shift reactors and physical absorption for low-CO2 emission IGCCs. J. Eng. Gas Turbines Power 121, 295–305 (1999)

Bishnoi, S., Rochelle, G.T.: Absorption of carbon dioxide into aqueous piperazine: reaction kinetics, mass transfer and solubility. Chem. Eng. Sci. 55, 5531–5543 (2000)

Rochelle, G.T.: Amine scrubbing for CO2 capture. Science 325, 1652–1654 (2009)

Harlick, P.J.E., Tezel, F.H.: An experimental adsorbent screening study for CO2 capture from N2. Microporous Mesoporous Mater. 76, 71–77 (2004)

Powell, C.E., Qiao, G.G.: Polymeric CO2/N2 gas separation membranes for the capture carbon dioxide from power plant flue gases. J. Membr. Sci. 279, 1–49 (2006)

Benson, S.M., Cole, D.R.: CO2 sequestration in deep sedimentary formations. Elements 4, 325–331 (2008)

Guoxin, H., Huang, H., Li, Y.H.: The gasification of wet biomass using Ca(OH)2 as CO2 absorbent: the microstructure of char and absorbent. Int. J. Hydrogen Energy 33, 5422–5429 (2008)

Siriwardane, R., Poston, J., Chaudhari, K., Zinn, A., Simonyi, T., Robinson, C.: Chemical-looping combustion of simulated synthesis gas using nickel oxide oxygen carrier supported on bentonite. Energy Fuels 21, 1582–1591 (2007)

Lee, S.C., Kim, J.C.: Dry potassium-based sorbents for CO2 capture. Catal. Surv. Asia 11, 171–185 (2007)

Abanades, J.C., Anthony, E.J., Wang, J., Oakey, J.E.: Fluidized bed combustion systems integrating CO2 capture with CaO. Environ. Sci. Technol. 39, 2861–2866 (2005)

Duan, Y., Sorescu, D.C.: CO2 capture properties of alkaline earth metal oxides and hydroxides: a combined density functional theory and lattice phonon dynamics study. J. Chem. Phys. 133, 074508 (2010)

Zhang, B., Duan, Y., Johnson, K.: Density functional theory study of CO2 capture with transition metal oxides and hydroxides. J. Chem. Phys. 136, 064516 (2012)

Duan, Y., Luebke, D., Pennline, H.: Efficient theoretical screening of solid sorbents for CO2 capture applications. Int. J. Clean Coal Energy 1, 1–11 (2012)

DOE-NETL, Cost and performance baseline for fossil energy plants, Volume 1: Bituminous Coal and Natural Gas to Electricity Final Report. August 2007

Nakagawa, K., Ohashi, T.J.: A novel method for CO2 capture from high temperature gases. J. Electrochem. Soc. 145, 1344–1346 (1998)

Ochoa-Fernández, E., Rusten, H.K., Jakobsen, H.A., Rønning, M., Holmen, A., Chen, D.: Sorption enhanced hydrogen production by steam methane reforming using Li2ZrO3 as sorbent: sorption kinetics and reactor simulation. Catal. Today 106, 41–46 (2005)

Pfeiffer, H., Vázquez, C., Lara, V.H., Bosch, P.: Thermal behavior and CO2 absorption of Li2−xNa x ZrO3 solid solutions. Chem. Mater. 19, 922–926 (2007)

Ida, J., Lin, Y.S.: Mechanism of high-temperature CO2 sorption on lithium zirconate. Environ. Sci. Technol. 37, 1999–2004 (2003)

Ida, J., Xiong, R., Lin, Y.S.: Synthesis and CO2 sorption properties of pure and modified lithium zirconate. Sep. Purif. Technol. 36, 41–51 (2004)

Pannocchia, G., Puccini, M., Seggiani, M., Vitolo, S.: Experimental and modeling studies on high-temperature capture of CO2 using lithium zirconate based sorbents. Ind. Eng. Chem. Res. 46, 6696–6706 (2007)

Veliz-Enriquez, M., González, G., Pfeiffer, H.: Synthesis and CO2 capture evaluation of Li2−xK x ZrO3 solid solutions and crystal structure of a new lithium–potassium zirconate phase. J. Solid State Chem. 180, 2485–2492 (2007)

Hernández, L.O.G., Gutiérrez, D.L., Martínez, V.C., Ortiz, A.L.: Synthesis, characterization and high temperature CO2 capture evaluation of Li2ZrO3-Na2ZrO3 mixtures. J. New Mater. Electrochem. Syst. 11, 137–142 (2008)

Essaki, K., Nakagawa, K., Kato, M., Uemoto, H.: CO2 absorption by lithium silicate at room temperature. J. Chem. Eng. Jpn. 37, 772–777 (2004)

Kato, M., Nakagawa, K., Essaki, K., Maezawa, Y., Takeda, S., Kogo, R., Hagiwara, Y.: Novel CO2 absorbents using lithium containing oxide. Int. J. Appl. Ceram. Technol. 2, 467–475 (2005)

Puccini, M., Seggiani, M., Vitolo, S.: Lithium silicate pellets for CO2 capture at high temperature. Chem. Eng. Trans. 35, 373–378 (2003)

Wang, K., Guo, X., Zhao, P., Wang, F., Zheng, C.: High temperature capture of CO2 on lithium-based sorbents from rice husk ash. J. Hazard. Mater. 189, 301–307 (2011)

Yamauchi, K., Murayama, N., Shibata, J.: Absorption and release of carbon dioxide with various metal oxides and hydroxides. Mater. Trans. 48, 2739–2742 (2007)

Quinn, R., Kitzhoffer, R.J., Hufton, J.R., Golden, T.C.: A high temperature lithium orthosilicate-based solid absorbent for post combustion CO2 capture. Ind. Eng. Chem. Res. 51, 9320–9327 (2012)

Figueroa, J.D., Fout, T., Plasynski, S., McIlvried, H., Srivastava, R.D.: Advances in CO2 capture technology—the U.S. Department of Energy’s Carbon Sequestration Program. Int. J. Greenhouse Gas Control 2, 9–20 (2008)

Korake, P.V., Gaikwad, A.G.: Capture of carbon dioxide over porous solid adsorbents lithium silicate, lithium aluminate and magnesium aluminate at pre-combustion temperatures. Front. Chem. Sci. Eng. 5, 215–226 (2011)

Gauer, C., Heschel, W.: Doped lithium orthosilicate for absorption of carbon dioxide. J. Mater. Sci. 41, 2405–2409 (2006)

Venegas, M.J., Fregoso-Israel, E., Escamilla, R., Pfeiffer, H.: Kinetic and reaction mechanism of CO2 sorption on Li4SiO4: study of the particle size effect. Ind. Eng. Chem. Res. 46, 2407–2412 (2007)

Xu, H., Cheng, W., Jin, X., Wang, G., Lu, H., Wang, H., Chen, D., Fan, B., Hou, T., Zhang, R.: Effect of the particle size of quartz powder on the synthesis and CO2 absorption properties of Li4SiO4 at high temperature. Ind. Eng. Chem. Res. 52, 1886–1891 (2013)

Seggiani, M., Puccini, M., Vitolo, S.: High-temperature and low concentration CO2 sorption on Li4SiO4 based sorbents: study of the used silica and doping method effects. Int. J. Greenhouse Gas Control 5, 741–748 (2011)

Mosqueda, R.R., Pfeiffer, H.: Thermo-kinetic analysis of the CO2 chemisorption on Li4SiO4 by using different gas flow rates and particle sizes. J. Phys. Chem. A 114, 435–454 (2010)

Lopez-Ortiz, A., Perez Rivera, N.G., Rojas, R.A., Gutierrez, D.L.: Novel carbon dioxide solid acceptors using sodium containing oxides. Sep. Sci. Technol. 39, 3559–3572 (2005)

Wu, X., Wen, Z., Xu, X., Wang, X., Lin, J.: Synthesis and characterization of Li4SiO4 nano-powders by a water-based sol–gel process. J. Nucl. Mater. 392, 471–475 (2009)

Bretado, M.E., Velderrain, V.G., Gutierrez, D.L., Collins-Martinez, V., Ortiz, L.A.: A new synthesis route to Li4SiO4 as CO2 catalytic/sorbent. Catal. Today 107–08, 863–867 (2005)

Shan, S., Li, S., Jia, Q., Jiang, L., Wang, Y., Peng, J.: Impregnation precipitation preparation and kinetic analysis of Li4SiO4-based sorbents with fast CO2 adsorption rate. Ind. Eng. Chem. Res. 52, 6941–6945 (2013)

Olivares-Marin, M., Drage, T.C., Maroto-Valer, M.M.: Novel lithium-based sorbents from fly ashes for CO2 capture at high temperatures. Int. J. Greenhouse Gas Control 4, 623–629 (2010)

Wang, K., Zhao, P., Guo, X., Li, Y., Han, D., Chao, Y.: Enhancement of reactivity in Li4SiO4-based sorbents from the nano-sized rice husk ash for high-temperature CO2 capture. Energy Convers. Manag. 81, 447–454 (2014)

Shan, S., Jia, Q., Jiang, L., Li, Q., Wang, Y., Peng, J.: Novel Li4SiO4-based sorbents from diatomite for high temperature CO2 capture. Ceram. Int. 39, 5437–5441 (2013)

Zhao, T., Rønning, M., Chen, D.: Preparation and high-temperature CO2 capture properties of nanocrystalline Na2ZrO3. Chem. Mater. 19, 3294–3301 (2007)

Pfeiffer, H., Lima, E., Bosch, P.: Lithium–sodium metazirconate solid solutions, Li2-xNaxZrO3 (0 ≤ x ≤ 2): a hierarchical architecture. Chem. Mater. 18, 2642–2647 (2006)

López-Ortiz, A., Perez-Rivera, N.G., Reyes-Rojas, A., Lardizabal-Gutierrez, D.: Novel carbon dioxide solid acceptors using sodium containing oxides. Sep. Sci. Technol. 39, 3559–3572 (2004)

Alcérreca-Corte, I., Fregoso-Israel, E., Pfeiffer, H.: CO2 absorption on Na2ZrO3: a kinetic analysis of the chemisorption and diffusion processes. J. Phys. Chem. C 112, 6520–6525 (2008)

Jimenez, D.B., Bretado, M.A.E., Gutierrez, D.L., Guiterrez, J.M.S., Ortiz, A.L., Martinez, V.C.: Kinetic study and modeling of the high temperature CO2 capture by Na2ZrO3 solid absorbent. Int. J. Hydrogen Energy 38, 2557–2564 (2013)

Ochoa-Fernández, E., Zhao, T., Ronning, M., Chen, D.: Effects of steam addition on the properties of high temperature ceramic CO2 acceptors. J. Environ. Eng. 37, 397–403 (2009)

Santillán-Reyes, G.G., Pfeiffer, H.: Analysis of the CO2 capture in sodium zirconate (Na2ZrO3): effect of water vapor addition. Int. J. Greenhouse Gas Control 5, 1624–1629 (2011)

Choi, S., Drese, J.H., Jones, W.C.: Adsorbent materials for carbon dioxide capture from large anthropogenic point sources. ChemSusChem 2, 796–854 (2009)

Cushing, B.L., Kolesnichenko, V.L., O’Connor, C.J.: Recent advances in the liquid-phase syntheses of inorganic nanoparticles. Chem. Rev. 104, 3893–3946 (2004)

Vasylkiv, O., Sakka, Y.: Nanoexplosion synthesis of multimetal oxide ceramic nanopowders. Nano Letter 5, 2598–2604 (2005)

Pfeiffer, H., Bosch, P.: Thermal stability and high-temperature carbon dioxide sorption on hexa-lithium zirconate (Li6Zr2O7). Chem. Mater. 17, 1704–1710 (2005)

Jimenez, B.D., Reyes Rojas, C.M., López-Ortiz, G.V.: Novel developments in adsorption; the effect of Li as a dopant in Na2ZrO3 high temperature CO2 acceptor. In: AIChE Annual Meeting (2004)

Yoshida, T.: Development of molten carbonate fuel cell (MCFC) power generation technology. Ishikawajima-Harima Eng. Rev. 4, 125–134 (1994)

Rodriguez, M.T., Pfeiffer, H.: Sodium metasilicate (Na2SiO3): a thermo-kinetic analysis of its CO2 chemical sorption. Thermochim. Acta 473, 92–95 (2008)

Rodríguez-Mosqueda, R., Pfeiffer, H.: High CO2 capture in sodium metasilicate (Na2SiO3) at low temperatures (30–60 C) through the CO2–H2O chemisorption process. J. Phys. Chem. C 117, 13452–13461 (2013)

Bhagiyalakshmi, M., Lee, J.Y., Jang, H.T.: Synthesis of mesoporous magnesium oxide: its application to CO2 chemisorption. Int. J. Greenhouse Gas Control 4, 51–56 (2010)

Feng, B., An, H., Tan, E.: Screening of CO2 adsorbing materials for zero emission power generation systems. Energy Fuels 21, 426–434 (2007)

Li, L., Wen, X., Fu, X., Wang, F., Zhao, N., Xiao, F., Wei, W., Sun, Y.: MgO/Al2O3 sorbent for CO2 capture. Energy Fuels 24, 5773–5780 (2010)

Lee, S.C., Chae, H.J., Lee, S.J., Choi, B.Y., Yi, C.K., Lee, J.B., Ryu, C.K., Kim, J.C.: Development of regenerable MgO-based sorbent promoted with K2CO3 for CO2 capture at low temperatures. Environ. Sci. Technol. 42, 2736–2741 (2008)

Ward, S.M., Braslaw, J., Gealer, R.L.: Carbon dioxide sorption studies on magnesium oxide. Thermochim. Acta 64, 107–114 (1983)

Fu, X., Zhao, N., Li, J., Xiao, F., Wei, W., Sun, Y.: Carbon dioxide capture by MgO-modified MCM-41 materials. Adsorpt. Sci. Technol. 27, 593–601 (2009)

Liu, S., Zhang, X., Li, J., Zhao, N., Wei, W., Sun, Y.: Preparation and application of stabilized mesoporous MgO–ZrO2 solid base. Catal. Commun. 9, 1527–1532 (2008)

Li, B., Wen, X., Zhao, N., Wang, X.Z., Wei, W., Sun, Y., Ren, Z.H., Wang, Z.J.: Preparation of high stability MgO-ZrO2 solid base and its high temperature CO2 capture properties. J. Fuel Chem. Technol. 38, 473–477 (2010)

Yong, Z., Mata, V., Rodrigues, A.E.: Adsorption of carbon dioxide onto hydrotalcite-like compounds (HTlcs) at high temperatures. Ind. Eng. Chem. Res. 40, 204–209 (2001)

Li, L., Li, Y., Wen, X., Wang, F., Zhao, N., Xiao, F., Wei, W., Sun, Y.: CO2 capture over K2CO3/MgO/Al2O3 dry sorbent in a fluidized bed. Energy Fuels 25, 3835–3842 (2011)

Lee, S.C., Choi, B.Y., Lee, T.J., Ryu, C.K., Soo, Y.S., Kim, J.C.: CO2 absorption and regeneration of alkali metal-based solid sorbents. Catal. Today 111, 385–390 (2006)

Ruminski, A.M., Jeon, K.J., Urban, J.J.: Size- and surface-dependent CO2 capture in chemically synthesized magnesium oxide nanocrystals. J. Mater. Chem. 21, 11486–11491 (2011)

Beruto, D., Botter, R., Searcy, A.W.: Thermodynamics of two, two-dimensional phases formed by carbon dioxide chemisorption on magnesium oxide. J. Phys. Chem. 91, 3578–3581 (1987)

Lu, W., Yuan, D., Sculley, J., Zhao, D., Krishna, R., Zhou, H.C.: Sulfonate-grafted porous polymer networks for preferential CO2 adsorption at low pressure. J. Am. Chem. Soc. 133, 18126–18129 (2011)

Fagerlund, J., Highfield, J., Zevenhoven, R.: Kinetics studies on wet and dry gas–solid carbonation of MgO and Mg(OH)2 for CO2 sequestration. RSC Adv. 2, 10380–10393 (2012)

Highfield, J., Bu, J., Fagerlund, J., Zevenhoven, R. ICCDU-XI (2011)

Butt, D.P., Pile, S.P., Park, Y., Vaidya, R., Lackner, K.S., Wendt, C.H., Nomura, K.: Report LA-UR-98-7631 (1998)

Hassanzadeh, A., Abbasian, J.: Regenerable MgO-based sorbents for high-temperature CO2 removal from syngas: 1. Sorbent development, evaluation, and reaction modeling. Fuel 89, 1287–1297 (2010)

Silaban, A., Harrison, D.P.: High temperature capture of carbon dioxide: characteristics of the reversible reaction between CaO (s) and CO2 (g). Chem. Eng. Commun. 137, 177–190 (1995)

Salvador, C., Lu, D., Anthony, E., Abanades, J.: Enhancement of CaO for CO2 capture in an FBC environment. Chem. Eng. J. 96, 187–195 (2003)

Hughes, R., Lu, D., Anthony, E., Wu, Y.: Improved long-term conversion of limestone-derived sorbents for in situ capture of CO2 in a fluidized bed combustor. Ind. Eng. Chem. Res. 43, 5529–5539 (2004)

Moranska, M.K., Tomaszewicz, G., Labojko, G.: Comparison of different methods for enhancing CO2 capture by CaO-based sorbents-review. Physicochem. Prob. Miner. Process. 48, 77–90 (2012)

Barker, R.: The reactivity of calcium oxide towards carbon dioxide and its use for energy storage. J. Appl. Chem. Biotech. 24, 221–227 (1974)

Bhatia, S.K., Perlmutter, D.D.: Effect of the product layer on the kinetics of the CO2-lime reaction. Am. Instit. Chem. Eng. J. 29, 79–86 (1983)

Lu, H., Smirniotis, P.G., Ernst, F.O., Pratsinis, S.E.: Nanostructured Ca-based sorbents with high CO2 uptake efficiency. Chem. Eng. Sci. 64, 1936–1943 (2009)

Lu, H., Reddy, E.P., Smirniotis, P.G.: Calcium oxide based sorbents for capture of carbon dioxide at high temperatures. Ind. Eng. Chem. Res. 45, 3944–3949 (2006)

Abanades, J.C., Alvarez, D.: Conversion limits in the reaction of CO2 with lime. Energy Fuels 17, 308–315 (2003)

Gruene, P., Belova, A.G., Yegulalp, T.M., Farrauto, R.J., Castaldi, M.J.: Dispersed calcium oxide as a reversible and efficient CO2—sorbent at intermediate temperatures. Ind. Eng. Chem. Res. 50, 4042–4049 (2011)

Wang, J., Manovic, V., Wu, Y., Anthony, E.: A study on the activity of CaO-based sorbents for capturing CO2 in clean energy processes. Appl. Energy 87, 1453–1458 (2010)

Bouquet, E., Leyssens, G., Schönnenbeck, C., Gilot, P.: The decrease of carbonation efficiency of CaO along calcination–carbonation cycles: experiments and modeling. Chem. Eng. Sci. 64, 2136–2146 (2009)

Lysikov, A., Trukhan, S., Okunev, A.: Sorption enhanced hydrocarbons reforming for fuel cell powered generators. Int. J. Hydrogen Energy 33, 3061–3066 (2008)

Stanmore, B., Gilot, P.: Review—calcination and carbonation of limestone during thermal cycling for CO2 sequestration. Fuel Process. Technol. 86, 1707–1743 (2005)

Li, Y., Zhao, Ch., Chen, H., Liang, C., Duan, L., Zhou, W.: Modified CaO-based sorbent looping cycle for CO2 mitigation. Fuel 88, 697–704 (2009)

Adanez, J., de Diego, L., Garcia-Labiano, F.: Calcination of calcium acetate and calcium magnesium acetate: effect of the reacting atmosphere. Fuel 78, 583–592 (1999)

Nimmo, W., Patsias, A., Hampartsoumian, E., Gibbs, B., Fairweather, M., Williams, P.: Calcium magnesium acetate and urea advanced reburning for NO control with simultaneous SO2 reduction. Fuel 83, 1143–1150 (2004)

Patsias, A., Nimmo, W., Gibbs, B., Williams, P.: Calcium-based sorbents for simultaneous NOx/Sox reduction in a down-fired furnace. Fuel 84, 1864–1873 (2005)

Silaban, A., Narcida, M., Harrision, D.: Characteristics of the reversible reaction between CO2 (g) and calcined dolomite. Chem. Eng. Commun. 146, 149–162 (1996)

Bandi, A., Specht, M., Sichler, P., Nicoloso, N.: In-situ gas. Conditioning in fuel reforming for hydrogen generation. 5th International Symposium on Gas Cleaning at High Temperature, Morgantown (2002)

Manovic, V., Anthony, E., Grasa, G., Abanades, J.: CO2 looping cycle performance of a high-purity limestone after thermal activation/doping. Energy Fuels 22, 3258–3264 (2008)

Wang, M., Lee, C.G.: Absorption of CO2 on CaSiO3 at high temperatures. Energy Convers. Manag. 50, 636–638 (2009)

Gupta, H., Fan, L.S.: Carbonation-calcination cycle using high reactivity calcium oxide for carbon dioxide separation from flue gas. Ind. Eng. Chem. Res. 41, 4035–4042 (2002)

Tilekar, G., Shinde, K., Kale, K., Raskar, R., Gaikwad, A.: The capture of carbon dioxide by transition metal aluminates, calcium aluminate, calcium zirconate, calcium silicate and lithium zirconate. Front. Chem. Sci. Eng. 5, 477–491 (2011)

Richter, H.J., Knoche, K. F.: Reversibility of combustion processes. In: Gaggioli, R.A. (ed.) Efficiency and Costing: Second Law Analysis of Processes. ACS Symposium Series, vol. 235, pp 71–85 (1983)

Fan, L.S., Zeng, L., Wang, W., Luo, S.: Chemical looping processes for CO2 capture and carbonaceous fuel conversion—prospect and opportunity. Energy Environ. Sci. 5, 7254–7280 (2012)

Adanez, J., Abad, A., Garcia-Labiano, F., Gayan, P., de Diego, L.: Progress in chemical-looping combustion and reforming technologies. Prog. Energy Combust. Sci. 38, 215–282 (2012)

Chiu, P.C., Ku, Y.: Chemical looping process—a novel technology for inherent CO2 capture. Aerosol Air Qual. Res. 12, 1421–1432 (2012)

Imtiaz, Q., Hosseini, D., Müller, C.R.: Review of oxygen carriers for the chemical looping with oxygen uncoupling: thermodynamics, material development, and synthesis. Energy Technol. 1, 633–647 (2013)

Mattisson, T.: Materials for chemical-looping with oxygen Uncoupling. ISRN Chem. Eng. 2013, 1–19 (2013)

Kim, H.R. Coal-direct chemical looping combustion process for in situ carbon dioxide capture—Operational Experience of Integrated 25-kWth Sub-Pilot Scale. Unit Document no. osu1352996758

Kumar, S., Drozd, V., Durygin, A., Saxena, S.K.: Method and system for sequestering carbon dioxide and producing hydrogen gas. U.S. Provisional Patent Application No. 61/733,297 (2012)

Habashi, F.: Can. Instit. Min. Bull. 94, 71–76 (2001)

Ohkuma, N., Funayama, Y., Ito, H., Mizutani, N., Kato, M.: Nihon kagaku kaishi 802 (1987)

Galvez, J., Arana, R.: Univ. Murcia Scie. 38, 153 (1979)

Chen, J., Zhao, R., Jiang, H.: Trans. Nonferrous Metals Soc. 8, 149–153 (1988)

Wang, Z.Y., Chou, H.C., Wu, J.C.S., Tsai, D.P., Mul, G.: CO2 photoreduction using NiO/InTaO4 in optical-fiber reactor for renewable energy. Appl. Catal. A 380, 172–177 (2010)

Chen, H.C., Chou, H.C., Wu, J.C.S., Lin, H.Y.: Sol–gel prepared InTaO4 and its photocatalytic characteristics. J. Mater. Res. 23, 1364–1370 (2008)

Pan, P.W., Chen, Y.W.: Photocatalytic reduction of carbon dioxide on NiO/InTaO4 under visible light irradiation. Catal. Commun. 8, 1546–1549 (2007)

Galven, C., Fourquet, J.L., Suard, E., Crosnier-Lopez, M.P., Le Berre, F.: Mechanism of a reversible CO2 capture monitored by the layered perovskite Li2SrTa2O7. Dalton Trans. 39, 4191–4197 (2010)

Pagnier, T., Rosman, N., Galven, C., Suard, E., Fourquet, J.L., Le Berre, F., Crosnier-Lopez, M.P.: Phase transition in the Ruddlesden-Popper layered perovskite Li2SrTa2O7. J. Solid State Chem. 182, 317–326 (2009)

Galven, C., Dittmer, J., Suard, E., Le Berre, F., Crosnier-Lopez, M.P.: Instability of lithium garnets against moisture. Structural characterization and dynamics of Li7-xH x La3Sn2O12 and Li5-xH x La3Nb2O12. Chem. Mater. 24, 3335–3345 (2012)

Galven, C., Fourquet, J.L., Crosnier-Lopez, M.P., Le Berre, F.: Instability of the lithium garnet Li7La3Sn2O12: Li+/H+ exchange and structural study. Chem. Mater. 23, 1892–1900 (2011)

Narayanan, S., Ramezanipour, F., Thangadurai, V.: Enhancing Li ion conductivity of garnet-type Li5La3Nb2O12 by Y-and Li-codoping: synthesis, structure, chemical stability, and transport properties. J. Phys. Chem. C 116, 20154–20162 (2012)

Nyman, M., Alam, T.M., McIntyre, S.K., Bleier, G.C., Ingersoll, D.: Alternative approach to increasing li mobility in Li-La-Nb/Ta garnet electrolytes. Chem. Mater. 22, 5401–5410 (2010)

Dunstan, M.T., Pavan, A.F., Kharton, V.V., Avdeev, M., Kimpton, J.A., Koltygin, V.A., Tsipis, E.V., Ling, C.D.: Phase behavior and mixed ionic–electronic conductivity of Ba4Sb2O9. Solid State Ionics 235, 1–7 (2013)

Dunstan, M.T., Liu, W., Pavan, A.F., Kimpton, J.A., Ling, C.D., Scott, S.A., Dennis, J.S., Grey, C.P.: Reversible CO2 absorption by the 6H Perovskite Ba4Sb2O9. Chem. Mater. 25, 4881–4891 (2013)

Yaghi, O.M., Keeffe, M., Ockwig, N., Hee, C., Eddaoudi, M., Kim, J.: Reticular synthesis and the design of new materials. Nature 423, 705–714 (2003)

Hudson, M., Queen, W., Mason, J., Fickel, D., Lobo, R., Brown, C.: Unconventional, highly selective CO2 adsorption in Zeolite SSZ-13. J. Am. Chem. Soc. 134, 1970–1973 (2012)

Pires, J., de Carvalho, M.B., Ribeiro, F.R., Derouane, E.G.: Carbon dioxide in Y and ZSM-20 zeolites: adsorption and infrared studies. J. Mol. Catal. 85, 295–303 (1993)

Samanta, A.K., Zhao, A., Shimizu, G.K.H., Sarkar, P., Gupta, R.: Post-combustion CO2 capture using solid sorbents: a review. Ind. Eng. Chem. Res. 51, 1438–1463 (2012)

Acknowledgments

S. Kumar would like to acknowledge the financial support from Florida International University Graduate School Dissertation Year Fellowship (DYF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Kumar, S., Saxena, S.K. A comparative study of CO2 sorption properties for different oxides. Mater Renew Sustain Energy 3, 30 (2014). https://doi.org/10.1007/s40243-014-0030-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-014-0030-9