Abstract

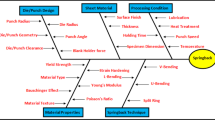

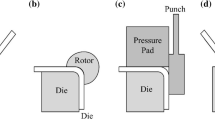

Springback is a geometrical defect that occurs due to the removal of the bending force acting on the component the end of the forming process. In the present study, springback behavior of Ti-Grade 2 sheets is studied by finite element method and experimentation. The process parameters considered are punch radius, die opening and sheet thickness. Based on Taguchi (L9) Orthogonal array, the simulation and experiments were conducted. Simulated springback values were found to be in good agreement with experimental values. Signal-to-noise (S/N) ratio is used to determine the optimal combination of parameters that minimizes springback. Analysis of variance is employed to study the influence of process parameter on springback.

Similar content being viewed by others

References

Thipprakmas S, Rojananan S (2008) Investigation of spring-go phenomenon using finite element method. Mater Des 29:1526–1532

Bakhshi Jooybari M, Rahmani B, Daeezadeh V, Gorji A (2009) The study of spring-back of CK67 steel sheet in V-die and U-die bending processes. Mater Des 30:2410–2419

Panthi SK, Ramakrishnan N, Ahmed M, Singh SS, Goel MD (2010) Finite element analysis of sheet metal bending process to predict the spring-back. Mater Des 31:657–662

Thipprakmas S, Phanitwong W (2011) Process parameter design of spring-back and spring-go in V-bending process using Taguchi technique. Mater Des 32:4430–4436

Eggertsen PA, Mattiasson K (2010) On constitutive modeling for springback analysis. Int J Mech Sci 52:804–818

Farsi MA, Arezoo B (2011) Bending force and spring-back in V-Die bending of perforated sheet- metal components. J Braz Soc Mech Sci Eng 33:45–51

Adamus J, Lacki P (2011) Forming of the titanium elements by bending. Comput Mater Sci 50:1305–1309

Hakan D, Mustafa Ö, Murat S (2013) Effects of material properties and punch tip radius on spring-forward in 90°V bending processes. J Iron Steel Res Int 20:64–69

Patel CK (2014) Investigation of springback behaviour of SS-304 steel and its bi-layer material in V bending. Mech Eng Int J 1(2):43–52

Zong Y, Liu P, Guo B, Shan D (2015) Springback evaluation in hot v-bending of Ti–6Al–4V alloy sheets. Int J Adv Manuf Technol 76(1–4):577–585

Leu D-K, Zhuang Z-W (2016) Spring-back prediction of the V bending process for High-Strength Steel sheets. J Mech Sci Technol 30:1077–1084

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva, Ph.D.

Rights and permissions

About this article

Cite this article

Ramadass, R., Sambasivam, S. & Thangavelu, K. Selection of optimal parameters in V-bending of Ti-Grade 2 sheet to minimize springback. J Braz. Soc. Mech. Sci. Eng. 41, 21 (2019). https://doi.org/10.1007/s40430-018-1521-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1521-x