Abstract

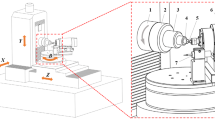

Grinding marks are regard as a great obstacle to manufacture spherical and aspheric surfaces with higher surface quality, lower energy and wastage. The scallop-height was studied for optimizing the grinding parameters firstly to reduce its effect on grinding marks. Secondly, the expression of grinding points distribution was established to characterize the grinding marks caused by the radial run-out of grinding wheel. And then, the aspheric grinding experiments of monocrystalline silicon were carried out to investigate the influence of grinding marks on surface quality. The experiments revealed that the remarkable grinding marks with patterned grinding points distribution would cause more fractures and roughness, deeper grooves, and more inhomogeneous surface quality compared with the weak grinding marks. The discriminating standard of grinding marks was established, and the grinding parameters were optimized for homogenizing the grinding points distribution by this discriminating standard to reduce the grinding marks in actual grinding process. Finally, the large size infrared lens was ground with high surface quality by the optimized grinding parameters, and the results of surface quality demonstrate that the discriminating standard was effective. This research provides references and ideas for grinding aspherical surface with high surface quality and efficiency, low energy and wastage.

Similar content being viewed by others

References

Guo, B. and Zhao, Q., “Mechanical Truing of V-Shape Diamond Wheels for Micro-Structured Surface Grinding,” International Journal of Advanced Manufacturing Technology, Vol. 78, 2015.

Chen, B., Guo, B., and Zhao, Q., “An Investigation into Parallel and Cross Grinding of Aspheric Surface on Monocrystal Silicon,” International Journal of Advanced Manufacturing Technology, Vol. 80, 2015.

Brinksmeier, E., Mutlugü nes, Y., Klocke, F., Aurich, J., Shore, P., et al., “Ultra-Precision Grinding,” CIRP Annals-Manufacturing Technology, Vol. 59, No. 2, pp. 652–671, 2010.

Chu, W.-S., Kim, C.-S., Lee, H.-T., Choi, J.-O., Park, J.-I., et al., “Hybrid Manufacturing in Micro/Nano Scale: A Review,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 1, pp. 75–92, 2014.

Zhi, S., Li, J., and Zarembski, A. M., “Grinding Motor Energy Saving Method Based on Material Removal Model in Rail Grinding Processes,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 2, No. 1, pp. 21–30, 2015.

Kuriyagawa, T., Zahmaty, M. S. S., and Syoji, K., “A New Grinding Method for Aspheric Ceramic Mirrors,” Journal of Materials Processing Technology, Vol. 62, No. 4, pp. 387–392, 1996.

Chen, F., Yin, S., Huang, H., and Ohmori, H., “Fabrication of Small Aspheric Moulds Using Single Point Inclined Axis Grinding,” Precision Engineering, Vol. 39, pp. 107–115, 2015.

Lee, E.-S. and Baek, S.-Y., “A Study on Optimum Grinding Factors for Aspheric Convex Surface Micro-Lens Using Design of Experiments,” International Journal of Machine Tools and Manufacture, Vol. 47, No. 3, pp. 509–520, 2007.

Rahman, M. S., Saleh, T., Lim, H., Son, S., and Rahman, M., “Development of an On-Machine Profile Measurement System in Elid Grinding for Machining Aspheric Surface with Software Compensation,” International Journal of Machine Tools and Manufacture, Vol. 48, No. 7, pp. 887–895, 2008.

Chen, F., Yin, S., Huang, H., Ohmori, H., Wang, Y., et al., “Profile Error Compensation in Ultra-Precision Grinding of Aspheric Surfaces with On-Machine Measurement,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 5, pp. 480–486, 2010.

Sun, W., Pei, Z., and Fisher, G., “Fine Grinding of Silicon Wafers: Effects of Chuck Shape on Grinding Marks,” International Journal of Machine Tools and Manufacture, Vol. 45, No. 6, pp. 673–686, 2005.

Huo, F., Kang, R., Li, Z., and Guo, D., “Origin, Modeling and Suppression of Grinding Marks in Ultra Precision Grinding of Silicon Wafers,” International Journal of Machine Tools and Manufacture, Vol. 66, pp. 54–65, 2013.

Park, C., Kim, H., Lee, S., and Jeong, H., “The Influence of Abrasive Size on High-Pressure Chemical Mechanical Polishing of Sapphire Wafer,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 2, No. 2, pp. 157–162, 2015.

Chidambaram, S., Pei, Z., and Kassir, S., “Fine Grinding of Silicon Wafers: A Mathematical Model for Grinding Marks,” International Journal of Machine Tools and Manufacture, Vol. 43, No. 15, pp. 1595–1602, 2003.

Wang, Y.-J., Xu, L.-M., Li, D.-D., Wang, J.-L., Shi, L., et al., “Sphere Generation Grinding Based Spherical Surface Marks Analysis,” Journal of Shanghai Jiaotong University, Vol. 46, No. 5, 2012.

Guo, B. and Zhao, Q., “Wheel Normal Grinding of Hard and Brittle Materials,” International Journal of Advanced Manufacturing Technology, Vol. 79, 2015.

Chen, B., Guo, B., and Zhao, Q., “On-Machine Precision Form Truing of Arc-Shaped Diamond Wheels,” Journal of Materials Processing Technology, Vol. 223, pp. 65–74, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, B., Li, S., Deng, Z. et al. Grinding marks on ultra-precision grinding spherical and aspheric surfaces. Int. J. of Precis. Eng. and Manuf.-Green Tech. 4, 419–429 (2017). https://doi.org/10.1007/s40684-017-0047-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-017-0047-5