Abstract

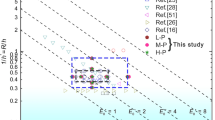

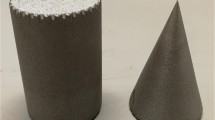

Selective laser melting (SLM) is one of the most widely used metal additive manufacturing technologies in producing high density parts. Energy density, a key-parameter combination, has been recognized to have a relationship with part formation, but such a relationship is extremely complex. This work aims to investigate energy density as a measure to evaluate energy demand in fabricating pore-free 316L stainless steel SLM parts. Key parameters in energy density were considered in the developed energy demand model. The impact of energy density on the porosity was analyzed with the data from experiments and existing works. Either low or high energy density can result in larger and more pore formation, and the influencing parameter was laser power, followed by layer thickness, scan speed, and hatch space. An effective energy-optimal (E2O) zone was proposed, where a relationship between energy density and porosity was developed. It is suggested that high laser power with high scan speeds can deliver energy to a thicker layer with relatively stable melt pool, fabricating high density parts. Hatch space can be decided accordingly to actual melt pool formation. This combination can effectively reduce energy density, and corresponding energy demand.

Similar content being viewed by others

References

Ahmadi, A., Mirzaeifar, R., Moghaddam, N. S., Turabi, A. S., Karaca, H. E., et al., “Effect of Manufacturing Parameters on Mechanical Properties of 316l Stainless Steel Parts Fabricated by Selective Laser Melting: A Computational Framework,” Materials & Design, Vol. 112, pp. 328–338, 2016.

Spierings, A., Schoepf, M., Kiesel, R., and Wegener, K., “Optimization of SLM Productivity by Aligning 17-4 ph Material Properties on Part Requirements,” Rapid Prototyping Journal, Vol. 20, No. 6, pp. 444–448, 2014.

Aboulkhair, N. T., Everitt, N. M., Ashcroft, I., and Tuck, C., “Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting,” Additive Manufacturing, Vol. 1, pp. 77–86, 2014.

Zhou, X., Wang, D., Liu, X., Zhang, D., Qu, S., et al., “3D-Imaging of Selective Laser Melting Defects in a Co-Cr-Mo Alloy by Synchrotron Radiation Micro-CT,” Acta Materialia, Vol. 98, pp. 1–16, 2015.

Thijs, L., Verhaeghe, F., Craeghs, T., Van Humbeeck, J., and Kruth, J.-P., “A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V,” Acta Materialia, Vol. 58, No. 9, pp. 3303–3312, 2010.

Gong, H., Rafi, K., Gu, H., Starr, T., and Stucker, B., “Analysis of Defect Generation in Ti–6Al–4V Parts Made Using Powder Bed Fusion Additive Manufacturing Processes,” Additive Manufacturing, Vol. 1, pp. 87–98, 2014.

Paul, R. and Anand, S., “Process Energy Analysis and Optimization in Selective Laser Sintering,” Journal of Manufacturing Systems, Vol. 31, No. 4, pp. 429–437, 2012.

Nimbalkar, S. and Visconti, K., “Life Cycle Energy Assessment Methodology, Tool and Case Studies for Additive Manufacturing, Prepared for Advanced Manufacturing Office, Energy Efficiency and Renewable Energy,” Oak Ridge National Laboratory, TM-2014/93, 2014.

Griffiths, C., Howarth, J., De Almeida-Rowbotham, G., Rees, A., and Kerton, R., “A Design of Experiments Approach for the Optimisation of Energy and Waste during the Production of Parts Manufactured by 3D Printing,” Journal of Cleaner Production, Vol. 139, pp. 74–85, 2016.

Li, R., Liu, J., Shi, Y., Du, M., and Xie, Z., “316L Stainless Steel with Gradient Porosity Fabricated by Selective Laser Melting,” Journal of Materials Engineering and Performance, Vol. 19, No. 5, pp. 666–671, 2010.

Yadroitsev, I., Gusarov, A., Yadroitsava, I., and Smurov, I., “Single Track Formation in Selective Laser Melting of Metal Powders,” Journal of Materials Processing Technology, Vol. 210, No. 12, pp. 1624–1631, 2010.

Campanelli, S. L., Casalinoa, G., Contuzzia, N., Angelastroa, A., and Ludovicoa, A. D., “Analysis of the Molten/Solidified Zone in Selective Laser Melted Parts,” Proc. of SPIE, Paper No. 896311, 2014.

Di, W., Yongqiang, Y., Xubin, S., and Yonghua, C., “Study on Energy Input and Its Influences on Single-Track, Multi-Track, and Multi-Layer in SLM,” The International Journal of Advanced Manufacturing Technology, Vol. 58, No. 9, pp. 1189–1199, 2012.

Xu, F.-L., Duan, J.-Z., Lin, C.-G., and Hou, B.-R., “Influence of Marine Aerobic Biofilms on Corrosion of 316L Stainless Steel,” Journal of Iron and Steel Research, Vol. 22, No. 8, pp. 715–720, 2015.

Cherry, J., Davies, H., Mehmood, S., Lavery, N., Brown, S., et al., “Investigation into the Effect of Process Parameters on Microstructural and Physical Properties of 316L Stainless Steel Parts by Selective Laser Melting,” The International Journal of Advanced Manufacturing Technology, Vol. 76, Nos. 5-8, pp. 869–879, 2015.

Yadroitsev, I., Yadroitsava, I., Bertrand, P., and Smurov, I., “Factor Analysis of Selective Laser Melting Process Parameters and Geometrical Characteristics of Synthesized Single Tracks,” Rapid Prototyping Journal, Vol. 18, No. 3, pp. 201–208, 2012.

Gu, D., Dai, D., Chen, W., and Chen, H., “Selective Laser Melting Additive Manufacturing of Hard-to-Process Tungsten-Based Alloy Parts with Novel Crystalline Growth Morphology and Enhanced Performance,” Journal of Manufacturing Science and Engineering, Vol. 138, No. 8, Paper No. 081003, 2016.

Hu, L., Peng, C., Evans, S., Peng, T., Liu, Y., et al., “Minimising the Machining Energy Consumption of a Machine Tool by Sequencing the Features of a Part,” Energy, Vol. 121, pp. 292–305, 2017.

Casalino, G., Campanelli, S., Contuzzi, N., and Ludovico, A., “Experimental Investigation and Statistical Optimisation of the Selective Laser Melting Process of a Maraging Steel,” Optics & Laser Technology, Vol. 65, pp. 151–158, 2015.

Simchi, A., “Direct Laser Sintering of Metal Powders: Mechanism, Kinetics and Microstructural Features,” Materials Science and Engineering: A, Vol. 428, No. 1, pp. 148–158, 2006.

Spierings, A. B., Herres, N., and Levy, G., “Influence of the Particle Size Distribution on Surface Quality and Mechanical Properties in AM Steel Parts,” Rapid Prototyping Journal, Vol. 17, No. 3, pp. 195–202, 2011.

Vo, T. Q. and Kim, B. H., “Molecular Dynamics Study of Thermodynamic Properties of Nanoclusters for Additive Manufacturing,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 4, No. 3, pp. 301–306, 2017.

Song, B., Dong, S., Zhang, B., Liao, H., and Coddet, C., “Effects of Processing Parameters on Microstructure and Mechanical Property of Selective Laser Melted Ti6Al4V,” Materials & Design, Vol. 35, pp. 120–125, 2012.

Ciurana, J., Hernandez, L., and Delgado, J., “Energy Density Analysis on Single Tracks Formed by Selective Laser Melting with CoCrMo Powder Material,” International Journal of Advanced Manufacturing Technology, Vol. 68, Nos. 5-8, pp. 1103–1110, 2013.

Hu, Z., Zhu, H., Zhang, H., and Zeng, X., “Experimental Investigation on Selective Laser Melting of 17-4ph Stainless Steel,” Optics & Laser Technology, Vol. 87, pp. 17–25, 2017.

Shi, X., Ma, S., Liu, C., Chen, C., Wu, Q., et al., “Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V,” Materials, Vol. 9, No. 12, pp. 975, 2016.

Kamath, C., El-dasher, B., Gallegos, G. F., King, W. E., and Sisto, A., “Density of Additively-Manufactured, 316L SS Parts Using Laser Powder-Bed Fusion at Powers Up to 400 W,” International Journal of Advanced Manufacturing Technology, Vol. 74, Nos. 1-4, pp. 65–78, 2014.

Bertoli, U. S., Wolfer, A. J., Matthews, M. J., Delplanque, J.-P. R., and Schoenung, J. M., “On the Limitations of Volumetric Energy Density as a Design Parameter for Selective Laser Melting,” Materials & Design, Vol. 113, pp. 331–340, 2017.

Matthews, M. J., Guss, G., Khairallah, S. A., Rubenchik, A. M., Depond, P. J., et al., “Denudation of Metal Powder Layers in Laser Powder Bed Fusion Processes,” Acta Materialia, Vol. 114, pp. 33–42, 2016.

Xu, X., Meteyer, S., Perry, N., and Zhao, Y. F., “Energy Consumption Model of Binder-Jetting Additive Manufacturing Processes,” International Journal of Production Research, Vol. 53, No. 23, pp. 7005–7015, 2015.

Vastola, G., Zhang, G., Pei, Q. X., and Zhang, Y.-W., “Modeling and Control of Remelting in High-Energy Beam Additive Manufacturing,” Additive Manufacturing, Vol. 7, pp. 57–63, 2015.

Peng, T. and Sun, W., “Energy Modelling for FDM 3D Printing from a Life Cycle Perspective,” International Journal of Manufacturing Research, Vol. 12, No. 1, pp. 83–98, 2017.

Yap, C., Chua, C., and Dong, Z., “An Effective Analytical Model of Selective Laser Melting,” Virtual and Physical Prototyping, Vol. 11, No. 1, pp. 21–26, 2016.

Darvish, K., Chen, Z., and Pasang, T., “Reducing Lack of Fusion during Selective Laser Melting of CoCrMo Alloy: Effect of Laser Power on Geometrical Features of Tracks,” Materials & Design, Vol. 112, pp. 357–366, 2016.

Wang, D., Wu, S., Fu, F., Mai, S., Yang, Y., et al., “Mechanisms and Characteristics of Spatter Generation in SLM Processing and Its Effect on the Properties,” Materials & Design, Vol. 117, pp. 121–130, 2017.

Gong, H., Rafi, K., Gu, H., Ram, G. J., Starr, T., et al., “Influence of Defects on Mechanical Properties of Ti-6Al-4V Components Produced by Selective Laser Melting and Electron Beam Melting,” Materials & Design, Vol. 86, pp. 545–554, 2015.

Kruth, J.-P., Froyen, L., Van Vaerenbergh, J., Mercelis, P., Rombouts, M., et al., “Selective Laser Melting of Iron-Based Powder,” Journal of Materials Processing Technology, Vol. 149, No. 1, pp. 616–622, 2004.

Sun, Z., Tan, X., Tor, S. B., and Yeong, W. Y., “Selective Laser Melting of Stainless Steel 316L with Low Porosity and High Build Rates,” Materials & Design, Vol. 104, pp. 197–204, 2016.

Chua, Z. Y., Ahn, I. H., and Moon, S. K., “Process Monitoring and Inspection Systems in Metal Additive Manufacturing: Status and Applications,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 4, No. 2, pp. 235–245, 2017.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, T., Chen, C. Influence of energy density on energy demand and porosity of 316L stainless steel fabricated by selective laser melting. Int. J. of Precis. Eng. and Manuf.-Green Tech. 5, 55–62 (2018). https://doi.org/10.1007/s40684-018-0006-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-018-0006-9