Abstract

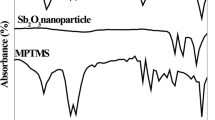

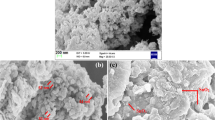

The incorporation of imidazole-modified nano-alumina on the corrosion protection properties of epoxy coating on mild steel was studied by electrochemical impedance spectroscopy (EIS) and scanning electrochemical microscopy (SECM) in 3.5% NaCl solution. The dispersability of the alumina nanoparticles was greatly improved by the surface modification using imidazole in the epoxy matrix. The imidazole-modified nanoparticle was analyzed by Fourier transform infrared spectroscopy. Both EIS and SECM studies confirmed that the corrosion resistance is higher for the alumina–epoxy nanocomposite coated steel than that of the pure epoxy-coated steel. It is evidenced that alumina–epoxy nanocomposite coated mild steel has higher charge transfer resistance values, 156,344 Ω cm2, compared to pure epoxy coated mild steel, 79,546 Ω cm2, at 40 days of immersion. The modified nanoparticles enhanced the adhesive properties of the coatings. Possible chemical interactions between epoxy matrix and surface-modified alumina nanoparticles in nanocomposites cause high protection properties and ionic resistances. FE-SEM/EDX analysis showed the presence of Fe, Al, and O in the corrosion products. Hardness and tensile strength measurements showed that the improved mechanical properties were noticed for alumina–epoxy nanocomposite coated mild steel.

Similar content being viewed by others

References

Kumar SA, Denchev Z (2009) Siliconized epoxy-bismaleimide inter-crosslinked networks. Prog Org Coat 66:1–7

Kang Y, Chen X, Song S, Yu L, Zhang P (2012) Friction and wear behavior of nanosilica filled epoxy resin composite coatings. Appl Surf Sci 258:6384–6390

Asiri AM, Hussein MA, Abu-Zied BM, Hermas A-EA (2013) Effect of NiLaxFe2 − xO4 nanoparticles on the thermal and coating properties of epoxy resin composites. Compos Part B: Eng 51:11–18

Brostow W, Dutta M, Rusek P (2010) Modified epoxy coatings on mild steel: tribology and surface energy. Eur Polym J 46:2181–2189

Legghe E, Aragraphenen E, Bélec L, Margaillan A, Melot D (2009) Correlation between water diffusion and adhesion loss: study of an epoxy primer on steel. Prog Org Coat 66:276–280

Popineau S, Rondeau-Mouro C, Sulpice-Gaillet C, Shanahan MER (2005) Free/bound water absorption in an epoxy adhesive. Polymer 46:10733–10740

Fu SY, Feng XQ, Lauke B, Mai YW (2008) Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos Part B: Eng 39:933–961

Ma PC, Siddiqui NA, Marom G, Kim JK (2010) Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos Part A Appl Sci Manuf 41:1345–1367

Moniruzzaman M, Winey KI (2006) Polymer nanocomposites containing carbon nanotubes. Macromolecules 39:5194–5205

Thostenson ET, Li CY, Chou TW (2005) Nanocomposites in context. Compos Sci Technol 65:491–516

Paul DR, Robeson LM (2008) Polymer nanotechnology: nanocomposites. Polymer 49:3187–3204

Johnsen BB, Kinloch AJ, Mohammed RD, Taylor AC, Sprenger S (2007) Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 48:530–541

Zou H, Wu SS, Shen J (2008) Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chem Rev 108:3893–3957

Akhil K, Raman B, Singh S, Akhtar M (2018) EDM machinability and parametric optimisation of 2014Al/Al2O3 composite by RSM. Int J Mach Mach Mater 20:536–555

Khajuria A, Akhtar M, Pandey M, Raina MA, Bedi R, Singh B (2019) Influence of ceramic Al2O3 particulates on performance measures and surface characteristics during sinker EDM of stir cast AMMCs. World J Eng 16:526–538

Zhang Z, Chen S, Li Y, Li S, Wang L (2009) A study of the inhibition of iron corrosion by imidazole and its derivatives self-assembled films. Corros Sci 51:291–300

Sorensen PA, Kiil S, Dam-Johansen K, Weinell CE (2009) Anticorrosive coatings: a review. Coat Technol Res 6:135–176

Le Pen C, Lacabanne C, Pebere N (2000) Structure of waterborne coatings by electrochemical impedance spectroscopy and a thermostimulated current method: influence of fillers. Prog Org Coat 39:167–175

Vilche JR, Bucharsky EC, Giúdice CA (2002) Application of EIS and SEM to evaluate the influence of pigment shape and content in ZRP formulations on the corrosion prevention of naval steel. Corros Sci 44:1287–1309

Bierwagen G, Battocchi D, Simões A, Stamness A, Tallman D (2007) The use of multiple electrochemical techniques to characterize mg-rich primers for Al alloys. Prog Org Coat 59:172–178

Liu X, Shao Y, Zhang Y, Meng G, Zhang T, Wang F (2015) Using high-temperature mechanochemistry treatment to modify iron oxide and improve the corrosion performance of epoxy coating—I. High- temperature ball milling treatment. Corros Sci 90:451–462

Liu X, Shao Y, Zhang Y, Meng G, Zhang T, Wang F (2015) Using high-temperature mechanochemistry treatment to modify iron oxide and improve the corrosion performance of epoxy coating – II. Effect of grinding temperature. Corros Sci 90:463–471

Xavier JR (2019) Investigation on the anticorrosion, adhesion and mechanical performance of epoxy nanocomposite coatings containing epoxy-silane treated nano MoO3 on mild steel. J Adhes Sci Technol. https://doi.org/10.1080/01694243.2019.1661658

Xavier JR (2019) Investigation into the effect of Cr2O3 nanoparticles on the protective properties of epoxy coatings on carbon steel in NaCl solution by scanning electrochemical microscopy. Prot Met Phys Chem 55(1):80–88. https://doi.org/10.1134/S2070205119010167

Xavier JR (2019) Effect of surface modified WO3 nanoparticle on the epoxy coatings for the adhesive and anticorrosion properties of mild steel. J Appl Polym Sci 137(5):48323. https://doi.org/10.1002/APP.48323

Zongxue Y, Haihui D, Yu M, Liang L, Yang P, Chunli Z, Yi H (2015) Fabrication of graphene oxide–alumina hybrids to reinforce the anti-corrosion performance of composite epoxy coatings. Appl Surf Sci 351:986–996

Mirabedini SM, Moradian S, Scantlebury JD, Thompson GE (2003) Characterization and corrosion performance of powder coated aluminium alloy. Iran Polym J 12:261–270

Hadavand BS, Ataeefard M, Bafghi HF (2015) Preparation of modified nano ZnO/polyester/TGIC powder coating nanocomposite and evaluation of its antibacterial activity. Compos Part B: Eng 82:190–195

Ashassi-Sorkhabi H, Seifzadeh D, Raghibi-Boroujeni M (2016) Analysis of electrochemical noise data in both time and frequency domains to evaluate the effect of ZnO nanopowder addition on the corrosion protection performance of epoxy coatings. Arab J Chem 9:S1320–S1327

Xavier JR (2017) Application of EIS and SECM studies for investigation of anticorrosion properties of epoxy coatings containing zinc oxide nanoparticles on mild steel in 3.5% NaCl solution. J Mater Eng Perform 26:3245–3253

Bazrgari D, Moztarzadeh F, Sabbagh-Alvani A, Rasoulianboroujeni M, Tahriri M, Tayebi L (2018) Mechanical properties and tribological performance of epoxy/Al2O3 nanocomposite. Ceram Int 44:1220–1224

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Boomadevi Janaki, G., Xavier, J.R. Evaluation of Mechanical Properties and Corrosion Protection Performance of Surface Modified Nano-alumina Encapsulated Epoxy Coated Mild Steel. J Bio Tribo Corros 6, 20 (2020). https://doi.org/10.1007/s40735-019-0316-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-019-0316-7