Abstract

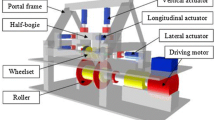

Proper values of the adhesion coefficient are the key to guarantee good operations of railway transportation systems in terms of safety, performances and punctuality during both braking and traction manoeuvres. Adhesion can drop to very low values due to contaminants lying on the track. However, the leading wheelsets have a cleaning effect on the rail, so that adhesion recovery can be observed on the following axles. A good knowledge of adhesion and adhesion recovery phenomenon is thus fundamental to optimize the dynamic behaviour of railway vehicles and to develop new algorithms for wheel slide protection (WSP) and antiskid systems. Several laboratory facilities are used to investigate adhesion, due to the high costs of on-track tests with full vehicles. Anyway, these devices do not allow a good simulation of the vehicle dynamics and of the real contact conditions. To overcome these issues, roller rigs usually represent a good compromise in terms of costs, safety, repeatability of the tests and simulation of the real contact conditions and vehicle dynamics. However, typical roller rigs consist of one or more wheelsets rolling over separate pair of rollers. An evolution of roller rigs, consisting of multiple wheelsets acting on the same contaminated surfaces, is thus needed to study the adhesion recovery phenomenon more properly. The paper concerns the experimental setup of an innovative 1:5 scaled multi-axle roller rig developed at Politecnico di Torino. The rig is intended to allow researchers to obtain a deep understanding of the mutual interaction of different following wheelsets running on a contaminated track.

Similar content being viewed by others

Abbreviations

- f :

-

Adhesion coefficient

- F b :

-

Braking force

- F s :

-

Suspension load

- F x :

-

Tangential load at the wheel-roller interface

- g :

-

Gravity acceleration

- I R,yy :

-

Polar inertia of the rollers

- I w,yy :

-

Polar inertia of the wheelset

- m :

-

Mass of the wheelset

- N :

-

Normal load at the wheel/roller interface

- p F\B :

-

F\b pressure at the outlet of the valves

- p SET :

-

Set pressure at the outlet of the valves

- R PAD :

-

Braking effective radius

- R R :

-

Roller radius

- R w :

-

Wheel radius

- T M :

-

Torque produced by the motor

- T R,0 :

-

Initial resistant torque

- T R,b :

-

Resistant torque due to braking effort

- V IN :

-

Set voltage

- V OUT :

-

FeedBack voltage

- α :

-

Angle of inclination of the wheelse

- ξ :

-

Creep

- τ :

-

Transmission ratio (ration between roller and wheel radius)

- ω R :

-

Angular speed of the rollers

- ω w :

-

Angular speed of the wheels

- \( {\dot{\omega}}_R \) :

-

Angular acceleration of the rollers

- \( {\dot{\omega}}_w \) :

-

Angular acceleration of the wheelset

- b :

-

Braking

- i :

-

Wheelset number (i = 1 ÷ 4)

- j :

-

Wheel number (j = 1,2)

- R :

-

Roller

- s :

-

Suspension

- w :

-

Wheelset

References

Harrison H, McCanney T, Cotter J (2002) Recent developments in coefficient of friction measurements at the rail/wheel interface. Wear 2002 253:114–123

Lewis R, Lewis SR, Zhu Y, Abbasi S, Olofsson U (2013) The modification of a slip resistance meter for measurement of railhead adhesion. P I Mech Eng F-J Rai 227(2):196–200

Olofsson U, Sundvall K (2004) Influence of leaf, humidity and applied lubrication on friction in the wheel-rail contact: pin-on-disc experiments. P I Mech Eng F-J Rai 218(3):235–242

Stolarski TA (1989) Friction in a pin-on-disc configuration. Mech Mach Theory 24(5):373–381

Zhu Y, Olofsson U, Persson K (2012) Investigation of factors influencing wheel-rail adhesion using a mini-traction machine. Wear 292-293:218–231

Galas R, Omasta M, Krupka I, Hartl M (2016) Laboratory investigation of ability of oil-based friction modifiers to control adhesion at wheel-rail Interface. Wear 368-369:230–238

Chen H, Ban T, Ishida M, Nakahara T (2008) Experimental investigation of influential factors on adhesion between wheel and rail under wet conditions. Wear 265(9–10):1504–1511

Wang WJ, Liu TF, Wang HY, Liu QY, Zhu MH, Jin XS (2014) Influence of friction modifiers on improving adhesion and surface damage of wheel/rail under low adhesion conditions. Tribol Int 75:16–23

Lewis SR, Lewis R, Cotter J, Lu X, Eadie DT (2016) A new method for the assessment of traction enhancers and the generation of organic layers in a twin-disc machine. Wear 366-367:258–267

Gallardo-Hernandez EA, Lewis R (2008) Twin disc assessment of wheel/rail adhesion. Wear 265(9–10):1309–1316

Fletcher DI, Lewis S (2013) Creep curve measurement to support Wear and adhesion modelling, using a continuously variable creep twin disc machine. Wear 298-299(1):57–65

Meymand, S, Hosseinipour, M., Ahmadian M. 2015. "The Development of a Roller Rig for Experimental Evaluation of Contact Mechanics for Railway Vehicles. ASME. ASME/IEEE Joint Rail Conference, 2015 Joint Rail Conference

Bosso N, Zampieri N (2014) Experimental and numerical simulation of wheel-rail adhesion and Wear using a scaled roller rig and a real-time contact code. Shock Vib 2014

Bosso N, Zampieri N (2013) Real-time implementation of a traction control algorithm on a scaled roller rig. Veh Syst Dyn 51(4):517–541

Bosso, N., A. Gugliotta, and N. Zampieri. 2014. "Study of adhesion and evaluation of the friction forces using a scaled roller-rig, 5th World Tribology Congress, WTC 2013, Volume 3, 2014, Pages 2640-2643

Bosso N, Zampieri N (2018) A novel analytical method to calculate wheel-rail tangential forces and validation on a scaled roller-rig. Advances in Tribology 2018. https://doi.org/10.1155/2018/7298236

Zhang W, Chen J, Wu X, Jin X (2002) Wheel/rail adhesion and analysis by using full scale roller rig. Wear 253(1–2):82–88

Jaschinski A, Chollet H, Iwnicki S, Wickens A, Von Würzen J (1999) The application of roller rigs to railway vehicle dynamics. Veh Syst Dyn 31(5–6):345–392

Ahn, K., J. Park, and S. Ryew. 2012. "The Construction of a Full-Scale wheel/rail Roller Rig in Korea

Myamlin, S., J. Kalivoda, and L. Neduzha. 2017. "Testing of Railway Vehicles using Roller Rigs

Chollet, H. 1998. "Essais en similitude a l’echelle 1r4 de bogies de wagons de la famille Y25

Iwnicki, S.D. and Shen, Z.Y. 1992. "Collaborative railway roller rig project

Jaschinski, A. 1990. "On the application of similarity Laws to a scaled railway bogie model

Liu B, Bruni S (2015) Analysis of wheel-roller contact and comparison with the wheel-rail case. Urban Rail Transit 1(4):215–226

Keylin, A., M. Ahmadian, M. Taheri, and A. Tajaddini. 2012. "Wheel-Rail Contact Characteristics on a Tangent Track Vs a Roller Rig

Nakazawa S-I, Hijikata D (2017) Wheel slide protection system by the use of the tangential force in the macro slip area. Quarterly Report of RTRI (Railway Technical Research Institute) 58(3):196–203

Barna, G. 2012. "Diagnosis of Wheel Slide Protection Systems for Rail Vehicles

Stützle, T., U. Viereck, A. Stribersky, W. Rulka, M. Enning, and D. Abel. 2006. "Creepage Control for use in Wheelslide Protection Systems

Kondo, K. 2012. "Anti-Slip Control Technologies for the Railway Vehicle Traction

Pichlík , P. Zděnek, j. (2014) Overview of slip control methods used in locomotives. Transactions on Electrical Engineering 3(2)

Lewis, S. R., R. Lewis, G. Evans, and L. E. Buckley-Johnstone. 2012. "Assessment of railway grease performance using a twin-disc tester

Omasta M, Machatka M, Smejkal D, Hartl M, Křupka I (2015) Influence of sanding parameters on adhesion recovery in contaminated wheel-rail contact. Wear 322-323:218–225

Arias-Cuevas O, Li Z, Lewis R, Gallardo-Hernández EA (2010) Rolling-sliding laboratory tests of friction modifiers in dry and wet wheel-rail contacts. Wear 268(3–4):543–551

Arias-Cuevas O, Li Z, Lewis R (2011) A laboratory investigation on the influence of the particle size and slip during sanding on the adhesion and Wear in the wheel-rail contact. Wear 271(1–2):14–24

Li Z, Arias-Cuevas O, Lewis R, Gallardo-Hernández EA (2009) Rolling-sliding laboratory tests of friction modifiers in leaf contaminated wheel-rail contacts. Tribol Lett 33(2):97–109

Voltr P, Lata M (2015) Transient wheel-rail adhesion characteristics under the cleaning effect of sliding. Veh Syst Dyn 53(5):605–618

Allotta, B., R. Conti, E. Meli, L. Pugi, and A. Ridolfi. 2014. "Development of a Full-Scale Roller-Rig to Test High Speed Trains Under Degraded Adhesion Conditions

Allotta, B., R. Conti, E. Meli, L. Pugi, and A. Ridolfi. 2014. "Study of high-speed train dynamics under degraded adhesion conditions: an innovative HIL architecture for full-scale roller-rigs

Bosso N, Gugliotta A, Zampieri N (2015) Strategies to simulate wheel-rail adhesion in degraded conditions using a roller-rig. Veh Syst Dyn 53(5):619–634

Bosso N, Gugliotta A, Zampieri N (2016) A test rig for multi-wheelset adhesion experiments, vol 110. Civil-Comp Proceedings

CEN-European Committee for Standardization: EN 15806, railway applications – braking – static brake testing. 2010

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bosso, N., Gugliotta, A., Magelli, M. et al. Experimental Setup of an Innovative Multi-Axle Roller Rig for the Investigation of the Adhesion Recovery Phenomenon. Exp Tech 43, 695–706 (2019). https://doi.org/10.1007/s40799-019-00327-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-019-00327-x