Abstract

The majority of particulate matter (PM) emitted from diesel engines is captured by advanced emission aftertreatment, here defined as the combination of a diesel particulate filter (DPF) and selective catalytic reduction (SCR). Some PM is still emitted, however, and because PM from uncontrolled diesel engines is known to be carcinogenic, any changes in diesel PM chemistry with aftertreatment would be of interest. Here, we present PM chemical composition from emissions of a 2010 compliant heavy-duty diesel vehicle (HDDV) with original equipment manufacturer aftertreatment collected on bulk filters and impactor stages. Results reported include inorganic ions, water-soluble organic carbon (WSOC), thermo-optical organic and elemental carbon (OC/EC), and specific polycyclic aromatic hydrocarbons (PAHs). We compare the model year 2010 composition to that emitted by a model year 1998 HDDV without DPF/SCR. We found that diesel PM mass emissions are reduced by one to two orders of magnitude by aftertreatment, but that a carbon-based accumulation mode (∼100 nm), the defining feature of traditional diesel PM, is still present in 2010 compliant HDDVs. Under heavier engine load conditions (high-speed cruise), the 2010 vehicle also emitted a sulfate-rich nucleation mode that, at times, made up the majority of particulate mass. OC and EC size distributions are similar for the two HDDVs, although during cruise, a second OC peak was found in the 2010 nucleation mode. PAH and WSOC data suggest that the OC emitted with aftertreatment is more oxidized and has a smaller relative contribution of unmodified fuel and lube hydrocarbons.

Similar content being viewed by others

1 Introduction

Heavy-duty diesel engines are essential to our current economy and way of life. As of 2012, diesel engines produced 86, 90, and 88 % of the energy used by buses, medium- and heavy-duty trucks (classes 3–8), and rail (including essentially all freight transport), respectively, in the USA [1]. Given the current transportation infrastructure and fleet composition, without heavy-duty diesel trucks, our ports would grind to a halt, our stores would be empty, and critical fuel and food deliveries would not occur. However, diesel engines are also significant emitters of air pollutants, most notably particulate matter (PM), oxides of nitrogen (NO x ), and hydrocarbons. Some of these emissions are toxic [2–5]. Most notably, the International Agency of Research on Cancer (IARC) designated diesel exhaust a probable carcinogen (Group 2A) in 1988 and, based on additional evidence, as a carcinogen in 2012 (group 1) [6]. Also, the state of California listed diesel particulate matter (PM) a toxic air contaminant in 1998 which led to policy and engine standards to reduce emissions [7].

The PM and NO x standards of 2007 and 2010 reduce emissions from on-road heavy-duty engines to 0.01 grams per brake horsepower hour (gPM/bhp-h) and 0.2 gNO x /bhp-h during certification testing. Each constitutes a 90 % reduction from standards that had already achieved significant emission reductions. To meet these standards, engine manufacturers are using advanced emissions aftertreatment for the first time to reduce emissions from diesel engines, specifically catalyzed diesel particle filters (DPFs) for PM and selective catalytic reduction (SCR) for NO x . As widely documented in the literature [8–10], the introduction of DPFs and SCR has drastically reduced emissions of almost all constituents of diesel exhaust, often by more than 90 %, and in some cases and for some constituents by more than 99 % (typically soot). 2010-compliant diesel with advanced aftertreatment in the form of DPF and SCR is herein referred to as “clean” diesel. When present, the DPF removes the vast majority of the traditional PM (soot) that is emitted by the engine, while the catalyst in the aftertreatment oxidizes the exhaust, changing the composition of what is emitted from the tailpipe.

While not all diesel aftertreatment systems are exactly the same, most systems approved for on-road heavy-duty diesel (HDD) engines in California since 2010 have similar basic components. Figure 1 shows the anatomy of the typical HDD aftertreatment system used in California for 2010 compliant vehicles. Diesel exhaust from the engine flows sequentially through a diesel oxidation catalyst (DOC), a catalyzed DPF, an SCR, and a small ammonia slip catalyst. Each of these components has their specific intended purpose: The DOC oxidizes CO and hydrocarbons (HC) and converts NO to NO2 which helps in DPF regeneration and SCR efficiency, the DPF physically removes a very large fraction of the emitted PM; the SCR removes NO x by reducing it to N2, and the final oxidation catalyst further removes CO and THC and any ammonia slip from the SCR (excess ammonia not reacted with NO x and released from the SCR catalyst). The DOC and DPF are packaged into a single canister (sometimes collectively referred to as the “DPF”), as are the SCR substrate and the ammonia slip catalyst (collectively referred to as the “SCR”). The intent of the overall aftertreatment system is threefold: (1) to oxidize the exhaust, (2) to remove PM, and (3) to reduce NO x .

Previous comparisons of the chemical composition of PM emitted from a diesel with and without aftertreatment show considerable differences, with less elemental carbon (EC) and larger fractions of organic carbon (OC) and inorganic ions, especially sulfate [10–12]. The purpose of this work is to take a detailed look at PM emissions from a 2010-compliant truck with original equipment manufacturer (OEM) integrated engine aftertreatment and provide insight into how and why the chemical composition of the diesel PM has changed relative to a baseline (uncontrolled) truck. This should help inform the basic question of whether clean diesel PM (i.e., w/DPF + SCR) is still diesel PM.

2 Methods

Vehicle emissions testing of a 2010 Volvo truck with OEM aftertreatment (“2010”) was conducted in 2012 and of an uncontrolled truck (here defined as a truck absent aftertreatment) with a 1998 Cummins engine (“1998”) in 2007. All tests were conducted at the California Air Resources Board’s (CARB) Heavy-Duty Emissions Testing Laboratory in Los Angeles, CA. The facility and sampling setup have been described in detail previously [3, 13] and are only discussed briefly here. The laboratory is equipped with a heavy-duty, Schenck-Pegasus chassis dynamometer driven by a direct current 600 hp motor. The 1998 truck was powered by a 1998 Cummins 11 L diesel engine, which does not have any aftertreatment. The 2010 truck was powered by a Volvo engine (D13, 405 HP/1450 lb-ft, 12.8 L displacement, 16:1 compression ratio) equipped with a diesel particulate filter (DPF) and selective catalytic reduction (SCR). All the testings were done using commercially available ultra-low sulfur diesel (required to be <15 ppm, but typically 5–10 ppm in California).

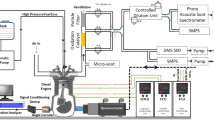

Vehicles operated on the chassis dynamometer have their exhaust connected to a full-exhaust dilution tunnel in the form of a Horiba critical flow venturi constant volume sampler (CVS). Filtered and carbon-scrubbed ambient air is used for dilution at test-averaged ratios ranging from 11:1 to 21:1. Figure S1 shows the sampling setup for the project in its entirety. A differential mobility spectrometer (DMS, Combustion Model 500) and a scanning mobility particle sizer (SMPS, TSI Model 3080) were connected directly to a sampling port in the CVS to measure particle number and size distribution. Similarly connected were filters for total suspended particle chemical speciation. Forty-seven-millimeter Teflon substrates (Teflo, R2PJ047, Pall Corp) were used for subsequent water-soluble ion analysis by ion chromatography. Quartz fiber filters (2500 QAO-UP, 47 mm, Pall Corp.), pre-baked at 550 °C for 4 h, were used for organic and elemental carbon (OC/EC) analysis using the IMPROVE_A thermo-optical method [14]. Organic matter (OM) emissions were calculated by multiplying the organic carbon result by 1.2 [15]. Also, a 13-stage micro-orifice uniform deposit impactor (MOUDI, MSP Corp, model 122-R) loaded with aluminum foil substrates was used to collect size segregated PM samples for subsequent OC/EC analyses for particles sized 10 nanometers (nm) to 1000 nm [16].

The vehicles were exercised over two driving modes: Cruise at constant 50 mph and a transient cycle. The transient cycle used was the US EPA Urban Dynamometer Driving Schedule (UDDS) for heavy-duty chassis dynamometer testing (Figure S2). The UDDS cycle duration is 17.67 min, has an average speed of 18.86 miles per h, a total length of 5.55 miles, and a maximum speed of 58 miles per h. The Cruise cycles were 45 min long at constant speed. Preconditioning for the UDDS cycle consisted of a single UDDS cycle and for Cruise by driving at 50 mph until steady-state temperature was reached in the SCR, typically 5–10 min of driving. No active regenerations took place during the sampling.

3 Results and Discussion

Changes in the chemical composition of diesel exhaust with the advent of aftertreatment can be explained in the context of the three main functions of the engine aftertreatment (oxidation, PM filtration, and NO x reduction; see Fig. 1). Figure 2 shows the chemical composition of the bulk PM sample from the 1998 and 2010 trucks. During both Cruise and transient operation, the PM emitted from the 1998 engine consists almost exclusively of organic and elemental carbon (OC and EC). These two chemical components have been widely reported to constitute the majority of diesel PM from trucks without aftertreatment, with the proportion of each dependent on the specific engine and engine operation [17, 18]. Although total PM from the 2010 truck is reduced by a factor of ∼50 relative to the 1998 truck, it still contains EC and OC. In the PM from the 2010 engine during the UDDS, these are still the dominant chemical species. However, ions, especially sulfate and to a lesser extent nitrate, are now present, constituting the majority of particulate mass under certain high-load (e.g., Cruise) conditions [10–12].

Figure 3 shows the average DMS particle number and mass distributions for both the 1998 and 2010 trucks during both Cruise and UDDS. Figure 3a shows the number distribution emitted by the 1998 truck during both cycles to be unimodal with a peak centered around 50–70 nm, typical of diesel PM. Particles in this size range are referred to as the accumulation mode. In the 2010 truck, this mode is drastically reduced for both cycles. The physical filtration that occurs in the DPF has removed the vast majority of these diesel particles, irrespective of cycle. However, a prominent mode of particles with Dp < 20 nm was consistently observed during the Cruise cycle for the 2010 truck (after exhaust, temperature reached steady state). Sulfur from fuel and engine oil is emitted from the engine in the form of SO2, but when sufficient temperatures exist in the catalyzed aftertreatment, SO2 is oxidized to SO3, which in turn will condense in combination with water or ammonia to form a nucleation mode of particles [11, 12, 19]. During the UDDS, exhaust temperatures were typically insufficient to convert SO2 to SO3, so nucleation mode particles are rarely present, while during the Cruise at 50 mph, higher exhaust temperature promotes this conversion and nucleation occurred. Unlike the accumulation mode, these nucleation mode particles are volatile and evaporate when heated to approximately 230 °C [20]. When nucleation did occur for the 2010 truck, the majority of the mass emitted was found in this mode (Fig. 3c). Figure S3 compares size distribution measured with the DMS and a more traditional scanning mobility particle sizer (SMPS).

In Fig. 3b, c, the particle size distributions have been converted to particle mass distributions by using standard diesel PM densities [21, 22, Table S1]. The mass distribution for the 1998 truck is unimodal with an accumulation mode centered around 100 nm during both Cruise and UDDS. The 2010 truck has the same peak in the accumulation mode during both cycles, but at drastically lower concentrations, as most of these particles have been removed by filtration in the DPF. When nucleation occurs during the high-load Cruise, a majority of particulate mass is comprised of particles smaller than 20 nm (Fig. 3c), contrary to the generally accepted notion that nucleation mode particles are too small to contribute to mass irrespective of number. It is also only during the Cruise, when nucleation occurred, that sulfur was dominant in the bulk PM sample (Fig. 2).

Figure 4 compares the organic and elemental carbon (OC/EC) size distributions in samples collected with a Nano-MOUDI during the Cruise cycle and shows that the EC PM size distributions are similar for 1998 and 2010 exhaust. From the 1998 truck, both OC and EC have a unimodal distribution with a peak in the traditional diesel PM accumulation mode. From the 2010 truck, EC is still unimodal and represents the small amount of EC not captured by the DPF, while OC is bimodal, as organic vapors condense onto both the accumulation and nucleation modes. Figure S4 shows images of all the size-segregated MOUDI filters during this sample. The filters containing the accumulation mode are the only dark filters. Nano-MOUDI samples were not available during the UDDS, but Fig. 2, showing that PM is mostly OC and EC, and Fig. 3c, showing all the mass is in the accumulation mode, suggest that the OC and EC mass distribution in 2010 during UDDS would be similar to the 1998 truck.

The chemical composition of the accumulation and nucleation modes from the 2010 compliant engine during Cruise is depicted in Fig. 5. The figure reflects the mass detected in each mode by DMS, the bulk PM chemistry, and the OC and EC detected in the nucleation mode with the MOUDI samples. Because inorganic composition was not available for MOUDI samples, we partitioned the sulfate and nitrate in the bulk sample between the modes such that the ratio of the total mass (essentially, sulfate + nitrate + EC + OC) in the nucleation to accumulation mode was equal to that ratio determined by the DMS. We achieve mass closure when 89 % of the sulfate and nitrate mass is assigned to the nucleation mode. The accumulation mode chemical composition is similar to the chemical composition of the bulk sample from the UDDS cycle, with some of the adsorbed sulfate generated during Cruise added. The nucleation mode is made up of only organics and ions, consistent with their demonstrated volatility.

Size-specific PM composition for 2010 Volvo (with aftertreatment) during the Cruise cycle. This data is equivalent to the bulk composition in Fig. 2 distributed amongst size fractions based on particle distributions (Fig. 3). The size of the pie charts indicates the amount of mass. a Accumulation mode PM. b Nucleation mode PM

The results above point to the following interpretation: 2010-compliant heavy-duty diesel vehicles (HDDVs) still emit traditional diesel PM out of the engine. However, what comes out of the tailpipe is now different due to the aftertreatment which filters and oxidizes the exhaust. Figures 2 and 3 show that the 2010 HDDV still emits a carbon-based accumulation mode that would be recognizable as diesel PM. This mode comprises the few traditional diesel particles emitted by the engine not filtered by the DPF, only relatively enriched in OC as the filtration of EC in the DPF is more effective than the removal of organics over the catalyzed surface of the OEM aftertreatment system examined. Although PM is reduced, sulfate is enriched in an absolute sense during Cruise, but nitrate is not. This is because under high engine load operations, when temperature in the aftertreatment is high enough to convert SO2 to SO3, some sulfate will condense onto the traditional accumulation mode but will mostly nucleate to form a nucleation mode. Some of the organic matter will also shift from the accumulation mode to the nucleation mode as it will condense onto both. In this case, the bulk PM consists of mostly sulfate (up to ∼70 %). The bimodal mass distribution of those particles suggests that two separate types of particles are being emitted as an external mixture (Fig. 5). One type comprises an organic carbon-based accumulation mode that is familiar from the 1998 engine and the other is a new sulfur and OC-dominated nucleation mode. The organics are likely to consist of the interim oxidation products between traditional diesel organics and CO2.

A proxy for this partially oxidized organic material is the fraction of organic carbon that is water-soluble (f WSOC), as both oil and unburned fuel are insoluble. For the 1998 truck, f WSOC was 8.7 and 14.2 % for the Cruise and UDDS cycles, respectively. This increased to 39.8 and 30.3 % for the 2010 truck (Fig. 6). An even greater increase in f WSOC occurred during tests on HDDVs retrofit with advanced aftertreatment [23] (Fig. 6). Overall, the increase in the fraction of OC that is water-soluble suggests selective removal of unburned and/or lightly oxygenated fuel and oil by the aftertreatment.

Fraction of emitted OC that is water-soluble for both the 1998 (uncontrolled) and 2010 Volvo (controlled) trucks. Also included is the range of values for trucks retrofit with 2010-compliant aftertreatment from [23]

A reduction in the proportion of unburned fuel/oil in diesel OC is also suggested by concentrations of individual polycyclic aromatic hydrocarbons (PAHs) in PM. The ratio of fluoranthene to pyrene has been used to distinguish between petrogenic and pyrolytic sources of organic matter in marine sediments [24], with ratios greater than ∼1 attributed to combustion. This ratio increased from 0.35/0.29 in the Cruise/UDDS cycles for the 1998 truck to 0.98/0.58 for the 2010 truck (with aftertreatment), similar to the elevated values of 0.46–1.8 previously observed for HDDVs retrofitted with engine aftertreatment (Fig. 7). As with the water-soluble organic carbon (WSOC) results, this is presumably due to a decrease in the proportion of unburned fuel and/or oil in the aftertreated exhaust. It should be noted, however, that the overall contribution of these compounds to emitted OC is strongly reduced by engine aftertreatment. For the 1998 truck, fluoranthene, pyrene, and chrysene comprised 104, 298, and 115 μg, respectively, of each gram OC emitted during the Cruise cycle. For the UDDS cycle, these values were 139, 499, and 209 μg/g OC. These three PAHs were much less prevalent in OC emitted by the 2010 truck, now comprising 72, 74, and 16 μg/g OC during the Cruise cycle and 16, 28, and 14 μg/g OC during the UDDS cycle (Fig. 7). This represents a 78 ± 24 % reduction in the proportion of these PAHs in diesel OC with aftertreatment, and like the WSOC data (Fig. 6), this change is similar to what has been observed in retrofitted HDDVs [23] (Fig. 7). Overall, although aftertreatment strongly reduces the concentrations of particulate OC emitted by HDDVs, the ratio of partially oxidized to unburned hydrocarbons is increased. In older engines retrofitted with aftertreatment, this increase is greatest and suggests that most of the overall reduction in particulate OC is due to reduced emission of hydrocarbons from unburned fuel/oil. The 2010 truck with OEM aftertreatment further reduced overall OC, and the similar fluoranthene-to-pyrene ratios suggest removal both of compounds formed in the engine and/or aftertreatment as well as unburned fuel/oil.

Total OC emission factors and fluoranthene/pyrene ratios for both the 1998 and 2010 Volvo (w/OEM aftertreatment), as well as for various HDDVs retrofit with 2010-compliant aftertreatment (see Pakbin et al.[27]). Fluoranthene and pyrene are PAH isomers, and their ratio is interpreted as an indicator of pyrolitic formation. For the retrofit aftertreatments, V indicates a vanadium-based SCR, Z indicates a zeolite-based SCR, and CRT stands for Continuously Regenerating Technology™ (this system does not include SCR)

4 Conclusions

There are two main implications for human exposure to PM from clean diesel engines. First, while the mass of PM emitted per kilometer driven is reduced by a factor of ∼50 with 2010-compliant aftertreatment, the chemical composition of the accumulation mode is similar, being largely comprised of soot and organic carbon. Second, when temperatures in the 2010-compliant aftertreatment are great enough (e.g., during the Cruise cycle), a similar or greater amount of mass is emitted in a nucleation mode. Due to the high surface area and likely acidic nature of this nucleation mode, future studies should examine the toxicology and chemistry of these particles. Furthermore, due to increased diffusion, deposition of these ∼10 nm particles in the human respiratory tract will be more efficient than for larger accumulation mode particles. This is especially true in the alveolar region of the respiratory system, where ∼50 % of inhaled 10 nm particles deposit compared to ∼20 % each in the tracheobronchial and upper respiratory tract [25].

The aftertreatment system for this 2010 truck is designed to rely primarily on passive regenerations of the DPF. A prominent nucleation mode has also been observed during active DPF regenerations once the temperature of the aftertreatment inlet exceeded ∼500 °C [26]. Thus, formation of new particles in the exhaust of clean diesel occurs during both active and passive regeneration, and future studies of PM emitted from HDDV should attempt to characterize this nucleation mode. This represents a challenge because particles smaller than 10 nm are difficult to detect, respond rapidly to changes in semivolatile gas phase concentrations due to their high surface/volume ratios, and can also rapidly disappear due to diffusional losses and coagulation. However, these results from a 2010-compliant HDDV, combined with observations during DPF regeneration, suggest that these particles will comprise an increasing proportion of diesel emission over the coming decades.

References

Aspen Environmental Group: Prepared for and published by The Diesel Technology Forum. www.dieselforum.org/files/dmfile/FINALWebPDFVersion-NoAppendices.pdf (2011). Accessed 28 Jan 2014

Diaz-Sanchez, D., Dotson, A.R., Takenaka, H., Saxon, A.: Diesel exhaust particles induce local IgE production in vivo and alter the pattern of IgE messenger RNA isoforms. J. Clin. Invest. 94(4), 1417–1425 (1994)

Saxon, A., Diaz-Sanchez, D.: Diesel exhaust as a model xenobiotic in allergic inflammation. Immunopharmacology 48, 325–327 (2000)

Li, N., Kim, S., Wang, M., Froines, J., Sioutas, C., Nel, A.: Use of a stratified oxidative stress model to study the biological effects of ambient concentrated and diesel exhaust particulate matter. Inhal. Toxicol. 14(5), 459–486 (2002)

Nel, A.E., Diaz-Sanchez, D., Ng, D., Hiura, T., Saxon, A.: Enhancement of allergic inflammation by the interaction between diesel exhaust particles and the immune system. J. Allergy Clin. Immunol. 102, 539–554 (1998)

International Agency for Research on Cancer: Diesel Engine Exhaust Carcinogenic. Press Release No 213. http://www.iarc.fr/en/media-centre/pr/2012/pdfs/pr213_E.pdf (2012). Accessed 28 Jan 2014

California Air Resources Board: Initial statement of reasons, proposed identification of diesel exhaust as a toxic air contaminant. http://www.arb.ca.gov/toxics/dieseltac/staffrpt.pdf (1998)

Herner, J.D., Hu, S., Robertson, W.H., Huai, T., Collins, J.F., Dwyer, H., Ayala, A.: Effect of advanced aftertreatment for PM and NOx control on heavy-duty diesel truck emissions. Environ. Sci. Technol. 43(15), 5928–5933 (2009)

Kittelson, D.B., Watts, W.F., Johnson, J.P., Thorne, C., Higham, C., Payne, M., Goodier, S., Warrens, C., Preston, H., Zink, U., Pickles, D., Goersmann, C., Twigg, M.V., Walker, A.P., Boddy, R.: Effect of fuel and lube oil sulfur on the performance of a diesel exhaust gas continuously regenerating trap. Environ. Sci. Technol. 42(24), 9276–9282 (2008)

Khalek, I.A., Bougher, T.L., Merritt, P.M., Zielinska, B.: Regulated and unregulated emissions from highway heavy-duty diesel engines complying with U.S. Environmental Protection Agency 2007 emissions standards. J. Air. Waste Manag. 61(4), 427–442 (2011)

Vaaraslahti, K., Virtanen, A., Ristimaki, J., Keskinen, J.: Nucleation mode formation in heavy-duty diesel exhaust with and without a particulate filter. Environ. Sci. Technol. 38(18), 4884–4890 (2004)

Herner, J.D., Hu, S., Robertson, W.H., Huai, T., Chang, M.-C., Rieger, P., Ayala, A.: Effect of advanced aftertreatment for PM and NOx reduction on heavy-duty diesel engine ultrafine particle emissions. Environ. Sci. Technol. 45(6), 2413–2419 (2011)

Ayala, A., Kado, N.Y., Okamoto, R.A., Holmén, B.A., Kuzmicky, P.A., Kobayashi, R., Stiglitz, K.E.: Diesel and CNG heavy-duty transit bus emissions over multiple driving schedules: regulated pollutants and project overview. SAE Trans. J. Fuels Lubricants 735–747 (2002)

California Air Resources Board: MLD Method 139—procedure for organic carbon and elemental carbon (OC/EC) analysis of vehicular exhaust particulate matter (PM) on quartz filters (2006)

Kleeman, M.J., Schauer, J.J., Cass, G.R.: Size and composition distribution of fine particulate matter emitted from motor vehicles. Environ. Sci. Technol. 34(7), 1132–1142 (2000)

Kleeman, M.J., Schauer, J.J., Cass, G.R.: Size and composition distribution of fine particulate matter emitted from wood burning, meat charbroiling, and cigarettes. Environ. Sci. Technol. 33, 3516–3523 (1999)

Robert, M.A., Kleeman, M.J., Jakober, C.A.: Size and composition distributions of particulate matter emissions: part 2—heavy-duty diesel vehicles. J. Air Waste Manag. 57(12), 1429–1438 (2007)

Burtscher, H.: Physical characterization of particulate emissions from diesel engines: a review. J. Aerosol Sci. 36(7), 896–932 (2005)

Kittelson, D.B., Watts, W.F., Johnson, J.P., Rowntree, C., Payne, M., Goodier, S., Warrens, C., Preston, H., Zink, U., Ortiz, M., Goersmann, C., Twigg, M.V., Walker, A.P., Caldow, R.: On-road evaluation of two diesel exhaust aftertreatment devices. J. Aerosol Sci. 37(9), 1140–1151 (2006)

Biswas, S., Hu, S., Verma, V., Herner, J.D., Robertson, W.H., Ayala, A., Sioutas, C.: Physical properties of particulate matter (PM) from late model heavy-duty diesel vehicles operating with advanced PM and NOx emission control technologies. Atmos. Environ. 42(22), 5622–5634 (2008)

Maricq, M.M., Xu, N.: The effective density and fractal dimension of soot particles from premixed flames and motor vehicle exhaust. J. Aerosol Sci. 35, 1251–1274 (2004)

Zheng, Z., Johnson, K.C., Liu, Z., Durbin, T.D., Hu, S., Huai, T., Kittelson, D.B., Jung, H.S.: Investigation of solid particle number measurement: existence and nature of sub-23nm particles under PMP methodology. J. Aerosol Sci. 42(12), 883–897 (2011)

Biswas, S., Verma, V., Schauer, J., Sioutas, C.: Chemical speciation of PM emissions from heavy-duty diesel vehicles equipped with diesel particulate filter (DPF) and selective catalytic reduction (SCR) retrofits. Atmos. Environ. 43, 1917–1925 (2009)

Budzinski, H., Jones, I., Bellocq, J., Piérard, C., Garrigues, P.: Evaluation of sediment contamination by polycyclic aromatic hydrocarbons in the Gironde estuary. Mar. Chem. 58, 85–97 (1997)

Oberdörster, G., Oberdörster, E., Oberdörster, J.: Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ. Health Perspect. 113(7), 823–839 (2005)

Quiros, D.C., Yoon, S., Dwyer, H.A., Collins, J.F., Zhu, Y., Huai, T.: Measuring particulate matter emissions during parked active diesel particulate filter regeneration of heavy-duty diesel trucks. J. Aerosol Sci. 73, 48–62 (2014)

Pakbin, P., Ning, Z., Schauer, J.J., Sioutas C.: Characterization of particle bound organic carbon from diesel vehicles equipped with advanced emission control technologies. Environ. Sci. Technol. 43(13), 4679–4686 (2009)

Acknowledgments

The authors thank Sharon Lemieux and Keshav Sahay for their valuable support during experimental phase.

Disclaimer

The statements and opinions expressed in this paper are solely the authors’ and do not represent the official position of the California Air Resources Board. The mention of trade names, products, and organizations does not constitute endorsement or recommendation for use. The Air Resources Board is a department of the California Environmental Protection Agency. CARB’s mission is to promote and protect public health, welfare, and ecological resources through effective reduction of air pollutants while recognizing and considering effects on the economy. CARB oversees all air pollution control efforts in California to attain and maintain health-based air quality standards.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Figure S1

The complete laboratory sampling setup. Red boxes indicate measurements that are the focus of this manuscript. (PNG 3007 kb)

Figure S2

The speed vs. time trace of the UDDS cycle. (PNG 248 kb)

Figure S3

Comparison of the number distributions observed during nucleation for the 2010 truck by the (a) DMS and (b) SMPS instruments. (PNG 965 kb)

Figure S4

Images of the MOUDI substrates collected during nucleation (i.e., the 2010 truck, Cruise cycle). (GIF 116 kb)

Table S1

(DOCX 14 kb)

Rights and permissions

About this article

Cite this article

Ruehl, C., Herner, J.D., Yoon, S. et al. Similarities and Differences Between “Traditional” and “Clean” Diesel PM. Emiss. Control Sci. Technol. 1, 17–23 (2015). https://doi.org/10.1007/s40825-014-0002-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-014-0002-7