Abstract

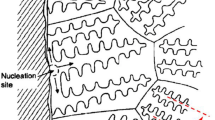

The aim of the present work was to investigate various means of obtaining a fine eutectic silicon structure in A356.2 alloy and therefore improve the alloy mechanical properties. The effects of solidification rate, Sr modification and melt thermal treatment (MTT) on the silicon particle characteristics of A356.2 (Al–7 %Si–0.4 %Mg) alloy were studied. The particle characteristics measured were the average particle area, average particle length, average particle roundness and average particle aspect ratio, using image analysis and optical microscopy. The results showed that Sr modification-, superheat- and Sr modification-MTT (SrMTT)-processed castings provide fine eutectic Si particles, the SrMTT process giving the best modification results. Both size and morphology of the eutectic silicon particles are affected by the modification process used. The Sr-grain-refined, Sr-melt superheat and SrMTT castings show well-modified fibrous Si particles, whereas the MTT casting exhibits Si particles that, although refined to a certain extent, still retain their acicular morphology. Solidification rate affects the eutectic Si particle size in that a higher solidification rate produces finer Si particles. However, within the range of solidification rates provided by the end-chill mold used in this work, the solidification rate does not affect the morphology of the Si particles.

Similar content being viewed by others

References

D. Apelian, S. Shivkumar, G. Sigworth, Fundamental aspects of heat treatment of Cast Al–Si–Mg alloys. AFS Trans. 97, 727–742 (1989)

S. Shivkumar, C. Keller, D. Apelian, Aging behavior in cast Al–Si–Mg alloys. AFS Trans. 98, 905–911 (1990)

J.R. Davis (ed.), Aluminum and aluminum alloys (ASM International, Ohio, 1993), p. 627

S. Shankar, Y.W. Riddle, M.M. Makhlouf, Nucleation mechanism of the eutectic phases in aluminum–silicon hypoeutectic alloys. Acta Mater. 52, 4447–4460 (2004)

J.E. Gruzleski, The art and science of modification: 25 years of progress, Silver Anniversary Paper. AFS Trans. 100, 673–683 (1992)

W. Jie, Z. Chen, W. Reif, K. Muller, Superheat treatment of Al–7Si–0.55Mg melt and its influences on the solidification structures and the mechanical properties. Metall. Mater. Trans. A 34A, 799–806 (2003)

B. Tolui, A. Hellawell, Phase separation and undersolidification in an Al–Si eutecticalloy—The influence of freezing rate and temperature gradient. Acta Metall. 24, 565–573 (1976)

L.M. Hogan, H. Song, Interparticle spacings and undersolidifications in Al–Si eutectic microstructures. Metall. Trans. A 18A, 235–237 (1970)

M.F. Ibrahim, E.M. Elgallad, S. Valtierra, H.W. Doty, F.H. Samuel, Metallurgical parameters controlling the eutectic silicon charateristics in be-treated Al–Si–Mg alloys. Mater. 9(2), 1–17 (2016)

P.E. Crosley, L.F. Mondolfo, The modification of aluminum-silicon alloys. AFS Trans. 74, 53–64 (1966)

P.S. Popel, V.E. Sidorov, Microheterogeneity of liquid metallic solutions and its influence on the structure and properties of rapidly quenched alloys. Mater. Sci. Eng. A 226–228, 237–244 (1997)

S. Eguskiza, A. Niklas, A.I. Fernández-Calvo, F. Santos, M. Djurdjevic, Study of strontium fading in Al–Si–Mg and Al–Si–Mg–Cu alloy by thermal analysis. Int. J. Metalcasting, 45–50 (2015)

J. Wang, S. He, B. Sun, Y. Zhou, Q. Guo, M. Nishio, A356 alloy refined by melt thermal treatment. Int. J. Cast Met. Res. 14, 165–168 (2001)

R. Lazarova-Mancheva, R. Kovacheva, G. Bachvarov, V. Manolov, Influence of the Solidification rate on the geometric parameters of eutectic silicon in AlSi7Mg castings. Prakische Metallographie 39, 28–35 (2002)

F. Paray, J.E. Gruzleski, Microstructure-mechanical property relationships in a 356 alloy. Part I: Microstructure. Cast Metals 7, 29–40 (1994)

S. Shivkumar, S. Ricci Jr., C. Keller, D. Apelian, Effect of solution treatment parameters on tensile properties of cast aluminum alloys. J. Heat. Treat. 8, 63–70 (1990)

J. Wang, S. He, B. Sun, K. Li, D. Shu, Y. Zhou, Effects of melt thermal treatment on hypoeutectic Al–Si alloys. Mater. Sci. Eng. A338, 101–107 (2002)

M. Drouzy, S. Jacob, M. Richard, Interpretation of tensile results by means of quality index and probable yield strength. AFS Int. Cast Metals J. 5, 43–50 (1980)

X. Cao, J. Campbell, Oxide inclusions defects in Al–Si–Mg cast alloys. Can. Metall. Q. 44, 435–448 (2005)

J. Campbell, An overview of the effect of bifilms on the microstructure and properties of cast alloys. Metall. Mater. Trans. B 37B, 857–863 (2006)

Z. Ma, A.M. Samuel, F.H. Samuel, H.W. Doty, S. Valtierra, A study of tensile properties in Al–Si–Cu and Al–Si–Mg alloys: effect of β-iron intermetallics and porosity. Mater. Sci. Eng. A 490(1–2), 36–51 (2008)

E. Samuel, A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Intermetallic phases in Al–Si based cast alloys: new perspective. Int. J. Cast Met. Res. 27, 107–114 (2014)

Acknowledgments

The authors would like to thank Dr. Ehab Samuel of the National Research Council Canada—Aluminium Technology Centre for editing the present research article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samuel, A.M., Doty, H.W., Valtierra, S. et al. New Method of Eutectic Silicon Modification in Cast Al–Si Alloys. Inter Metalcast 11, 475–493 (2017). https://doi.org/10.1007/s40962-016-0089-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-016-0089-4