Abstract

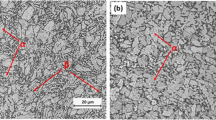

The present study was undertaken to investigate the capacity of the ultrasonic technique for measuring various particles in liquid aluminum and commercial 356 alloy at two different temperatures each. Particles of TiB2, AlSr, Al3Ti, and Al2O3 were studied using a Metalvision MV20/20 ultrasonic machine. The data provided plots of (1) the cleanliness value, (2) average particle size, and (3) particle count for each particle size range, as a function of testing time. An examination of the microstructure of solidified samples obtained from samplings of the melt was also carried out using Jeol JXA-8900L electron probe microanalyzer. Other techniques, including the liquid metal cleanliness analyzer and all the filtration techniques, can only detect TiB2 particulates when the concentration is very low (less than 10 ppm B). By applying the ultrasonic technique, measurements may be conducted properly for concentrations as high as 90 ppm B; thus, the ultrasonic technique provides an improved alternative for the measurement of TiB2 particulates in liquid aluminum. This fact is of significance, since particles are invariably present because the addition of TiB2 is essential to the grain-refining processes used for aluminum alloys.

Similar content being viewed by others

References

W.S. Hudson, D. Apelian, Inclusion Detection in Molten Aluminum: Current Art and New Avenues for In Situ Analysis. Int. J. Met. 10(3), 289–305 (2016)

S. Shivkumar, D. Apelian, H. Brucher, Melt Cleanliness in Die Cast Aluminum Alloys, in Transactions of the 16th International Die Casting Congress and Exposition (Detroit, Michigan, USA, 30 September-3 October, 1991), pp. 143–152

F. Chiesa, D. Levasseur, G. Morin, Effect of Particles on the Tensile Properties Inside a LPPM A356 Casting. Int. J. Met. 10(2), 216–223 (2016)

M.J. Lessiter, W.M. Rasmussen, To Pour or Not to Pour: The Dilemma of Assessing Your Aluminum Melt’s Cleanliness. Mod. Cast. 86, 45–48 (1996)

J.E. Gruzleski, B.M. Closset, The Treatment of Liquid Aluminum–Silicon Alloys (American Foundrymen’s Society Inc, Des Plaines, 1990), p. 1

S. Viswanathan, A.J. Duncan, Q. Han, W.D. Porter, B.V. Rimers, Modeling of Solidification and Porosity in Aluminum Alloy Castings. AFS Trans. 106, 411–417 (1998)

C. Sztur, F. Balestreri, J.L. Meyer, B. Hannart, Settling of Particles in Holding Furnaces: Modeling and Experimental Results. Light Met. 1990, 709–716 (1990)

S.L. Soo, Fluid Dynamics of Multiphase Systems (Blaisdell Publishing Co, Massachusetts, 1967)

S.T. Johansen, S. Taniguchi, Prediction of Agglomeration and Break Up of Particles During Metal Refining. Light Met. 1998, 855–861 (1998)

M. Maniruzzaman, M. Makhlouf, The Removal of Solid Particles from Aluminum Alloys Melts by Flotation—A Mathematical Model, in 5th International AFS Conference on Molten Aluminum Processing, 8–10 Nov 1998, Orlndo, FL, American Foundry Society (1998), pp. 61–76

L.C.B. Martins, G.K. Sigworth, Inclusion Removal by Flotation and Stirring, in 2nd International Conference on Molten Aluminum Processing (American Foundry Society, 1989), pp. 16-1–16-28

D.V. Neff, B.P. Cochran, Chlorination Technology in Aluminum Recycling. Light Met. 1993, 1053–1060 (1993)

S. Makarov, D. Apelian, R. Ludwig, Inclusion Removal and Detection in Molten Aluminum: Mechanical, Electromagnetic, and Acoustic Techniques. AFS Trans. 107, 725–735 (1999)

L. Pavlak, J.C. Sturm, Reduction of Oxide Inclusions in Aluminum Cylinder Heads Through Autonomous Designs of Experiments. Int. J. Met. (2016). doi:10.1007/s40962-016-0096-5

T.L. Mansfield, C.L. Bradshaw, Ultrasonic Inspection of Molten Aluminum. Tran. Am. Foundrymen’s Soc. 93, 317–322 (1985). (Paper 85-46)

J.F. Guo, H. Tahiri, F.H. Samuel, A.M. Samuel, D. Paluch, Detection of Grain Refiners Using the Ultrasonic Technique. AFS Trans. 117, 187–201 (2009). (Paper 09-079)

J.F. Guo, F.H. Samuel, A.M. Samuel, D. Paluch and S. Valtierra, Use of the Ultrasonic Technique for Measuring Particles in Al-Si Alloy Melts, in Transactions of the American Foundry Society : 112th Metalcasting Congress, May 17 - 20, 2008, Atlanta, Georgia. 2008, pp. 61-78

R. Gallo, H. Mountford, I. Sommerville, Ultrasound for On-Line Inclusion Detection in Molten Aluminum Alloys: Technology Assessment, in Proceedings from the AFS International Conference on Structural Aluminum Casting, 2–4, November 2003, Orlando, FL (2003), pp. 179–194

DD Smith, LS Aubrey, WC Miller, LiMCA II Evaluation of the Performance Characteristics of Single Element and Staged Ceramic Foam Filtration. Light Met. 1998, 89–915 (1998)

M.M. Niedzinski, E.M. Williams, D.D. Smith, L.S. Aubrey, Staged Filtration Evaluation at an Aircraft Plate and Sheet Manufacturer. Light Met. 1999, 1019–1030 (1999)

J. Shirandasht, Evaluation of the LiMCA II Technique for Inclusion Measurements in Pure Aluminum and Al–6%Si Cast Alloys: Role of Melt Temperature (Université du Québec à Chicoutimi, Mémoire de thèse, 2005)

N. Habibi, Évaluation des particles et des oxydes dans les alliages Al–Si en utilisant le technique prefil (Université du Québec à Chicoutimi, Mémoire de thèse, 2002), pp. 62–65

F. Gazanion, X.G. Chen, C. Dupuis, Studies on the Sedimentation and Agglomeration Behavior of Al–Ti–B and Al–Ti–C Grain Refiners. Mater. Sci. Forum 396–402, 45–52 (2002)

Acknowledgements

The authors would like to thank Amal Samuel for enhancing the quality of the images presented in this article, and Dr. A.M. Samuel for final proofreading of the article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, J.F., Doty, H.W., Valtierra, S. et al. Measurement of Particles in Molten Al–Si Alloys Applying the Ultrasonic Technique. Inter Metalcast 12, 235–250 (2018). https://doi.org/10.1007/s40962-017-0154-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0154-7