Abstract

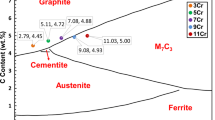

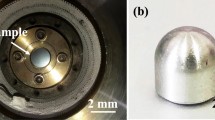

Frictional heat-induced severe adhesive wear has been limiting the lifetime of metal-to-metal wear systems for many years. Five graphitic white irons were previously designed and produced to introduce flake graphite into white iron, with the goal to expedite heat dissipation and reduce the frictional heat effect. This paper focused on the graphite addition effect on adhesive wear resistance for graphitic white irons and its comparison with abrasive wear. Adhesive wear resistance was assessed with a block on ring apparatus in accordance with ASTM G77. An empirical model was formulated to quantitatively evaluate graphite additions’ effect on the adhesive wear resistance. The model indicated that 1 vol.% graphite addition had the same effect as a hardness increase of 2.66 HRC, which was a 14% higher contribution than previously observed for three-body abrasive wear of the same alloys studied following ASTM G65. The improved wear resistance was related to an increased thermal diffusivity of the composite microstructure, and the surface lubricating effect of graphite.

Similar content being viewed by others

References

X. Ai, C. A. Moyer, Rolling Element Bearings, in Modern Tribology Handbook, (CRC, 2001), pp. 1041–1093

H. S. Cheng, Gears, in Modern Tribology Handbook, (CRC, 2001), pp. 1095–1129

R.F. Salant, Rotary Dynamic Seals, in Modern Tribology Handbook, (CRC, 2001), pp. 1131–1157

J.A. Hawk, R.D. Wilson, J.H. Tylczak, O.N. Dogan, Laboratory Abrasive Wear Tests: investigation of Test Methods and Alloy Correlation. Wear 225, 1031–1042 (1999)

J. H. Tylczak, A. Oregon, Abrasive Wear, in ASM Handbook Volume 18, (ASM International, 1992), p. 184

M. Riddihough, Stellite as a wear-resistant material. Tribology 3(4), 211–215 (1970)

K.C. Antony, Wear-resistant cobalt-based alloys. J. Metals 35(2), 52–60 (1983)

J. Shin, J. Doh, J. Yoon, D. Lee, J. Kim, Effect of molybdenum on the microstructure and wear resistance of cobalt-base Stellite hardfacing alloys. Surf. Coat. Technol. 166(2–3), 117–126 (2003)

J. Wan, J. Qing, M. Xu, Designing a Graphitic White Iron: Microstructures and Properties, in Association for Iron & Steel Technology 2019, (Pittsburgh, PA, 2019)

J. Wan, D. C. Van Aken, J. Qing, M. Xu, Microstructural Characterization and Failure Analysis of a Wear Resistant, High Molybdenum and Chromium White Iron, 2019

K. Sipos, M. Lopez, M. Trucco, Surface Martensite White Layer Produced by Adhesive Sliding Wear-Friction in AISI 1065 Steel. Revista Latinoamericana de Metalurgia Materiales 28(1), 46–50 (2008)

F. Klocke, E. Brinksmeier, K. Weinert, Capability profile of hard cutting and grinding processes. Ann. CIRP 54(2), 22–45 (2005)

S. Smith, S.N. Melkote, L. Curzio, E.T. Watkins, R. Allard, L. Riester, Effect of surface integrity of hard turned AISI 52100 steel on fatigue performance. Mater. Sci. Eng. A 459, 337–346 (2007)

Y.B. Guo, G.M. Janowski, Microstructural characterization of white layers by hard turning and grinding. Trans. NAMRI/SME 32, 367–374 (2004)

J. Wan, J. Qing, M. Xu, Designing a Novel Graphitic White Iron for Metal-to-metal Wear Systems. Metallurg. Mater. Trans. A 50(3), 1162–1174 (2019)

H. Berns, W. Theisen, Tribological properties, in Ferrous Materials, (Bochum, Springer, 2008), p. 103

A. Kagawa, T. Okamoto, K. Saito, M. Ohta, Hot hardness of (Fe, Cr)3C and (Fe, Cr)7C3 carbides. J. Mater. Sci. 19, 2546–2554 (1984)

J. Wang, W. Guo, H. Sun, H. Li, H. Gou, J. Zhang, Plastic deformation behaviors and hardening mechanism of M7C3 carbide. Mater. Sci. Eng. A 662, 88–94 (2016)

M.A. Guitar, U.P. Nayak, D. Britz et al., The effect of thermal processing and chemical composition on secondary carbide precipitation and hardness in high-chromium cast irons. Inter Metalcast (2020). https://doi.org/10.1007/s40962-020-00407-4

S. Inthidech, P. Sricharoenchai, Y. Matsubara, Effect of sub-critical heat treat parameters on hardness and retained austenite in mo-containing high chromium cast irons. Inter Metalcast 6, 25–34 (2012). https://doi.org/10.1007/BF03355536

A. Hadji, K. Bouhamla, H. Maouche, Improving wear properties of high-chromium cast iron by manganese alloying. Inter Metalcast 10, 43–55 (2016). https://doi.org/10.1007/s40962-015-0003-5

S. Inthidech, K. Yamamoto, Y. Matsubara, Effect of tungsten equivalent on heat treatment behavior of semi-multi-alloyed white cast iron for abrasive wear resistance. Inter Metalcast (2020). https://doi.org/10.1007/s40962-020-00449-8

J. Wan, J. Qing, M. Xu, Developing a graphitic white cast iron, in Materials Science and Technology 2018, (Columbus, 2018)

J. Wan, P.W. Habecker, J. Qing, M. Xu, Evolution of phases in a graphitic white iron, in AFS, (Atlanta, 2019)

J. Wan, J. Qing, M. Xu, Investigation of wear performance for the first generation graphitic white iron,” in Materials Science & Technology 2019, (Portland, OR, 2019)

J. Wan, J. Qing, M. Xu, Investigation of thermal diffusivity for the first generation graphitic white iron,” in Materials Sci ence & Technology 2019, (Portland, OR, 2019)

J. Wan, D.C. Van Aken, J. Qing, T. J. Yaniak, T. C. Clements, M. Xu, Developing a graphitic white iron for abrasive wear application: thermal and wear properties, Wear, 436–437, 202967 (2019)

Annual Book of ASTM Standards, “ASTM Designation E1461-13,” ASTM, 2013

Annual Book of ASTM Standards, “ASTM Designation G65-16,” ASTM, 2016

G. Sutter, N. Ranc, Flash temperature measurement during dry friction process at high sliding speed. Wear 268(11–12), 1237–1242 (2010)

Annual Book of ASTM Standards, “ASTM Designation G77-17,” ASTM, 2017

D.C. Van Aken, W.F. Hosford, Reporting Results: A Practical Guide for Engineers and Scientists (Cambridge University, Cambridge, 2008), pp. 87–91

G.P. Alejandro, A.A. Florentino, A.L. Juan, Improvement of adhesive wear behavior by variable heat treatment of a tool steel for sheet metal forming. Materials 12, 1–10 (2019)

M.S. Narassima, S. Hangovan, S.P. Anbuudayasankar, P. Pavithran, Effect of reinforcement and aging time on wear behavior and mechanical properties of Aluminium LM4. Int. J. Eng. Adv. Technol. 8(5), 2426–2433 (2019)

M.F. Buchely, J.C. Gutierrez, L.M. Leon, A. Toro, The effect of microstructure on abrasive wear of hardfacing alloys. Wear 259, 52–61 (2005)

S.B. Hosseini, U. Klement, Y. Yao, K. Ryttberg, Formation mechanisms of white layers induced by hard turning of AISI 52100 steel. Acta Mater. 89, 258–267 (2015)

S. Goto, C. Liu, S. Aso, Y. Komatsu, Proceedings of the 9th International Conference on Creep and Fracture of Engineering Materials and Structures,” in The Institute of Materials, London, 2001

S. Goto, S. Aso, Y. Komatsu, Proceedings of abrasion wear resistant alloyed white cast iron for rolling and pulverizing mills, in Japan Foundry Eng. Soc., (Fukuoka, 2002)

L. Xu, S. Wei, J. Xing, Chin. J. Mech. Eng. 44, 50–55 (2008)

K. Kato, K. Adachi, Wear Mechanisms, in Modern Tribology Handbook, (CRC Press, 2010), pp. 273–300

E. Rabinowicz, An adhesive wear model based on variations in strength values. Wear 63, 175–181 (1980)

S. Wu, H.S. Cheng, A sliding wear model for partial-EHL contacts. Trans. ASME 113, 134–141 (1991)

H. Wang, C. Zhou, Y. Lei, Z. Liu, An adhesive wear model for helical gears in line-contact mixed elastohydrodynamic lubrication. Wear 426–427, 896–909 (2019)

J.F. Archard, Contact and rubbing on flat surfaces. J. Appl. Phys. 24, 981–988 (1953)

H. Torres, M. Varga, M.R. Ripoll, High temperature hardness of steels and iron-based alloys. Mater. Sci. Eng., A 671, 170–181 (2016)

R. Kumar, T.S. Sudarshan, Self-Lubricating Composites: graphite-Copper. Mater. Technol. 11(5), 191–194 (1996)

H. Goto, K. Uchijo, Wear mechanism of Al–Si alloy impregnated graphite composite under dry sliding. Wear 259(1–6), 613–619 (2005)

H. Goto, S. Omori, Friction and wear characterisitics of aluminum alloy impregnated carbon composite. J. Tribol. 121(2), 294–300 (1999)

H. Goto, S. Omori, K. Uchijo, Wear behaviro of Al–Si alloy impregnated graphite composite. Tribol. Trans. 44(4), 551 (2001)

D.J. Boes, P.H. Bowen, Friction-wear characteristics of self-lubricating composites developed for vacuum service. ASLE Trans. 6, 192–200 (1963)

S. Boubendir, S. Larbi, M. Malki, R. Bennacer, Hydrodynamic self-lubricating journal bearings analysis using Rabinowitsch fluid lubricant. Tribol. Int. 140, 105856 (2019)

J.D. Mello, C. Binder, G. Hammes, R. Binder, A.N. Klein, Tribological behaviour of sintered iron based self-lubricating composites. Friction 5(3), 285–307 (2017)

Acknowledgements

The authors would like to thank Perrin W. Habecker for his assistance with the experiments and sample preparations. The FEI Helios NanoLab SEM was obtained with a Major Research Instrumentation grant from the National Science Foundation under contract DMR-0723128.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, J., Van Aken, D.C., Qing, J. et al. A Comparison of Adhesive Wear with Three-Body Abrasive Wear Characteristics of Graphitic White Irons Designed for Metal-to-Metal Wear Systems. Inter Metalcast 15, 447–458 (2021). https://doi.org/10.1007/s40962-020-00502-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00502-6