Abstract

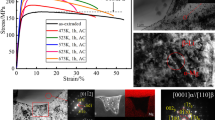

In order to further improve the thermal conductivity and mechanical properties simultaneously of the base alloy (Al-7Si-0.6Fe-0.5Zn alloy) treated by B/La/Sr modification, the La content was further optimized in the B/La/Sr-modified process, and the Ce element was added into the melt treated by B/La/Sr modification to get higher improvement. For the B/La/Sr-modified alloys, when the content of La decreases from 0.15 to 0.05%, the thermal conductivity (λ) and integrated mechanical properties index (Q) increase 3.1W/(m·K) and 21.1MPa, respectively. In the B/La/Ce/Sr-modified alloys, the λ and Q increase simultaneously with the increase of the Ce content, reaching the maximum of 179.2W/(m·K) and 380.2MPa, respectively, when the Ce content reaches 0.5%, and then decrease simultaneously with the further increase of the Ce content. When the Ce content is not more than 0.5%, the morphology change of the Fe-rich phases is the main reason for the simultaneous improvement of the thermal conductivity and the mechanical properties of the B/La/Ce/Sr-modified alloys. When the Ce content is more than 0.5%, the precipitation of the needle flake-like Ce-rich phases and coarse flake-like Si phases is the main reason for the simultaneous deterioration of the mechanical properties and thermal conductivity.

Similar content being viewed by others

References

M. Ayabe, T. Nozute, K. Shibata, H. Nozute, Effect of high thermal conductivity die steel in aluminum casting. Inter Metalcast 08, 47–55 (2008). https://doi.org/10.1007/BF03355427

C. Wen, J.Q. Gan, C.B. Li, Y.J. Huang, J. Du, Comparative study on relationship between modification of Si phase and thermal conductivity of Al-7Si alloy modified by Sr/RE/B/Sb elements. Inter Metalcast 15, 194–205 (2021). https://doi.org/10.1007/s40962-020-00436-z

L. Kumar, J.C. Jang, K.S. Shin et al., Effect of secondary phase on mechanical and thermal conductivity of Al-Si-xFe-Mg-yCu-Mn die casting alloys. Mater Lett 314(1), 131889 (2022)

A. Monroe, P. Sanders, The need for a new approach to soldering in high pressure die casting [J]. Inter Metalcast 15, 391–397 (2021). https://doi.org/10.1007/s40962-020-00504-4

J. Gan, J. Du, C. Wen, G. Zhang, M. Shi, Z. Yuan, The effect of Fe content on the solidification pathway, microstructure and thermal conductivity of hypoeutectic Al–Si alloys. Inter Metalcast 16, 178–190 (2022). https://doi.org/10.1007/s40962-021-00580-0

J.K. Chen, H.Y. Hung, C.F. Wang et al., Thermal and electrical conductivity in Al-Si/Cu/Fe/Mg binary and ternary Al alloys [J]. J. Mater. Sci. 50(16), 5630–5639 (2015)

G. Graf, P. Spoerk-Erdely, P. Staron et al., Quench rate sensitivity of age-hardenable Al-Zn-Mg-Cu alloys with respect to the Zn/Mg ratio: an in situ SAXS and HEXRD study. Acta Mater. 227, 117727 (2022)

V.N. Chuvil’deev, A.V. Nokhrin, V.I. Kopylov et al., Investigation of mechanical properties and corrosion resistance of fine- grained aluminum alloys Al-Zn with reduced zinc content. J. Alloy. Compd. 891, 162110 (2021)

Gan JQ, Huang YJ, Du J, Wen C, Liu J (2020) Synchronous improvement in thermal conductivity and mechanical properties of Al-7Si-0.6Fe-0.5Zn cast alloy by B/La/Sr composite modification. Materials Research Express. 7(8)

W.H. Yuan, Z.Y. Liang, C.Y. Zhang et al., Effects of La addition on the mechanical properties and thermal-resistant properties of Al-Mg-Si-Zr alloys based on AA 6201[J]. Mater. Des. 34, 788–792 (2012)

G. Mousavi, M. Emamy, J. Rassizadehghani, The effect of mischmetal and heat treatment on the microstructure and tensile properties of A357 Al-Si casting alloy [J]. Mater Sci Eng A. 556, 573–581 (2012)

B. Pourbahari, M. Emamy, Effects of La intermetallics on the structure and tensile properties of thin section gravity die-cast A357 Al alloy[J]. Mater. Des. 94, 111–120 (2016)

L. Tian, I. Anderson, T. Riedemann et al., Modeling the electrical resistivity of deformation processed metal-metal composites[J]. Acta Mater. 77, 151–161 (2014)

D.K.C. Macdonald, K. Sarginson, Size Effect variation of the electrical conductivity of metals [J]. Proceedings of the Royal Society A 203(1073), 223–240 (1950)

F. Heringhaus, H.J. Schneider-Muntau, G. Gottstein, Analytical modeling of the electrical conductivity of metal matrix composites: application to Ag-Cu and Cu-Nb[J]. Mater. Sci. Eng., A 347(1–2), 9–20 (2003)

J.Q. Gan, Y.J. Huang, C. Wen, J. Du, Effect of Sr modification on microstructure and thermal conductivity of hypoeutectic Al-Si alloys. Trans Nonferr Metals Soc China. 30, 2879–2890 (2020)

Z.H. Li, H. Yan, Modification of primary α-Al, eutectic silicon and β-Al5FeSi phases in as-cast AlSi10Cu3 alloys with (La+Yb) addition[J]. J. Rare Earths 33, 995–1003 (2015)

S. Beroual, Z. Boumerzoug, P. Paillard et al., Effects of heat treatment and addition of small amounts of Cu and Mg on the microstructure and mechanical properties of Al-Si-Cu and Al-Si-Mg cast alloys. J. Alloy. Compd. 784, 1026–1035 (2019)

Marcelino D, Ricardo O, Amauri G et al (2020) Effects of solidification thermal parameters and Bidoping on silicon size, morphology and mechanical properties of Al-15wt.% Si-3.2wt.% Bi and Al-18wt.% Si-3.2wt.% Bi alloys. J Mater Res Technol. 9(3): 3460-3470

Y.S. Rao, H. Yan, Z. Hu, Modification of eutectic silicon and β-Al5FeSi phases in as-cast ADC12 alloys by using samarium addition[J]. J. Rare Earths 31(9), 916–922 (2013)

Sha M, Wu SS, Wan L et al (2013) Effects of Co addition on Fe-bearing intermetallic compounds and mechanical properties of AlSi20Cu2Ni1Fe0.7–1 alloys[J]. J Alloys and Comp, 551: 468-474

S.X. Luo, Z.M. Shi, N.Y. Li et al., Crystallization inhibition and microstructure refinement of Al-5Fe alloys by addition of rare earth elements[J]. J. Alloy. Compd. 789, 90–99 (2019)

Zhu M, Jian ZY, Yao LJ et al (2011) Effect of mischmetal modification treatment on the microstructure, tensile properties, and fracture behavior of Al-7.0%Si-0.3%Mg foundry aluminum alloys[J]. J Mater Sci, 46(8): 2685-2694

M. Akoshima, B. Hay, M. Neda, M. Grelard, Experimental Verification to Obtain Intrinsic Thermal Diffusivity by Laser-Flash Method. Int. J. Thermophys. 34, 778–791 (2013)

W.J. Parker, R.J. Jenkins, C.P. Butler, G.L. Abbott, Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J. Appl. Phys. 32(9), 1679–1684 (1961)

M. Akoshima, B. Hay, M. Neda et al., Experimental Verification to Obtain Intrinsic Thermal Diffusivity by Laser-Flash Method. Int J Thermophys 34, 778–791 (2013)

M. Drouzy, S. Jacob, M. Richard, Interpretation of tensile results by means of quality index and probable yield strength. Int. J. Cast Met. Res. 5, 43–50 (1980)

C.H. Caceres, A phenomenological approach to the quality index of Al-Si-Mg casting alloys. Int. J. Cast Met. Res. 12, 367–375 (2000)

Alexopoulos ND, Pantelakis SPG. (2004) Quality evaluation of A357 cast aluminum alloy specimens subjected to different artificial aging treatment. Materials and Design 25:419-430.

Yu. Chen, Ye. Pan, Lu. Tao et al., Effects of combinative addition of lanthanum and boron on grain refinement of Al-Si casting alloys. Mater. Des. 64, 423–426 (2014)

Chenlin Li, Ye P, Tao Lu et al (2018) Effects of Ti and La additions on the microstructures and mechanical properties of B-refined and Sr-modified Al-11Si alloys. Metals and Mater Int. 08(3)

Kang J, Su R, Liu CH et al (2019) Synergistic effects of Ce and Mg on the microstructure and tensile properties of Al-7Si-0.3Mg-0.2Fe alloy[J]. J Alloys and Comp, 796: 267-278

Q.L. Li, T.D. Xia, Y.F. Lan et al., Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al-20%Si alloy[J]. J. Alloy. Compd. 562, 25–32 (2013)

Y.L. Zhang, F. Wei, J. Mao et al., The difference of La and Ce as additives of electrical conductivity aluminum alloys[J]. Mater. Charact. 158, 109963 (2019)

G. Heiberg, K. Nogita, A.K. Dahle et al., Columnar to equiaxed transition of eutectic in hypoeutectic aluminium-silicon alloys[J]. Acta Mater. 50, 2537–2546 (2002)

S.D. Mcdonald, A.K. Dahle, J.A. Taylor et al., Eutectic grains in unmodified andstrontium-modified hypoeutectic aluminum-silicon alloys[J]. Metall. and Mater. Trans. A. 35(6), 1829–1837 (2004)

Bolzoni L, Nowak M, Hari Babu N (2015) On the effect of Nb-based compounds on the microstructure of Al-12Si alloy. Mater Chem and Phys 162 340-345

Bolzoni L, Nowak M, Hari Babu N (2015) Grain refining potency of Nb-B inoculation on Al-12Si-0.6Fe-0.5Mn alloy. J Alloys and Comp. 623 79-82

Bolzoni L, Hari Babu N (2019) Towards industrial Al-Nb-B master alloys for grain refining Al-Si alloys. J Mater Res Technol. 8(6): 5631-5638

E.O. Hall, The deformation and ageing of mild steel: II characteristics of the luders deformation [J]. Proceedings of the Physical Society B 64(9), 742–749 (1951)

N.J. Petch, The cleavage strengh of polycrystals [J]. Jounal of the Iron and Steel Inst 174, 25–28 (1953)

Liu Y, Luo L, Han C, Ou L, Wang J, Liu C (2016) Effect of Fe, Si and cooling rate on the formation of Fe- and Mn-rich intermetallics in Al–5Mg–0.8Mn alloy, J. Mater. Sci.Technol. 32 305–312

Y.L. Liu, G.R. Huang, Y.M. Sun, L. Zhang, Z.W. Huang, J.J. Wang, C.Z. Liu, Effect of Mn and Fe on the formation of Fe- and Mn-rich intermetallics intermetallics in Al-5Mg-Mn alloys solidified under near-rapid cooling. Mater. 9, 88–101 (2016)

Acknowledgements

The authors are very grateful to the Key scientific research platforms and projects of ordinary universities in Guangdong Province in 2021 (2021KCXTD076).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Junqi, G., Mengyao, P., Qiming, C. et al. Effect of Ce Addition on the Thermal Conductivity and Mechanical Properties of Al-7Si-0.6Fe-0.5Zn Cast Alloy Treated by B/La/Sr Modification. Inter Metalcast 17, 874–887 (2023). https://doi.org/10.1007/s40962-022-00807-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00807-8