Abstract

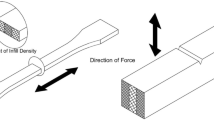

This paper presents the effect of process parameters of the fused deposition modelling (FDM) method on mechanical properties of 3D-printed carbon fibre (CF)-reinforced polylactic acid (PLA) composite. Building direction, infill percentage, and layer height are the process variables considered for studies due to their high influencing factor in mechanical properties of product. Tensile strength and impact strength are the response parameters considered in the study. Multi-optimisation is done using TOPSIS (Technique for Order Preferences by Similarity to Ideal Solution) analysis to find the best set of parameters that would provide the maximum strength using minimum material. The material used is CF-reinforced PLA composite filament (1.75-mm diameter) for 3D printing.

Similar content being viewed by others

References

Boschetto A, Bottini L (2014) Accuracy prediction in fused deposition modeling. Int J Adv Manuf Technol 73(5–8):913–928

De Laurentis KJ, Mavroidis C (2004) Rapid fabrication of a non-assembly robotic hand with embedded components. Assem Autom 24(4):394–405

Thomas DS, Gilbert SW (2014) Costs and cost effectiveness of additive manufacturing. NIST Spec Publ 1176:12

Basavaraj CK, Vishwas M (2016) Studies on effect of fused deposition modelling process parameters on ultimate tensile strength and dimensional accuracy of nylon. In IOP conference series: materials science and engineering, 149(1): 012035. IOP Publishing, Bristol.

Griffiths CA, Howarth J, Rowbotham GDA, Rees A (2016) Effect of build parameters on processing efficiency and material performance in fused deposition modelling. Proc CIRP 49:28–32

Fernandes J, Deus AM, Reis L, Vaz MF, Leite M (2018) Study of the influence of 3D printing parameters on the mechanical properties of PLA. 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018) 14–17 May 2018, Singapore. https://doi.org/10.25341/D4988C

Zhang H, Zhang Z, Breidt C (2004) Comparison of short carbon fibre surface treatments on epoxy composites: I. Enhancement of the mechanical properties. Compos Sci Technol 64(13–14):2021–2029

Wan Y, Takahashi J (2016) Tensile and compressive properties of chopped carbon fiber tapes reinforced thermoplastics with different fiber lengths and molding pressures. Compos A Appl Sci Manuf 87:271–281

Rezaei F, Yunus R, Ibrahim NA, Mahdi ES (2008) Development of short-carbon-fiber-reinforced polypropylene composite for car bonnet. Polym Plast Technol Eng 47(4):351–357

Ning F, Cong W, Qiu J, Wei J, Wang S (2015) Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos B Eng 80:369–378. https://doi.org/10.1177/0021998316646169

Qattawi A, Alrawi B, Guzman A (2017) Experimental optimization of fused deposition modelling processing parameters: a design-for-manufacturing approach. Proc Manuf 10:791–803

Kuznetsov V, Solonin A, Urzhumtsev O, Schilling R, Tavitov A (2018) Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 10(3):313

Wu J (2018) Study on optimization of 3D printing parameters. In IOP conference series: materials science and engineering 392(6): 062050. IOP Publishing, Bristol

Pavić Z, Novoselac V (2013) Notes on TOPSIS method. Int J Res Eng Sci 1(2):5–12

Sakthivel G, Ilangkumaran M, Gaikwad A (2015) A hybrid multi-criteria decision modeling approach for the best biodiesel blend selection based on ANP-TOPSIS analysis. Ain Shams Eng J 6(1):239–256

Acknowledgements

We would like to thank R&D Labs, JSS Academy of technical education, NOIDA for letting us carry out the experimentations and also Ypanx technologies pvt ltd. for providing their top-notch service.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kamaal, M., Anas, M., Rastogi, H. et al. Effect of FDM process parameters on mechanical properties of 3D-printed carbon fibre–PLA composite. Prog Addit Manuf 6, 63–69 (2021). https://doi.org/10.1007/s40964-020-00145-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-020-00145-3