Abstract

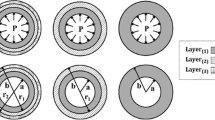

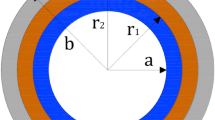

This paper addresses the effect of shrink-fitting on the optimal design of pressurized multi-layer composite tubes. Analytical solutions for structural response calculations are provided for axially constrained two- and three-layer shrink-fitted tubes under both internal and external pressure. A recently developed numerical evolutionary optimization algorithm is employed for weight and cost minimization of these assemblies. In order to investigate the effect of shrink-fitting, first, optimal material selection and thickness optimization of tightly fitted tubes, under either internal or both internal and external pressure, are accomplished without shrink-fitting. Next, under the same loading and boundary conditions the assemblies are optimized where shrink-fitting parameters are taken into account for weight and cost minimization. The numerical results obtained for multi-layer composite tubes with and without shrink-fitting indicate that more economical or lightweight assemblies can be obtained if shrink-fitting parameters are treated as additional design variables of the optimization problem. Furthermore, it is observed that considering the shrink-fitting parameters for optimal design becomes more advantageous in the test cases with a higher ratio of internal pressure to external pressure.

Similar content being viewed by others

References

Akis T, Eraslan AN (2005) Yielding of long concentric tubes under radial pressure based on von Mises criterion. J Fac Eng Archit Gazi Univ 20:365–372 (in Turkish)

Arora J, Wang Q (2005) Review of formulations for structural and mechanical system optimization. Struct Multidiscip Optim 30(4):251–272

Boresi AP, Schmidt RJ, Sidebottom OM (1993) Advanced mechanics of materials, 5th edn. Wiley, New York

Chen YZ, Lin XY (2008) Elastic analysis for thick cylinders and spherical pressure vessels made of functionally graded materials. Comput Mater Sci 44:581–587

Eraslan AN, Akis T (2005) Yielding of two-layer shrink-fitted composite tubes subject to radial pressure. Forsch Ingenieurwesen/Eng Res 69:187–196

Eraslan AN, Akis T (2006) Plane strain analytical solutions for a functionally graded elastic-plastic pressurized tube. Int J Press Vessels Pip 83:635–644

Eraslan AN, Akis T (2015) Analytical solutions to elastic functionally graded cylindrical and spherical pressure vessels. J Multidiscip Eng Sci Technol 2:2687–2693. ISSN:3159-0040

Eraslan AN, Akış T (2004) Deformation analysis of elastic-plastic two layer tubes subject to pressure: an analytical approach. Turk J Eng Environ Sci 28:261–268

Eraslan AN, Akış T (2005) Elastoplastic response of a long functionally graded tube subjected to internal pressure. Turk J Eng Environ Sci 29:361–368

Eraslan AN, Akis T, Akis E (2016) Deformation analysis of two-layer composite tubes under cyclic loading of external pressure. J Basic Appl Res Int 13:107–119

Erol OK, Eksin I (2006) A new optimization method: big bang-big crunch. Adv Eng Softw 37:106–111

Hasançebi O, Kazemzadeh Azad S (2014) Discrete size optimization of steel trusses using a refined big bang–big crunch algorithm. Eng Optim 46(1):61–83

Horgan CO, Chan AM (1999) The pressurized hollow cylinder or disk problem for functionally graded isotropic linearly elastic materials. J Elasticity 55:43–59

Jabbari M, Sohrabpour S, Eslami MR (2002) Mechanical and thermal stresses in a functionally graded hollow cylinder due to radially symmetric loads. Int J Press Vessels Pip 79:493–497

Jahed H, Farshi B, Karimi M (2006) Optimum autofrettage and shrink-fit combination in multi-layer cylinders. J Press Vessel Technol Trans ASME 128:196–200

Kazemzadeh Azad S, Akış T (2018) Automated selection of optimal material for pressurized multi-layer composite tubes based on an evolutionary approach. Neural Comput Appl 29:405–416.

Lellep J, Paltsepp A (2010) Optimization of inelastic cylindrical shells with internal supports. Struct Multidiscip Optim 41(6):841–852

Ma L, Feng XQ, Gau KW, Yu SW (2003) Elastic and plastic analyses of functionally graded elements. Funct Grad Mater VII Mater Sci Forum 423–424:731–736

Magnucki K, Szyc W (1996) Optimal design of a cylindrical shell loaded by internal pressure. Struct Optim 11(3):263–266

Majumder T, Sarkar S, Mondal SC, Mandal DK (2014) Optimum design of three layer compound cylinder. IOSR J Mech Civ Eng 11:33–41

Mendelson A (1986) Plasticity: theory and application. MacMillan, New York

Miraje AA, Patil SA (2011) Minimization of material volume of three layer compound cylinder having same materials subjected to internal pressure. Int J Eng Sci Technol 3:26–40

Nadai A (1931) Plasticity. Mc-Graw-Hill, New York

Parker AP (2001) Autofrettage of open-end tubes–pressures, stresses, strains, and code comparisons. J Press Vessel Technol-Trans ASME 123:271–281

Perry J, Aboudi J (2003) Elasto–plastic stresses in thick walled cylinders. J Press Vessel Technol-Trans ASME 125:248–252

Qiu J, Zhou M (2016) Analytical solution for interference fit for multi-layer thick-walled cylinders and the application in crankshaft bearing design. Appl Sci 6:167

Saka MP (2007) Optimum design of steel frames using stochastic search techniques based on natural phenomena: a review. In: Topping BHV (ed) Civil engineering computations: tools and techniques. Saxe-Coburg Publications, Stirlingshire, pp 105–147

Sharifi M, Arghavani J, Hematiyan MR (2012) An analytical solution for optimum design of shrink-fit multi-layer compound cylinders. Int J Appl Mech 4:1250043

Sharifi M, Arghavani J, Hematiyan MR (2014) Optimum arrangement of layers in multi-layer compound cylinders. Int J Appl Mech 6:1450057

Timoshenko SP, Goodier JN (1970) Theory of elasticity, 3rd edn. McGraw-Hill, New York

Tutuncu N, Ozturk M (2001) Exact solutions for stresses in functionally graded pressure vessels. Compos B 32:683–686

Ugural AC, Fenster SK (1987) Advanced strength and applied elasticity, 2nd edn. Prentice Hall, New Jersey

Vu VT (2010) Minimum weight design for toroidal pressure vessels using differential evolution and particle swarm optimization. Struct Multidiscip Optim 42(3):351–369

Xin L, Dui G, Yang S, Zhang J (2014) An elasticity solution for functionally graded thick walled tube subjected to internal pressure. Int J Mech Sci 89:344–349

Xin L, Dui G, Yang S, Liu Y (2016) Elastic-plastic analysis for functionally graded thick-walled tube subjected to internal pressure. Adv Appl Math Mech 8:331–352

Yuan G, Liu H, Wang Z (2010) Optimum design for shrink-fit multilayer vessels under ultrahigh pressure using different materials. Chin J Mech Eng 23:582–589

Yuan G, Liu H, Wang Z (2011) Optimum design of compound cylinders with sintered carbide inner liner under ultrahigh pressure. Gong Lixue/Eng Mech 28:212–218

Zheng B, Chang C, Gea HC (2009) Topology optimization with design-dependent pressure loading. Struct Multidiscip Optim 38:535

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kazemzadeh Azad, S., Akış, T. A Study of Shrink-Fitting for Optimal Design of Multi-Layer Composite Tubes Subjected to Internal and External Pressure. Iran J Sci Technol Trans Mech Eng 43 (Suppl 1), 451–467 (2019). https://doi.org/10.1007/s40997-018-0170-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-018-0170-0