Abstract

The presence of chromium in industrial effluents has become a huge problem worldwide as hexavalent chromium is highly toxic to animals due to its ability to generate reactive oxygen species in cells. The trivalent state of chromium, on the other hand, is significantly less toxic and also serves as an essential element in trace amounts. When industries such as electroplating, tannery, dyeing and others release their effluents into water bodies, hexavalent chromium enters the food chain and, consequently, reaches humans in a biomagnified form. Many remediation processes for removal of hexavalent chromium have been researched and reviewed extensively. These include chemical reduction to trivalent chromium, solvent extraction, chelation and adsorption, among others. It has been generally concluded that adsorption (and/or subsequent reduction) of hexavalent chromium is the best method. However, relatively little is known about the potential of using nanoparticles as adsorbents for the removal of hexavalent chromium from industrial effluents. This method of nanoremediation is more effective than conventional remediation methods and is cost-effective for the industry in the long run. This article reviews the various remediation methods of hexavalent chromium, with emphasis on the field of nanoremediation.

Similar content being viewed by others

Introduction

Chromium has widespread applications in various industrial processes such as electroplating, printing, dyeing, tanning and metallurgy. However, improper disposal of effluents from these industries results in environmental pollution [1,2,3]. This has fatal consequences on the environment, plants and animals as it exerts carcinogenic, mutagenic and teratogenic effects and causes tissue damage [4].

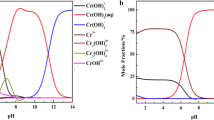

Chromium most commonly occurs in trivalent/Cr(III) and hexavalent/Cr(VI) states [5]. While the trivalent state of chromium is an important trace element, its hexavalent state is non-essential and toxic to animals [6] and may cause dermatitis, lung cancer, kidney and gastric damage, irritation to respiratory tract and eyes [7]. Continuous accumulation of toxic Cr(VI) along food chains often leads to biomagnification, putting humans at great risk [8].

The global requirement of water for industrial uses has been increasing by leaps and bounds. However, abuse of this valuable resource and adequate lack of timely treatment often lead to water pollution, resulting in its scarcity. To overcome this problem, industries need to adopt several technologies of water purification, for use in manufacturing processes. There are many conventional processes currently in use for remediation of Cr(VI) from industrial effluents. These processes mainly involve immobilisation of Cr(VI) and/or reduction of toxic Cr(VI) to the less-toxic Cr(III). The latter can be achieved chemically by means of a variety of sulphur or iron-based compounds, such as Fe(II) [9], amorphous FeS2 [10], calcium polysulphide (CaSx) [11], sodium thiosulphate (Na2S2O3) [12] and many more. The major disadvantage of chemical reduction is the generation of a huge amount of toxic sludge. Some other methods of Cr(VI) removal include membrane filtration, solvent extraction, leaching [13, 14] and electrokinetic procedures [15, 16]. These methods, though commonly used, have certain limitations. The major disadvantage of such conventional treatment methods is the high cost, which dissuades many industries from adopting any remediation methods.

Another commonly used method involves the adsorption of Cr(VI) onto various surfaces like titanium dioxide, goethite, activated carbon, zeolites and many more. In some cases, reduction to Cr(III) may follow. Biosorption is a subdivision of adsorption, in which Cr(VI) is adsorbed onto biomaterials found in abundance in nature, like microbial biofilms [17, 18]. Adsorption is considered to be an effective method due to the low initial cost, flexibility in design and ease of operation [19]. Moreover, adsorption does not involve the formation of any secondary wastes such as sludge.

In this context, nanoparticles have gained prominence as adsorbents of Cr(VI). While choosing suitable nanomaterials for environmental remediation, the characteristics usually explored are size, solubility, surface area, surface charge and surface chemical composition [20]. Having large surface areas and being highly stable, nanoparticles have demonstrated themselves to be excellent adsorbents for environmental remediation [19]. Due to their high catalytic activity, some nanoparticles, such as nanoscale zero-valent iron, are capable of reducing Cr(VI) to Cr(III). Moreover, using nanoscale zero-valent iron does not produce intermediate by-products, which are usually observed when bulk Fe powders are used [21]. This review describes the various methods used for remediation of Cr(VI) with special emphasis on the rapidly emerging field of nanoremediation.

Chromium in industrial effluents

The hexavalent state of chromium, which exists primarily as the tetrahedral chromate ion in aqueous solution (CrO −24 ), is able to penetrate cellular membranes using various permeases, and this penetration of membrane occurs 500–1000 times more effectively than the trivalent form [22, 23]. Once inside the cell, Cr(VI) is reduced enzymatically and/or non-enzymatically to the reactive intermediates, Cr(V), Cr(IV) and Cr(III) [24], which are capable of generating reactive oxygen species (ROS) [25]. Under physiological conditions, overproduction of ROS causes damage to cellular proteins, lipids and DNA [26].

Industries such as electroplating, tannery, paints, petroleum and dyeing contain Cr(VI) in their effluents [1]. For example, textile industries use synthetic dyes to impart colour to raw materials or products. These dyes contain many toxic heavy metals, especially chromium [27,28,29]. Examples of other industries contributing to Cr(VI) pollution are summarised in Fig. 1 [1, 30].

The release of several industrial effluents containing Cr(VI) into water bodies exposes aquatic life to this toxic and corrosive element. It readily gets accumulated and consequently biomagnified in the species at the top of the aquatic food chain, viz, fishes [31]. This phenomenon manifests itself physically in fishes in the form of an increased mortality, erosion of scales, discolouration, mucous secretion, irregular swimming and disruption of their osmoregulatory functions [8, 32].

As a result, Cr(VI) enters the terrestrial food chain and reaches humans in highly biomagnified amounts. This leads to several health problems such as damage to liver and kidney, carcinogenesis (mostly lung cancer), genotoxicity, neurotoxicity, immunotoxicity, asthma, skin ulcerations and many more [6, 33,34,35]. Rats intraperitoneally injected with Cr(VI) have been reported to develop both structural and functional anomalies of the pituitary and thyroid glands [36]. Potassium dichromate, administered subcutaneously into rats, had led to accumulation of chromium mainly in the renal cortex [37] and had caused cellular degradation of the proximal convoluted tubule and formation of hyaline casts in the lumen of renal tubules [22]. Hence, there is an urgent need to develop an effective technique for chromium remediation from wastewater.

Conventional processes for chromium remediation

Like all heavy metals, Cr(VI) cannot be completely removed from the environment. However, its toxicity can be reduced (by reduction to the trivalent state), or it can be adsorbed onto a surface to be dumped at a different site, or a combination of both approaches may be used.

The various conventional methods of Cr(VI) remediation have been reviewed by Kalidhasan et al. [38], and these methods have been summarised and are compared in Table 1 [39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69].

The conventional chemical reduction method comprises of two steps—the reduction of Cr(VI) to Cr(III) by a reducing agent, at an acidic pH, and the precipitation of Cr(III) as an insoluble hydroxide at an alkaline pH. The chemical reductant can be any sulphur-based or iron-based salt. These two steps can be combined into a single step by the electrochemical addition of ferrous ion, rather than the addition of a ferrous salt (FeSO4 or FeCl2) which necessitates the use of an acidic and an alkaline pH, making it a two-step process. The removal of Cr(VI) by the former can be illustrated using the following reaction [70]:

The major limitation of this method is the formation of toxic solid sludge during the precipitation of Cr(III) [38]. Moreover, in the treatment of soil contaminated by Cr(VI) from industrial effluents, the chemical reduction method is disadvantageous as the contaminated soil needs to be physically mixed with the reducing agent, making the entire process labour-intensive. An alternative method which can be used in this situation is electrokinetic remediation, which involves passing of low-voltage direct current through the soil, thus providing in situ remediation [16]. The toxic metals move towards the electrodes, primarily by electromigration. This method can be further enhanced by using metal chelators such as citric acid and polyaspartic acid [15].

Adsorption is the most effective and economical solution to remediation of Cr(VI), especially if it is coupled with proper regeneration of the adsorbent [71]. Activated carbon (AC) is one such highly effective adsorbent, which resembles granular or powder charcoal and possesses high porosity, internal surface area and mechanical strength. AC is especially useful in remediation of low concentrations of effluent stream. However, commercially available ACs are not economically feasible, and hence, any material with a high organic content and low inorganic content can be used for manufacturing of AC [72]. For example, AC developed from Tamarind wood activated with zinc chloride has shown 99% efficiency in removal of Cr(VI) from wastewater [72]. AC prepared from Fox nutshell and activated by zinc chloride showed a maximum Cr(VI) removal efficiency of 99.08% at a pH of 2 [73]. Under the conditions of pH 2, biomass dose 2.5 g/100 ml and equilibrium time of 150 min, AC prepared from mango kernel and activated with H3PO4 reported a maximum Cr(VI) removal rate of 7.8 mg/g [74].

Another adsorption method is the use of silica-based adsorbents, which has both reduction and sorption capabilities in a single solid [75]. Mostly prepared by the sol–gel process, these adsorbents consist of a silica backbone and attached functional organic groups capable of complexing with the concerned metallic ion [76]. The presence of hydroxyl groups in the silica gel allows for easy modification for effective performance [77]. These adsorbents are considered advantageous as they possess a defined pore geometry, large surface area, high porosity, good mechanical strength, high thermal resistance, stability in a wide range of pH, and are insoluble in water, environmentally benign and cost low [78, 79]. Kumar et al. [80] used aniline formaldehyde condensate (AFC) as the functional organic group to be attached on the silica backbone and reported 85% removal of Cr(VI) and 70% removal of total chromium (Cr(VI) and Cr(III)), while also reporting 56% recovery of chromium from the adsorbent in the presence of NaOH. The protonated amino (–NH2) groups of AFC may electrostatically attract CrO −24 , lead to reduction of Cr(VI) to Cr(III) and form bonds with Cr(III) for their adsorption. Similarly, polyaniline (PANI) can form coordinate bonds with the metal ions and reduce Cr(VI) to Cr(III) by surface chemical reaction. These PANI/silica composites have shown a maximum adsorption capacity of 63.41 mg/g at an equilibrium concentration of 50 mg/l [77]. The silica backbone can also be modified by ionic liquids, imidazolium-based ones being an attractive option. The imidazolium ring can be covalently bonded onto silica, linked by alkyl group chains (provided by silane-coupling agents). These alkyl branches can be attached to different positions of the imidazolium ring [81]. In a study by Whang et al. [82], imidazole-modified silica adsorbent with chloride as counter ion (SilprIm-Cl) was used to adsorb Cr(VI) with a maximum capacity of 47.79 mg/g (from an initial concentration of 150 mg/l) at pH of 2. Sulphonic acid-functionalised silica adsorbent was reported to remove Cr(III) (as CrAc +22 ) at a rate of 72.8 mg/g at pH 3 [83]. Shevchenko et al. [84] studied the potential of bifunctionalised mesoporous silica, with the two functional groups chosen being thiol and sulphonic acid moieties. This adsorbent suffered from two main limitations—very little scavenging property of the material, and the weak interaction between Cr(III) cations and sulphonate groups. A few years later, Zaitseva et al. [75] explored another bifunctionalised silica adsorbent, with the functional groups being mercaptopropyl and ethylenediaminetriacetate. The former can reduce Cr(VI), while the latter can “scavenge” the Cr(III) present via complex formation. Microscale silica gel can also be used along with granular zero-valent metals as reductants. For example, granular zero-valent zinc was used along with the silica gel to satisfactory results. Silica gel prevents the formation of a passivating film on the surface of the zero-valent zinc particles [79].

An improvement over the conventionally used ion-exchange resins is the use of metal–organic frameworks (MOFs), which are essentially clusters of metal cations co-ordinately bonded to polytopic organic linkers. Kumar et al. [85] have efficiently reviewed the applications of MOFs in the removal of Cr(VI). Some examples include 1-ClO4, ABT.2ClO4, FIR-54, ZJU-101, 1′-SO4, Ag-3, SLUG-21 and many more. Taking it a step further, Hasan et al. [86] used an MOF-derived composite for this purpose. A Cu-based MOF, named HKUST-1, was subjected to single-step calcination at 550 and 650 °C under inert conditions. Under optimum conditions, it was able to reduce 200 mg/l of Cr(VI) within 15 min in the presence of HCOOH. A loss in its catalytic activity was observed after reusing it for four consecutive cycles.

Zeolites, also termed as molecular sieves, are hydrated aluminosilicate materials having three-dimensional frameworks of SiO4 and AlO4 tetrahedra, giving it a connected cage-like or channel structure. The lattice has a net negative charge due to the isomorphous replacement of Si+4 by Al+3, and this is balanced by the exchangeable cation (sodium, potassium or calcium) [87]. Zeolites do not have a strong affinity for Cr(VI) or Cr(III) since they exist as anions in aqueous phase. However, this can be changed by suitable modification of the zeolite lattice. Natural zeolite can be modified by cationic surfactants, as reviewed by Jiménez-Castañeda and Medina [88]. Attachment of reductants, such as Fe(II), to natural zeolites allows for adsorption and subsequent reduction of Cr(VI). Such a system showed a Cr(VI) removal rate of 90 mg per kg of zeolite, but suffered from extensive leaching of iron [89]. Natural zeolite can also be coated with biofilms for Cr(VI) removal [90]. For example, NaY zeolite coated with a biofilm of Arthrobacter viscosus (a good exopolysaccharide producer) showed a Cr(VI) uptake rate of 3 mg/g of zeolite [87]. The biofilm is able to reduce Cr(VI) to Cr(III), which is retained in the zeolite by ion exchange. Habiba et al. [91] prepared a chitosan/polyvinyl alcohol/zeolite composite for Cr(VI) removal. To reduce swelling of chitosan-based adsorbents by strengthening them, polyvinyl alcohol (PVA) was used, while reusability of the adsorbent was improved by the addition of zeolite. This composite adsorbent reported a Cr(VI) adsorption capacity of 450 mg/g.

Several bacteria of the Pseudomonas, Bacillus, Enterobacter, Deinococcus, Shewanella, Agrobacter, Escherichia, Thermus genera are resistant to Cr(VI) and can be used for Cr(VI) remediation [17, 92,93,94,95]. Many mechanisms for this have been proposed, such as generation of Cr(V) by bacterial enzymes mediating transfer of an electron to Cr(VI) and reduction of Cr(VI) to Cr(III) by bacterial chromate reductase [93]. However, bacteria in the form of planktonic cells are ineffective in Cr(VI) remediation as high concentrations of Cr(VI) can kill the cells. On the other hand, bacteria in the form of biofilms exhibit an increased tolerance to Cr(VI) and better settlement [18, 68]. Moreover, biofilms allow easy separation of the treated liquid from the biomass [18]. As has been appropriately noted by Pan et al. [17], more research needs to be focused on the immobilisation of Cr(III) obtained after reducing Cr(VI) by biofilms, as the insoluble Cr(III) can form organo-Cr(III) complexes, which become toxic for cells in high concentrations. Biosorption is an advantageous technique as it costs less, is highly effective, does not have any toxic side effects, the biosorbent can be rebuilt, and the adsorbed metal can be recovered for possible later usage [96].

The initial cost of most adsorbents is high, especially if they need to be pre-treated. However, in the long run, these techniques are cost-effective. Also, using greener techniques such as biomass reduces the initial cost of chemicals to a great extent [38].

The major disadvantage of bulk adsorbents is the generation of enormous mass transfer resistance due to large surface areas and large diffusion lengths [97]. Thus, use of adsorbents with nanofeatures allows higher accessibility of the industrial effluent to the adsorbent, leading to higher efficiency.

Remediation using nanotechnology

Out of the many adsorption processes discussed above for the remediation of Cr(VI), nanomaterials possess certain properties which make them an ideal adsorbent. These include a suitable particle size, large surface area, accessible pores and high stability [19]. Moreover, due to their extremely small size, they can be easily transported through a water body simply by Brownian motion, without the aid of any external force. As a result, the nanoparticles remain suspended longer to establish an in situ remediation zone [98]. These nanoparticles can be synthesised by various physical, chemical and biological processes, and the adsorptive capacity of the particle varies according to the method of production.

Nanoadsorbents for chromium remediation

Zero-valent iron nanoparticles (nZVI) have become one of the most used metal nanoparticles for environmental remediation of Cr(VI). Since the redox potential of chromium is much more positive than that of Fe0, it reduces the hexavalent form of chromium to its trivalent form (itself getting oxidised to Fe+3), which then precipitates along with Fe+3 on the surface of the nanoparticles [99,100,101]. This can be illustrated using the following chemical equations [102]:

Ion-exchange resins can be used as supporting material for the nZVI particles. While conventional ion-exchange resins can remove either a cation or an anion, resin-supported nZVI can eliminate both forms. Such resin-supported nZVI have been reported to remove Cr(VI) with an efficiency of 84.4% at optimal conditions [103]. Using carboxymethyl cellulose (CMC) as a stabiliser for nZVI, 100% of Cr(VI) was reduced to Cr(III) from a solution containing 10 mg of Cr(VI)/l [104]. A major problem of using nZVI particles is the formation of a Fe(III)–Cr(III) (oxy)hydroxide film on the surface of the nanoparticles, rendering the surface passive, as it does not allow the Fe0 particles at the core to react with the Cr(VI) particles on the surface. This problem is usually overcome by cementing a second metal (preferably inert, such as Ag, Cu, Ni, Pd, Co) on to the surface of the transition metal, thus preventing the formation of the self-inhibiting film [105, 106]. Such bimetallic combinations, for example nZVI/Cu, demonstrate pseudo-first-order kinetics or Langmuir–Hinshelwood first-order kinetics [105, 107]. The second metal acts as an electron shuttle between the two metal systems, thus forming a catalyst. It also protects the surface of nZVIs from corrosion [106]. Another drawback of using nZVI particles is that their removal from treated water is tedious. This can be overcome by using magnetised nZVI nanoparticles, i.e. nZVI nanoparticles coated with magnetic Fe3O4 nanoparticle which could be removed easily with the help of an external magnetic field [108]. Such ZVI-Fe3O4 nanocomposites form a heterogeneous Fenton-like system [109, 110], which showed an increase in Cr(VI) removal efficiency from 48.8% (using bare nFe3O4) to 96.4% (using nZVI-Fe3O4 nanocomposites) in 2 h [19]. nZVI has also been assembled on magnetic Fe3O4/graphene nanocomposites to tackle both the drawbacks mentioned above, and it shows a Cr(VI) removal efficiency of 83.8%, following pseudo-second-order kinetics [111]. Use of ultrasound technology contributes to an increase in the available surface area and induces new reactive sites for the reduction reaction of Cr(VI) [112].

Formic acid is an organic and non-toxic reducing agent that reduces Cr(VI) to Cr(III), while itself getting converted to CO2 and H2, which can be recycled for industrial purposes. This reaction occurs in the presence of metallic heterogeneous catalysts, namely graphene oxide-supported Ni nanoparticles [113], TiO2-supported Pd nanoparticles [114], Pd nanoparticles supported on amine-functionalised SiO2 [115], among others. More recently, 3D urchin-shaped monometallic palladium was used as a nanocatalyst for the detoxification process of Cr(VI)-contaminated industrial effluents using formic acid. It was found that the rate of detoxification process could be enhanced by exposure to light of appropriate intensity. Further, this nanocatalyst exhibited stable catalytic activity even after six cycles of reaction [116].

Several metal oxide nanoparticles have also been used for the remediation of heavy metals, especially Cr(VI). Besides being used as nanocomposites as discussed above, magnetite (Fe3O4) nanoparticles can also be used individually for removal of Cr(VI) from wastewater [117]. Maghemite (γ-Fe2O3) coated with polydopamine (a catecholamine) showed a Cr(VI) removal efficiency of 97% at pH of 3 [118]. ZnO nanoparticles were used as photocatalysts for the reduction of Cr(VI) to Cr(III) in the presence of solar radiation [119, 120]. Such photocatalytic reduction experiments have also been carried out on TiO2 [121, 122] and WO3 [123]. The mechanism of photocatalysis is based on the principle of semiconductor solid catalysis, wherein electrons move from valence band to conduction band on being stimulated by light of appropriate wavelength. The charge carriers on the surface of the catalysts (such as O2) take up the electron promoted to the conduction band, and the O2 − thus formed engages in redox reactions with the adsorbed pollutants. The resulting electron deficiency in the valence band is fulfilled by H2O [124]. Cerium oxide nanoparticles stabilised with hexamethylenetetramine were able to remove Cr(VI) with 96.5% efficiency, and after the treatment process, the nanoparticles could be centrifuged out of the water, while chromium could be desorbed using NaOH [125]. Taking it a step further, the ability of hydrous cerium oxide nanoparticles to adsorb Cr(VI) was also investigated, which yielded positive results [126]. The potential of CoFe2O4 nanoparticles (synthesised in a cost-effective manner) for remediation of Cr(VI) from wastewater released from a printing press was quantified to be 67%, with no major loss of adsorption capacity up to three reaction cycles [127]. In a novel approach, manganese dioxide/iron oxide/acid oxidised multi-walled carbon nanotube magnetic nanocomposites (MnO2/Fe3O4/o-MWCNTs) were used for Cr(VI) removal from wastewater. Apart from being highly efficient in this purpose, Cr(VI) can be desorbed and the adsorbent may be regenerated by using an alkali. However, the efficiency of Cr(VI) adsorption efficiency reduces to 85% after five cycles of reuse of these nanotubes [128].

Ionically modified nanoparticles have also been studied for applications in the field of nanoremediation. Magnetic Fe3O4 nanoparticles were modified by phosphonium silane, which enhanced their adsorption capacity of Cr(VI) at optimum pH. However, desorption of chromium from these modified nanoparticles using NaOH was poor [129]. Aminosilicate-functionalised titanium dioxide nanotubes modified with gold nanoparticles supported on EDAS (EDAS/(TiO2 NTs-Au)NCM) photocatalytically reduce Cr(VI) to Cr(III) (using oxalic acid as electron donor) with 77% efficiency. Light induces interfacial charge transfer from the (TiO2 NTs)NCM to Cr(VI) through the gold nanoparticles, which act as sinks for the photogenerated electrons [130].

To overcome the problem of mass transfer resistance in the case of bulk adsorbents, nanoparticles can be embedded in the bulk materials, thus facilitating the contact of contaminants to large surface area and encouraging internal mass transfer. This was achieved by the synthesis of a magnetic zeolite/polypyrrole composite, which consisted of magnetic zeolite (embedded with magnetic Fe3O4 nanoparticles) mixed with the organic polymer polypyrrole. This adsorbent showed a removal efficiency of 99.99% when the pH was 2 and the initial Cr(VI) concentration was 300 mg/l [97]. A similar study was conducted by using chitosan as the polymer instead of polypyrrole, and a removal efficiency of 98% was reported at pH 2 and initial Cr(VI) concentration of 200 mg/l [96]. A cross-linked silica gel/chitosan-g-poly(butyl acrylate) nanocomposite showed a maximum Cr(VI) adsorption capacity of 55.71 mg/g [131]. While bulk iron sulphide (FeS) has been used as a chemical reductant in the remediation of Cr(VI), FeS nanoparticles show higher reactivity due to larger surface area. These nanoparticles can be stabilised using CMC, and biochar can be used as a mechanical support to disperse the nanoparticles. Such a composite adsorbent showed a Cr(VI) adsorption capacity of 130.5 mg/g at a pH of 5.5 [132].

As previously mentioned, TiO2 is a good candidate for photocatalytic reduction of Cr(VI). Addition of carbon nanotubes (CNTs) to the photocatalytic material increases its adsorption capacity and electron-conducting ability [133]. Polymer-based composite materials (incorporation of semiconductor nanoparticles in polymeric nanofibers) are being explored to improve the recovery of the photocatalytic powder from treated solutions after the completion of reaction [134]. Polyacrylonitrile (PAN) is widely used for producing the polymeric nanofibers [135]. In a recent study, composite nanofibers of PAN and multi-walled CNTs were synthesised and were further cross-linked by amino-modified TiO2 nanoparticles. When irradiated with visible light, this system showed complete photoreduction of Cr(VI) after 30 min. It underwent five cycles of adsorption–desorption before its photoreduction efficiency decreased by 3% [136].

Nanoparticles can also be applied on membranes used to enhance removal of chromium ions from an aqueous solution. For example, the polysulphone (Psf) membrane is widely used for this purpose. To increase the hydrophilicity of the membrane, it was doped with SiO2 nanoparticles (PSf/SiO2), thus enhancing the chromium flux through the membrane [137].

Limitations of nanoadsorbents

The major challenge in any remediation process is the disposal of the material containing concentrated Cr(VI) away from the treated water. In many of the remediation processes discussed here, Cr(VI) is reduced to its non-toxic trivalent form. Many methods have been proposed to dispose the nanomaterial containing concentrated adsorbed chromium. Several nanomaterials, such as titania, have been observed to improve the physicochemical properties of cement, mortar and concrete [138]. This fact can be used to immobilise the adsorbed chromium by using the titanium oxide nanoparticles in the preparation of mortar. The photocatalytically reduced Cr(III) was successfully immobilised in mortar with a specimen containing 15% titania powder by weight. Even after a period of 90 days, the leachate of chromium from such a mortar specimen was insignificant [139]. TiO2 nanoparticles can also be immobilised on glass, stainless steel, silica films, ceramic particles and fibres [140,141,142,143,144].

This, however, does not solve all problems. Employing nanoremediation as a suitable alternative to conventional methods of remediation is limited by the toxic effects exerted by the nanoparticles on the environment and to the people exposed to them. Moreover, an analysis of the cost of employing nanoremediation with respect to its efficiency is important before persuading industries to adopt this method. These two aspects have been discussed in detail below.

Toxicity of nanoparticles

It is believed that the toxicity of nanoparticles stems from their physicochemical characteristics, which includes their size, shape, surface area/volume ratio, chemical composition and surface chemistry [145, 146].

Rod-shaped cerium oxide nanoparticles have been shown to enhance pro-inflammatory and cytotoxicity responses in the RAW264.7 cell line [147]. Nanoparticles tend to get accumulated in the liver, kidney and lungs, where they exert their toxic effects. In the liver, these nanoparticles induce oxidative stress and may also trigger the inflammatory cytokines cascade, resulting in inflammatory cell chemotaxis and apoptosis [148, 149]. Xia et al. [150] proposed a hierarchical oxidative stress model which integrates the interlinked protective responses to nanoparticle toxicity. At the lowest tier of the hierarchy, the transcription factor Nrf2 induces various antioxidant and detoxification enzymes. The second tier involves pro-inflammatory responses, such as the activation of MAP kinases and NF-κB cascade. At the highest tier, the electron transfer chain of the inner mitochondrial membrane is disturbed, and apoptosis is triggered by the increased permeability of the outer mitochondrial membrane. Xia et al. [150] also performed a comparative study on the cytotoxic effects of nanoparticles of TiO2, ZnO and CeO2. It was reported that, while TiO2 nanoparticles did not elicit any cytotoxic effects under dark conditions, ZnO nanoparticles could induce spontaneous ROS production as an injurious response. Surprisingly, however, CeO2 nanoparticles induced a protective response even though they generated ROS.

Nanoparticles have the ability to organise a protein corona around them, depending on particle size, curvature, shape, functionalised groups on the surface and free energy. This often leads to protein unfolding, thiol cross-linking, fibrillation and loss of enzymatic activity [151, 152]. Certain nanoparticles can also dissolute in the medium (or biological environment), leading to release of toxic ions. For example, ZnO nanoparticles dissolve under aqueous conditions, forming hydrated Zn+2 cations, and this dissolution is accelerated under acidic conditions or in the presence of amino acids and peptides [153]. ZnO nanoparticles that reach the alveoli cause pulmonary inflammation through increased TNF-α, IL-6 and IL-8 production [154]. Linking Fe3O4 nanoparticles to neurodegenerative diseases, it was reported that Fe3O4 nanoparticles resulted in an increase in lipid peroxidation and ROS formation, along with elevated levels of mitochondrial enzymes and swelling (and corresponding decrease in respiration levels), TNF-α and caspase-3 (pro-apoptotic protein) activity [155]. Two-dimensional graphene oxide nanomaterials showed greatest rate of efflux of haemoglobin from suspended RBCs, while aggregated graphene sheets showed lowest haemolytic activity. Coating graphene oxide with chitosan, however, nearly eliminated haemolytic activity [156].

Water-solubilised aminoclay nanoparticles showed toxicity against eukaryotic microalga Pseudokirchneriella subcapitata at a concentration of 1.29 mg/l (possibly due to entrapment of the algal cells in the nanoparticle aggregations), but showed no inhibitory effect towards the marine bioluminescent bacteria Vibrio fisheri up to 25,000 mg/l [157]. Pereira et al. [158] studied the ecotoxic effects of various nanoparticles, including those of TiO2, TiSO4, CdSe/ZnS and many more, and reported the occurrence of toxic effects on V. fisheri and Salmonella typhimurium. A detailed toxicology investigation of CeO2 nanoparticles revealed that the nanoparticles aggregated at a pH of 7.4, and showed no toxicity towards Daphnia magna, Thamnocephalus platyurus and embryos of Danio rerio up to concentrations of 1000, 5000 and 200 mg/l, respectively, but showed a significant toxicity towards P. subcapitata at concentrations of 2.6–5.4 mg/l [159]. Moreover, the stability and toxicity of CeO2 nanoparticles is significantly affected by pH, natural organic matter and ionic strength. For example, the natural organic matter gets adsorbed to the surface of the nanoparticles, decreasing their bioavailability and, hence, reducing their toxicity [160]. Chen et al. [161] reported that CMC-stabilised nZVI showed more acute toxicity to larvae of Oryzias latipes (medaka fish) than bare nZVI and bare nFe3O4, arguing that CMC-nZVI led to increased hypoxia and increased production of ROS and aqueous Fe(II) than unsupported nZVI. The toxicity of ZnO nanoparticles against Gram-positive bacteria has long been exploited in their use as antibacterial agents. However, as reviewed by Ma et al. [162], they are also able to inhibit photosynthesis in Anabaena flos-aquae, cause cell death in Euglena gracilis euglenoid, affect root elongation of garden cress and even reduce biomass of wheat under field conditions. There are very few articles on the ability of nanoparticles to inhibit various enzymes secreted by soil-dwelling microbes. Silver nanoparticles can inhibit the activities of phosphomonoesterase, arylsulphatase, β-D-glucosidase and leucine aminopeptidase [163], while ZnO nanoparticles can inhibit the activities of acid phosphatase, β-glucosidase and dehydrogenase [164]. CeO2 nanoparticles have been reported to inhibit urease and β-glucosidase, while stimulating phosphatase activity. The former is attributed to the accumulation of ROS that damages the microbial cells, while the latter effect is due to either a shift in microbial community or due to the antioxidant property of CeO2 nanoparticles [165]. These soil enzymes are markers of soil fertility and nutrient recycling via the various biogeochemical cycles of nature.

In a review by Niyas Ahamed [166], the ecotoxic effects of nZVI were summarised. It was noted that the toxic effect of iron is due to its catalytic activity towards production of ROS. While nZVIs can be used for environmental remediation, their dosage should not exceed the maximum permissible concentration before being detrimental to bacteria. Aquatic invertebrates, such as Daphia magna, are very sensitive to certain nanoparticles. Germination of plants, such as Zea mays, is affected in the presence of silver nanoparticles.

However, the review [166] notes that supplementing the nanoparticles with bovine serum albumin reduces their toxic effects. Coating nZVIs with a biodegradable material also reduces their toxicity [166]. Similarly, biodegradable materials such as porous orange peel pith can be used as a supporting material for iron nanoparticles. This system has a Cr(VI) removal efficiency of 71% [167]. Another eco-friendly alternative available to industries is the green synthesis of nanoparticles using plant extracts and micro-organisms. CuO nanoparticles were synthesised using the extracts of Citrus limon (lemon juice) as a bioreductant and were used for Cr(VI) remediation [168]. The first biogenic nZVI were produced from tea (Camellia sinensis) polyphenols [169]. Since then, nZVI have been produced biogenically and investigated for Cr(VI) remediation. For example, nZVI particles were synthesised using the leaf extracts of Eucalyptus globules, and they showed a Cr(VI) removal efficiency of 98.1% in 30 min at a limited dosage of 0.8 g of nZVIs per litre of solution [170]. Iron-based nanoparticles were produced by reacting FeCl3 with Syzygiumjambos (L.) Alston leaf extract, the latter being used as both reducing and capping agents. The Cr(VI) removal efficiency of the same, which was strongly dependent on temperature and pH, was 983.2 Cr(VI)/g Fe [171]. Sharma et al. [172] have reviewed the various methods of biogenic production of nanoparticles. Biogenic selenium nanoparticles, produced by employing Bacillus sp. as a reductant, are less toxic than synthetic selenium nanoparticles [173]. Even in the review by de Lima et al. [174], it was concluded that biogenic silver nanoparticles are much less genotoxic than chemically synthesised ones, while also noting that chemically capped nanoparticles induced severe cell damage in contrast to protein-capped silver nanoparticles, which showed no genotoxic effects.

Cost versus efficiency analysis of nanoremediation

From the above section, it is evident that besides the disposal problem, another major limitation of nanoremediation is the cost constraints. This problem can be addressed by improving the reusability of nanoadsorbents. Reusability of nanoparticles can be increased by immobilising them. For example, TiO2 and ZnO nanoparticles were immobilised in poly(vinylidene difluoride)-co-trifluoroethylene to reduce their dispersibility, and it was observed that these nanoparticles could be used up to three cycles [175]. The dye-degradation efficiency of ZnO1000 (ZnO nanoparticles with particle size of 120 nm) was reported to decrease from 99.2 to 99.12% after four trials [176]. Further research is needed for the development of nanoparticles which retain their high adsorption capacity after multiple usages. Nanoparticles have a strong tendency to aggregate and are chemically unstable, thus limiting their application. To prevent this, a supporting material is used, many of which have been elaborated above. Supporting materials enhance the dispersity of the nanoparticles [177,178,179,180]. Use of a supporting material, however, raises the budget of the industry and may not always be an economic solution.

Future aspects

In today’s society of unstable economy, industries are reluctant to spend adequate money on remediation processes. Industrialists should be made aware of such remediation processes and their benefits in the long run. The capital cost of cleaning industrial effluents may be high, but with the use of cost-effective techniques, such an investment may be profitable for the industry. Using greener and eco-friendly techniques, such as use of biogenic nanoparticles, reduces the cost even more with a simultaneous increase in efficiency. Future research should focus on developing less toxic, more efficient, cost-effective and increasingly reusable nanoadsorbents.

References

Saha B, Orvig C (2010) Biosorbents for hexavalent chromium elimination from industrial and municipal effluents. Coord Chem Rev 254:2959–2972

Narayani M, Vidya Shetty K (2014) Reduction of hexavalent chromium by a novel Ochrobactrum sp.—microbial characteristics and reduction kinetics. J Basic Microbiol 54:296–305

Sandana Mala JG, Sujatha D, Rose C (2015) Inducible chromate reductase exhibiting extracellular activity in Bacillus methylotrophicus for chromium bioremediation. Microbiol Res 170:235–241

Zahoor A, Rehman A (2009) Isolation of Cr(VI) reducing bacteria from industrial effluents and their potential use in bioremediation of chromium containing wastewater. J Environ Sci 21:814–820

Shekhawat A, Kahu S, Saravanan D, Jugade R (2015) Synergistic behaviour of ionic liquid impregnated sulphate-crosslinked chitosan towards adsorption of Cr(VI). Int J Biol Macromol 80:615–626

Tagliari KC, Cecchini R, Rocha JAV, Vargas VMF (2004) Mutagenicity of sediment and biomarkers of oxidative stress in fish from aquatic environments under the influence of tanneries. Mutat Res Genet Toxicol Environ Mutagen 561:101–117

Cohen MD, Kargacin B, Klein CB, Costa M (1993) Mechanisms of chromium carcinogenicity and toxicity. Crit Rev Toxicol 23:255–281

Vutukuru S (2005) Acute effects of hexavalent chromium on survival, oxygen consumption, hematological parameters and some biochemical profiles of the Indian major carp, Labeo rohita. Int J Env Res Public Health 2:456–462

Jagupilla SC, Moon DH, Wazne M, Christodoulatos C, Kim MG (2009) Effects of particle size and acid addition on the remediation of chromite ore processing residue using ferrous sulfate. J Hazard Mater 168:121–128

Li Y, Liang J, He X, Zhang L, Liu Y (2016) Kinetics and mechanisms of amorphous FeS2 induced Cr(VI) reduction. J Hazard Mater 320:216–225

Chrysochoou M, Johnston CP (2015) Polysulfide speciation and reactivity in chromate-contaminated soil. J Hazard Mater 281:87–94

Feng J, Li Y, Shi S, Liu Y, Wang Q (2015) Remediation of Cr6+ in chromite ore processing residue by sodium thiosulfate and sodium phosphate. China Environ Sci 35:3333–3339

Kanchinadham SBK, Loganathan VD, Kalyanaraman C (2013) A preliminary study on leachability of chromium from a contaminated site. Environ Prog Sustain Energy 32:1096–1110

Xiao-bin L, Wen-bin X, Qiu-sheng Z, Zhi-hong P, Gui-hua L (2011) Leaching kinetics of acid-soluble Cr(VI) from chromite ore processing residue with hydrofluoric acid. J Cent South Univ Technol 18:399–405

Fu R, Wen D, Xia X, Zhang W, Gu Y (2017) Electrokinetic remediation of chromium (Cr)-contaminated soil with citric acid (CA) and polyaspartic acid (PASP) as electrolytes. Chem Eng J 316:601–608

Cundy A, Pollock R, Hopkinson L (2009) Electrokinetic ferric iron remediation and stabilisation (FIRS) of hexavalent chromium contaminated soils: an ex situ demonstration field scale. Contam L Appl Real Environ 9:6

Pan X, Liu Z, Chen Z, Cheng Y, Pan D, Shao J, Lin Z, Guan X (2014) Investigation of Cr(VI) reduction and Cr(III) immobilization mechanism by planktonic cells and biofilms of Bacillus subtilis ATCC-6633. Water Res 55:21–29

Nancharaiah YV, Dodge C, Venugopalan VP, Narasimhan SV, Francis AJ (2010) Immobilization of Cr(VI) and Its reduction to Cr(III) phosphate by granular biofilms comprising a mixture of microbes. Appl Environ Microbiol 76:2433–2438

Lv X, Xu J, Jiang G, Tang J, Xu X (2012) Highly active nanoscale zero-valent iron (nZVI)-Fe3O4 nanocomposites for the removal of chromium(VI) from aqueous solutions. J Colloid Interface Sci 369:460–469

Stone V, Nowack B, Baun A et al (2010) Nanomaterials for environmental studies: classification, reference material issues, and strategies for physico-chemical characterisation. Sci Total Environ 408:1745–1754

Lowry GV, Johnson KM (2004) Congener-specific dechlorination of dissolved PCBs by microscale and nanoscale zerovalent iron in a water/methanol solution. Environ Sci Technol 38:5208–5216

Oliveira H, Santos TM, Ramalho-Santos J, de Lourdes PM (2006) Histopathological effects of hexavalent chronium in mouse kidney. Bull Environ Contam Toxicol 76:977–983

Belagyi J, Pas M, Raspor P, Pesti M, Páli T (1999) Effect of hexavalent chromium on eukaryotic plasma membrane studied by EPR spectroscopy. Biochim Biophys Acta Biomembr 1421:175–182

Susa N, Ueno S, Furukawa Y, Ueda J, Sugiyama M (1997) Potent protective effect of melatonin on chromium (VI)-induced DNA single-strand breaks. Cytotox Lipid Peroxidation Prim Cult Rat Hepatoc 384:377–384

O’Brien TJ, Ceryak S, Patierno SR (2003) Complexities of chromium carcinogenesis: role of cellular response, repair and recovery mechanisms. Mutat Res Fundam Mol Mech Mutagen 533:3–36

Nordberg J, Arnér ESJ (2001) Reactive oxygen species, antioxidants, and the mammalian thioredoxin system1 1 this review is based on the licentiate thesis “thioredoxin reductase—interactions with the redox active compounds 1-chloro-2,4-dinitrobenzene and lipoic acid” by Jonas Nordberg. Free Radic Biol Med 31:1287–1312

Gopalakrishnan K, Manivannan V, Jeyadoss T (2010) Comparative study on biosorption of Zn (II), Cu (II) and Cr(VI) from textile dye effluent using sawdust and neem leaves powder. E J Chem 7:S504–S510

Ugoji E, Aboaba O (2004) Biological treatments of textile industrial effluents in Lagos metropolis, Nigeria. J Env Biol 25:497–502

Deepali KKG (2010) Metals concentration in textile and tannery effluents, associated soils and ground water. N Y Sci J 3:82–89

Das AP, Mishra S (2008) Hexavalent chromium (VI): environment pollution and health hazard. J Environ Res Dev 2:386–392

Burger J, Gochfeld M, Kosson D, Powers CW, Friedlander B, Eichelberger J, Barnes D, Duffy LK, Jewett SC, Volz CD (2005) Science, policy, and stakeholders: developing a consensus science plan for Amchitka Island, Aleutians, Alaska. Environ Manag 35:557–568

Mishra AK, Mohanty B (2008) Acute toxicity impacts of hexavalent chromium on behavior and histopathology of gill, kidney and liver of the freshwater fish, Channa punctatus (Bloch). Environ Toxicol Pharmacol 26:136–141

von Burg R, Liu D (1993) Chromium and hexavalent chromium. J Appl Toxicol 13:225–230

Kawanishi S, Hiraku Y, Murata M, Oikawa S (2002) The role of metals in site-specific DNA damage with reference to carcinogenesis. Free Radic Biol Med 32:822–832

Salnikow K, Room E (2009) NIH public access. DNA Repair (Amst). doi:10.1021/tx700198a.Genetic

Mahmood T, Qureshi IZ, Nadeem MS, Khan MA (2008) Hexavalent chromium toxicity in pituitary and thyroid glands. Pak J Zool 40:91–97

Gumbleton M, Nicholls P (1988) Dose-response and time-response biochemical and histological study of potassium dichromate-induced nephrotoxicity in the rat. Food Chem Toxicol 26:37–44

Kalidhasan S, Santhana Krishna Kumar A, Rajesh V, Rajesh N (2016) The journey traversed in the remediation of hexavalent chromium and the road ahead toward greener alternatives-A perspective. Coord Chem Rev 317:157–166

Suresh A, Brahmmananda Rao CVS, Srinivasulu B, Sreenivasan NL, Subramaniam S, Sabharwal KN, Sivaraman N, Srinivasan TG, Natarajan R, Vasudeva Rao PR (2013) Development of alternate extractants for separation of actinides. Energy Proced 39:120–126

Someda HH, El-Shazly EA, Sheha RR (2005) The role of some compounds on extraction of chromium(VI) by amine extractants. J Hazard Mater 117:213–219

Senol A (2004) Amine extraction of chromium(VI) from aqueous acidic solutions. Sep Purif Technol 36:63–75

Kalidhasan S, Sricharan S, Ganesh M, Rajesh N (2010) Liquid–liquid extraction of chromium (VI) with tricaprylmethylammonium chloride using isoamylalcohol as the diluent and its application to industrial effluents. J Chem Eng Data 55:5627–5633

Venkateswaran P, Palanivelu K (2004) Solvent extraction of hexavalent chromium with tetrabutyl ammonium bromide from aqueous solution. Sep Purif Technol 40:279–284

Kalidhasan S, Ganesh M, Sricharan S, Rajesh N (2009) Extractive separation and determination of chromium in tannery effluents and electroplating waste water using tribenzylamine as the extractant. J Hazard Mater 165:886–892

Boast D (1988) Large scale chrome recovery from chrome wash liquors. J Am Leather Chem Assoc 83:17–33

Vasileva E, Hadjiivanov K, Mandjukov P (1994) Adsorption of Cr+ 6 oxo anions on pure and peroxide-modified TiO2 (anatase). Colloids Surf A Physicochem Eng Asp 90:15

Mesuere K, Fish W (1992) Chromate and oxalate adsorption on goethite. 1. Calibration of surface complexation models. Environ Sci Technol 26:2357–2364

Babel S (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97:219–243

Oliver SRJ (2009) Cationic inorganic materials for anionic pollutant trapping and catalysis. Chem Soc Rev 38:1868

Zhang J, Shang T, Jin X, Gao J, Zhao Q (2015) Study of chromium(VI) removal from aqueous solution using nitrogen-enriched activated carbon based bamboo processing residues. RSC Adv 5:784–790

Song Z, Li W, Liu W, Yang Y, Wang N, Wang H, Gao H (2015) Novel magnetic lignin composite sorbent for chromium(VI) adsorption. RSC Adv 5:13028–13035

Camel V (2003) Solid phase extraction of trace elements. Spectrochim Acta Part B 58:1177–1233

Rengaraj S, Joo CK, Kim Y, Yi J (2003) Kinetics of removal of chromium from water and electronic process wastewater by ion exchange resins: 1200H, 1500H and IRN97H. J Hazard Mater B 102:257–275

Qian L, Zhang H (2010) Green synthesis of chitosan-based nanofibers and their applications. Green Chem 12:1207–1214

Deans JR, Dixon BRNG, Cod C, St POBM, Bay B (1992) Uptake of Pb Z+ and Cu+ by novel biopolymers. Water Res 26:3–6

Gładysz-Płaska A, Majdan M, Pikus S, Sternik D (2012) Simultaneous adsorption of chromium(VI) and phenol on natural red clay modified by HDTMA. Chem Eng J 179:140–150

Bhattacharyya KG, Sen GS (2006) Adsorption of chromium(VI) from water by clays. Ind Eng Chem Res 45:7232–7240

Wu P, Li S, Ju L, Zhu N, Wu J, Li P, Dang Z (2012) Mechanism of the reduction of hexavalent chromium by organo-montmorillonite supported iron nanoparticles. J Hazard Mater 219–220:283–288

Brum MC, Capitaneo JL, Oliveira JF (2010) Removal of hexavalent chromium from water by adsorption onto surfactant modified montmorillonite. Miner Eng 23:270–272

Santhana Krishna Kumar A, Ramachandran R, Kalidhasan S, Rajesh V, Rajesh N (2012) Potential application of dodecylamine modified sodium montmorillonite as an effective adsorbent for hexavalent chromium. Chem Eng J 211–212:396–405

Liu X, Pan L, Lv T, Zhu G, Lu T, Sun Z, Sun C (2011) Microwave-assisted synthesis of TiO2-reduced graphene oxide composites for the photocatalytic reduction of Cr(vi). RSC Adv 1:1245

Ma H-L, Zhang Y, Hu Q-H, Yan D, Yu Z-Z, Zhai M (2012) Chemical reduction and removal of Cr(vi) from acidic aqueous solution by ethylenediamine-reduced graphene oxide. J Mater Chem 22:5914

Dubey R, Bajpai J, Bajpai AK (2015) Green synthesis of graphene sand composite (GSC) as novel adsorbent for efficient removal of Cr(VI) ions from aqueous solution. J Water Process Eng 5:83–94

Troiano JM, Jordan DS, Hull CJ, Geiger FM (2013) Interaction of Cr(III) and Cr(VI) with hematite studied by second harmonic generation. J Phys Chem C 117:5164–5171

Kumar R, Bishnoi NR, Garima BK (2008) Biosorption of chromium(VI) from aqueous solution and electroplating wastewater using fungal biomass. Chem Eng J 135:202–208

Han X, Wong YS, Wong MH, Tam NFY (2007) Biosorption and bioreduction of Cr(VI) by a microalgal isolate, Chlorella miniata. J Hazard Mater 146:65–72

Anjana K, Kaushik A, Kiran B, Nisha R (2007) Biosorption of Cr(VI) by immobilized biomass of two indigenous strains of cyanobacteria isolated from metal contaminated soil. J Hazard Mater 148:383–386

Pattanapipitpaisal P, Brown NL, Macaskie LE (2001) Chromate reduction by microbacterium liquefaciens immobilised in polyvinyl alcohol. Biotechnol Lett 23:61–65

Hsu LC, Wang SL, Lin YC, Wang MK, Chiang PN, Liu JC, Kuan WH, Chen CC, Tzou YM (2010) Cr(VI) removal on fungal biomass of Neurospora crassa: the importance of dissolved organic carbons derived from the biomass to Cr(VI) reduction. Environ Sci Technol 44:6202–6208

Mukhopadhyay B, Sundquist J, Schmitz RJ (2007) Removal of Cr(VI) from Cr-contaminated groundwater through electrochemical addition of Fe(II). J Environ Manag 82:66–76

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) A review of potentially low cost sorbents for heavy metals. Water Res 33:2469–2479

Acharya J, Sahu JN, Sahoo BK, Mohanty CR, Meikap BC (2009) Removal of chromium(VI) from wastewater by activated carbon developed from Tamarind wood activated with zinc chloride. Chem Eng J 150:25–39

Kumar A, Jena HM (2017) Adsorption of Cr(VI) from aqueous phase by high surface area activated carbon prepared by chemical activation with ZnCl2. Process Saf Environ Prot 109:63–71

Rai MK, Shahi G, Meena V, Meena R, Chakraborty S, Singh RS, Rai BN (2016) Removal of hexavalent chromium Cr(VI) using activated carbon prepared from mango kernel activated with H3PO4. Resour Technol 2:S63–S70

Zaitseva N, Zaitsev V, Walcarius A (2013) Chromium (VI) removal via reduction–sorption on bi-functional silica adsorbents. J Hazard Mater 250–251:454–461

Quirarte-Escalante CA, Soto V, De La Cruz W, Porras GR, Manríquez R, Gomez-Salazar S (2009) Synthesis of hybrid adsorbents combining sol-gel processing and molecular imprinting applied to lead removal from aqueous streams. Chem Mater 21:1439–1450

Karthik R, Meenakshi S (2014) Journal of water process engineering removal of hexavalent chromium ions using polyaniline/silica gel composite. J Water Process Eng 1:37–45

Xi Y, Liangying Z, Sasa W (1995) Pore size and pore-size distribution control of porous silica. Sens Actuators B Chem 25:347–352

Guo J, Li Y, Dai R, Lan Y (2012) Rapid reduction of Cr(VI) coupling with efficient removal of total chromium in the coexistence of Zn(0) and silica gel. J Hazard Mater 243:265–271

Kumar PA, Ray M, Chakraborty S (2007) Hexavalent chromium removal from wastewater using aniline formaldehyde condensate coated silica gel. J Hazard Mater 143:24–32

Wang Y, Tian M, Bi W, Kyung HR (2009) Application of ionic liquids in high performance reversed-phase chromatography. Int J Mol Sci 10:2591–2610

Wang Z, Ye C, Wang X, Li J (2013) Applied surface science adsorption and desorption characteristics of imidazole-modified silica for chromium (VI). Appl Surf Sci 287:232–241

Gomez-Gonzalez SE, Carbajal-Arizaga GG, Manriquez-Gonzalez R, De La Cruz-Hernandez W, Gomez-Salazar S (2014) Trivalent chromium removal from aqueous solutions by a sol-gel synthesized silica adsorbent functionalized with sulphonic acid groups. Mater Res Bull 59:394–404

Shevchenko N, Zaitsev V, Walcarius A (2008) Bifunctionalized mesoporous silicas for Cr(VI) reduction and concomitant Cr(III) immobilization. Environ Sci Technol 42:6922–6928

Kumar P, Pournara A, Kim KH, Bansal V, Rapti S, Manos MJ (2017) Metal-organic frameworks: challenges and opportunities for ion-exchange/sorption applications. Prog Mater Sci. doi:10.1016/j.pmatsci.2017.01.002

Hasan Z, Cho J, Rinklebe J, Ok YS, Cho DW, Song H (2016) Metal organic framework derived Cu-carbon composite: an efficient non-noble metal catalyst for reduction of hexavalent chromium and pendimethalin. J Ind Eng Chem. doi:10.1016/j.jiec.2017.04.006

Silva B, Figueiredo H, Quintelas C, Neves IC, Tavares T (2008) Zeolites as supports for the biorecovery of hexavalent and trivalent chromium. Microporous Mesoporous Mater 116:555–560

Jiménez-Castañeda ME, Medina DI (2017) Use of surfactant-modified zeolites and clays for the removal of heavy metals from water. Water (Switzerland). doi:10.3390/w9040235

Lofù A, Mastrorilli P, Dell’Anna MM, Mali M, Sisto R, Vignola R (2016) Iron(II) modified natural zeolites for hexavalent chromium removal from contaminated water. Arch Environ Prot 42:35–40

Erdogan BC, Ülkü S (2012) Cr(VI) sorption by using clinoptilolite and bacteria loaded clinoptilolite rich mineral. Microporous Mesoporous Mater 152:253–261

Habiba U, Siddique TA, Joo TC, Salleh A, Ang BC, Afifi AM (2017) Synthesis of chitosan/polyvinyl alcohol/zeolite composite for removal of methyl orange, Congo red and chromium(VI) by flocculation/adsorption. Carbohydr Polym 157:1568–1576

Ohtake H, Fujii E, Toda K (1990) Reduction of toxic chromate in an industrial effluent by use of a chromate-reducing strain of Enterobacter cloacae. Environ Technol 11:663–668

Thatoi H, Das S, Mishra J, Rath BP, Das N (2014) Bacterial chromate reductase, a potential enzyme for bioremediation of hexavalent chromium: a review. J Environ Manag 146:383–399

Kathiravan MN, Karthick R, Muthukumar K (2011) Ex situ bioremediation of Cr(VI) contaminated soil by Bacillus sp.: batch and continuous studies. Chem Eng J 169:107–115

Desai C, Jain K, Madamwar D (2008) Evaluation of In vitro Cr(VI) reduction potential in cytosolic extracts of three indigenous Bacillus sp. isolated from Cr(VI) polluted industrial landfill. Bioresour Technol 99:6059–6069

Song Z, Li W, Liu W, Yang Y, Wang N, Wang H, Haiyan G (2015) Novel magnetic lignin composite sorbent for chromium (VI) adsorption. RSC Adv 5:13028–13035

Mthombeni NH, Onyango MS, Aoyi O (2015) Adsorption of hexavalent chromium onto magnetic natural zeolite-polymer composite. J Taiwan Inst Chem Eng 50:242–251

Zhang W, Cao J, Elliot D (2005) Iron nanoparticles for site remediation. In: Karn B, Masciangioli T, Zhang W, Colvin V, Alivisatos P (eds) Nanotechnology and the environment: applications and implications. Oxford University Press, Washington, pp 248–261

Qiu X, Fang Z, Yan X, Cheng W, Lin K (2013) Chemical stability and toxicity of nanoscale zero-valent iron in the remediation of chromium-contaminated watershed. Chem Eng J 220:61–66

Manning BA, Kiser JR, Kwon H, Kanel SR (2007) Spectroscopic investigation of Cr(III)- and Cr(VI)-treated nanoscale zerovalent iron. Environ Sci Technol 41:586–592

Li X, Elliott DW, Zhang W (2006) Zero-valent iron nanoparticles for abatement of environmental pollutants: materials and engineering aspects. Crit Rev Solid State Mater Sci 31:111–122

Ezzatahmadi N, Ayoko GA, Millar GJ, Speight R, Yan C, Li J, Li S, Zhu J, Xi Y (2017) Clay-supported nanoscale zero-valent iron composite materials for the remediation of contaminated aqueous solutions: a review. Chem Eng J 312:336–350

Fu F, Ma J, Xie L, Tang B, Han W, Lin S (2013) Chromium removal using resin supported nanoscale zero-valent iron. J Environ Manag 128:822–827

Wang Q, Qian H, Yang Y, Zhang Z, Naman C, Xu X (2010) Reduction of hexavalent chromium by carboxymethyl cellulose-stabilized zero-valent iron nanoparticles. J Contam Hydrol 114:35–42

Rivero-Huguet M, Marshall WD (2009) Reduction of hexavalent chromium mediated by micro- and nano-sized mixed metallic particles. J Hazard Mater 169:1081–1087

Qin YM, Wang DQ, Liang MN (2016) Preparation of mulberry stem activated carbon/Fe–Mn oxide composite sorbent and its effects on the adsorption of Cr(VI). Environ Chem 35:783–792

Zhu F, Li L, Ma S, Shang Z (2016) Effect factors, kinetics and thermodynamics of remediation in the chromium contaminated soils by nanoscale zero valent Fe/Cu bimetallic particles. Chem Eng J. doi:10.1016/j.cej.2016.05.072

Shen YF, Tang J, Nie ZH, Wang YD, Ren Y, Zuo L (2009) Preparation and application of magnetic Fe3O4 nanoparticles for wastewater purification. Sep Purif Technol 68:312–319

Costa RCC, Moura FCC, Ardisson JD, Fabris JD, Lago RM (2008) Highly active heterogeneous Fenton-like systems based on Fe0/Fe3O4 composites prepared by controlled reduction of iron oxides. Appl Catal B Environ 83:131–139

Moura FCC, Araujo MH, Costa RCC, Fabris JD, Ardisson JD, Macedo WAA, Lago RM (2005) Efficient use of Fe metal as an electron transfer agent in a heterogeneous Fenton system based on Fe0/Fe3O4 composites. Chemosphere 60:1118–1123

Lv X, Xue X, Jiang G, Wu D, Sheng T, Zhou H, Xu X (2014) Nanoscale zero-valent iron (nZVI) assembled on magnetic Fe3O4/graphene for chromium (VI) removal from aqueous solution. J Colloid Interface Sci 417:51–59

Zhou X, Lv B, Zhou Z, Li W, Jing G (2015) Evaluation of highly active nanoscale zero-valent iron coupled with ultrasound for chromium(VI) removal. Chem Eng J 281:155–163

Bhowmik K, Mukherjee A, Mishra MK, De G (2014) Stable Ni nanoparticles—reduced graphene oxide composites for the reduction of highly toxic aqueous Cr(VI) at room temperature. Langmuir 30:3209–3216

Chen H, Shao Y, Xu Z, Wan H, Wan Y, Zheng S, Zhu D (2011) Effective catalytic reduction of Cr(VI) over TiO2 nanotube supported Pd catalysts. Appl Catal B Environ 105:255–262

Celebi M, Yurderi M, Bulut A, Kaya M, Zahmakiran M (2016) Palladium nanoparticles supported on amine-functionalized SiO2 for the catalytic hexavalent chromium reduction. Appl Catal B Environ 180:53–64

Markad US, Kalekar AM, Naik DB, Sharma KKK, Kshirasagar KJ, Sharma GK (2017) Photo enhanced detoxification of chromium (VI) by formic acid using 3D palladium nanocatalyst. J Photochem Photobiol A Chem 338:115–122

Rajput S, Pittman CU, Mohan D (2016) Magnetic magnetite (Fe3O4) nanoparticle synthesis and applications for lead (Pb2+) and chromium (Cr6+) removal from water. J Colloid Interface Sci 468:334–346

Nematollahzadeh A, Seraj S, Mirzayi B (2015) Catecholamine coated maghemite nanoparticles for the environmental remediation: hexavalent chromium ions removal. Chem Eng J 277:21–29

Banerjee P, Chakrabarti S, Maitra S, Dutta BK (2012) Zinc oxide nano-particles—sonochemical synthesis, characterization and application for photo-remediation of heavy metal. Ultrason Sonochem 19:85–93

Chakrabarti S, Chaudhuri B, Bhattacharjee S, Ray AK, Dutta BK (2009) Photo-reduction of hexavalent chromium in aqueous solution in the presence of zinc oxide as semiconductor catalyst. Chem Eng J 153:86–93

Ku Y, Jung IL (2001) Photocatalytic reduction of Cr(VI) in aqueous solutions by UV irradiation with the presence of titanium dioxide. Water Res 35:135–142

Schrank SG, José HJ, Moreira RFPM (2002) Simultaneous photocatalytic Cr(VI) reduction and dye oxidation in a TiO2 slurry reactor. J Photochem Photobiol A Chem 147:71–76

Khalil LB, Mourad WE, Rophael MW (1998) Photocatalytic reduction of environmental pollutant Cr(VI) over some semiconductors under UV/visible light illumination. Appl Catal B Environ 17:267–273

Ahmad R, Ahmad Z, Khan AU, Mastoi NR, Aslam M, Kim J (2016) Photocatalytic systems as an advanced environmental remediation: recent developments, limitations and new avenues for applications. J Environ Chem Eng 4:4143–4164

Recillas S, Colón J, Casals E, González E, Puntes V, Sánchez A, Font X (2010) Chromium VI adsorption on cerium oxide nanoparticles and morphology changes during the process. J Hazard Mater 184:425–431

Albadarin AB, Yang Z, Mangwandi C, Glocheux Y, Walker G, Ahmad MNM (2014) Experimental design and batch experiments for optimization of Cr(VI) removal from aqueous solutions by hydrous cerium oxide nanoparticles. Chem Eng Res Des 92:1354–1362

Srivastava V, Kohout T, Sillanpää M (2016) Potential of cobalt ferrite nanoparticles (CoFe2O4) for remediation of hexavalent chromium from synthetic and printing press wastewater. J Environ Chem Eng. doi:10.1016/j.jece.2016.06.002

Luo C, Tian Z, Yang B, Zhang L, Yan S (2013) Manganese dioxide/iron oxide/acid oxidized multi-walled carbon nanotube magnetic nanocomposite for enhanced hexavalent chromium removal. Chem Eng J 234:266–275

Badruddoza AZM, Shawon ZBZ, Rahman MT, Hao KW, Hidajat K, Uddin MS (2013) Ionically modified magnetic nanomaterials for arsenic and chromium removal from water. Chem Eng J 225:607–615

Pandikumar A, Ramaraj R (2013) Photocatalytic reduction of hexavalent chromium at gold nanoparticles modified titania nanotubes. Mater Chem Phys 141:629–635

Nithya R, Gomathi T, Sudha PN, Venkatesan J, Anil S, Kim SK (2016) Removal of Cr(VI) from aqueous solution using chitosan-g-poly(butyl acrylate)/silica gel nanocomposite. Int J Biol Macromol 87:545–554

Lyu H, Tang J, Huang Y, Gai L, Zeng EY, Liber K, Gong Y (2017) Removal of hexavalent chromium from aqueous solutions by a novel biochar supported nanoscale iron sulfide composite. Chem Eng J 322:516–524

De Volder MFL, Tawfick SH, Baughman RH, Hart AJ (2013) Carbon nanotubes: present and future commercial applications. Science 339(80):535–539

Kongkanand A, Kuwabata S, Girishkumar G, Kamat P (2006) Single-wall carbon nanotubes supported platinum nanoparticles with improved electrocatalytic activity for oxygen reduction reaction. Langmuir 22:2392–2396

Lipomi DJ, Bao Z (2011) Stretchable, elastic materials and devices for solar energy conversion. Energy Environ Sci 4:3314

Mohamed A, Osman TA, Toprak MS, Muhammed M, Yilmaz E, Uheida A (2016) Visible light photocatalytic reduction of Cr(VI) by surface modified CNT/Titanium dioxide composites nanofibers. J Mol Catal A Chem 424:45–53

Habibi S, Nematollahzadeh A, Mousavi SA (2015) Nano-scale modification of polysulfone membrane matrix and the surface for the separation of chromium ions from water. Chem Eng J 267:306–316

Chen J, Kou SC, Poon CS (2012) Hydration and properties of nano-TiO2 blended cement composites. Cem Concr Compos 34:642–649

Husnain A, Qazi IA, Khaliq W, Arshad M (2016) Immobilization in cement mortar of chromium removed from water using titania nanoparticles. J Environ Manag 172:10–17

Hosseini SN, Borghei SM, Vossoughi M, Taghavinia N (2007) Immobilization of TiO2 on perlite granules for photocatalytic degradation of phenol. Appl Catal B Environ 74:53–62

Byrne JA, Eggins BR, Brown NMD, McKinney B, Rouse M (1998) Immobilisation of TiO2 powder for the treatment of polluted water. Appl Catal B Environ 17:25–36

Castañeda-Contreras J, Marañón-Ruiz VF, Chiu-Zárate R, Pérez-Ladrón De Guevara H, Rodriguez R, Michel-Uribe C (2012) Photocatalytic activity of erbium-doped TiO2 nanoparticles immobilized in macro-porous silica films. Mater Res Bull 47:290–295

Kanki T, Hamasaki S, Sano N, Toyoda A, Hirano K (2005) Water purification in a fluidized bed photocatalytic reactor using TiO2-coated ceramic particles. Chem Eng J 108:155–160

Cossich E, Bergamasco R, Pessoa De Amorim MT, Martins PM, Marques J, Tavares CJ, Lanceros-Méndez S, Sencadas V (2015) Development of electrospun photocatalytic TiO < inf > 2</inf > -polyamide-12 nanocomposites. Mater Chem Phys 164:91–97

Fruijtier-Pölloth C (2012) The toxicological mode of action and the safety of synthetic amorphous silica—A nanostructured material. Toxicology 294:61–79

Van Hoecke K, De Schamphelaere KAC, Van der Meeren P, Lucas S, Janssen CR (2008) Ecotoxicity of silica nanoparticles to the green alga pseudokirchneriella subcapitata: importance of surface area. Environ Toxicol Chem 27:1948

Forest V, Leclerc L, Hochepied J-F, Trouvé A, Sarry G, Pourchez J (2017) Impact of cerium oxide nanoparticles shape on their in vitro cellular toxicity. Toxicol Vitr 38:136–141

Wang J, Zhou G, Chen C et al (2007) Acute toxicity and biodistribution of different sized titanium dioxide particles in mice after oral administration. Toxicol Lett 168:176–185

Attia HF, Soliman MM, Abdel-Rahman GH, Nassan MA, Ismail SA, Farouk M, Solcan C (2013) Hepatoprotective effect of N-acetylcystiene on the toxic hazards of titanium dioxide nanoparticles. Am J Pharmacol Toxicol 8:141–147

Xia T, Kovochich M, Liong M, Mädler L, Gilbert B, Shi H, Yeh JI, Zink JI, Nel AE (2009) Comparison of the mechanism of toxicity of zinc oxide and cerium oxide nanoparticles based on dissolution and oxidative stress properties. Chemie Ing Tech 81:1167

Cedervall T, Lynch I, Lindman S, Berggard T, Thulin E, Nilsson H, Dawson KA, Linse S (2007) Understanding the nanoparticle-protein corona using methods to quantify exchange rates and affinities of proteins for nanoparticles. Proc Natl Acad Sci 104:2050–2055

Chen M, Von Mikecz A (2005) Formation of nucleoplasmic protein aggregates impairs nuclear function in response to SiO2 nanoparticles. Exp Cell Res 305:51–62

Gadd GE, Casey PS (2007) Comparative toxicity of nanoparticulate ZnO, bulk ZnO and ZnCl2 to a freshwater microalga (Pseudokirchnerilla subcapitata): the importance of particle solubility. Environ Sci Technol 41:1–27

Kuschner WG, D’Alessandro A, Wintermeyer SF, Wong H, Boushey HA, Blanc PD (1995) Pulmonary responses to purified zinc oxide fume. J Invest Med 43:371–378

Chahinez T, Rachid R, Salim G et al (2016) Toxicity of Fe3O4 nanoparticles on oxidative stress status, stromal enzymes and mitochondrial respiration and swelling of Oryctolagus cuniculus brain cortex. Toxicol Environ Health Sci 8:349–355

Liao KH, Lin YS, MacOsko CW, Haynes CL (2011) Cytotoxicity of graphene oxide and graphene in human erythrocytes and skin fibroblasts. ACS Appl Mater Interfaces 3:2607–2615

Choi MH, Hwang Y, Lee HU, Kim B, Lee GW, Oh YK, Andersen HR, Lee YC, Huh YS (2014) Aquatic ecotoxicity effect of engineered aminoclay nanoparticles. Ecotoxicol Environ Saf 102:34–41

Pereira R, Rocha-Santos TAP, Antunes FE, Rasteiro MG, Ribeiro R, Gonçalves F, Soares AMVM, Lopes I (2011) Screening evaluation of the ecotoxicity and genotoxicity of soils contaminated with organic and inorganic nanoparticles: the role of ageing. J Hazard Mater 194:345–354

Hoecke KV, Quik JTK, Mankiewicz-Boczek J et al (2009) Fate and effects of CeO2 nanoparticles in aquatic ecotoxicity tests. Environ Sci Technol 43:4537–4546

Van Hoecke K, De Schamphelaere KAC, Van Der Meeren P, Smagghe G, Janssen CR (2011) Aggregation and ecotoxicity of CeO2 nanoparticles in synthetic and natural waters with variable pH, organic matter concentration and ionic strength. Environ Pollut 159:970–976

Chen PJ, Tan SW, Wu WL (2012) Stabilization or oxidation of nanoscale zerovalent iron at environmentally relevant exposure changes bioavailability and toxicity in medaka fish. Environ Sci Technol 46:8431–8439

Ma H, Williams PL, Diamond SA (2013) Ecotoxicity of manufactured ZnO nanoparticles—a review. Environ Pollut 172:76–85

Peyrot C, Wilkinson KJ, Desrosiers M, Sauvé S (2014) Effects of silver nanoparticles on soil enzyme activities with and without added organic matter. Environ Toxicol Chem 33:115–125

Kim S, Kim J, Lee I (2011) Effects of Zn and ZnO nanoparticles and Zn2+ on soil enzyme activity and bioaccumulation of Zn in Cucumis sativus. Chem Ecol 27:49–55

Li B, Chen Y, Zhen LW, Mu L, Bridges WC, Jacobson AR, Darnault CJG (2017) Influence of cerium oxide nanoparticles on the soil enzyme activities in a soil-grass microcosm system. Geoderma 299:54–62

Niyas Ahamed MI (2016) Ecotoxicity concert of nano zero-valent iron particles—a review. J Crit Rev 1:36–39

López-Téllez G, Barrera-Díaz CE, Balderas-Hernández P, Roa-Morales G, Bilyeu B (2011) Removal of hexavalent chromium in aquatic solutions by iron nanoparticles embedded in orange peel pith. Chem Eng J 173:480–485

Mohan S, Singh Y, Verma DK, Hasan SH (2015) Synthesis of CuO nanoparticles through green route using Citrus limon juice and its application as nanosorbent for Cr(VI) remediation: process optimization with RSM and ANN-GA based model. Process Saf Environ Prot. doi:10.1016/j.psep.2015.05.005

Hoag GE, Collins JB, Holcomb JL, Hoag JR, Nadagouda MN, Varma RS (2009) Degradation of bromothymol blue by “greener” nano-scale zero-valent iron synthesized using tea polyphenols. J Mater Chem 19:8671

Madhavi V, Prasad TNVKV, Reddy AVB, Ravindra Reddy B, Madhavi G (2013) Application of phytogenic zerovalent iron nanoparticles in the adsorption of hexavalent chromium. Spectrochim Acta Part A Mol Biomol Spectrosc 116:17–25

Xiao Z, Zhang H, Xu Y, Yuan M, Jing X, Huang J, Li Q, Sun D (2017) Ultra-efficient removal of chromium from aqueous medium by biogenic iron based nanoparticles. Sep Purif Technol 174:466–473

Sharma D, Kanchi S, Bisetty K (2015) Biogenic synthesis of nanoparticles: a review. Arab J Chem. doi:10.1016/j.arabjc.2015.11.002

Shakibaie M, Shahverdi AR, Faramarzi MA, Hassanzadeh GR, Rahimi HR, Sabzevari O (2013) Acute and subacute toxicity of novel biogenic selenium nanoparticles in mice. Pharm Biol 51:58–63

de Lima R, Seabra AB, Durán N (2012) Silver nanoparticles: a brief review of cytotoxicity and genotoxicity of chemically and biogenically synthesized nanoparticles. J Appl Toxicol 32:867–879

Teixeira S, Martins PM, Lanceros-Méndez S, Kühn K, Cuniberti G (2016) Reusability of photocatalytic TiO2 and ZnO nanoparticles immobilized in poly(vinylidene difluoride)-co-trifluoroethylene. Appl Surf Sci 384:497–504

Kitture R, Koppikar SJ, Kaul-Ghanekar R, Kale SN (2011) Catalyst efficiency, photostability and reusability study of ZnO nanoparticles in visible light for dye degradation. J Phys Chem Solids 72:60–66

Antiochia R, Campanella L, Ghezzi P, Movassaghi K (2007) The use of vetiver for remediation of heavy metal soil contamination. Anal Bioanal Chem 388:947–956

Xi Y, Mallavarapu M, Naidu R (2010) Reduction and adsorption of Pb 2+ in aqueous solution by nano-zero-valent iron—A SEM, TEM and XPS study. Mater Res Bull 45:1361–1367

Yan W, Herzing AA, Kiely CJ, Zhang W (2010) Nanoscale zero-valent iron (nZVI): aspects of the core-shell structure and reactions with inorganic species in water. J Contam Hydrol 118:96–104

Karabelli D, Çaǧri Ü, Shahwan T, Eroǧlu AE, Scott TB, Hallam KR, Lieberwirth I (2008) Batch removal of aqueous Cu2+ ions using nanoparticles of zero-valent iron: a study of the capacity and mechanism of uptake. Ind Eng Chem Res 47:4758–4764

Acknowledgements

The authors would like to thank VIT University, Vellore, for providing the facilities required to write this review article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mitra, S., Sarkar, A. & Sen, S. Removal of chromium from industrial effluents using nanotechnology: a review. Nanotechnol. Environ. Eng. 2, 11 (2017). https://doi.org/10.1007/s41204-017-0022-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41204-017-0022-y