Abstract

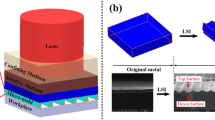

Steel is used as a mold material for press/injection molding of plastic products. High accuracy and releasing ability are required for a steel mold surface. This paper proposes a surface finishing method for steel molds by using picosecond pulsed laser irradiation. The process involves two steps: one is surface flattening by removing the surface asperity through laser ablation, and the other is forming nanoscale laser-induced periodic surface structures (LIPSS) on the flattened surface. The two steps are realized by using the same laser at controlled laser fluence and focus position. Experimental results showed that LIPSS was successfully formed after surface flattening under specific ranges of laser fluence and defocus length. Furthermore, plastic forming experiments demonstrated that a steel surface with LIPSS significantly decreased the effective contact area and, in turn, reduced the mold releasing force. These findings provide the possibility of fabricating high-performance steel molds by picosecond pulsed laser irradiation.

Similar content being viewed by others

References

Pfefferkorn FE, Duffie NA, Li X, Vadali M, Ma C (2013) Improving surface finish in pulsed laser micro polishing using thermocapillary flow, CIRP. Ann-Manuf Technol 62:203–206

Lamikiz A, Sánchez JA, López de Lacalle LN, Arana JL (2007) Laser polishing of parts built up by selective laser sintering. Int J Mach Tool Manuf 47:2040–2050

Schmidt J, Scholz R, Riegel H (2015) Laser polishing of aluminum by remelting with high energy pulses. Materialwiss Werksttech 46:686–691

Ukar E, Lamikiz A, López de Lacalle LN, del Pozo D, Arana JL (2010) Laser polishing of tool steel with CO2 laser and high-power diode laser. Int J Mach Tool Manuf 50:115–125

Chichkov BN, Momma C, Nolte S, von Alevensleben F, Tiinnermann A (1996) Femtosecond, picosecond and nanosecond laser ablation of solids. Appl Phys A 63:109–115

Borowiec A, Haugen HK (2004) Femtosecond laser micromachining of grooves in indium phosphide. Appl Phys A 79:521–529

Crawford THR, Borowiec A, Haugen HK (2005) Femtosecond laser micromachining of grooves in silicon with 800 nm pulses. Appl Phys A 80:1717–1724

Kamlage G, Bauer T, Ostendorf A, Chichkov BN (2003) Deep drilling of metals by femtosecond laser pulses. Appl Phys A 77:307–310

Vorobyev AY, Makin VS, Guo C (2007) Periodic ordering of random surface nanostructures induced by femtosecond laser pulses on metals. J Appl Phys 101:034903

Bonse J, Krüger J, Höhm S, Rosenfeld A (2012) Femtosecond laser-induced periodic surface structures. J Laser Appl 24:042006

Tomita T, Kinoshita K, Matsuo S, Hashimoto S (2007) Effect of surface roughening on femtosecond laser-induced ripple structures. Appl Phys Lett 90:153115

Vorobyev AY, Guo C (2007) Femtosecond laser structuring of titanium implants. Appl Surf Sci 253:7272–7280

Albu C, Dinescu A, Filipescu M, Ulmeanu M, Zamfirescu M (2013) Periodical structures induced by femtosecond laser on metals in air and liquid environments. Appl Surf Sci 278:347–351

Vorobyev AY, Guo C (2008) Femtosecond laser-induced periodic surface structure formation on tungsten. J Appl Phys 104:063523

Reif J, Varlamova O, Costache F (2008) Femtosecond laser induced nanostructure formation: self-organization control parameters. Appl Phys A 92:1019–1024

Sakabe S, Hashida M, Tokita S, Namba S, Okamuro K (2009) Mechanism for self-formation of periodic grating structures on a metal surface by a femtosecond laser pulse. Phys Rev B 79:033409

Gregorčič P, Sedlaček M, Podgornik B, Reif J (2016) Formation of laser-induced periodic surface structures (LIPSS) on tool steel by multiple picosecond laser pulses of different polarizations. Appl Surf Sci 387:698–706

Martens JR, Uhlig S, Ratzke M, Varlamova O, Valette S, Benayoun S (2015) On large area LIPSS coverage by multiple pulses. Appl Surf Sci 336:249–254

Zhang Y, Zou G, Liu L, Zhao Y, Liang Q, Wu A, Zhou YN (2016) Time-dependent wettability of nano-patterned surfaces fabricated by femtosecond laser with high efficiency. Appl Surf Sci 389:554–559

Calderon MM, Rodríguez A, Ponte AD, Miñana MCM, Aranzadi MG, Olaizola SM (2016) Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl Surf Sci 374:81–89

Wu B, Zhou M, Li J, Ye X, Li G, Cai L (2009) Superhydrophobic surfaces fabricated by microstructuring of stainless steel using a femtosecond laser. Appl Surf Sci 256:61–66

Vorobyev AY, Guo C (2008) Colorizing metals with femtosecond laser pulses. Appl Phys Lett 92:041914

Yao J, Zhang C, Liu H, Dai Q, Wu L, Lan S, Gopal AV, Trofimov VA, Lysak TM (2012) Selective appearance of several laser-induced periodic surface structure patterns on a metal surface using structural colors produced by femtosecond laser pulses. Appl Surf Sci 258:7625–7632

Bonse J, Koter R, Hartelt M, Spaltmanm D, Pentzien S, Höhm S, Rosenfeld A, Krüger J (2014) Femtosecond laser-induced periodic surface structures on steel and titanium alloy for tribological applications. Appl Phys A 117:103–110

Hashida M, Semerok AF, Gobert O, Petite G, Izawa Y, Wagner JF (2002) Ablation threshold dependence on pulse duration for copper. Appl Surf Sci 197–198:862–867

Bonse J, Munz M, Sturm H (2005) Structure formation on the surface of indium phosphide irradiated by femtosecond laser pulses. J Appl Phys 97:013538

Shaheen ME, Gagnon JE, Fryer BJ (2013) Laser ablation of iron: a comparison between femtosecond and picosecond laser pulses. J Appl Phys 114:083110

Dufft D, Rosenfeld A, Das SK, Grunwald R, Bonse J (2009) Femtosecond laser-induced periodic surface structures revisited: a comparative study on ZnO. J Appl Phys 105:034908

Dar MH, Kuladeep R, Saikiran V, Rao ND (2016) Femtosecond laser nanostructuring of titanium metal towards fabrication of low-reflective surfaces over broad wavelength range. Appl Surf Sci 371:479–487

Yoo YE, Kim TH, Choi DS, Hyun SM, Lee HJ, Lee KH, Kim SK, Kim BH, Seo YH, Lee HG, Lee JS (2009) Injection molding of a nanostructured plate and measurement of its surface properties. Curr Appl Phys 9:12–18

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kobayashi, T., Sera, H., Wakabayashi, T. et al. Surface Flattening and Nanostructuring of Steel by Picosecond Pulsed Laser Irradiation. Nanomanuf Metrol 1, 217–224 (2018). https://doi.org/10.1007/s41871-018-0023-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41871-018-0023-x