Abstract

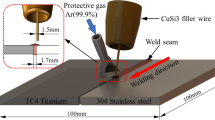

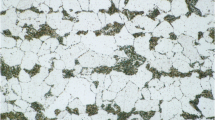

High chromium (9–12% Cr) steels with excellent heat resistance and CrMoV steels with good toughness were potential candidates for combined rotor for steam turbine operated over 620 °C. Two welding techniques were used to fabricate 9% Cr and CrMoV dissimilar welded joint. The results show that the carbon migration only appears in the specimen using narrow gap submerged arc welding (NG-SAW) technique, yet it can be effectively prevented by adding tungsten inert gas (TIG) overlaying process before the NG-SAW. The carbon migration occurred in NG-SAW resulting from the sharp transition of the strong carbide-forming element Cr between the weld (~ 2.7 wt%) and the base metal (~ 9 wt%). On the contrary, the application of TIG overlaying layers can promote the diffusion of Cr element, and therefore result in its much smaller concentration gradient. That is to say, a gentle transition zone of Cr element can be created among the SAW weld, TIG overlaying layers and the base metal, which effectively prevents the carbon migration and therefore produces a decreased carbon concentration adjacent to the fusion line.

Similar content being viewed by others

References

T. Ohtani, H. Ogi, M. Hirao, Acta Mater. 54 (2006) 2705–2713.

S.R. Holdsworth, E. Mazza, L. Binda, L. Ripamonti, Nucl. Eng. Des. 237 (2007) 2292–2301.

B.Z. Wang, W.T. Fu, Y. Li, P. Jiang, W.H. Zhang, Y.J. Tian, Mater. Charact. 59 (2008) 1133–1136.

Z.H. Wang, W.T. Fu, B.Z. Wang, W.H. Zhang, Z.Q. Lv, P. Jiang, Mater. Charact. 61 (2010) 25–30.

A. Moitra, P. Parameswaran, P.R. Sreenivasan, S.L. Mannan, Mater. Charact. 48 (2002) 55–61.

J.I. Jang, S. Shim, S.I. Komazaki, T. Honda, J. Mater. Res. 22 (2007) 175–185.

Y. Chang, Z. Meng, L. Ying, X. Li, N. Ma, P. Hu, J. Iron Steel Res. Int. 18 (2011) No. 5, 59–63.

F.G. Lu, X. Liu, P. Wang, Q.J. Wu, H.C. Cui, X. Huo, J. Mater. Res. 30 (2015) 2108–2116.

A. Joarder, N.S. Chenruvu, D.S. Sarma, Mater. Charact. 28 (1992) 121–131.

C.D. Shao, F.G. Lu, Z.G. Li, Y. Cai, J. Mater. Res. 31 (2015) 292–301.

Y.Y. You, R.K. Shiue, J. Mater. Sci. Lett. 20 (2001) 1429–1432.

H.S. Hosseini, M. Alishahi, M. Shamanian, Mater. Lett. 67 (2012) 259–262.

S.G. Wang, Q.H. Ma, Y. Li, Mater. Des. 32 (2011) 831–837.

Q.J. Wu, F.G. Lu, H.C. Cui, X. Liu, P. Wang, X.H. Tang, Mater. Des. 59 (2014) 165–175.

N. Arivazhagan, S. Singh, S. Prakash, G.M. Reddy, Int. J. Adv. Manuf. Technol. 39 (2008) 679–689.

R. Yılmaz, M. Tümer, Int. J. Adv. Manuf. Technol. 67 (2013) 1433–1447.

Q.J. Wu, F.G. Lu, H.C. Cui, X. Liu, P. Wang, Y.L. Gao, Mater. Lett. 141 (2015) 242–244.

A. Ul-Hamid, H.M. Tawancy, N.M. Abbas, Eng. Fail. Anal. 12 (2005) 181–191.

R. Paventhan, P.R. Lakshminarayanan, V. Balasubramanian, Mater. Des. 32 (2011) 1888–1894.

C.D. Lundin, Weld. J. 61 (1982) 58s–63s.

C. Sudha, A.L.E. Terrance, S.K. Albert, M. Vijayalakshmi, J. Nucl. Mater. 302 (2002) 193–205.

J. Kucera, Defect Diffus. Forum 66-69 (1990) 1395–1400.

B.J. Qi, M.X. Yang, B.Q. Cong, F.J. Liu, Int. J. Adv. Manuf. Technol. 66 (2013) 1545–1553.

V.M.J. Varghese, M.R. Suresh, D.S. Kumar, Int. J. Adv. Manuf. Technol. 64 (2013) 749–754.

F.G. Lu, P. Liu, H.J. Ji, Y.M. Ding, X.J. Xu, Y.L. Gao, Mater. Charact. 92 (2014) 149–158.

H.L. Xu, W. Liu, F.G. Lu, P. Wang, Y.M. Ding, Mater. Charact. 130 (2017) 270–277.

X.L. Deng, F.G. Lu, H.C. Cui, X.H. Tang, Z.G. Li, Mater. Sci. Eng. A 651 (2016) 1018–1030.

C. Jang, P.Y. Cho, M. Kim, S.J. Oh, J.S. Yang, Mater. Des. 31 (2010) 1862–1870.

D.H. Meng, F.G. Lu, H.C. Cui, Y.M. Ding, X.H. Tang, X. Huo, J. Mater. Res. 30 (2015) 197–205.

Q. Guo, F.G. Lu, X. Liu, R.J. Yang, H.C. Cui, Y.L. Gao, Mater. Sci. Eng. A 638 (2015) 240–250.

S.S.M. Tavares, J.M. Pardal, G.C. Souza, P.S.P. Garcia, E.S. Barbosa, C. Barbosa, I. Cardote Fiho, Eng. Fail. Anal. 56 (2015) 464–473.

E. Essuman, G.H. Meier, J. Zurek, M. Hänsel, L. Singheiser, W.J. Quadakkers, Scripta Mater. 57 (2007) 845–848.

S.R.J. Saunders, M. Monteiro, F. Rizzo, Prog. Mater. Sci. 53 (2008) 775–837.

S. Rahman, G. Priyadarshan, K.S. Raja, C. Nesbitt, M. Misra, Mater. Lett. 62 (2008) 2263–2266.

D.W. Rathod, S. Pandey, S. Aravindan, P.K. Singh, Metallogr. Microstruct. Anal. 5 (2016) 450–460.

W. Liu, X. Liu, F.G. Lu, X.H. Tang, H.C. Cui, Y.L. Gao, Mater. Sci. Eng. A 644 (2015) 337–346.

Acknowledgements

The authors gratefully acknowledge the financial support by Shanghai Science and Technology Committee (No. 13DZ1101502), and the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning (No. TP2014042), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, K., Ji, Hj., Liu, X. et al. Prevention of carbon migration in 9% Cr/CrMoV dissimilar welded joint by adding tungsten inert gas overlaying layer. J. Iron Steel Res. Int. 25, 847–853 (2018). https://doi.org/10.1007/s42243-018-0124-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0124-1