Abstract

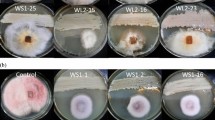

The chitinases have extensive biotechnological potential but have been little exploited commercially due to the low number of good chitinolytic microorganisms. The purpose of this study was to identify a chitinolytic fungal and optimize its production using solid state fermentation (SSF) and agroindustry substrate, to evaluate different chitin sources for chitinase production, to evaluate different solvents for the extraction of enzymes produced during fermentation process, and to determine the nematicide effect of enzymatic extract and biological control of Meloidogyne javanica and Meloidogyne incognita nematodes. The fungus was previously isolated from bedbugs of Tibraca limbativentris Stal (Hemiptera: Pentatomidae) and selected among 51 isolated fungal as the largest producer of chitinolytic enzymes in SSF. The isolate UFSMQ40 has been identified as Trichoderma koningiopsis by the amplification of tef1 gene fragments. The greatest chitinase production (10.76 U gds−1) occurred with wheat bran substrate at 55% moisture, 15% colloidal chitin, 100% of corn steep liquor, and two discs of inoculum at 30 °C for 72 h. Considering the enzymatic inducers, the best chitinase production by the isolated fungus was achieved using chitin in colloidal, powder, and flakes. The usage of 1:15 g/mL of sodium citrate-phosphate buffer was the best ratio for chitinase extraction of SSF. The Trichoderma koningiopsis UFSMQ40 showed high mortality of M. javanica and M. incognita when applied to treatments with enzymatic filtrated and the suspension of conidia.

Similar content being viewed by others

References

Dahiya N, Tewari R, Hoondal GS (2006) Biotechnological aspects of chitinolytic enzymes: a review. Appl Microbiol Biotechnol 71:773–782. https://doi.org/10.1007/s00253-005-0183-7

Halder SK, Maity C, Jana A, Das A, Paul T, Das Mohapatra PK, Pati BR, Mondal KC (2013) Proficient biodegradation of shrimp shell waste by Aeromonas hydrophila SBK1 for the concomitant production of antifungal chitinase and antioxidant chitosaccharides. Int Biodeterior Biodegrad 79:88–97. https://doi.org/10.1016/j.ibiod.2013.01.011

Brzezinska MS, Jankiewicz U, Walczak M (2013) Biodegradation of chitinous substances and chitinase production by the soil actinomycete Streptomyces rimosus. Int Biodeterior Biodegrad 84:104–110. https://doi.org/10.1016/j.ibiod.2012.05.038

Merzendorfer H (2011) The cellular basis of chitin synthesis in fungi and insects: common principles and differences. Eur J Cell Biol 90:759–769. https://doi.org/10.1016/j.ejcb.2011.04.014

Halder SK, Maity C, Jana A, Pati BR, Mondal KC (2012) Chitinolytic enzymes from the newly isolated Aeromonas hydrophila SBK1: study of the mosquitocidal activity. BioControl. 57:441–449. https://doi.org/10.1007/s10526-011-9405-3

Schrank A, Vainstein MH (2010) Metarhizium anisopliae enzymes and toxins. Toxicon. 56:1267–1274. https://doi.org/10.1016/j.toxicon.2010.03.008

Halder SK, Jana A, Das A, Paul T, Das Mohapatra PK, Pati BR, Mondal KC (2014) Appraisal of antioxidant, anti-hemolytic and DNA shielding potentialities of chitosaccharides produced innovatively from shrimp shell by sequential treatment with immobilized enzymes. Food Chem 158:325–334. https://doi.org/10.1016/j.foodchem.2014.02.115

Patil NS, Waghmare SR, Jadhav JP (2013) Purification and characterization of an extracellular antifungal chitinase from Penicillium ochrochloron MTCC 517 and its application in protoplast formation. Process Biochem 48:176–183. https://doi.org/10.1016/j.procbio.2012.11.017

Khan A, Williams KL, Nevalainen HKM (2004) Effects of Paecilomyces lilacinus protease and chitinase on the eggshell structures and hatching of Meloidogyne javanica juveniles. Biol Control 31:346–352. https://doi.org/10.1016/j.biocontrol.2004.07.011

Binod P, Sukumaran RK, Shirke SV, Rajput JC, Pandey A (2007) Evaluation of fungal culture filtrate containing chitinase as a biocontrol agent against Helicoverpa armigera. J Appl Microbiol 103:1845–1852. https://doi.org/10.1111/j.1365-2672.2007.03428.x

Patil NS, Jadhav JP (2015) Significance of Penicillium ochrochloron chitinase as a biocontrol agent against pest Helicoverpa armigera. Chemosphere. 128:231–235. https://doi.org/10.1016/j.chemosphere.2015.01.038

Karthik N, Akanksha K, Pandey A (2014) Production, purification and properties of fungal chitinases--a review. Indian J Exp Biol 52:1025–1035 http://www.ncbi.nlm.nih.gov/pubmed/25434097 (accessed Mar 26, 2020)

Chavan SB, Deshpande MV (2013) Chitinolytic enzymes: an appraisal as a product of commercial potential. Biotechnol Prog 29:833–846. https://doi.org/10.1002/btpr.1732

Oliveira PC, de Brito AR, Pimentel AB, Soares GA, Pacheco CSV, Santana NB, da Silva EGP, Fernandes AG d A, Ferreira MLO, Oliveira JR, Franco M (2019) Cocoa shell for the production of endoglucanase by Penicillium roqueforti ATCC 10110 in solid state fermentation and biochemical properties. Rev Mex Ing Química 18:777–787. https://doi.org/10.24275/UAM/IZT/DCBI/REVMEXINGQUIM/2019V18N3/OLIVEIRA

Marques G, Silva TP, Lessa OA, de Brito AR, Reis NS, Fernandes AG d A, Ferreira MLO, Oliveira JR, Franco M (2019) Production of xylanase and endoglucanase by solid-state fermentation of jackfruit residue. Rev Mex Ing Química 18:673–680. https://doi.org/10.24275/uam/izt/dcbi/revmexingquim/2019v18n2/Marques

Souza LO, de Brito AR, Bonomo RCF, Santana NB, de Almeida Antunes Ferraz JL, Aguiar-Oliveira E, de Araújo Fernandes AG, Ferreira MLO, de Oliveira JR, Franco M (2018) Comparison of the biochemical properties between the xylanases of Thermomyces lanuginosus (Sigma®) and excreted by Penicillium roqueforti ATCC 10110 during the solid state fermentation of sugarcane bagasse. Biocatal Agric Biotechnol 16:277–284. https://doi.org/10.1016/j.bcab.2018.08.016

Ferraz JL d AA, Souza LO, Fernandes AG d A, Oliveira MLF, de Oliveira JR, Franco M (2020) Optimization of the solid-state fermentation conditions and characterization of xylanase produced by Penicillium roqueforti ATCC 10110 using yellow mombin residue ( Spondias mombin L.). Chem Eng Commun 207:31–42. https://doi.org/10.1080/00986445.2019.1572000

dos Santos TC, Filho GA, Oliveira AC, Rocha TJO, de Paula Pereira Machado F, Bonomo RCF, Mota KIA, Franco M (2013) Application of response surface methodology for producing cellulolytic enzymes by solid-state fermentation from the puple mombin (Spondias purpurea L.) residue. Food Sci Biotechnol 22:1–7. https://doi.org/10.1007/s10068-013-0001-4

Granato D, Ribeiro JCB, Castro IA, Masson ML (2010) Sensory evaluation and physicochemical optimisation of soy-based desserts using response surface methodology. Food Chem 121:899–906. https://doi.org/10.1016/j.foodchem.2010.01.014

Marques GL, dos Santos Reis N, Silva TP, Ferreira MLO, Aguiar-Oliveira E, de Oliveira JR, Franco M (2018) Production and characterisation of xylanase and endoglucanases produced by Penicillium roqueforti ATCC 10110 through the solid-state fermentation of rice husk residue. Waste Biomass Valor 9:2061–2069. https://doi.org/10.1007/s12649-017-9994-x

Stoykov YM, Pavlov AI, Krastanov AI (2015) Chitinase biotechnology: production, purification, and application. Eng Life Sci 15:30–38. https://doi.org/10.1002/elsc.201400173

Doyle JJ, Doyle JL (1990) Isolation of plant DNA from fesh tissue, 1st ed., Focus

O’Donnell K, Cigelnik E (1997) Two divergent intragenomic rDNA ITS2 types within a monophyletic lineage of the fungus Fusarium are nonorthologous. Mol Phylogenet Evol 7:103–116. https://doi.org/10.1006/mpev.1996.0376

Schmitz A, Riesner D (2006) Purification of nucleic acids by selective precipitation with polyethylene glycol 6000. Anal Biochem 354:311–313. https://doi.org/10.1016/j.ab.2006.03.014

Staden R, Judge DP, Bonfield JK (2003) Analyzing sequences using the Staden Package and EMBOSS, in: Introd. to Bioinforma., Humana Press: pp. 393–410. https://doi.org/10.1007/978-1-59259-335-4_24

Hall TA (1999) BioEdit: a user-friendly biological sequence alignment program for windows 95/98/NT. Nucleic Acids Symp Ser 41:95–98

Tamura K, Stecher G, Peterson D, Filipski A, Kumar S (2013) MEGA6: molecular evolutionary genetics analysis version 6.0. Mol Biol Evol 30:2725–2729. https://doi.org/10.1093/molbev/mst197

Posada D, Crandall KA (1998) MODELTEST: testing the model of DNA substitution. Bioinformatics. 14:817–818. https://doi.org/10.1093/bioinformatics/14.9.817

Liu CL, Lan CY, Fu CC, Juang RS (2014) Production of hexaoligochitin from colloidal chitin using a chitinase from Aeromonas schubertii. Int J Biol Macromol 69:59–63. https://doi.org/10.1016/j.ijbiomac.2014.05.028

R Core Team (2018) R: a language and environment for statistical Computing

Kovacs K, Szakacs G, Pusztahelyi T, Pandey A (2004) Production of chitinolytic enzymes with Trichoderma longibrachiatum IMI 92027 in solid substrate fermentation. Appl Biochem Biotechnol - Part A Enzym Eng Biotechnol, Springer:189–204. https://doi.org/10.1385/ABAB:118:1-3:189

Miller GL (1959) Use of Dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Hussey R, Baker K (1973) Comparison of methods of collecting inocula for Meloidogyne spp., including a new technique

Abbott WS (1925) A method of computing the effectiveness of an insecticide. J Econ Entomol 18:265–267. https://doi.org/10.1093/jee/18.2.265a

Anees M, Tronsmo A, Edel-Hermann V, Hjeljord LG, Héraud C, Steinberg C (2010) Characterization of field isolates of Trichoderma antagonistic against Rhizoctonia solani. Fungal Biol 114:691–701. https://doi.org/10.1016/j.funbio.2010.05.007

Kullnig-Gradinger CM, Szakacs G, Kubicek CP (2002) Phylogeny and evolution of the genus Trichoderma: a multigene approach. Mycol Res 106:757–767. https://doi.org/10.1017/S0953756202006172

Samuels GJ (2006) Trichoderma: Systematics, the sexual state, and ecology, in: Phytopathology: pp. 195–206. https://doi.org/10.1094/PHYTO-96-0195

Dhillon GS, Brar SK, Kaur S, Valero JR, Verma M (2011) Chitinolytic and chitosanolytic activities from crude cellulase extract produced by A. niger grown on apple pomace through Koji fermentation. J Microbiol Biotechnol 21:1312–1321. https://doi.org/10.4014/jmb.1106.06036

Thadathil N, Kuttappan AKP, Vallabaipatel E, Kandasamy M, Velappan SP (2013) Statistical optimization of solid state fermentation conditions for the enhanced production of thermoactive chitinases by mesophilic soil fungi using response surface methodology and their application in the reclamation of shrimp processing by-products. Ann Microbiol 64:671–681. https://doi.org/10.1007/s13213-013-0702-1

Nampoothiri KM, Baiju TV, Sandhya C, Sabu A, Szakacs G, Pandey A (2004) Process optimization for antifungal chitinase production by Trichoderma harzianum. Process Biochem 39:1583–1590. https://doi.org/10.1016/S0032-9592(03)00282-6

Patil NS, Jadhav JP (2014) Enzymatic production of N-acetyl-D-glucosamine by solid state fermentation of chitinase by Penicillium ochrochloron MTCC 517 using agricultural residues. Int Biodeterior Biodegrad 91:9–17. https://doi.org/10.1016/j.ibiod.2014.03.003

Berger LRR, Stamford TCM, Stamford-Arnaud TM, De Oliveira Franco L, Do Nascimento AE, Horacinna HM, Macedo RO, De Campos-Takaki GM (2014) Effect of corn steep liquor (CSL) and cassava wastewater (CW) on chitin and chitosan production by cunninghamella elegans and their physicochemical characteristics and cytotoxicity. Molecules. 19:2771–2792. https://doi.org/10.3390/molecules19032771

Hamano PS, Kilikian BV (2006) Production of red pigments by Monascus ruber in culture media containing corn steep liquor. Braz J Chem Eng 23:443–449. https://doi.org/10.1590/S0104-66322006000400002

Nascimento R d AL, Alves MHM, Freitas JHE, Manhke LC, Luna MAC, de Santana KV, do Nascimento AE, da Silva CAA (2015) Aproveitamento da água de maceração de milho para produção de compostos bioativos por Aspergillus niger (UCP/WFCC 1261). E-Xacta 8:15–29. https://doi.org/10.18674/exacta.v8i1.1421

Fenice M, Leuba JL, Federici F (1998) Chitinolytic enzyme activity of Penicillium janthinellum P9 in bench-top bioreactor. J Ferment Bioeng 86:620–623. https://doi.org/10.1016/S0922-338X(99)80020-8

Rattanakit N, Yang S, Wakayama M, Plikomol A, Tachiki T (2003) Saccharification of chitin using solid-state culture of Aspergillus sp. S1-13 with shellfish waste as a substrate. J Biosci Bioeng 95:391–396. https://doi.org/10.1016/s1389-1723(03)80073-7

Binod P, Sandhya C, Suma P, Szakacs G, Pandey A (2007) Fungal biosynthesis of endochitinase and chitobiase in solid state fermentation and their application for the production of N-acetyl-d-glucosamine from colloidal chitin. Bioresour Technol 98:2742–2748. https://doi.org/10.1016/j.biortech.2006.09.030

Nawani NN, Kapadnis BP (2005) Optimization of chitinase production using statistics based experimental designs, process Biochem

Leger RJS, Cooper RM, Charnley AK (1986) Cuticle degrading enzymes of entomopathogenic fungi: regulation of production of chitinolytic enzymes. J Gen Microbiol 132:1509–1517. https://doi.org/10.1099/00221287-132-6-1509

Florido EB, Camilo PB, Mayorga-Reyes L, Cervantes RG, Cruz PM, Azaola A (2009) β-N-Acetylglucosaminidase production by Lecanicillium (Verticillium) lecanii ATCC 26854 by solid-state fermentation utilizing shrimp shell. Interciencia 34:356–360

Barranco-Florido JE, Alatorre-Rosas R, Gutiérrez-Rojas M, Viniegra-González G, Saucedo-Castañeda G (2002) Criteria for the selection of strains of entomopathogenic fungi Verticillium lecanii for solid state cultivation. Enzym Microb Technol 30:910–915. https://doi.org/10.1016/S0141-0229(02)00032-7

Gkargkas K, Mamma D, Nedev G, Topakas E, Christakopoulos P, Kekos D, Macris BJ (2004) Studies on a N-acetyl-β-D-glucosaminidase produced by Fusarium oxysporum F3 grown in solid-state fermentation. Process Biochem 39:1599–1605. https://doi.org/10.1016/S0032-9592(03)00287-5

Rattanakit N, Plikomol A, Yano S, Wakayama M, Tachiki T (2002) Utilization of shrimp shellfish waste as a substrate for solid-state cultivation of Aspergillus sp. S1–13: evaluation of a culture based on chitinase formation which is necessary for chitin-assimilation. J Biosci Bioeng 93:550–556. https://doi.org/10.1016/s1389-1723(02)80236-5

Rattanakit N, Yano S, Plikomol A, Wakayama M, Tachiki T (2007) Purification of Aspergillus sp. S1-13 chitinases and their role in saccharification of chitin in mash of solid-state culture with shellfish waste. J Biosci Bioeng 103:535–541. https://doi.org/10.1263/jbb.103.535

Rustiguel CB, Jorge JA, Guimarães LHS (2012) Optimization of the Chitinase production by different Metarhizium anisopliae strains under solid-state fermentation with silkworm Chrysalis as substrate using CCRD. Adv Microbiol 02:268–276. https://doi.org/10.4236/aim.2012.23032

Patidar P, Agrawal D, Banerjee T, Patil S (2005) Chitinase production by Beauveria felina RD 101: optimization of parameters under solid substrate fermentation conditions. World J Microbiol Biotechnol 21:93–95. https://doi.org/10.1007/s11274-004-1553-5

Patidar P, Agrawal D, Banerjee T, Patil S (2005) Optimisation of process parameters for chitinase production by soil isolates of Penicillium chrysogenum under solid substrate fermentation. Process Biochem 40:2962–2967. https://doi.org/10.1016/j.procbio.2005.01.013

Fernández-Lahore HM, Fraile ER, Cascone O (1998) Acid protease recovery from a solid-state fermentation system. J Biotechnol 62:83–93. https://doi.org/10.1016/S0168-1656(98)00048-0

Freitas MA, Pedrosa EMR, Mariano RLR, Maranhão SRVL (2012) Screening Trichoderma spp. as potential agents for biocontrol of Meloidogyne incognita in sugarcane. Neotropica 42:115–122

Zhang S, Gan Y, Xu B (2015) Biocontrol potential of a native species of Trichoderma longibrachiatum against Meloidogyne incognita. Appl Soil Ecol 94:21–29. https://doi.org/10.1016/j.apsoil.2015.04.010

Moura Mascarin G, Ferreira M, Junior B, Vieira J, Filho A (2012) Trichoderma harzianum reduces population of Meloidogyne incognita in cucumber plants under greenhouse conditions. J Entomol Nematol 4:54–57. https://doi.org/10.5897/JEN12.007

Pan M, Li J, Lv X, Du G, Liu L (2019) Molecular engineering of chitinase from Bacillus sp. DAU101 for enzymatic production of chitooligosaccharides. Enzym Microb Technol 124:54–62. https://doi.org/10.1016/j.enzmictec.2019.01.012

Khan FI, Bisetty K, Singh S, Permaul K, Hassan MI (2015) Chitinase from Thermomyces lanuginosus SSBP and its biotechnological applications. Extremophiles. 19:1055–1066. https://doi.org/10.1007/s00792-015-0792-8

Patil RS, Ghormade V, Deshpande MV (2000) Chitinolytic enzymes: an exploration. Enzym Microb Technol 26:473–483. https://doi.org/10.1016/S0141-0229(00)00134-4

Inokuma K, Takano M, Hoshino K (2013) Direct ethanol production from N-acetylglucosamine and chitin substrates by Mucor species. Biochem Eng J 72:24–32. https://doi.org/10.1016/j.bej.2012.12.009

Chen L, Jiang H, Cheng Q, Chen J, Wu G, Kumar A, Sun M, Liu Z (2015) Enhanced nematicidal potential of the chitinase pachi from Pseudomonas aeruginosa in association with Cry21Aa. Sci Rep 5:1–11. https://doi.org/10.1038/srep14395

Acknowledgments

The authors would like to thank the Coordination for the Improvement of Higher Education Personnel (CAPES) and the National Council for Scientific and Technological Development (CNPq) for providing scholarship and funding to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Inês Conceição Roberto.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Trichoderma koningiopsis UFSMQ40 presents highest production of chitinase.

• The best chitinase production was found using wheat bran substrate in 55% of moisture.

• Chitin in flakes was used as enzymatic inducers without altering chitinase production.

• Trichoderma koningiopsis UFSMQ40 offer potential for industrial chitinase production.

• The isolated fungi present high mortality effectiveness of phytopathogenic nematodes.

Rights and permissions

About this article

Cite this article

Baldoni, D.B., Antoniolli, Z.I., Mazutti, M.A. et al. Chitinase production by Trichoderma koningiopsis UFSMQ40 using solid state fermentation. Braz J Microbiol 51, 1897–1908 (2020). https://doi.org/10.1007/s42770-020-00334-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42770-020-00334-w