Abstract

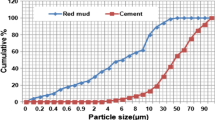

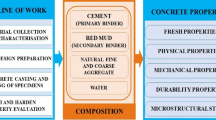

Recent trends in the construction industry involve the use of industrial by-products as building materials to improve waste management and reduce excessive CO2 emissions from the cement industry. Red mud (RM) is a by-product of alumina refinery plants. When improperly disposed, red mud harms the surrounding area, owing to its highly alkaline nature. In the current work, up to 15% of the cement in concrete was replaced with red mud, in increments of 2.5%. In addition, to enhance the pozzolanic reaction, metakaolin was used as a ternary mineral; it replaces 10% of the cement. A slump cone test was conducted to evaluate the workability. Compressive, flexural, and split tensile strength tests were conducted to observe the mechanical properties. A rapid chloride penetration test and water absorption tests were conducted to determine the durability properties of the concrete. X-ray fluorescence analysis was conducted to determine the chemical composition of both the red mud and the metakaolin. A scanning electron microscope analysis was conducted to characterize the microstructure of the RM concrete. The 12.5% red-mud replacement mix showed the greatest improvement in mechanical properties among all the mixes. As the red-mud replacement increased, the chloride-ion passage was reduced. Moreover, a denser microstructure formation was observed with the red-mud replacement, as compared to standard concrete.

Similar content being viewed by others

References

M.A. Raheem, S.L.M. Gómez, C.M.A. Piñeiro, M.B. Olazaran, Uses of red mud as a construction material. AEI. (2017). https://doi.org/10.1061/9780784480502.032

I.M. Nikbin, M. Aliaghazadeh, S. Charkhtab, A. Fathollahpour, Environmental impacts and mechanical properties of lightweight concrete containing bauxite residue (red mud). J. Clean. Prod. 172, 2683–2694 (2018). https://doi.org/10.1016/j.jclepro.2017.11.143

C. Venkatesh, M.S.R. Chand, N. Ruben, A state of the art on red mud as a substitutional cementitious material. Ann. Chim. Sci. Mater. 43(2), 99–106 (2019). https://doi.org/10.18280/acsm.430206

Y. Liu, R. Naidu, Hidden values in bauxite residue (red mud): recovery of metals. Waste Manag. 34(12), 2662–2673 (2014). https://doi.org/10.1016/j.wasman.2014.09.003

V. Mymrin, K. Alekseev, O.M. Fortini, Y.K. Aibuldinov, C.L. Pedroso, A. Nagalli, E.B. Costa, Environmentally clean materials from hazardous red mud, ground cooled ferrous slag and lime production waste. J. Clean. Prod. 161, 376–381 (2017). https://doi.org/10.1016/j.jclepro.2017.05.109

P.E. Tsakiridis, S.A. Leonardou, P. Oustadakis, Red mud addition in the raw meal for the production of Portland cement clinker. J. Hazard. Mater. 116(1–2), 103–110 (2004). https://doi.org/10.1016/j.jhazmat.2004.08.002

S. Samal, A.K. Ray, A. Bandopadhyay, Proposal for resources, utilization and processes of red mud in India—a review. Int. J. Miner. Process. 118, 43–55 (2013). https://doi.org/10.1016/j.minpro.2012.11.001

D.V. Ribeiro, J.A. Labrincha, M.R. Morelli, Effect of red mud addition on the corrosion parameters of reinforced concrete evaluated by electrochemical methods. RevistaIBRACON de Estruturas e Materiais 5(4), 451–467 (2012). https://doi.org/10.1590/S1983-41952012000400004

Ć.G. Topličić, V. Mitic, D. Grdić, N. Ristić, Z. Grdić Environmental aspects of red mud and its utilization as a component of building materials. in Proceedings of the IV advanced ceramics and applications conference (Atlantis Press, Paris, 2017), pp. 447–474. https://doi.org/10.2991/978-94-6239-213-7_31

V. Dentoni, B. Grosso, G. Massacci, Environmental sustainability of the alumina industry in Western Europe. Sustainability 6(12), 9477–9493 (2014). https://doi.org/10.3390/su6129477

R.B. Rao, L. Besra, B.R. Reddy, G.N. Banerjee, The effect of pretreatment on magnetic separation of ferruginous minerals in bauxite. Phys. Sep. Sci. Eng. 8(2), 115–123 (1997). https://doi.org/10.1155/1997/53574

K.K. Shetty, G. Nayak, V. Vijayan, Effect of red mud and iron ore tailings on the strength of self compacting concrete. Eur. Sci. J. (2014). https://doi.org/10.19044/esj.2014.v10n21p%25p

J.A. Rossignolo, Interfacial interactions in concretes with silica fume and SBR latex. Constr. Build. Mater. 23(2), 817–821 (2009). https://doi.org/10.1016/j.conbuildmat.2008.03.005

S. Bhasin, N. Chandra, Studies on sintering behavior of pyrophyllite based ceramic tiles using di-potassium phosphatic binder. Silic. Ind. 69(1–2), 14–18 (2004)

D.L. Metilda, C. Selvamony, R. Anandakumar, A. Seeni, Investigations on optimum possibility of replacing cement partially by red mud in concrete. Sci. Res. Essays 10(4), 137–143 (2015). https://doi.org/10.5897/SRE2015.6166

R.R. Raj, E.P. Pillai, A.R. Santhakumar, Strength and corrosion properties of concrete incorporating metakaolin and red mud. Eur. J. Sci. Res. 91(4), 569–579 (2012)

S. Nenadovic, G. Mucsi, L. Kljajevic, M. Mirkovic, M. Nenadovic, F. Kristaly, I. Vukanac, Physicochemical, mineralogical and radiological properties of red mud samples as secondary raw materials. Nucl. Technol. Radiat. Prot. 32(3), 261–266 (2017). https://doi.org/10.2298/ntrp1703261n

D.V. Ribeiro, J.A. Labrincha, M.R. Morelli, Potential use of natural red mud as pozzolan for Portland cement. Mater. Res. 14(1), 60–66 (2011). https://doi.org/10.1590/S1516-1439201100500000

C. Venkatesh, S.K. Mohiddin, N. Ruben, Corrosion inhibitors behaviour on reinforced concrete—a review. In Sustainable Construction and Building Materials (Springer, Singapore, 2019), pp. 127–134. https://doi.org/10.1007/978-981-13-3317-0

L. Senff, D. Hotza, J.A. Labrincha, Effect of red mud addition on the rheological behaviour and on hardened state characteristics of cement mortars. Constr. Build. Mater. 25(1), 163–170 (2011)

A. Al Menhosh, Y. Wang, Y. Wang, N.L. Augusthus, Long term durability properties of concrete modified with metakaolin and polymer admixture. Constr. Build. Mater. 172, 41–51 (2018). https://doi.org/10.1016/j.conbuildmat.2018.03.215

G. Dhinakaran, S. Thilgavathi, J. Venkataramana, Compressive strength and chloride resistance of metakaolin concrete. KSCE J. Civ. Eng. 16(7), 1209–1217 (2012). https://doi.org/10.1007/s12205-012-1235-z

R.R. Rajendran, E.P. Pillai, Regression analysis of OPC-MK-RM-based ternary-blended concrete based on its experimental results. In Global Civil Engineering Conference (Springer, Singapore, 2017), pp. 323–332. https://doi.org/10.1007/978-981-10-8016-6_26

BIS, IS 12269-1987: Specifications for 53 Grade Ordinary Portland Cement (Bureau of Indian Standards, New Delhi, 1987)

BIS, IS 4031-I (1996) Specifications for Method of Physical Tests for Hydraulic Cement (Bureau of Indian Standards, New Delhi, 1996)

BIS, IS 383-2016: Specification for Coarse and Fine Aggregates from Natural Sources for Concrete (Bureau of Indian Standards, New Delhi, 2016)

BIS, IS2386-1963 Specification for Method of Tests for Aggregates for Concrete (Bureau of Indian Standards, New Delhi, 1963)

ASTM, ASTM C494: Standard Specification for Chemical Admixtures for Concrete (ASTM, West Conshohocken, 2005)

BIS, IS 10262-2019 Specification for Method of Preparation of Mix Calculations of Concrete (Bureau of Indian Standards, New Delhi, 2019)

BIS, IS: 516-2013 Specification for Method of Tests for Concrete (Bureau of Indian Standards, New Delhi, 2013)

BIS, IS: 516-1959 Specification for Flexural Strength of Concrete—Method of Test (Bureau of Indian Standards, New Delhi, 1959)

BIS, IS 5816-1999 Specification for Splitting Tensile Strength of Concrete—Method of Test (Bureau of Indian Standards, New Delhi, 1999)

BIS, IS 1124-1974 Specification for Water Absorption for Concrete (Bureau of Indian Standards, New Delhi, 1974)

BIS, IS: 9013-1978 Specification for Method of Curing of Concrete (Bureau of Indian Standards, New Delhi, 1978)

ASTM C1202: Standard Specification for Rapid Chloride Penetrable Test ASTM, West Conshohocken

X. Cheng, X. Yang, C. Zhang, X. Gao, Y. Yu, K. Mei, X. Guo, C. Zhang, Effect of red mud addition on oil well cement at high temperatures. Adv. Cem. Res. (2019). https://doi.org/10.1680/jadcr.18.00224

W.C. Tang, Z. Wang, Y. Liu, H.Z. Cui, Influence of red mud on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 178, 288–300 (2018). https://doi.org/10.1016/j.conbuildmat.2018.05.171

D.V. Ribeiro, A.S. Silva, J.A. Labrincha, M.R. Morelli, Rheological properties and hydration behavior of portland cement mortars containing calcined red mud. Can. J. Civ. Eng. 40(6), 557–566 (2013). https://doi.org/10.1139/cjce-2012-0230

Acknowledgements

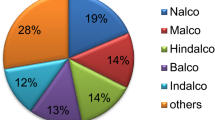

We thank Dr. P.K. Pattajoshi and V. Krishna Kumari, AGM (Chemical) R&D, Nalco, India, for providing the red mud.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Publisher's Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

About this article

Cite this article

Venkatesh, C., Nerella, R. & Chand, M.S.R. Experimental investigation of strength, durability, and microstructure of red-mud concrete. J. Korean Ceram. Soc. 57, 167–174 (2020). https://doi.org/10.1007/s43207-019-00014-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-019-00014-y